Silicon Energy SiE2900 User manual

Owner’s Manual

Silicon Energy Solar Inverter

SiE2900 / SiE3840

SiE4900 / SiE5300

ZOMG-8253USYUS0

1

© 2011 SILICON ENERGY All rights reserved SiEV2.3

2

3

4

Safety

SAVE THESE INSTRUCTIONS– This manual contains important instructions for

the Silicon Energy Solar Inverter Models SiE5300, SiE4900, SiE3840 & SiE2900

that shall be followed during installation and maintenance of the Silicon Energy

Solar Inverter [hereafter SiE Inverter(s)].

Safety Precautions/Safety Notes

Only trained qualified electrical personnel are to perform the electrical installation,

wiring, opening and repair of the SiE Inverters. Even when no external voltage is

present, the SiE Inverters can still contain high voltages and the risk of electrical

shock.

The temperature of the heat sinks outside of the device can reach over 70°C (158°F)

in normal operation (Ambient temperature rating: 55°C / 131°F). There is the risk

of burn injury when these parts are touched.

The following general safety precautions must be observed during all phases of

operation, service, installation and repair of this device. Failure to comply with

these precautions or with specific warnings elsewhere in this manual violates safety

standards of design, manufacture, and intended use of the device. The manufacturer

assumes no liability for the customer’s failure to comply with these requirements.

5

Safety Symbols

To reduce the risk of injury and to ensure the continued safe operation of this

product, the following safety instructions and warnings are marked in this manual.

Warning, risk of electric shock

Presents safety information to prevent injury or death to users and/or

installers.

Earth ground symbol

!

Caution (refer to accompanying documents)

Presents information to prevent damage to this product.

6

General Safety Precautions

Personnel must remove all conductive jewelry or personal equipment prior

to installation or service of the device, parts, connectors, and/or wiring.

Trained qualified personnel are required to mount, reconfigure or repair this

device.

Licensed electricians are required to install permanently wired equipment.

Stand on an insulated surface when working on the operating device (i.e.,

ensure that there is no grounding).

Instructions in this manual must be precisely followed and all information

on cautions or warnings must be adhered to.

Use proper lifting techniques whenever handling enclosure, equipment or

parts.

The SiE Inverter must be provided with an equipment-grounding conductor

connected according to local codes and regulations.

The SiE Inverter must be provided with a DC grounding connection

according to NEC and Local Electrical codes. The grounded conductor must

be ungrounded and energized when a ground fault is indicated.

The AC Neutral connection is only for voltage sensing and shall be neither

used to carry currents nor bonded to ground inside the inverter.

These precautions/warnings do not contain all measures pertinent to the safe

operation of the device. If special problems arise which are not described in

sufficient detail for the purposes of the buyer, contact your specialized

dealer or technician.

7

Safe Installation and Operation

Installation of the device must be in accordance with the safety regulations

(e.g., UL1741) and all other relevant national or local regulations. Correct

grounding and short circuit protection must be provided to ensure

operational safety.

Read all instructions and cautionary remarks in the manual before

installation.

Switch off the circuit breakers before installation and wirings. Avoid

standing water when working on the inverter.

PV arrays will be energized when exposed to light. Cover the arrays with

opaque (dark) material during installation and wiring.

Check both of the AC and DC connections with a digital volt meter prior to

any installation or removal procedures.

Attach the outer cover correctly before switching on the circuit breakers.

Install the inverter out of direct sunlight.

When no external voltage is present; the SiE Inverter can still contain high

voltages and the risk of electrical shock.

Allow at least 5 minutes for the inverter to discharge completely after

disconnecting the AC and DC sources from the inverter.

External heat sinks can reach high enough temperatures in normal operation

to cause skin burn injury when these parts are touched. Pay attention to high

temperature components.

To prevent the risk of fire hazard, do not cover or obstruct the heat sink.

Allow changes in your electrical system to be carried out only by qualified

electricians.

8

Repair and Maintenance

The SiE Inverter contains no user serviceable parts, except for the fan, the

PV string fuses and the GFDI fuse. Only SILICON ENERGY trained staff is

authorized to carry out internal repair and maintenance of the unit. Please

return the device for repair and maintenance for faults caused by parts other

than the fan and the fuses described above. For maintenance and

replacement of the fuses, please refer to the section 5.4.

WARNING!

DO NOT make alterations or tamper with the assembly in the

inverter without manufacturer’s authorization unless specified

elsewhere in this Manual. This may result in injury, electric

shock, or fire and void the warranty.

