EG4 6000EX-48HV User manual

EG4 6000EX-48

INVERTER / CHARGER

User Manual

Version 1.2.0 January 2023 - Information subject to change without notice.

Table Of Contents

ABOUT THIS MANUAL ..................................................................................................................... 1

Purpose ............................................................................................................................................... 1

Scope .................................................................................................................................................. 1

SAFETY INSTRUCTIONS .................................................................................................................. 1

INTRODUCTION .............................................................................................................................. 3

Product Overview ................................................................................................................................. 4

INSTALLATION ................................................................................................................................ 5

Unpacking and Inspection ..................................................................................................................... 5

Preparation .......................................................................................................................................... 5

Mounting the Unit ................................................................................................................................. 5

Battery Connection ............................................................................................................................... 6

AC Input/Output Connection ................................................................................................................ 7

PV Connection ..................................................................................................................................... 8

Final Assembly ..................................................................................................................................... 9

Communication Connection ................................................................................................................. 10

Dry Contact Signal .............................................................................................................................. 10

OPERATION ................................................................................................................................... 11

Power ON/OFF ................................................................................................................................... 11

Operation and Display Panel ................................................................................................................. 11

LCD Display Icons ................................................................................................................................ 12

LCD Setting ......................................................................................................................................... 13

Display Setting .................................................................................................................................... 19

Operating Mode Description ................................................................................................................. 24

SPECIFICATIONS ............................................................................................................................ 2

TROUBLESHOOTING..................................................................................................................... 38

PARALLEL FUNCTION ........... ........................................................................................................ 27

BATTERY BASED COMMISSIONING GUIDE................................................................................... 36

WI-FI OPERATION GUIDE IN REMOTE PANEL .................. ........................................................... 42

BMS Communication Install................................................................................................................... 32

PARAMETER SETTING LIST .......................................................................................................... 50

1

ABOUT THIS MANUAL

Purpose

This manual describes the assembly, installation, operation and troubleshooting of this unit. Please read

this manual carefully before installation and operation. 3OHDVHNeep this manual for future reference.

Scope

This manual provides safety and installation guidelines as well as information on tools and wiring.

SAFETY INSTRUCTIONS

WARNING: This chapter contains important safety and operating instructions. Read and

keep this manual for future reference.

Before installing or using the unit, read all instructions and cautionary markings on theunit,

the batteries, and all appropriate sections of the manual.

CAUTION- Do not disassemble the unit. Take it to a qualified service center when service or

repair is required. Incorrect re-assembly may result in a risk of electric shock or fire.

To reduce risk of electric shock, shutdown and disconnect all wiring DQG SRZHU

LQSXWV RI DQ\ NLQG beforeattempting any maintenance or cleaning. Turning off the unit

alone will not reducethe risk of shock or injury.

CAUTION - Only qualified (OHFWULFDOO\WUDLQHGpersonnel can install this equipmentVDIHO\.

NEVER charge a battery below specified minimum temperature; refer to the battery data sheet.

Wire size is critical for safe operation, and optimal performance of the equipment. Refer to a

accredited sizing resource orWR cable manufacturer specifications to meet inverter/

chargerequirements.

Use caution when working with metal tools on or around all systems and batteries. Risk of

electrical arcs and/or short circuiting of equipment can lead to severe injury and damage.

Strictly follow installation procedure when connecting and disconnecting AC or DC terminals.

Refer to INSTALLATION section of the manual for details.

The iQWHUQDORYHUFXUUHQWGHYLFH is not a guarantee of battery protection. Size and install the

correct '&EUHDNHURUIXVH for the batteries if not included with the product.

GROUNDING -This inverter/charger should be connected to a permanent grounded wiring

system. The grounding system must meet the Authority Having Jurisdiction (AHJ)

requirements in your area.

NEVER short AC output and DC inputs. Do NOT connect to the grid with a shorted DC input.

Warning!! Only qualified service personQHO are able to service this device. If errors still

persist after following troubleshooting table, please contact your retailer for further

assistance.

WARNING: Because this inverter is non-isolated, only three types of PV modules are

acceptable: Monocrystalline, Polycrystalline with class A-rated, and CIGS modules. To avoid

any malfunction, do not connect any PV modules with possible current leakage to the

inverter. For example, grounded PV modules will cause current leakage to the inverter. When

using CIGS modules, please be sure NOT to groundHLWKHU39SROHV.

CAUTION: DC breakers and surge protection on PV lines DUH recommended. Without

breakers the equipment is at higher risk of damage from sources such as surges and

lighting strikesZKLFKDUHQRWXQGHUZDUUDQW\.

DISCLAIMER

EG4 reserves the right to make changes to the material herein at any time without notice. You may

refer to the EG4 website at www.eg4electronics.com for the most updated version of our manual.

2

SPECIFICATIONS

MODEL 6KW

RATED OUPUT POWER 6000W

PV INPUT

(

DC

)

Max. PV Power 7500W

Max. Input voltage

(

Maximum PV o

p

en volta

g

e

)

500 VDC

Max2XWSXW DC Power MPPT range 2 VDC~480 VDC

Workin

g

MPP ran

g

e 120 VDC~480 VDC

Max. DC Input current / 7RWDODUUD\DPSV 27A

Number of MPP TrackerV 1

GRID-TIE OPERATION,QWHUQDWLRQDO8VH2QO\

GRID OUTPUT

(

AC

)

Nominal Out

p

ut Volta

g

e 110-120VAC

(

L-N

)

/ 220-240VAC

(

L1-L2

)

Feed-in Grid Voltage Range 93.5~126.5 VAC For 110 Vac model

102~138 VAC For 120 Vac model

Feed-in Grid Fre

q

uenc

y

Ran

g

e57Hz~63Hz

Nominal Output Current 27.3A (for 110VAC)

25A

(

for 120VAC

)

Power Factor Ran

g

e >0.99

Maximum Conversion Efficienc

y

(

DC/AC

)

95%

OFF-GRID, HYBRID OPERATION

GRID INPUT

Acce

p

table In

p

ut Volta

g

e Ran

g

e 65 - 140 VAC

(

A

pp

liances

)

or 95 - 140 VAC

(

UPS

)

Fre

q

uenc

y

Ran

g

e 50 Hz/60 Hz

(

Auto sensin

g)

Ratin

g

of AC Transfer Rela

y

40A

BATTERY MODE OUTPUT

(

AC

)

Nominal Out

p

ut Volta

g

e 110-120VAC

(

L-N

)

/ 220-240VAC

(

L1-L2

)

Out

p

ut Waveform Pure Sine Wave

Efficienc

y

(

DC to AC

)

93%

BATTERY & CHARGER

Nominal DC Volta

g

e48VDC

Maximum Char

g

in

g

Current

(

from Grid

)

120A

Maximum Char

g

in

g

Current

(

from PV

)

120A

Maximum 7RWDOCharging Current 120A

GENERAL

Dimension, + X W X ' 23-3/8” x 14-3/8” x 5-1/2”

(

593.6 x 365 x 138.4 mm

)

Net Wei

g

ht lbs.( kgs)

INTERFACE

ParalleOYesUp to 9

Communication RS232/Dr

y

-Contact/Wi-Fi

ENVIRONMENT

Humidit

y

0 ~ 90% RH

(

No condensin

g)

O

p

eratin

g

Tem

p

erature 14°F to 122°F

(

-10°C to 50°C

)

3

INTRODUCTION

This is a residential self-consumption multi-function inverter, combining the functions of an inverter,

solar charge controller, and battery charger to offer uninterrupted power system in a single package. The

comprehensive LCD display offers user-configurable and easily-accessible button operations such as battery

charging current, AC or solar charging priority, and acceptable input voltage based on different applications.

