4 5

MXF COS350

Original instructions

Originalbetriebsanleitung

Notice originale

Istruzioni originali

Manual original

Oorspronkelijke gebruiksaan-

wijzing

Original brugsanvisning

Original bruksanvisning

Bruksanvisning i original

Alkuperäiset ohjeet

ȆȡȦIJȩIJȣʌȠȠįȘȖȚȫȞȤȡȒıȘȢ

2ULMLQDOLúOHWPHWDOLPDWÕ

3ĤYRGQtPQiYRGHPN

SRXåtYiQt

3{YRGQêQiYRGQDSRXåLWLH

,QVWUXNFMąRU\JLQDOQą

(UHGHWLKDV]QiODWLXWDVtWiV

,]YLUQDQDYRGLOD

Originalne pogonske upute

,QVWUXNFLMƗPRULƧLQƗOYDORGƗ

Originali instrukcija

$OJXSlUDQHNDVXWXVMXKHQG

Ɉɪɢɝɢɧɚɥɶɧɨɟɪɭɤɨɜɨɞɫɬɜɨ

ɩɨɷɤɫɩɥɭɚɬɚɰɢɢ

Ɉɪɢɝɢɧɚɥɧɨɪɴɤɨɜɨɞɫɬɜɨɡɚ

ɟɤɫɩɥɨɚɬɚɰɢɹ

,QVWUXFĠLXQLGHIRORVLUHRULJL-

nale

Ɉɪɢɝɢɧɚɥɟɧɩɪɢɪɚɱɧɢɤɡɚ

ɪɚɛɨɬɚ

Ɉɪɢɝɿɧɚɥɿɧɫɬɪɭɤɰɿʀɡ

ɟɤɫɩɥɭɚɬɚɰɿʀ

ΔϳϠλϷΕΎϣϳϠόΗϟ

MXF COS350

Original instructions

Originalbetriebsanleitung

Notice originale

Istruzioni originali

Manual original

Oorspronkelijke gebruiksaan-

wijzing

Original brugsanvisning

Original bruksanvisning

Bruksanvisning i original

Alkuperäiset ohjeet

ȆȡȦIJȩIJȣʌȠȠįȘȖȚȫȞȤȡȒıȘȢ

2ULMLQDOLúOHWPHWDOLPDWÕ

3ĤYRGQtPQiYRGHPN

SRXåtYiQt

3{YRGQêQiYRGQDSRXåLWLH

,QVWUXNFMąRU\JLQDOQą

