Simba X-Press Installation and operation manual

X-PRESS

OPERATORS MANUAL

& PARTS LIST

ENGLISH

P17897B

19/07/11

ENG If you require a copy of this document in your native language

pleasecontactyourdealerorSimbaInternationalLtd.(P17897)

CZE Požadujete-li kopii tohoto dokumentu ve svém rodném jazyce,

obraťte se prosím na svého prodejce nebo na společnost Simba

InternationalLtd.(P17962)

HUN Haszeretnéeztaleírástmagyarulismegkapni,kérjük,értesítsea

forgalmazójátvagyaSimbaInternationalLtd.-t.(P17963)

FRA Pourobtenirunexemplaireduprésent document dans la langue

de votre choix, veuillez contacter votre représentant ou Simba

InternationalLtd.(P17964)

LIT JeiprireiktųšiodokumentokopijosJūsųgimtąjakalba,kreipkitėsį

savoplatintojąarbaį„SimbaInternationalLtd“.(P17965)

BUL Ако ви е необходимо копие на този документ на родния ви

език, моля да се обърнете към вашия дилър или към Simba

InternationalLtd.(P17966)

RUM Dacă aveţi nevoie de o copie a acestui document în limba

dumneavoastră natală vă rugăm să vă contactaţi dealerul sau

SimbaInternationalLtd.(P17967)

RUS Чтобы получить копию данного документа на вашем родном

языке, обратитесь к своему дилеру или в компанию «Simba

InternationalLtd.»(P17968)

GER WennSieeinExemplardiesesDokumentsinIhrerMuttersprache

brauchen,dannwendenSiesichbitteanIhrenHändleroderandie

SimbaInternationalLtd.(P17969)

3X-Press

Operating Instructions

DeclarationofConformity

DECLARATION OF CONFORMITY

Simba International Limited hereby declare that the Simba X-Press, as dened by the Serial Number

attachedtotheMachineChassis,conformswiththefollowingDirectivesandRegulations,andhasbeen

certiedaccordingly.

EC Machinery Directive 2006/42/EC.

The Supply of Machinery (Safety) Regulations 2008.

The Provision and Use of Work Equipment Regulations 1998.

Specicallyrelatedharmonisedstandardsare:

EN ISO 12100-1: 2003 (Safety of Machinery).

EN ISO 12100-2: 2003 (Safety of Machinery).

EN ISO 4254-1: 2009 (Agricultural machinery - Safety - General Requirements).

THEMANUFACTURER:

SimbaInternationalLimited

WoodbridgeRoad

SLEAFORD

Lincolnshire

NG347EW

England

Telephone(+44)(0)1529304654.

CERTIFIEDONBEHALFOFSIMBAINTERNATIONALLIMITED:

ColinAdams

ManagingDirector

X-Press

Operating Instructions

4

WARRANTY

TERMS AND CONDITIONS

InthiswarrantySimbaInternationalLtd.,isreferredtoas“theCompany”.

1. SubjecttotheprovisionsofthiswarrantytheCompanywarrantseachnewmachinesoldbyitto

besoldfreefromanydefectinmaterialorworkmanshipforaperiodof12monthsfromdateof

installationwiththeend-user.

Somespecicitemshaveadditionalwarrantyoverandabovethestandard12months.Detailsof

thesecanbeobtaineduponrequestdirectlyfromthedistributororSimbaInternationalLtd.

2. IfthemachineorpartthereofsuppliedbytheCompanyisnotinaccordancewiththewarranty

giveninclause1theCompanywillatitsoption:

(a) makegoodthemachineorpartthereofattheCompany’sexpense,or

(b) makeanallowancetothepurchaseragainstthepurchasepriceofthemachineorpart

thereof,or

(c) acceptthereturnofthemachineandatthebuyersoptioneither:

I) repayorallowthebuyertheinvoicepriceofthemachineorpartthereof,or

II) replacethemachineorpartthereofasisreasonablypractical.

3. ThiswarrantyshallnotobligetheCompanytomakeanypaymentinrespectoflossofprotor

otherconsequentiallossorcontingentliabilityofthePurchaserallegedtoarisefromanydefect

inthemachineorimposeanyliabilityontheCompanyotherthanthatcontainedinclause2.

4. AnyclaimunderthiswarrantymustbenotiedtotheCompanyinwritingspecifyingthematters

complainedofwithin14daysfromthedateofrepair.

5. Anyclaimunderthiswarrantymustbemadebytheoriginalpurchaserofthemachineandisnot

assignabletoanythirdparty.

6. Ifthepurchaserhiresoutthemachinetoanythirdpartythewarrantyshallapplyonlytomatters

notiedtotheCompanyinwritingwithin90daysofthedateofdeliveryandclause1shallberead

asiftheperiodof90daysweresubstitutedfortheperiodof12months.