Figure 1 Basic hybrid PV System Overview

Depending on different power situations, this hybrid inverter is designed to manage power from PV modules

(solar panels), battery bank, and the utility or generator AC input. When MPP input voltage of PV modules is

within acceptable range (see specification for the details), this inverter is able to charge the battery.

NOTE: Never connect the positive or negative poles of the solar equipment to ground.

NOTE: This inverter is only compatible with 240V Split-phase grid or generator input. The voltage between

Line 1 and Line 2 is equal to Line 1 to Neutral plus Line 2 to Neutral. The equipment does not support single-

phase or three-phase input or output.

6KW

L1

N

Grid

connection Load

Output

L1

N

L2 L2

L1

L2

N

L1

N

120V

L2

240V

The phase angle between L1 and L2 is 180°.

120V

120V

120V

240V

Electric

g

rids

4

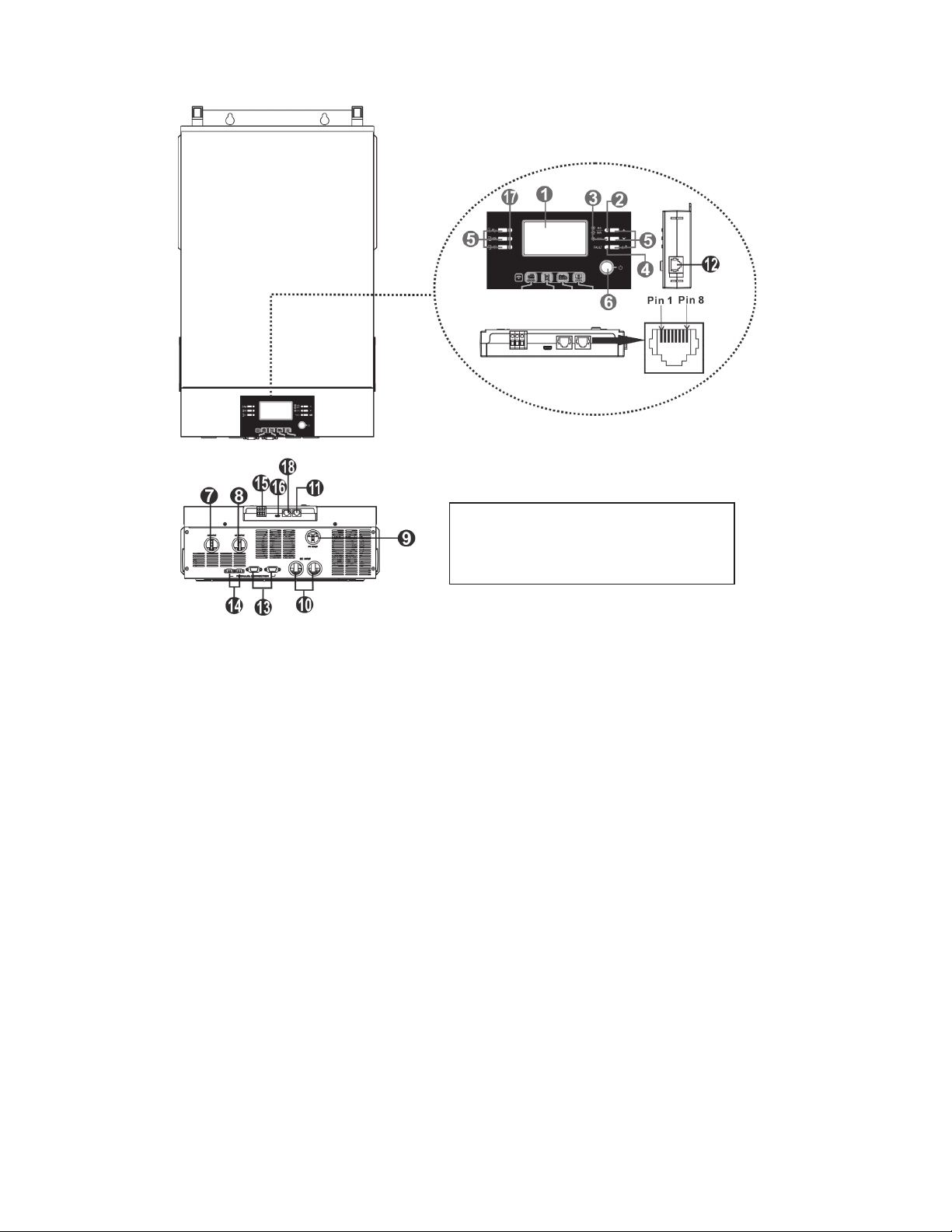

Product Overview

1. LCD display

2. Status indicator

3. Charging indicator

4. Fault indicator

5. Function buttons

6. Power on/off switch

7. AC input connectors

8. AC output connectors (Load connection)

9. PV connections

10. Battery connections

11. RS-232 communication port

12. Remote LCD panel communication port

13. Parallel communication port (only for use in parallel setups)

14. Current sharing port (only for parallel model)

15. Dry contact

16. USB communication port

17. LED indicators for USB function setting / Output source priority timer / Charger source priority setting

18. BMS communication port (RS-485)

NOTE: For parallel installation and

operation, refer to the commissioning

guide and connection diagrams.