Wiring the inverter

Input/Output Terminals: Use wire size #10 AWG to #6, 90°C (194°F)

Copper Wire.

Reconfirm that all connections have been performed properly and all

screws are properly tightened.

WARNING!

All electrical installation and the wiring methods shall be done

in accordance with the local and National Electrical codes

ANSI/NFPA 70 and should follow the important safety

instructions in this manual.

WARNING!

Make sure that you use suitable connecting cables for both the

AC and DC wiring. The cable must be adequately dimensioned

and suitably inert to temperature fluctuation, UV radiation

and other possible hazards.

9

!

Connection of theAC cable

WARNING!

Reconfirm that the circuit breaker to the main utility is

switched OFF before connecting the power cable from the

breaker to the AC connector.

Connection of the DC cable

CAUTION!

Identify the different polarity of DC voltage on each PV string

and connect respectively to the input terminals marked

“UNGROUNDED CONDUCTOR” and “GROUNDED

CONDUCTOR”. Make sure the DC voltage that PV arrays

generate is equal or less than 600 VDC in any case.

WARNING!

Route the DC connection cables to the SiE Inverters away from

any possible hazards that could damage the cables.

WARNING!

Hazardous voltage is still present on the device after

disconnection of all PV DC inputs. Allow 5 minutes for the

inverter to discharge the energy completely.

WARNING!

PV arrays will be energized when exposed to light. Cover the

arrays with opaque (dark) materials during installation and

wiring.

10

Contents

1. INTRODUCTION 15

1.1 GENERAL 15

1.2 SPECIFICATIONS 17

1.3 ACCESSORIES 23

2. INSTALLATION 24

2.1 PLACEMENT 24

2.2 MOUNTING 25

2.3 WIRING THE INVERTER 31

2.3.1 Connection of the AC cable............................................................38

2.3.2 Connection of the DC cable............................................................40

2.3.2.1 Connection of the DC wires for Negative Ground Arrays..............43

2.3.2.2 Connection of the DC wires for Positive Ground Arrays ...............45

2.3.2.3 Connection of the DC wires for Negative Ground Arrays without

Internal DC Fuses.........................................................................................47

2.3.2.4 Connection of the DC wires for Positive Ground Arrays without

Internal DC Fuses.........................................................................................50

2.3.3 Connection of the Communication cable........................................53

2.4 WIRING INVERTER IN PARALLEL 56

3. OPERATION 58

3.1 OVERVIEW 58

3.2 OPERATION FE AT U R E 60

3.3 LED INDICATION 62

3.4 LCD DISP LAY 64

3.5 COMMUNICATION 80

3.6 EXPLANATIONS OF ERROR MESSAGES 80

11

4. WARRANTY INFORMATION 84

5. TECHNICAL DOCUMENTATION 88

5.1 OUTLINE DRAWING 88

5.2 EFFICIENCY 90

5.3 DE-RAT IN G OPERATION 94

5.4 MAINTENANCE 97

5.4.1 Exchange of the GFDI Fuse...........................................................97

5.4.2 Exchange of the PV String Fuses....................................................98

5.4.3 Factory Service.............................................................................100

5.4.3.1 Remove the Inverter......................................................................101

5.4.3.2 Re-install the Inverter...................................................................108

6. WEATHER PROOF SHIELD (OPTIONAL) 115

12

List of Figures

Fig1.1.1 Grid Connected Solar System Overview .............................................16

Fig 2.1.1 Clearances required for SiE Inverter installation...............................25

Fig 2.2.1 Remove the bracket from the inverter..................................................26

Fig 2.2.2 Inverter mounting bracket...................................................................27

Fig 2.2.3 Fasten the mounting bracket...............................................................28

Fig 2.2.4Fasten the Inverter on the mounting bracket ......................................31

Fig 2.3.1 Turn the DC/AC disconnect switch OFF.............................................32

Fig 2.3.2 Loosen the screws................................................................................33

Fig 2.3.3 Remove the cover of the wiring box ....................................................33

Fig 2.3.4 Remove the covers for the cable through holes...................................34

Fig 2.3.5 Wiring box front view ..........................................................................35

Fig 2.3.6 Utility configuration jumpers..............................................................37

Fig 2.3.7 Utility configurations ..........................................................................38

Fig 2.3.1.1 AC Terminal Block for AC cable connections.................................39

Fig 2.3.2.1 SiE2900 supports only three (3) PV string fuses..................................41