7. Thewarrantywillceasetoapplyif:

(a) anypartsnotmade,suppliedorapprovedinwritingbytheCompanyarettedtothemachineor

(b) anyrepairiscarriedouttothemachineotherthanbyorwiththeexpresswrittenapprovalofthe

Companyor

(c) anyalterationsnotexpresslyauthorizedbytheCompanyinwritingaremadetothemachineor

(d) themachineisdamagedbyaccidentor

(e) themachineisabusedoroverloadedorusedforapurposeorloadbeyonditsdesigncapabilities,

orusedinconjunctionwithatractorwhosepoweroutputcapabilityexceedsthestatedimplement

powerrequirementbymorethan40%.Forthepurposeofthesetermsandconditions,“stated

implementpowerrequirement”referstowheeledtractorsunlessspecicallystated.Thesepower

requirementsshouldbereducedby20%whenusedinconjunctionwithtrackedtractors.

(f) themachineisoperatedaspartofa‘cultivationtrain’wheremorethanoneimplementisbeing

towed,withouttheexpresswrittenapprovalofSimbaInternationalLtd.

(g) anymaintenanceisnotcarriedoutinaccordancewiththeserviceschedulesintheoperator’s

manual.

(h) theInstallationandWarrantyRegistrationCerticateisnotreceivedbySimbaInternationalLtd.,

ServiceDept.,WoodbridgeRoad,Sleaford,Lincolnshire,England,NG347EW,within7daysof

installinganewmachine.

Warranty

5X-Press

Operating Instructions

Machine Identication

Entertherelevantdatainthefollowinglistuponacceptanceofthemachine:

OperatingInstructions/SparePartsList:July2011

Dealer Address: Name: ________________________________________

Street: ________________________________________

Place: ________________________________________

Tel.: ________________________________________

Dealer’sCustomerNo.: ______________________________

SIMBA Address: SIMBA

WoodbridgeRoadInd.Est.

Sleaford

Lincolnshire

NG347EW

Tel.: +44(0)1529304654

Fax: +44(0)1529413468

SIMBACustomerNo.: ______________________________

Serial Number

Type of Machine

Machine Width

Year of Construction

Delivery Date

First Operation

Accessories

MachineIdentication

X-Press

Operating Instructions

6

Contents

Contents

MachineIdentication.............................................................................................................5

Introduction ..............................................................................................8

Foreword..........................................................................................................................8

WarrantyGuidelines.........................................................................................................8

1. Safety Data .......................................................................................9

1.1 SafetySymbols......................................................................................................9

1.2 UsefortheIntendedPurpose............................................................................. 11

1.3 OperationalSafety................................................................................................ 11

1.4 NoLiabilityforConsequentialDamage................................................................ 11

1.5 RoadTrafcSafety...............................................................................................12

1.6 AccidentPrevention.............................................................................................12

1.6.1HitchingUptheMachine......................................................................................12

1.6.2OntheHydraulicSystem......................................................................................12

1.6.3ChangingEquipment............................................................................................13

1.6.4DuringOperation..................................................................................................13

1.7 Servicing&Maintenance......................................................................................13

1.8 OperatingAreas...................................................................................................14

1.9 AuthorisedOperators...........................................................................................14

1.10 ProtectiveEquipment...........................................................................................14

2. Transportation and Installation .....................................................15

2.1 Delivery................................................................................................................15

2.2 Transportation......................................................................................................15

2.3 Installation............................................................................................................15

2.4 HitchingUp...........................................................................................................16

2.4.1HitchingupaTractortotheX-Press/PreparingforTransport............................16

2.5 FoldingandUnfolding..........................................................................................17

2.5.1UnfoldingintotheWorkPosition..........................................................................17

2.5.2FoldingintotheTransportPosition.......................................................................17

2.6 AirBrakeCouplingProcedure..............................................................................18

2.6.1WhenCoupling....................................................................................................18

2.6.2WhenDe-coupling................................................................................................18

2.7 Preceding&TrailingImplements.........................................................................19

2.7.1HitchingaDiscHarrowtotheX-Press.................................................................19

2.7.2TransportinganX-PressTowedBehindaDiscHarrow......................................20

2.7.3ChangingfromWorktoRoadTransport(X-PressBehindaDiscHarrow)...........20

2.7.4HitchingaRearRolltotheX-Press.....................................................................20

2.8 WhenDrivingontheRoad...................................................................................21

2.9 ParkingtheMachine.............................................................................................21

3. Technical Data X-Press ..................................................................23

7X-Press

Operating Instructions

Contents

4. Adjustment/Operation ....................................................................24

4.1 Description...........................................................................................................24

4.2 DiscUnits.............................................................................................................26