5

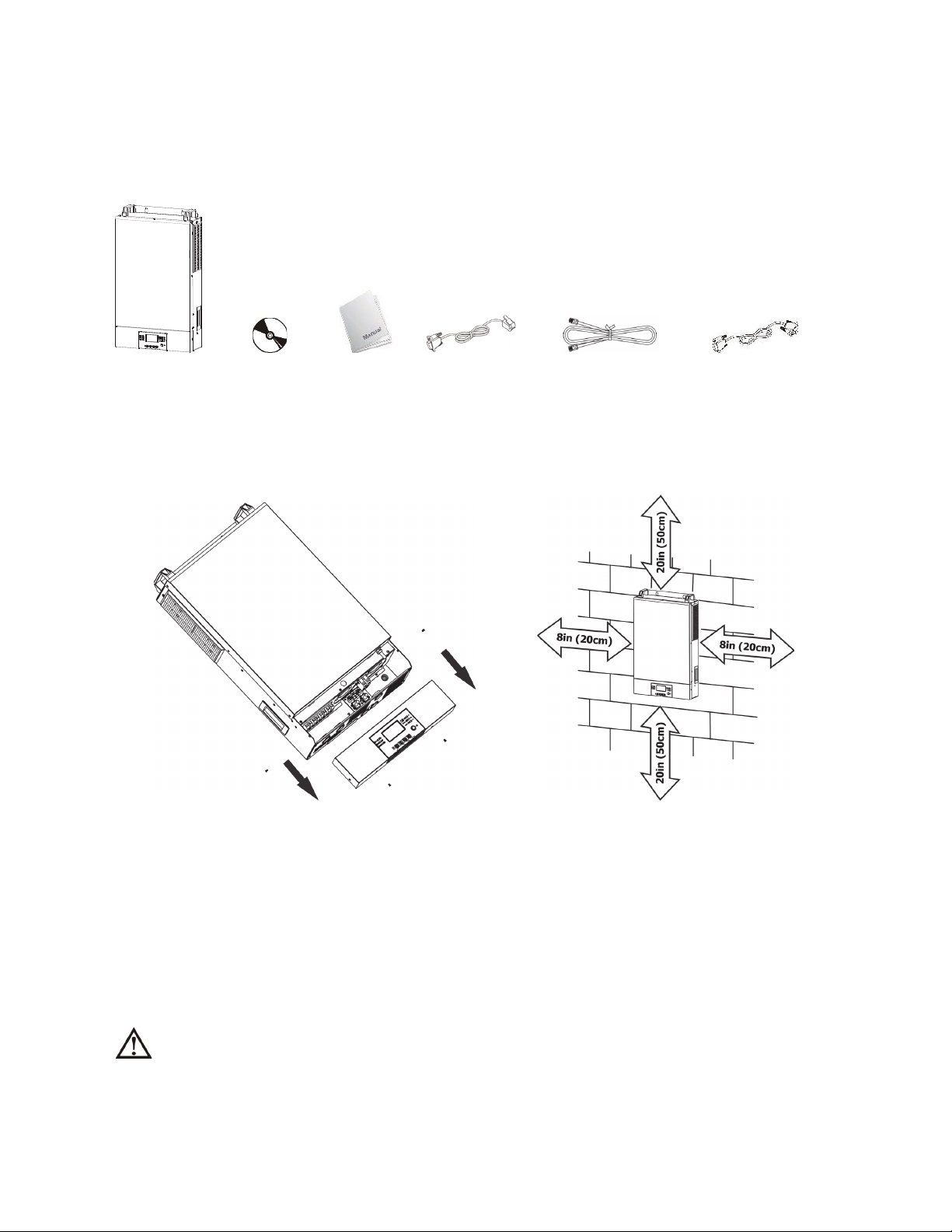

Inverter unit Software CD Manual RS-232 Cable Battery Comms Cable Parallel Cables

Preparation

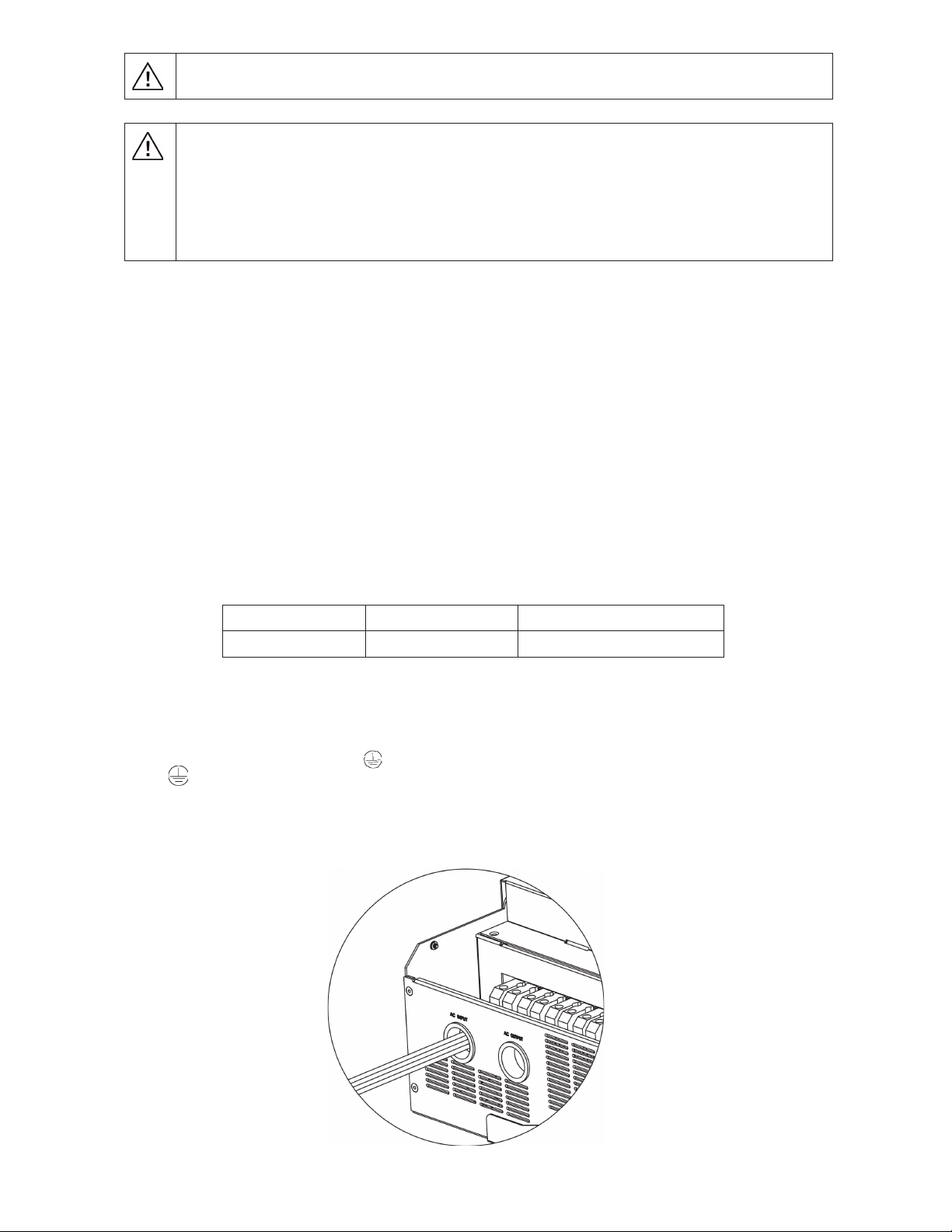

To prepare for the wiring step of installation, remove the bottom cover as shown below.

Mounting the Unit

Consider the following points before selecting a location for installation:

zAvoid mounting the inverter on combustible construction materials. Masonry or fire-resistant surfaces for

mounting are recommended.

zMount on a solid surface or appropriate strut/frame.

zInstall this inverter at the operator’s eye level in order to allow the LCD display to be read at all times.

zThe ambient temperature should be between 14°F(-10°C) and 122°F(50°C) to ensure optimal operation.

zInstall the inverter vertically and follow local AHJ requirements for equipment clearances.

zEnsure enough clearance based on the diagram above for proper cooling/ventilation.

SUITABLE FOR MOUNTING ON CONCRETE OR OTHER NON-COMBUSTIBLE SURFACES ONLY.

INSTALLATION

Unpacking and Inspection

Before installation, please inspect the unit. Be sure nothing inside the package is damaged. Check to ensure the

following items are included with each inverter:

6

Battery Connection

CAUTION: For safe operation and regulation compliance, it is required to install a separate DC over-current

protector or disconnect device between battery and inverter. It may not be required to have a disconnect

device in some applications, however, you are required to have over-current protection installed. Please refer

to typical amperage in the below table for required fuse or breaker size.

WARNING! All wiring must be performed by electrically trained personnel

WARNING! It's critically important for system safety and efficient operation to

use appropriate cable sizes for battery connections. To reduce risk of injury,

please use the proper recommended cable and terminal sizes below.