Fig 2.3.2.2 PV- terminal connection.................................................................42

Fig 2.3.2.1.1 Negative Ground Setting and DC wires connections.................44

Fig 2.3.2.1.2 DC terminal blocks for DC cable connection in Negative

Ground ....................................................................................................44

Fig 2.3.2.2.1 Positive Ground Setting and DC wire connections....................46

Fig 2.3.2.2.2 DC terminal blocks for DC cable connection in Positive

Ground ....................................................................................................46

Fig 2.3.2.3.1 Negative Ground Setting and DC wires connections array

without internal DC fuses........................................................................................48

Fig 2.3.2.3.2 DC terminal blocks for DC cable connection in Negative

Ground array without internal DC Fuses ...............................................................49

13

Fig 2.3.2.4.1 Positive Ground Setting and DC wires connections

array without internal DC fuses..............................................................................51

Fig 2.3.2.4.2 DC terminal blocks for DC cable connection in Positive

Ground array without internal DC Fuses ...............................................................52

Fig 2.3.3.1 Positions of the communication ports and termination switch.......54

Fig 2.3.3.2 RJ-45 Pins and Signals...................................................................54

Fig 2.3.3.3 RS-232 connection..........................................................................55

Fig 2.3.3.4 RS-485 connection..........................................................................56

Fig 2.4.1 Parallel configuration of inverter .......................................................57

Fig 3.3.1 Front panel of the SiE Inverter............................................................62

Fig 3.4.1 SiE Inverter LCD display lay-out........................................................79

Fig 5.1.1 Outline Drawing of SiE2900/3840......................................................88

Fig 5.1.2 Outline Drawing of SiE4900/5300......................................................89

Fig 5.2.1 CEC Efficiency of the SiE2900 = 96.0% (240V).................................90

Fig 5.2.2 CEC Efficiency of the SiE2900 = 95.5% (208V).................................90

Fig 5.2.3 CEC Efficiency of the SiE3840 = 96.0% (240V).................................91

Fig 5.2.4 CEC Efficiency of the SiE3840 = 95.5% (208V).................................91

Fig 5.2.5 CEC Efficiency of the SiE4900 = 96.0% (240V).................................92

Fig 5.2.6 CEC Efficiency of the SiE4900 = 96.0% (208V).................................92

Fig 5.2.7 CEC Efficiency of the SiE5300 = 96.0% (240V).................................93

Fig 5.2.8 CEC Efficiency of the SiE5300 = 95.5% (208V).................................93

Fig 5.3.1 Temperature derating curve of the SiE2900........................................95

Fig 5.3.2 Temperature derating curve of the SiE3840........................................96

Fig 5.3.3 Temperature derating curve of the SiE4900........................................96

Fig 5.3.4 Temperature derating curve of the SiE5300........................................97

Fig 5.4.1.1 Open the cap of the GFDI fuse holder............................................98

Fig 5.4.2.1 Replacement of the PV string fuses ................................................99

Fig 5.4.3.1.1 Remove the cover of the Inverter.............................................102

14

Fig 5.4.3.1.2 Remove the DC and AC wires..................................................103

Fig 5.4.3.1.3 Keep the well-wrapped DC and AC wires stored in the wiring

box.........................................................................................................................103

Fig 5.4.3.1.4 Remove the screws and nuts bonding between the inverter and

wiring box ..................................................................................................104

Fig 5.4.3.1.5 Un-hang the inverter carefully.................................................105

Fig 5.4.3.1.6 Locate the cover plate in place and fasten the screws.............107

Fig 5.4.3.2.1 Re-install the cover plate and fix it on the top of the wiring

box ..................................................................................................109

Fig 5.4.3.2.2 Hang the inverter onto the mounting bracket carefully...........110

Fig 5.4.3.2.3 Fasten the screws and nuts bonding between the inverter and

the wiring box for its construction and grounding continuity ...............................111

Fig 5.4.3.2.4 Connect the AC wirings to their correct terminals individually .... 111

Fig 5.4.3.2.5 Fasten the screws of cover of the inverter firs, then the wiring

box ..................................................................................................112

Fig 6.1 Step 1: Release the screw of the inverter cover.................................115

Fig 6.2 Step 2: Put the shield on the sides of the inverter..............................116

Fig 6.3 Step 3: Fasten the shields with the screws.........................................116

Fig 6.4 An inverter with the weather proof shield.........................................117

15

1. Introduction

1.1 General

We appreciate your choice of Silicon Energy Solar Inverters for your power

conversion devices in your solar power system. This document contains the

information you need for the installation and settings of the SiE Inverters.