4.3 DoubleDiscRoller................................................................................................27

4.4 DDlightRoll.........................................................................................................33

4.5 WorkSettings.......................................................................................................28

4.6 UsingShims.........................................................................................................29

4.7 StartingSettings...................................................................................................29

4.7.1VariationofSettings.............................................................................................30

4.8 AdjustingDiscFrameDepth.................................................................................31

4.9 WorkInstructions..................................................................................................31

4.10 Checks.................................................................................................................31

5. Servicing and Maintenance ...........................................................32

5.1 Servicing...............................................................................................................32

5.2 Cleaning...............................................................................................................32

5.3 DiscHubMaintenance........................................................................................32

5.3.1TighteningDiscHubs...........................................................................................32

5.3.2BearingSeals.......................................................................................................33

5.4 Brakes&WheelHubs..........................................................................................33

5.5 DoubleDiscAxles................................................................................................33

5.6 DDLightRoll........................................................................................................33

5.7 ToAdjusttheSystemPressure............................................................................34

5.8 PreparationforStorage........................................................................................35

5.9 OperatorSupport..................................................................................................35

5.10 MaintenanceIntervals..........................................................................................35

5.11 MaintenanceOverview.........................................................................................36

5.12 LubricatingtheMachine.......................................................................................37

5.13 HandlingofLubricants..........................................................................................37

5.14 Lubricants&HydraulicOil...................................................................................38

6. Faults and Remedies ......................................................................39

7. Parts & Assembly ...........................................................................41

X-Press

Operating Instructions

8

Introduction

Foreword

Make sure you have read and follow the

OperatingInstructionscarefullybeforeusing

the machine. By doing so, you will avoid

accidents,reducerepaircostsanddowntime

andincreasethereliabilityandservicelife

ofyourmachine.Payattentiontothesafety

instructions!

SIMBA will not accept any responsibility

for any damage or malfunctions resulting

from failure to comply with the Operating

Instructions.

These Operating Instructions will assist

youingettingtoknowyourmachineandin

usingitcorrectlyforitsintendedpurposes.

First,youaregivengeneralinstructionsin

handlingthemachine.Thisisfollowedby

sections on servicing, maintenance and

theactiontobetakenshouldamalfunction

occur.

Theseoperatinginstructionsaretoberead

andfollowedbyallpersonsworkingonor

withthemachine,e.g.:

• Operation (including preparation,

remedying of faults in the operating

sequenceandservicing).

• Maintenance (maintenance and

inspection)

• Transportation.

Together with the Operating Instructions,

you receive a Spare Parts List and a

Machine Registration form. Field service

technicianswillinstructyouintheoperation

and servicing of your machine. Following

this, the Machine Registration form is to

be returned to your dealer. This conrms

your formal acceptance of the machine.

Thewarrantyperiodbeginsonthedateof

delivery.

We reserve the right to alter

illustrations as well as technical

dataandweightscontainedinthese

OperatingInstructionsforthepurpose

ofimprovingthemachine.

Warranty Guidelines

Theperiodofliabilityformaterialdefects

(warranty) relating to our products is 12

months. Inthecaseofwrittendeviationsfrom

thestatutoryprovisions,theseagreements

shallapply.

Theyshallbecomeeffectiveuponinstallation

ofthemachinewiththeendcustomer.All

wearpartsareexcludedfromthewarranty.

All warranty claims must be submitted to

SIMBAviayourdealer.

Introduction

9X-Press

Operating Instructions

1. Safety Data

Thefollowingwarningsandsafetyinstruc-

tionsapplytoallsectionsoftheseOperating

Instructions.