Recommended battery cable and terminal size:

Model Typical

Amperage

Minimum

Battery

Capacity

Wire Size Ring Terminal Torque Value

Min size Dimensions

D (mm) L (mm)

6KW 137A 300AH 2AWG 2AWG/

38mm2

M10

13mm nut

39 ~ (2-3 Nm)

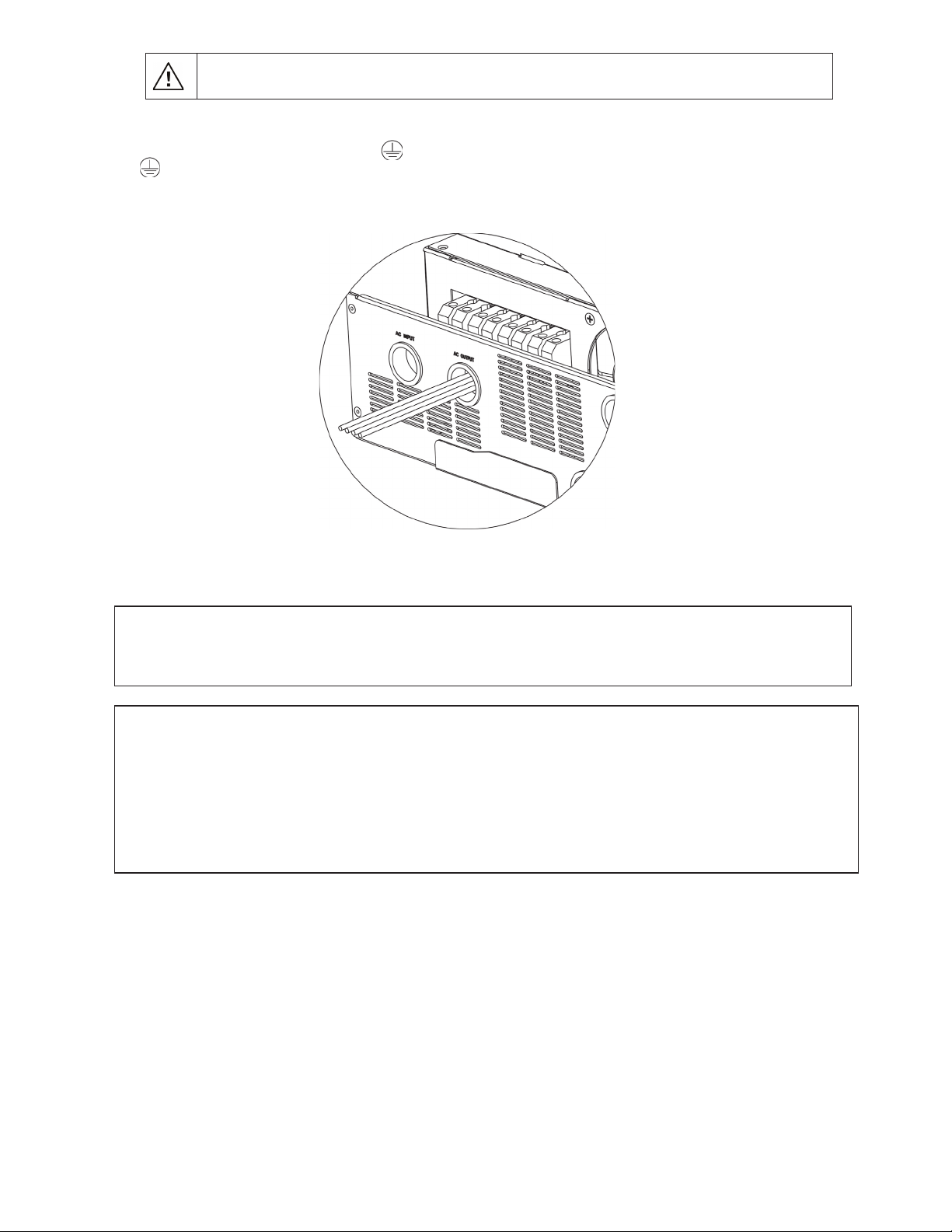

Please follow below steps to implement battery connection:

1. Assemble battery ring terminal based on

recommended battery cable and terminal size.

2. Insert the ring terminal of battery cable flatly into

battery connector of inverter and make sure the nuts

are tightened with a torque of 17-27 in-lbs/ 2-3 Nm.

Make sure polarity at both the battery and the inverter/

charger is correctly connected and ring terminals are

tightly screwed to the battery terminals.

Ring terminal:

Mounting the Inverter

Install the unit using all three screw holes. Use #8 (M4) or #10 (M5) screws.

WARNING: Shock Hazard

Installation must be performed carefully; arc and shock hazards are present.

CAUTION! Do not place anything between the flat part of the inverter terminal and the ring

terminal. Mixed materials, gaps, and loose connections can all lead to overheating.

CAUTION! Do not apply anti-oxidant substance on the terminals before terminals are connected.

CAUTION! Before connecting the DC circuit, ensure proper polarity of the system. Ensure the

positive (+) terminal of the inverter is properly connected to the battery, and disconnect/fusing or

breaker, as well as the polarity of the negative (-) connections.

AC Input/Output Connection

CAUTION! Before connecting to AC input power source, install a separate AC breaker (40A max) between

inverter and AC input power source. Ensure the input breaker and conductor ratings match. Installation of a

breaker on the AC input is required for OCP and means of disconnect. Check with your AHJ and ensure correct

system design for regulatory compliance.

CAUTION! There are two sets of terminal blocks, one for input and the other for output. While the terminals

are marked “IN” and “OUT”, double check to ensure wires throughout the system are connected and phased

correctly. Use fine stranded 90C rated wiring of the correct type based on code requirements.

WARNING! All wiring must be performed by qualified personnel. Follow the requirements of your local AHJ.

WARNING! For all AC wiring, proper sizing is required. Refer to the wire type and ampacity calculations required

by the specific design, site, and local regulatory requirements. To reduce risk of injury and damage to equipment,

please use the minimum recommended cable size as below.

Suggested minimum cable requirement for AC wiring:

Model Gauge Terminal Torque Value

6KW 10 AWG ~10-14 in-lbs (1.2-1.6 Nm)

Please follow the below steps to implement AC input/output connection:

1. Before making AC input/output connection, disconnect all DC sources of energy.

2. Remove ~7/16” (10mm) of insulation from all eight wires (L1, N, L2, G).

3. Insert AC input wires according to labeling on the terminal blocks and tighten the terminal screws. Be sure to

connect the grounding conductor ( ) first.

→Ground (Green or Green with Yellow stripe)

L1 → Line (Black)

L2 → Line (Red)

N → Neutral (White or Gray)

1RWH Cord grips, conduit, or other

approved methods of securing wires must be

used.

1RWH Wire colors

may vary.

WARNING:

Ensure all AC power sources and loads are disconnected before wiring the unit.

4. Insert the AC output wires according to labeling on the terminal block and tighten terminal screws. Be sure

5. Make sure the wires are securely connected, and use required cord grips or conduit.

PV Connection

CAUTION: Before connecting to PV modules/strings, install separate DC circuit breakers or a means of

disconnect paired with properly sized fuses between inverter and PV modules/strings. DO NOT work with or

connect live PV conductors to the unit EVER. Ensure all exposed conductors are safely disconnected from the

power source.

NOTE: Use 600V/30A rated circuit breakers. DC rated breakers must be used. The over voltage category of the

PV input is II. Please Follow the steps below to complete PV connections.

WARNING! All wiring must be performed by qualified personnel.

WARNING: Making connections with live a PV source will damage the inverter!

WARNING! It's very important for system safety and efficient operation to use appropriate cables for PV

module connection. To reduce risk of injury, use the proper recommended cable size below.

CAUTION: Appliances with heavy start and run demands, such as air conditioners, require special

consideration. For many air conditioners for example, at least 2~3 minutes to restart might be required to

allow enough time to balance refrigerant gases. If a power outage occurs and recovers in a short time, it may

cause damage to the connected appliances. To prevent damage, please check with the manufacturer of the

appliance to see if it is equipped with a time-delay function or soft-start feature before installation. Overload of

the inverter/charger may trigger a fault leading to a sudden loss of AC output power, which may cause

damage to appliances with motors/compressors.

CAUTION: Important

Connect AC wire to correct terminals. If either Line 1 or 2 are reversed with Ground/Neutral it will cause a

short-circuit and damage the equipment and loads connected to the system.

to connect the grounding conductor ( ) first.

→ Ground (Green or Green with a Yellow stripe)

L1 → Line 1 (Black) 1RWH Cord grips or other approved

L2 → Line 2 (Red) methods of securing wires must be used.