Therefore, it is strongly recommended to read this manual carefully before the

SiE Inverter installation and settings.

The Silicon Energy Solar Inverter [hereafter SiE Inverter(s)] product family is

a series of grid-connected photovoltaic inverters which are designed to convert

DC power generated by photovoltaic arrays to AC power that is delivered to the

home loads and then fed into the utility grid with any excess power. The

SiE2900, SiE3840, SiE4900, and SiE5300 are the members of the family for the

North American market. The overview of the grid-tied solar energy system is

shown in figure 1.1.1. SiE Inverters utilize state-of-the-art technology, reliability

and ease of use and comply with the requirements of UL1741 Standard for

Inverters, Converters, Controllers and Interconnection System Equipment for

Use With Distributed Energy Resources. SiE Inverters also comply with the

IEEE 1547 Standard for Interconnecting Distributed Resources with the Electric

Power Systems; and IEEE 1547.1 Standard Conformance Test Procedures for

Equipment Interconnecting Distributed Resources with Electric Power Systems;

and FCC Part 15 Subpart B EMI/EMC Emissions Regulations for a Class B

device.

The SiE Inverter is designed to operate automatically once it is installed and

commissioned correctly. When the DC input voltage generated by the

photovoltaic array rises above the pre-set threshold value, the embedded

16

controller starts and goes through a system check mode and then into monitoring

mode until the PV Start Voltage is reached. During this time, the SiE Inverter

will not generate AC power. Once all conditions necessary for grid connection

are satisfied, the SiE Inverter goes into the Grid/MPPT mode and begins feeding

the AC power into the grid. When the input DC voltage falls below the

minimum MPP voltage setting, the SiE Inverter will then shut itself down. The

SiE Inverter will be awakened automatically should the input DC voltage rise

above the pre-set threshold value.