(UHGHWLKDV]QiODWLXWDVtWiV

,]YLUQDQDYRGLOD

Originalne pogonske upute

,QVWUXNFLMƗPRULƧLQƗOYDORGƗ

Originali instrukcija

$OJXSlUDQHNDVXWXVMXKHQG

Ɉɪɢɝɢɧɚɥɶɧɨɟɪɭɤɨɜɨɞɫɬɜɨ

ɩɨɷɤɫɩɥɭɚɬɚɰɢɢ

Ɉɪɢɝɢɧɚɥɧɨɪɴɤɨɜɨɞɫɬɜɨɡɚ

ɟɤɫɩɥɨɚɬɚɰɢɹ

,QVWUXFĠLXQLGHIRORVLUHRULJL-

nale

Ɉɪɢɝɢɧɚɥɟɧɩɪɢɪɚɱɧɢɤɡɚ

ɪɚɛɨɬɚ

Ɉɪɢɝɿɧɚɥɿɧɫɬɪɭɤɰɿʀɡ

ɟɤɫɩɥɭɚɬɚɰɿʀ

ΔϳϠλϷΕΎϣϳϠόΗϟ

MXF COS350

Original instructions

Originalbetriebsanleitung

Notice originale

Istruzioni originali

Manual original

Oorspronkelijke gebruiksaan-

wijzing

Original brugsanvisning

Original bruksanvisning

Bruksanvisning i original

Alkuperäiset ohjeet

ȆȡȦIJȩIJȣʌȠȠįȘȖȚȫȞȤȡȒıȘȢ

2ULMLQDOLúOHWPHWDOLPDWÕ

3ĤYRGQtPQiYRGHPN

SRXåtYiQt

3{YRGQêQiYRGQDSRXåLWLH

,QVWUXNFMąRU\JLQDOQą

(UHGHWLKDV]QiODWLXWDVtWiV

,]YLUQDQDYRGLOD

Originalne pogonske upute

,QVWUXNFLMƗPRULƧLQƗOYDORGƗ

Originali instrukcija

$OJXSlUDQHNDVXWXVMXKHQG

Ɉɪɢɝɢɧɚɥɶɧɨɟɪɭɤɨɜɨɞɫɬɜɨ

ɩɨɷɤɫɩɥɭɚɬɚɰɢɢ

Ɉɪɢɝɢɧɚɥɧɨɪɴɤɨɜɨɞɫɬɜɨɡɚ

ɟɤɫɩɥɨɚɬɚɰɢɹ

,QVWUXFĠLXQLGHIRORVLUHRULJL-

nale

Ɉɪɢɝɢɧɚɥɟɧɩɪɢɪɚɱɧɢɤɡɚ

ɪɚɛɨɬɚ

Ɉɪɢɝɿɧɚɥɿɧɫɬɪɭɤɰɿʀɡ

ɟɤɫɩɥɭɚɬɚɰɿʀ

ΔϳϠλϷΕΎϣϳϠόΗϟ

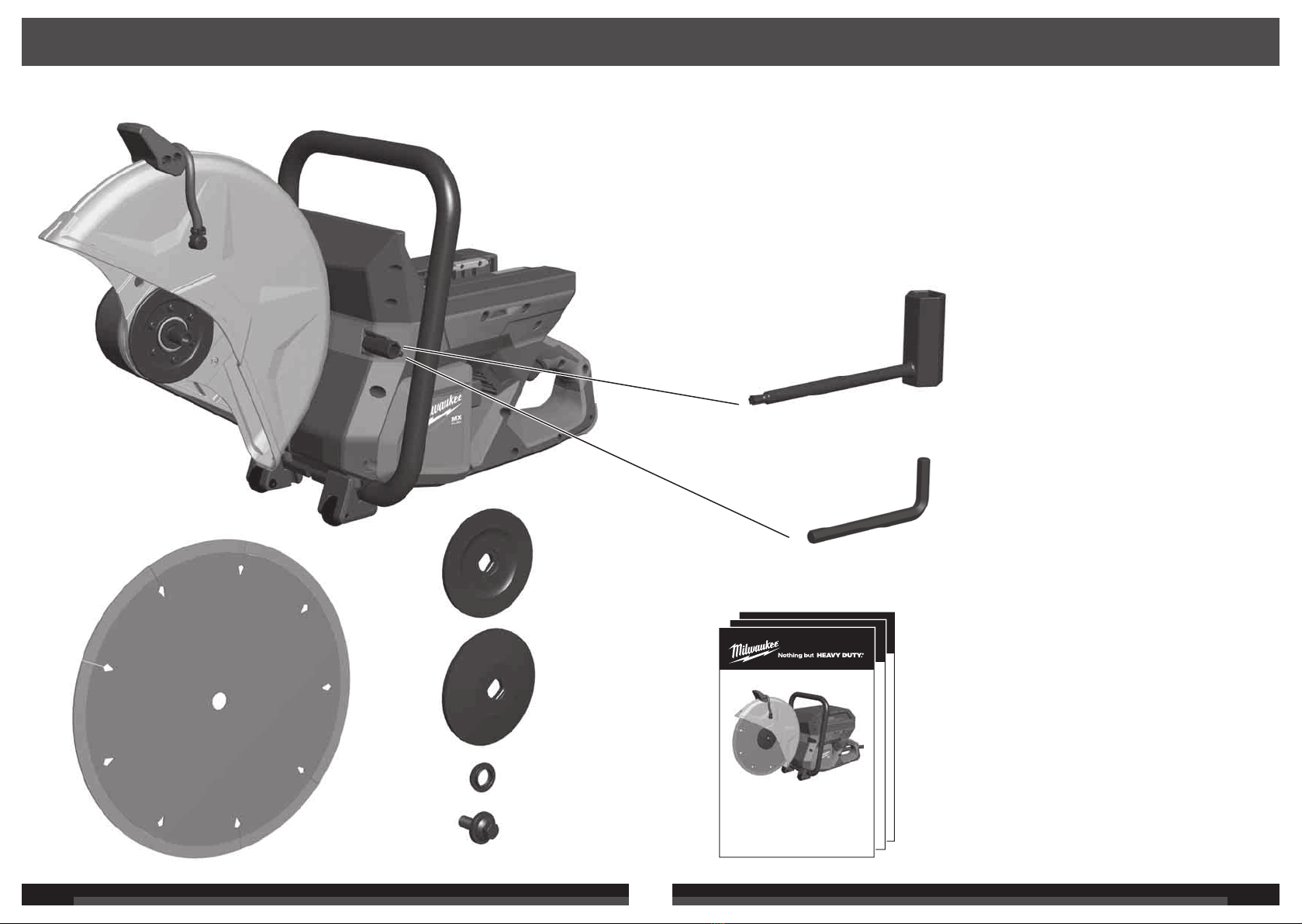

Package Contents