N → Neutral (White or Gray)

1RWH Wire colors

may vary.

9

CAUTION: It is required to use a PV surge protection device. Damage to the inverter can occur from surges

such as lighting or short circuits.

Model Typical Amperage Cable Size Torque

6KW 27A 10AWG ~17-21 in-lbs (-2.0-2.4Nm)

PV Module Selection:

1. Open Circuit Voltage (Voc) of the PV modules/strings must not exceed the unit's maximum rating. Voc

must be calculated including the environmental impacts, such as temperature in accordance to the

module manufacturer's data sheet and reliable weather data for the installation location.

2. Voltage at Maximum Power (Vmp) of PV strings must be higher than the start-up voltage of the inverter.

WARNING: Exceeding the maximum input voltage will destroy the unit!

Solar Charging Mode

INVERTER MODEL 6KW

Max. PV Array Open Circuit Voltage 500 Vdc

PV Array MPPT Voltage Range 120-480Vdc

MPP Number 1

Follow the below steps to complete PV connection:

1. Remove 10 mm (3/8in) of insulation from positive and negative conductors.

2. Check for correct polarity of connections at the PV inputs at the disconnect,

with the disconnecting means off to ensure the exposed output in not live.

Connect the positive pole (+) of the PV source to the positive pole (+) of PV

input terminal. Connect the negative pole (-) of the PV source to the

negative pole (-) of the PV input terminal. Tighten the terminals.

Final Assembly

After connecting all wiring, please put the bottom cover back by screwing four screws as shown below.

7KLVFRYHULVFULWLFDOIRUVDIHXVHRIWKLVGHYLFHDV/(7+$/YROWDJHVRFFXUEHKLQGLW

11RWH Cord grips or Conduit must be used.

1

Communication Connection

Serial Connection

Please use the supplied communication cable to connect to inverter and PC. Insert the bundled CD into a

computer and follow the on-screen instructions to install the monitoring software. For the detailed

software operation instructions, please check the user manual of the software stored on the CD.

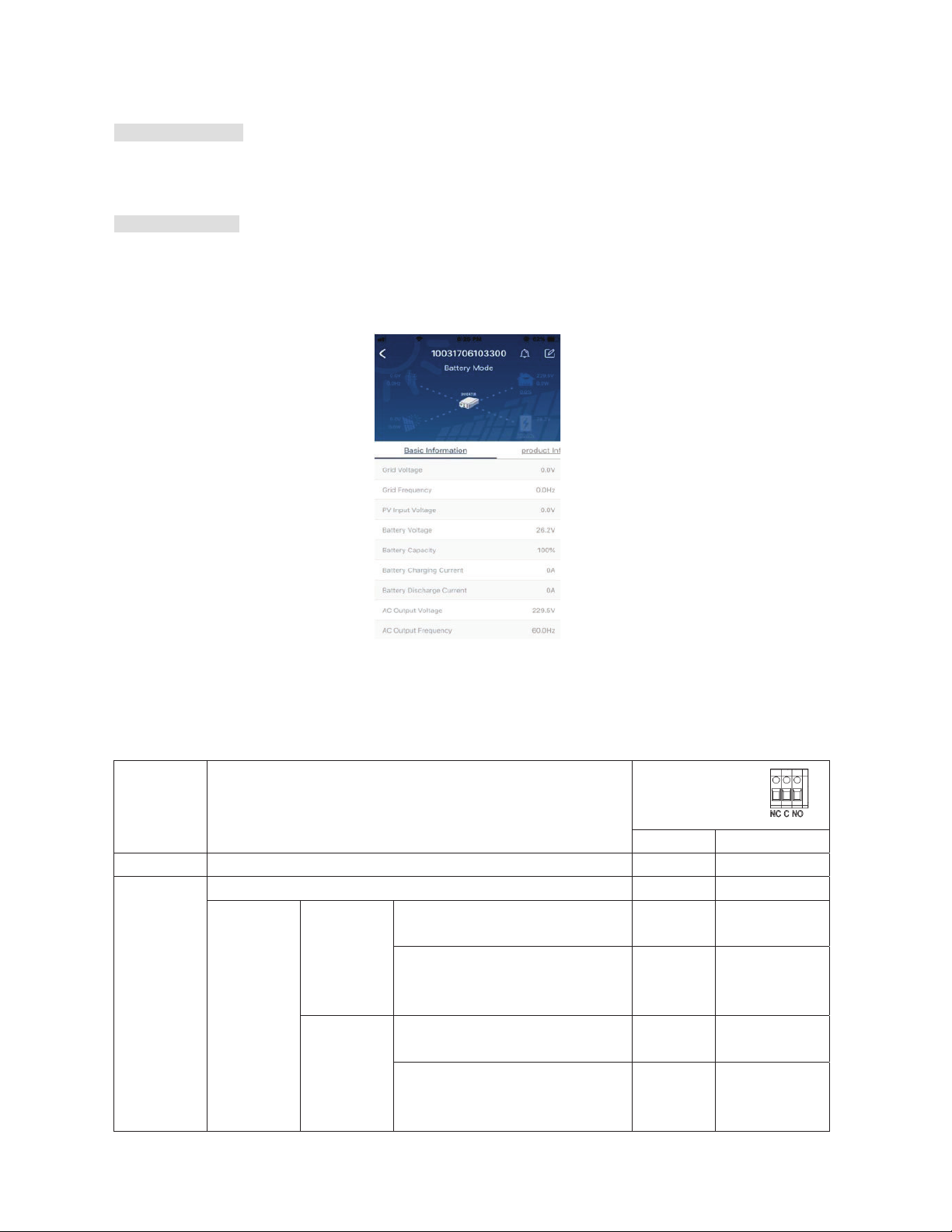

Wi-Fi Connection

Wi-Fi module can enable wireless communication between off-grid inverters and the cloud monitoring

platform. Users have complete remote monitoring and control capacity for inverters when combining the Wi-

Fi module with the SolarPower APP, available for both iOS and Android based device. All data loggers and

parameters are saved in the cloud. Refer to Appendix IV for detailed operation.

Dry Contact Signal

There is one dry contact (3A/250VAC) available on the rear panel. It could be used to deliver a signal to an

external device when battery voltage reaches a warning level.

Unit Status Condition Dry contact port:

NC & C NO & C

Power Off Unit is off and no output is powered. Close Open

Power On

Output is powered from Utility. Close Open

Output is

powered

from

Battery or

Solar.

Program 01

set as SUB

Battery voltage < Low DC warning

voltage Open Close

Battery voltage > Setting value in

Program 21 or battery charging

reaches floating stage

Close Open

Program 01

is set as

SBU

Battery voltage < Setting value in

Program 20 Open Close

Battery voltage > Setting value in

Program 21 or battery charging

reaches floating stage

Close Open

1

OPERATION

Power ON/OFF

After completing installation of the unit, the next step is powering on for setup. Start by pressing the

On/Off switch (located on display unit) to power on the system.