Fig1.1.1 Grid Connected Solar System Overview

Photovoltaic Array

Utility Grid

Meter

SiE Inverter

17

1.2 Specifications

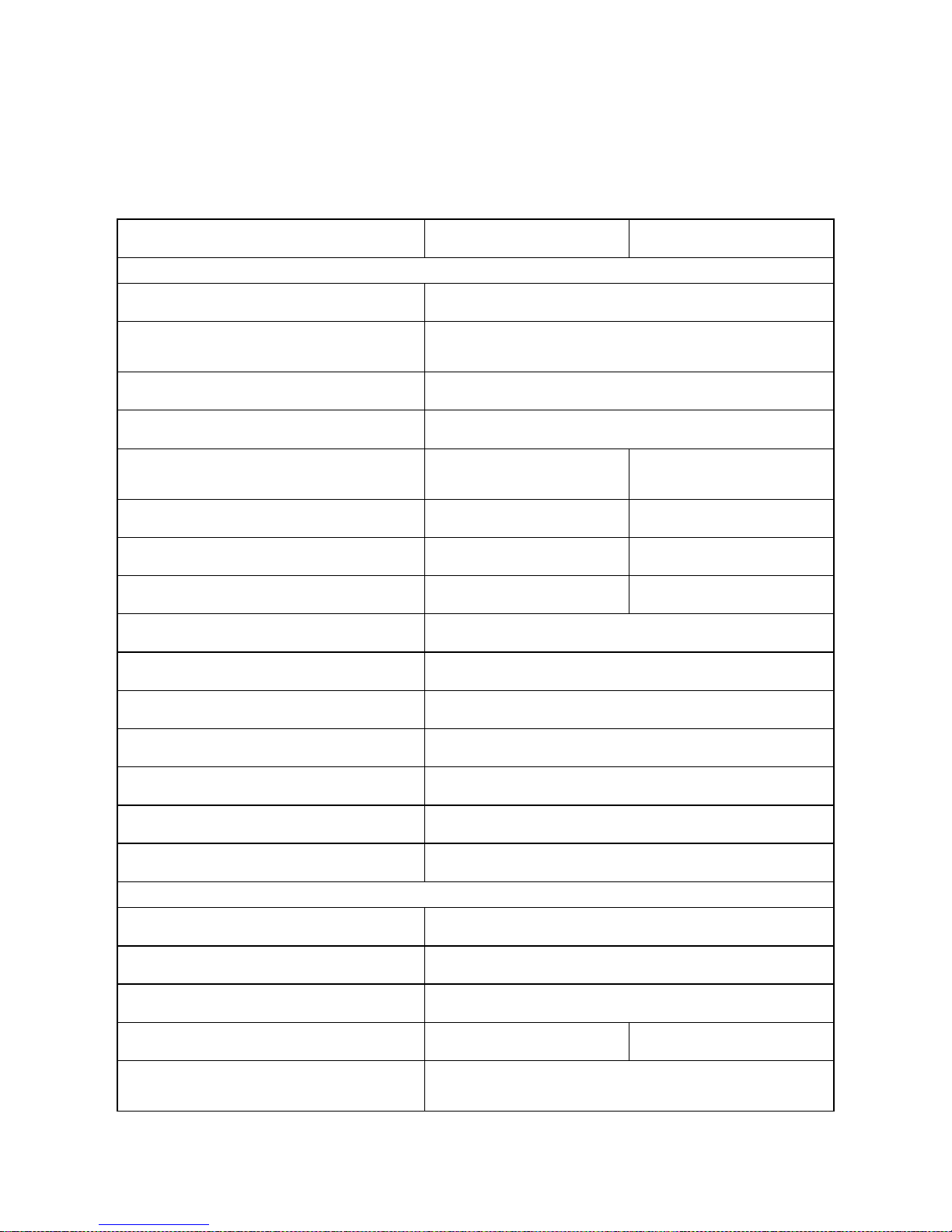

Specifications for SiE2900 and SiE3840

Name-Part number SiE2900 SiE3840

Grid output (AC)

Grid voltage, nominal 240/208 VAC

Grid voltage, operating range

211~264@240VAC(adjustable) *

183~228@208VAC (adjustable)*

Grid frequency, nominal 60 Hz

Grid frequency, operating range 59.3~60.5 Hz (adjustable)*

Maximum output power

2900W@240VAC

2700W@208VAC

3840W@240VAC

3330W@208VAC

Maximum output current 13 A 16.3 A

Output over current protection 20A 20 A

Maximum output fault current 15A 20 A

Startup current < 2 A

Maximum grid backfeed current 0 A

Waveform True sine

Power factor >0.99 @ nominal power

Total Harmonic Distortion <3%

DC Component <0.5%

Phase Split Phase or Single phase 240

Solar input (DC)

Input voltage range 200~550 VDC

Maximum input voltage 600 VDC

PV start voltage 235 VDC (adjustable)

Maximum input current 16 A 20 A

Maximum input short circuit

current

24A

18

Name-Part number SiE2900 SiE3840

Solar input (DC)

Number of fused string inputs 3 4

Efficiency

Maximum efficiency

96.7%@240VAC

96.4%@208VAC

96.7%@240VAC

96.5%@208VAC

CEC efficiency

96.0%@240VAC

95.5 %@208VAC

96.0%@240VAC

95.5%@208VAC

Night-time tare loss 0.5W

Environmental

Operating temperature range -25° ~ +55°C (-13° ~ +131°F)

Storage temperature range -25° ~ +55°C (-13° ~ +131°F)

Maximum full power operating

ambient

55°C (131°F) 55°C (131°F)

Relative humidity Max. 95%

Mechanical

Outdoor enclosure NEMA 3R, Rainproof

Cooling Natural Cooling fan

Input and output terminals

Accept wire size of 4 to 16 mm2

(#12 to #6 AWG)

Weight/Shipping weight 23 kg / 27 kg (50.7 lb / 59.5 lb)

Dimensions (HxWxD) 732x454x175 mm (28.8x17.9x6.9 inches)

Shipping dimensions (HxWxD) 840x540x275 mm (33.1 x21.3x10.8 inches)

Interface

Communication RS232 and RS485 (Option with wireless)

