SE905 9 rev. 10/09/15

SE510 Herramienta de corte 3"

EL INCUMPLIMIENTO DE OBSERVAR ESTAS ADVERTENCIAS PUEDEN RESULTAR EN ALGUNA LESIÓN

ESTE MANUAL DE INSTRUCCIONES CONTIENE

INFORMACIÓN IMPORTANTE DE SEGURIDAD.

LEA CUIDADOSAMENTE ESTE MANUAL INSTRUCTIVO Y

COMPRENDA TODA INFORMACIÓN ANTES DE OPERAR

ESTA HERRAMIENTA.

• Lea y comprenda todas las instrucciones. Hacer caso

omiso a todas las instrucciones alistadas a continuación

podría ocasionar choque eléctrico, incendio, una explosión

y/o lesiones personales serias. Lea y comprenda todas las

instrucciones. Hacer caso omiso al seguir todas las

instrucciones alistadas a continuación podría ocasionar el

choque eléctrico, incendio, explosiones y/o lesiones

personales serias. Es las responsabilidad del propietario

asegurarse que todo el personal lea este manual previo

al uso de este dispositivo. También es la responsabilidad

del propietario del dispositivo mantener intacto este manual

y en un lugar conveniente para que todos lo lean y vean. Si

el manual o las etiquetas se hayan perdido o no sean

legibles, comuníquese con Monstor Mobile por algunos

repuestos. Si el operador no domina el idioma inglés, las

instrucciones del producto y de seguridad le serán leídas

y discutidas con el operador en el idioma materno del

operador por parte del comprador/propietario o su designado,

asegurándose que el operador comprenda el contenido.

• Opere, inspeccione y mantenga siempre esta herramienta

de acuerdo con el Código de Seguridad del Instituto

Americano de Estándares Nacionales para las

Herramientas Portátiles Neumáticas (ANSI B186.1) y

cualquier otro código o regulación aplicables.

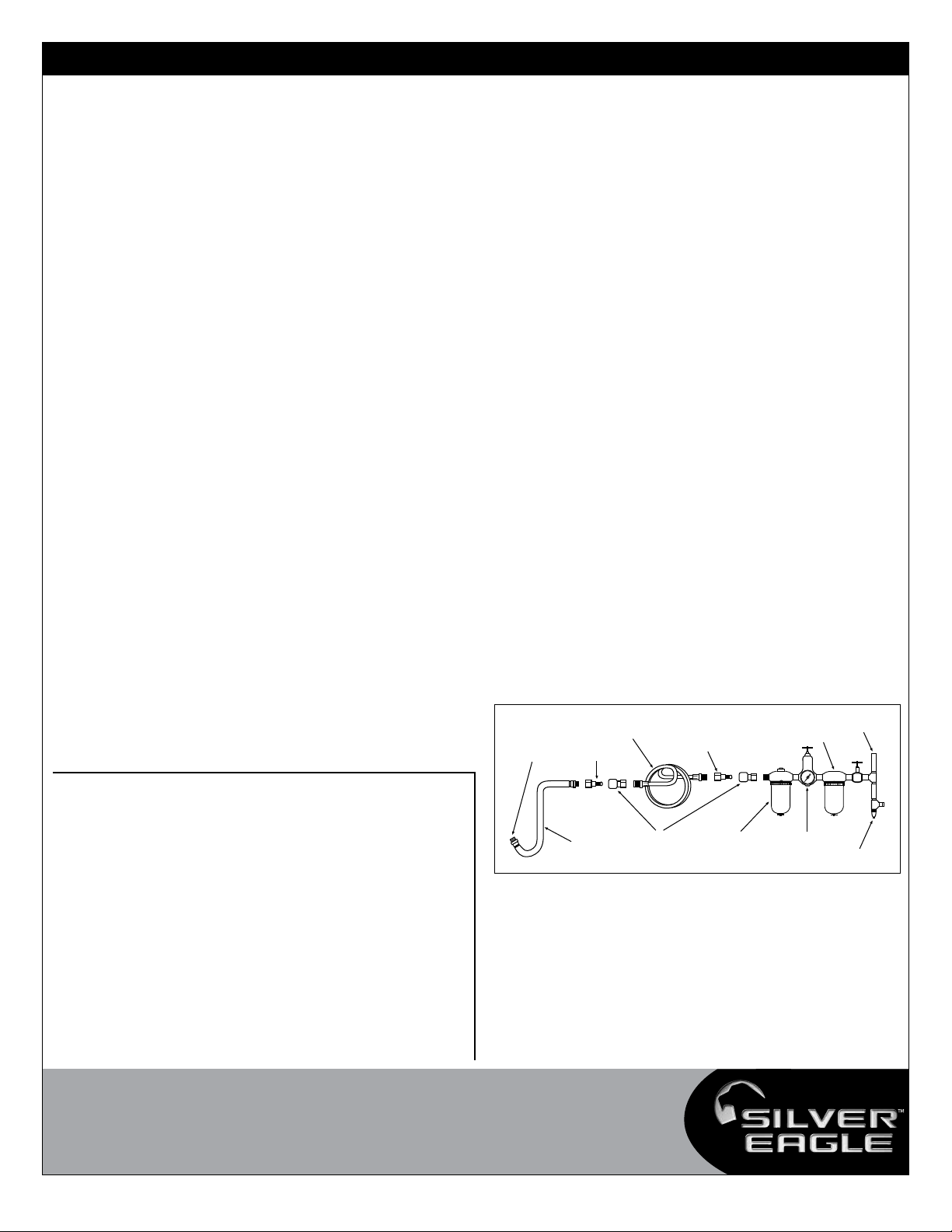

• Por seguridad, desempeño superior y durabilidad máxima

de las refacciones, opere esta herramienta a la máxima

presión de aire al 90 psig; 6.2 barg. con una manguera de

alimentación de aire de 3/8" en diámetro.