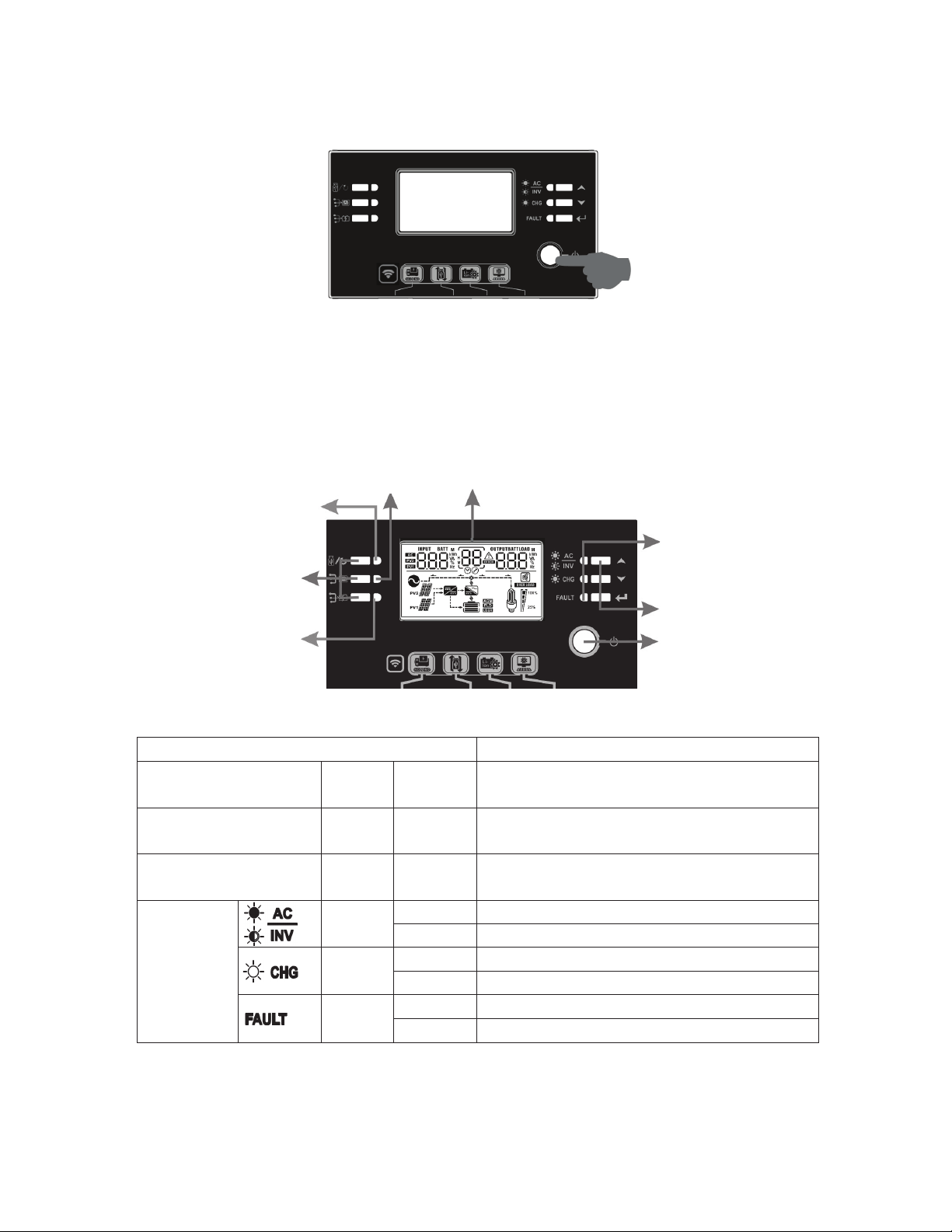

Operation and Display Panel

Refer to the diagram and table below for details on the operation and display panel. There are three

indicators, four function keys, and an LCD display.

LCD display

LED Indicators

LED Indicator Messages

Setting LED1 Green Solid On Reserved for future features

Setting LED2 Green Solid On Reserved for future features

Setting LED3 Green Solid On Reserved for future features

Status

Indicator

Green Solid On Output is powered by utility in Line mode.

Flashing Output is powered by battery or PV in battery mode.

Green Solid On Battery is fully charged

Flashing Battery is charging.

Red Solid On Fault mode

Flashing Warning mode

Status

indicators

Function keys

On/off switch

Function keys

Setting LED 3

Setting LED 1

Setting LED 2

1

Function Keys

Function Key Description

ESC Exit the setting/go back

Reserved Reserved

Reserved Reserved

Up Scroll to previous selection

Down Scroll to next selection

Enter To confirm/enter the selection in setting mode

LCD Display Icons

Icon Function

Input source information

Indicates AC input information is being displayed

Indicates PV1 input information is being displayed (PV2 not used)

Left digital display information

Indicates input voltage, input frequency, battery voltage, PV

voltage, charger current

Middle digital display information

Indicates the setting when cycling through options.

Indicates the warning and fault codes.

Warning: Flashing with warning code

Fault: display with fault code

Right digital display information

Displays the output voltage, output frequency, load percent, load VA, load

W, PV charger power, DC discharging current based on current unit being

displayed and cycled through.

Battery information

Displays battery state of charge (SOC) by ranges from 0-24%, 25-49%,

50-74%, and 75-100% per bar, and charging status.

1

Load information

Indicates output overload.

Indicates the load level by 0-24%, 25-49%, 50-74%, and 75-100%.

0%~24% 25%~49% 50%~74% 75%~100%

Mode operation information

Indicates connection to an AC input source.

Indicates connection of the PV array.

Indicates solar is being used to charge the battery bank.

Indicates the DC/AC inversion is working.

Mute operation

Alarm is disabled. Warning: Will not signal a fault when disabled!

LCD Setting

After pressing and holding ENTER button for 3 seconds, the unit will enter setting mode. Press “UP” or “DOWN”

buttons to select setting programs. Then, press the “ENTER” button to confirm the selection or the ESC

button to exit.