Display LED/LCD

Positive ground inverters

Model name SiE2900-PG SiE3840-PG

Certifications

UL 1741, FCC Part 15 B, IEEE 1547, IEEE C62.41.2, IEEE C37.90.1

This manual suits for next models

3

Table of contents

Popular Inverter manuals by other brands

SEW-Eurodrive

SEW-Eurodrive MDX9 A-0020-5E3-4-T Series Compact operating instructions

Siel

Siel Soleil SPX Series user manual

Carrier

Carrier ASPAX1CCA015 Installation and owner's manual

Goodwe

Goodwe SDT G2 Series user manual

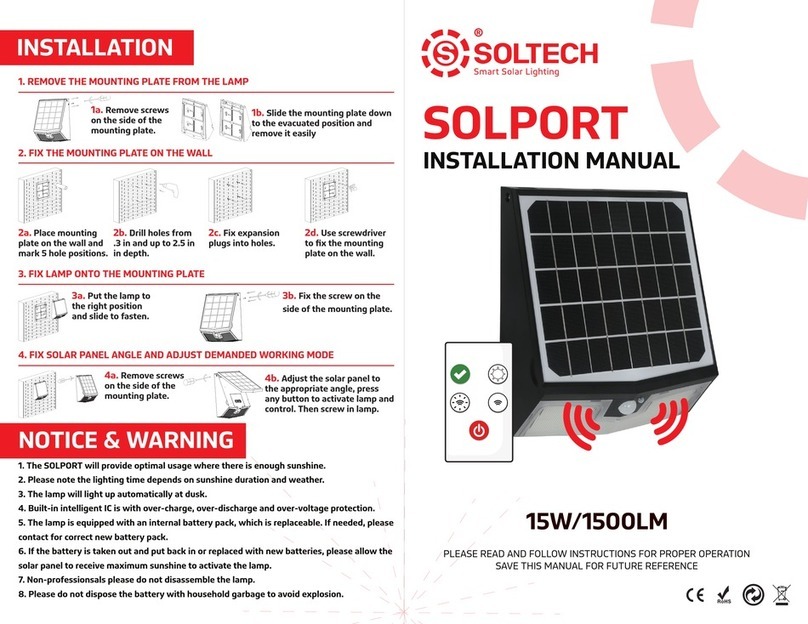

Soltech

Soltech SOLPORT 15W installation manual

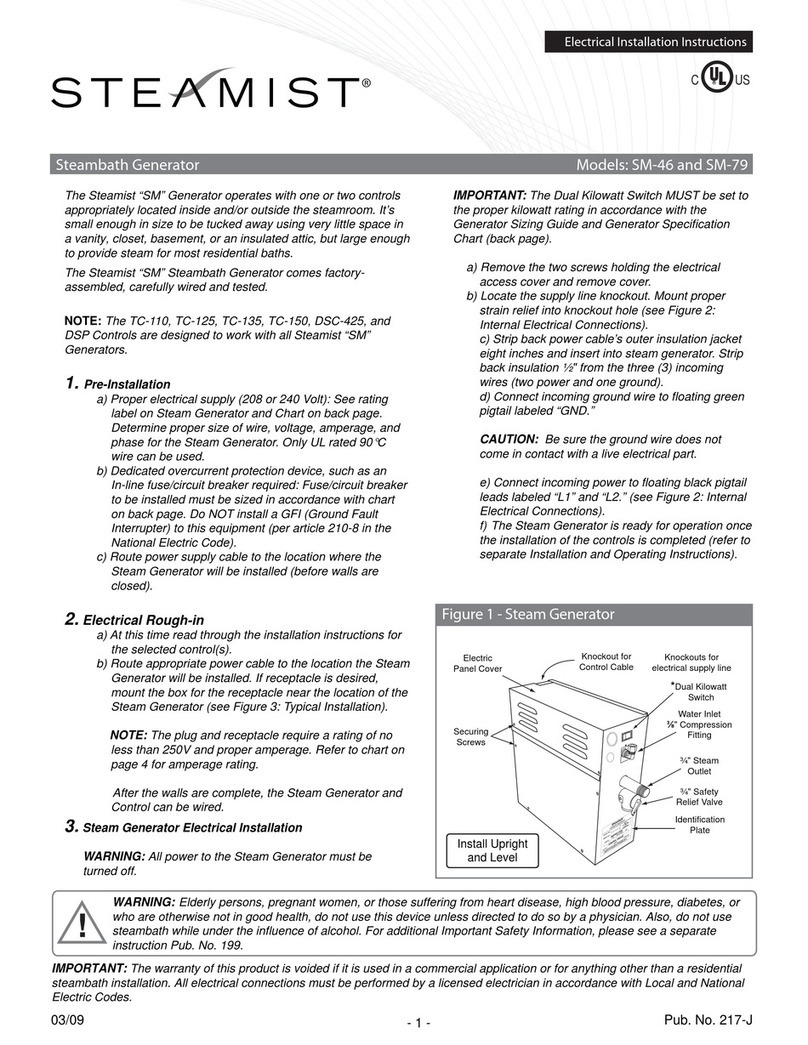

Steamist

Steamist SM-46 installation instructions