• Siempre lleve protección de ojos y cara resistentes al impacto,

al momento de operar o realiza mantenimiento a esta

herramienta. (usuarios y espectadores).

• Niveles de sonidos altos pueden provocar una pérdida

permanente del oído. Utilice una protección para las

orejas según las recomendaciones de su patrón las

regulaciones OSHA (usuarios y espectadores).

• Mantenga esta herramienta en condición eficiente de

operación.

• Los operadores y personal de mantenimiento deben poder

físicamente manejar el volumen, peso y potencia de esta

herramienta.

• La operación podría ocasionar algún impacto, corte, abrasión

y/o calentamiento. Lleve puesto guantes para protegerse

las manos.

• El aire bajo presión puede ocasionar alguna herida

severa. Nunca dirija el aire hacia usted ni a otros.

Apague siempre la alimentación de aire, vacíe la

manguera de toda presión de aire y separe la herramienta

de la alimentación de aire antes de instalar, quitar o

ajustar cualquier accesorio de esta herramienta, o antes

de realizar cualquier mantenimiento de esta herramienta.

La falla en hacerlo podría resultar en alguna lesión.

Las mangueras de látigo pueden ocasionar alguna herida

seria. Revise siempre las mangueras y herrajes por daños,

deshilachas o solturas, y repóngalos inmediatamente.

No use en la herramienta los acoplamientos de rápida

separación. Vea las instrucciones por la instalación

correcta.

• Mantengalejosdelalcancedelosniños.

• Las herramientas neumáticas pueden vibrar con su uso. Las

vibraciones, movimientos repetitivos o posiciones incómodas

durante períodos extendidos de tiempo pueden ser dañinos

para sus manos y brazos. Suspenda el uso de la herramienta

si experimente molestias, estremecimiento o dolor. Antes de

continuarusándola,soliciteelconsejomédico.

• Resbalarse, tropezarse y/o caerse durante la operación de

herramientas neumáticas puede ser una causa mayor de

lesión seria o la muerte. Sea consciente de la manguera

excedente,dejadaporlasuperficieparacaminarotrabajar.

• Mantenga balanceada y firme la postura corporal de trabajo.

Noseextralimitealoperarestaherramienta.

• Note el sentido de la rotación ANTES de operar esta

herramienta.

• Anticipe y sea alerto por cambios repentinos de movimiento

durante el arranque inicial y operación de cualquier

herramienta neumática.

• No lleve la herramienta por la manguera. Proteja la manguera

deobjetosafiladosydelcalor.

• El eje de la herramienta puede seguir rotando brevemente

después de que se libere la válvula reguladora. Evite el

contacto directo con los accesorios durante y después del

uso. Los guantes reducirán el riesgo de alguna cortada o

quemadura.

• Manténgase lejos del extremo rotador de la herramienta.

No lleve puesto ni joyería ni ropa suelta. Fije el pelo largo.

Se puede arrancar el cabello si no se lo mantenga a distancia

de la herramienta y accesorios. Mantenga a distancia de la

herramienta y de los accesorios los accesorios del cuello

para evitar el ahogamiento.

• NO use (ni altere) la herramienta para ningún otro uso

excepto él para el cual fue diseñado, sin consultar primero a

algúnrepresentanteautorizadodelfabricante.

• El montaje correcto de la rueda de corte es necesario para

la prevención de lesiones provenientes de ruedas rotas. No

use ruedas de corte astilladas o agrietadas. Las ruedas de

corte deberán caber libremente en el eje con el fin de

prevenir tensión en al agujero. Use sólo collarines de rueda

las que viene adjunto con la herramienta para el montaje de

la rueda de corte. Las arandelas planas u otros adaptadores

podrían crear una sobretensión para la rueda. Apriete la

rueda en el eje con el fin de prevenir las salidas cuando la

herramienta está apagada.

• lAs rpM del coMpleMento deberÁn exceder lAs

• Use partes y accesorios de repuesto recomendados

por Matco Tools.

• No lubrique las herramientas con soluciones inflamables ni

volátiles, tales como el queroseno, el gasóleo ni el

combustible para aviones.

•

Estaherramientanoestáaisladacontraelchoqueeléctrico.

•

Estaherramientanodebeemplearseenambientesexplosivos.

• Las reparaciones y mantenimiento deben realizarse sólo por

parte de un centro de servicio autorizado.

• No fuerce las herramientas más allá de su capacidad

nominal.

• Noquiteningunaetiqueta.Repongalasetiquetasdañadas.

•Este producto puede contener sustancias químicas

consideradas por el Estado de California como causantes

de cáncer, de malformaciones congénitas u otros daños en

el sistema reproductivo. Lávese bien las manos después de

manipular el producto.

• Hacer caso omiso a estas advertencias puede ocasionar

lesiones personales potenciales y/o daños a la propiedad.

ADVERTENCIA

RPMRPMRPM