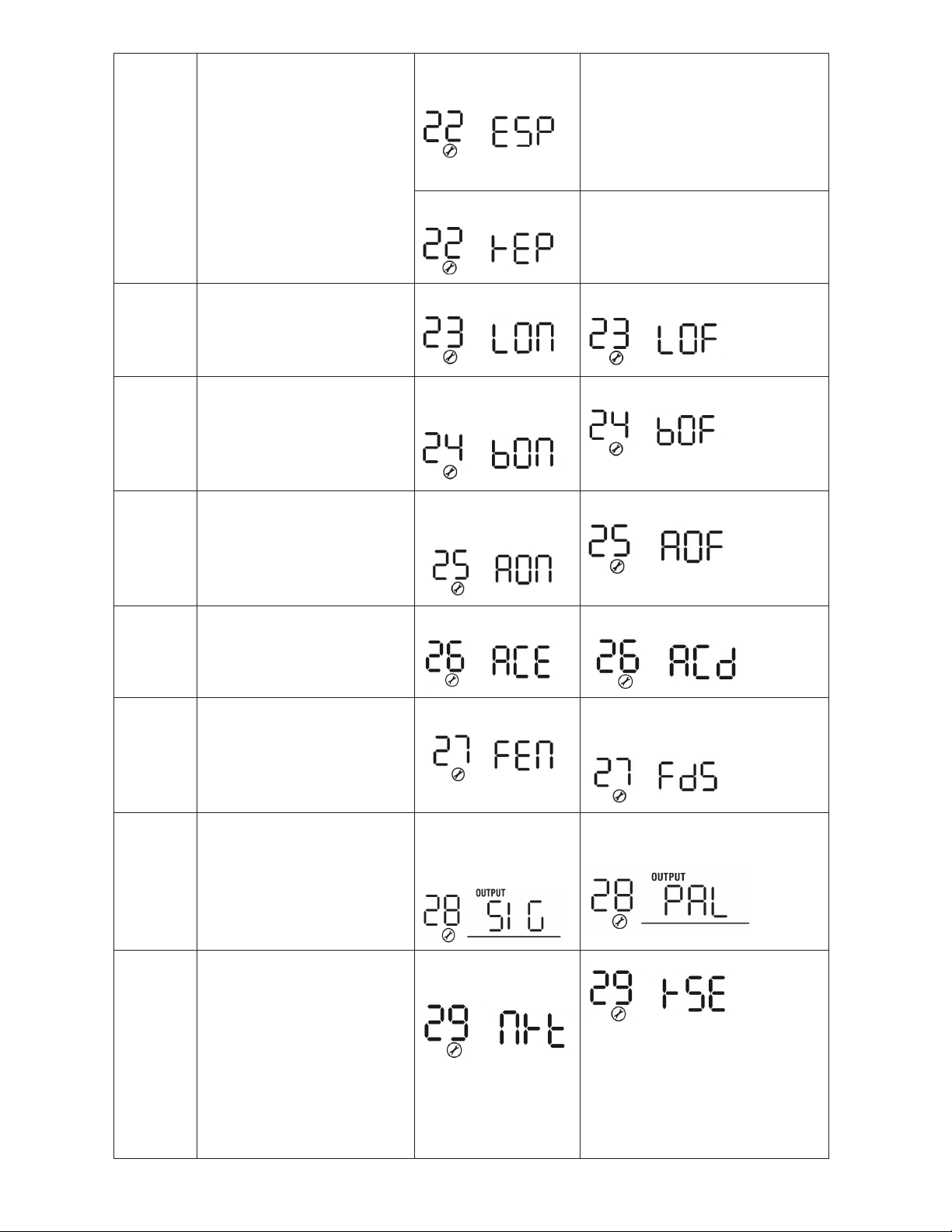

Program Description Selectable option

00 Exit setting menu

Escape

01 Output source priority selection

SUB (Default) Solar energy provides power to the

loads as first priority.

If solar energy is not sufficient to

power all connected loads, Utility

energy will supply power to the loads

at the same time.

SBU Solar energy provides power to the

loads as first priority.

If solar energy is not sufficient to

power all connected loads, battery

energy will supply power to the loads

at the same time.

Utility provides power to the loads

only when battery voltage drops to

either low-level warning voltage or

the setting point in program 20, or if

solar and battery is not sufficient.

1

02 AC input voltage range

Appliances

(Default setting)

If selected, acceptable AC input

voltage range will be set to

65-140VAC.

UPS If selected, acceptable AC input

voltage range will be set to

95-140VAC.

03 Output voltage

110Vac 120V (Default setting)

04 Output frequency

50Hz 60Hz (Default setting)

05 Solar supply priority

Available power will

charge battery first

(default setting)

Solar energy provides power to

charge battery as first priority.

Power supplies the

loads first

Solar energy provides power to the

loads as first priority.

06

Overload bypass:

When enabled, the unit will

transfer to line mode if

overload occurs in battery

mode.

Bypass disabled Bypass enable (default setting)

07 Auto restart when overload

occurs

Restart disable

(default setting)

Restart enabled

08 Auto restart when over

temperature occurs

Restart disable

(default setting)

Restart enabled

09

Solar energy feed to grid

configuration

WARNING: THIS SETTING

IS NOT &(57,),(')25

7+(81,7('67$7(6

$/:$<6*(763(&,),&

3(50,66,21)520

<28587,/,7<$1'$+-

7223(5$7(7+,602'(

Feed to grid disable

(default setting)

Solar energy back-feed to grid

disable.

Feed to grid enable Solar energy back-feed to grid

enable.

1

10

Charger source priority:

Configure battery charger

source priority

If this inverter/charger is working in Line, Standby or Fault

mode, charger source can be programmed as below:

Solar first Solar energy will charge battery as

first priority.

Utility/AC input will charge battery

only when solar energy is not

available.

Solar and Utility

(default)

Solar energy and utility/AC input will

charge battery at the same time.

Solar only Solar energy will be the only charger

source, even when utility/AC input

power is available.

If this inverter/charger is working in Battery mode, only

solar energy can charge the battery. Solar energy will

charge battery if it's available and sufficient.

11

Maximum charging current:

To configure total charging

current for solar and utility

chargers.

(Max charging current =

utility/AC input charging

current + solar charging

current)

60A (default setting) The setting range is from 10A to

120A. Each click is a 10A increment.

13 Maximum utility/AC input

charging current

30A (default setting) The setting range is from 10A to

120A. Each click is a 10A increment.

14 Battery type

AGM (default) Flooded

User-Defined If “User-Defined” is selected, battery

charge voltage and low DC cut-off

voltage can be set up in program 17,

18 and 19.

EG4 If this is selected, programs 11,

17, 18 and 19 will be automatically

set up. Please contact the battery

supplier for installation procedure.

$LVQHHGHGIRU

N:39FDSDFLW\

1

LIb-protocol Select “ LIb” if using Lithium battery

compatible to Lib protocol. If

selected, programs of 11, 17, 18 and

19 will be automatically set up. No

need for further setting.

3rd party Lithium

battery

If selected, programs of 11, 17, 18

and 19 will be automatically set up.

Please contact the battery supplier

for installation procedure.

17 Bulk charging voltage

(C.V voltage)

Default setting: 56.4V

If self-defined is selected in program 14, this program can

be set up. Setting range is from 48.0V to 64.0V. Each click is

an increment of 0.1V.

18 Float charge voltage

Default setting: 54.0V

If self-defined is selected in program 14, this program can

be set up. Setting range is from 48.0V to 64.0V. Each click is

an increment of 0.1V.

19 Low DC cut off battery voltage

setting

Default setting: 40.8V

If self-defined is selected in program 14, this program can be

set up. Setting range is from 40.8V to 48.0V. Each click is an

increment of 0.1V. Low DC cut-off voltage will be fixed to

setting value no matter what percentage of load is

connected.

20 Bypass loads to grid when

grid is present.

default setting: 46V

Setting range is from 44V to 51V

and each click is an increment of

1V.

In EG4 Mode you will see a

percentage instead

21 Set point for transfer back to

off-grid operation if system is

bypassed based on 20

Battery fully charged The setting range is from 48V to

58V, Each click is an increment of

1V.

In EG4 Mode you will see a

percentage instead

Default setting: 54V

22 Auto return to default display

screen

Return to default

display screen (default)

If selected, no matter how users

switch display screen, it will

automatically return to default

display screen (Input voltage

/output voltage) after no button is

pressed for 1 minute.

Stay at latest screen If selected, the display screen will

stay at latest screen user selects

(good for keeping your favorite

view up)

23 Backlight control

Backlight on (default) Backlight off

24 Alarm control

Alarm on (default

setting)

Alarm off

25 Beeps while primary power

source is interrupted/faults

Alarm on (default

setting)

Alarm off

26 AC coupling (may require

firmware update not available

at release date of this model)

Enable Disable

27

Record Fault codes

(this is best to

enable)

Record enabled (default) Record disable

28

AC output mode

*This setting is only available

when the inverter is in standby

mode (Switch off).

Single: When selected,

the unit is used in

standalone operation.

Parallel: When selected, Parallel

stacking of up to 9 units is enabled

29 Reset PV energy storage kwh

history

Not reset (default

setting)

Reset

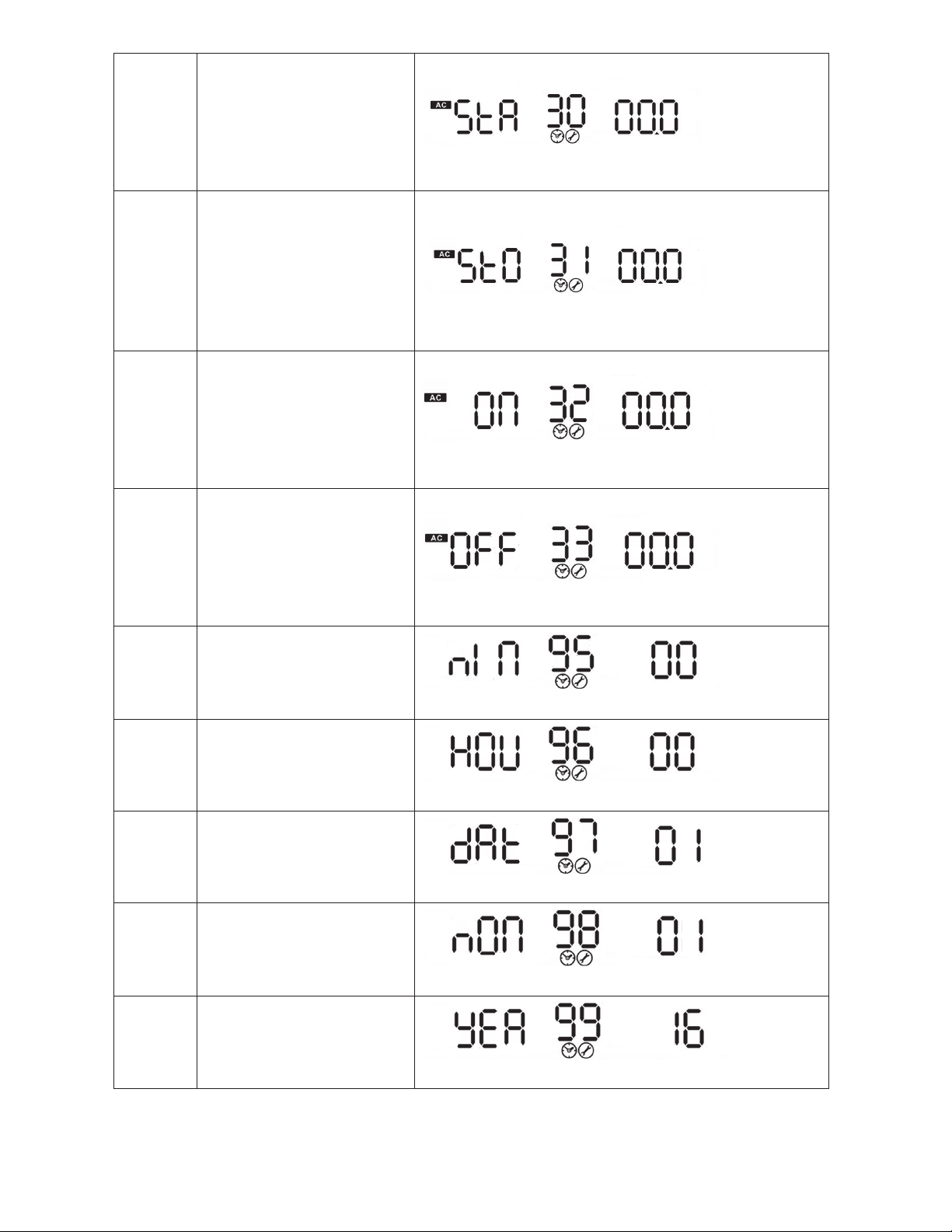

30 Scheduled Start charging

time for AC charger

00:00 (default setting)

The setting range of starting time for the AC charger is from

00:00 to 23:00, each click is 1 hour.

31 Scheduled Stop charging

time for AC charger

00:00 (default setting)

The setting range of stop charging time for AC charger is

from 00:00 to 23:00, each click is 1 hour.

32 Scheduled time for AC output

on

00:00 (default setting)

The setting range of scheduled time for AC output on is from

00:00 to 23:00, each click is 1 hour.

33 Scheduled time for AC output

off

00:00 (default setting)

The setting range of scheduled time for AC output off is from

00:00 to 23:00, each click is 1 hour.

95 Current time setting – Minute

For minute setting, the range is from 00 to 59.

96 Current time setting – Hour

For hour setting, the range is from 00 to 23.

97 Current time setting– Day

For day setting, the range is from 00 to 31.

98 Current time setting– Month

For month setting, the range is from 01 to 12.

99 Current time setting – Year

For year setting, the range is from 16 to 99.

This manual suits for next models

1

Table of contents

Other EG4 Inverter manuals

Popular Inverter manuals by other brands

Mitsubishi Electric

Mitsubishi Electric FR-F820-00046 instruction manual

Viessmann

Viessmann Vitosol-F XL manual

MMD Equipment

MMD Equipment IGR2000P user manual

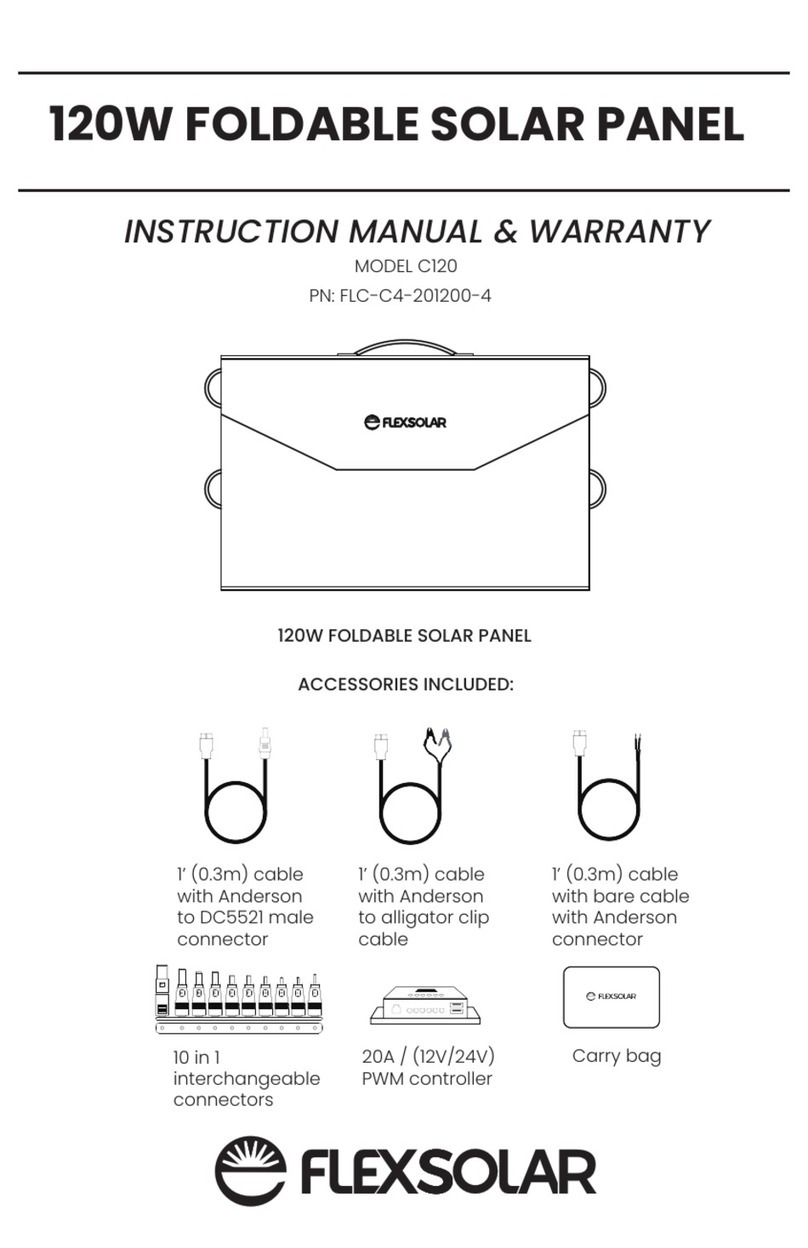

Flexsolar

Flexsolar C120 Instruction manual & warranty information

FujiFilm

FujiFilm FRENIC-Mini instruction manual

Bryant

Bryant ASPAS1BBL025 owner's manual