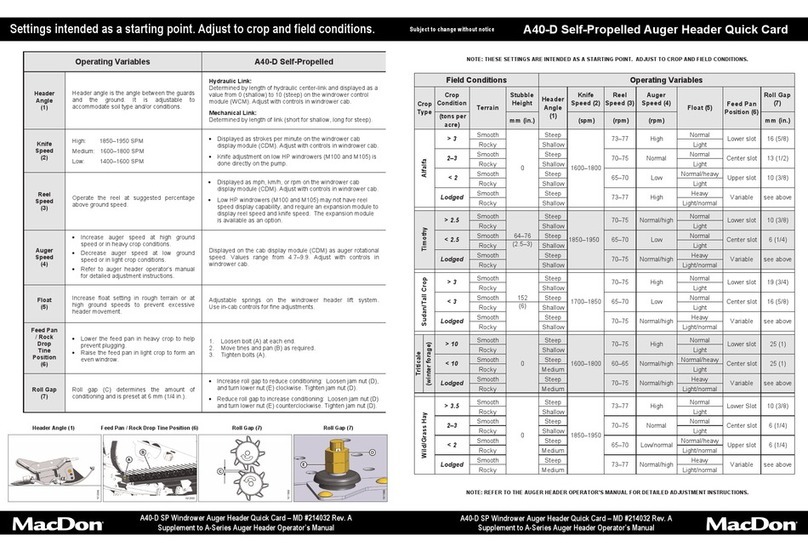

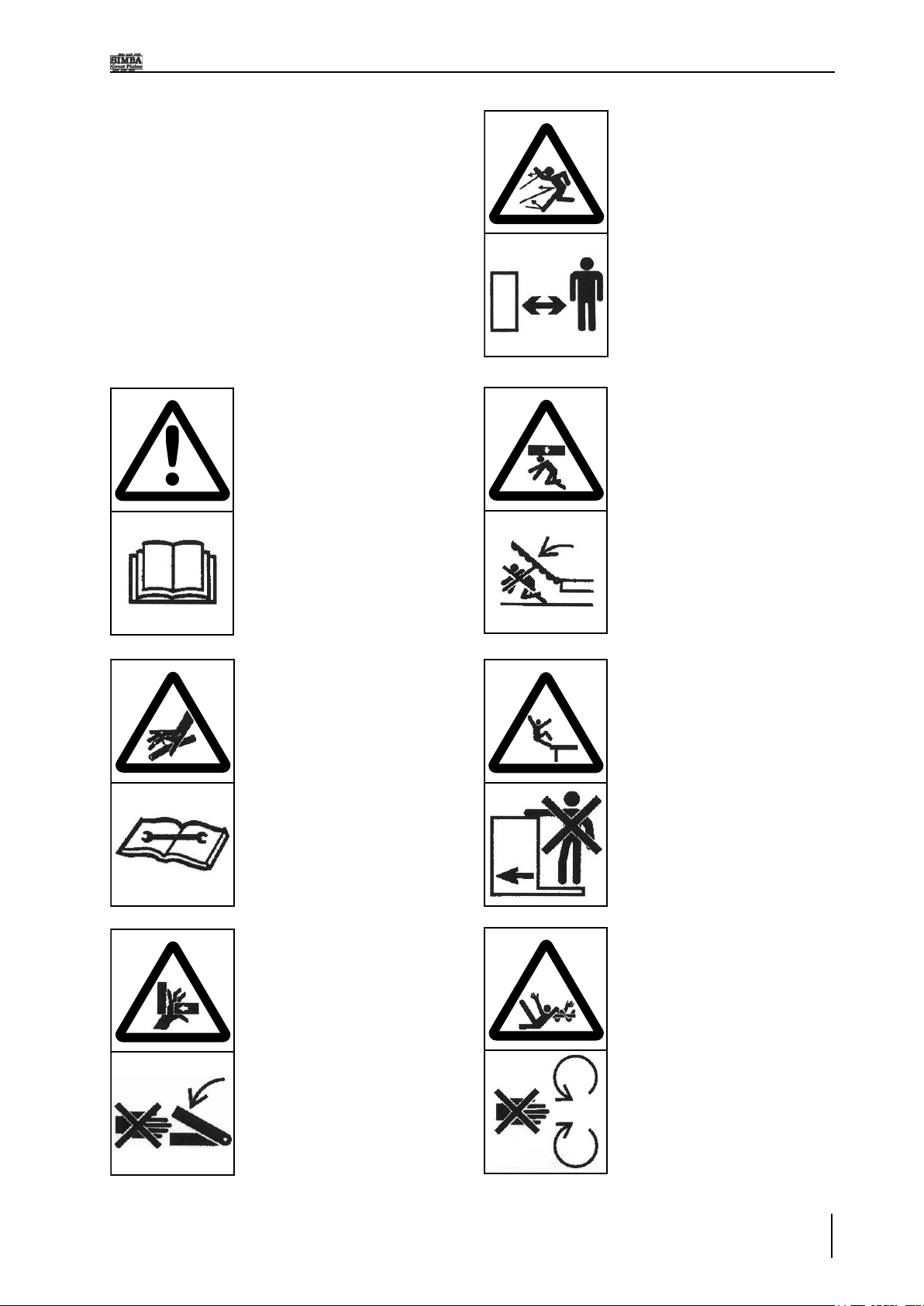

1.1 Safety Symbols

On the machine

Nopassengersareallowed

onthemachine!

Keep clear of the working

rangeoffoldablemachine

components!

Never reach into areas

wherethereisadangerof

being crushed by moving

parts!

Watch out for escaping

pressurised uids! Follow

the instructions in the

OperatingInstructions!

Read and observe the

Operating Instructions

before starting up the

machine!

Never reach into any

revolvingparts!

Parts may fly off during

operation. Keep a safe

distance away from the

machine!

1.SafetyData

X-Press

Operating Instructions

10

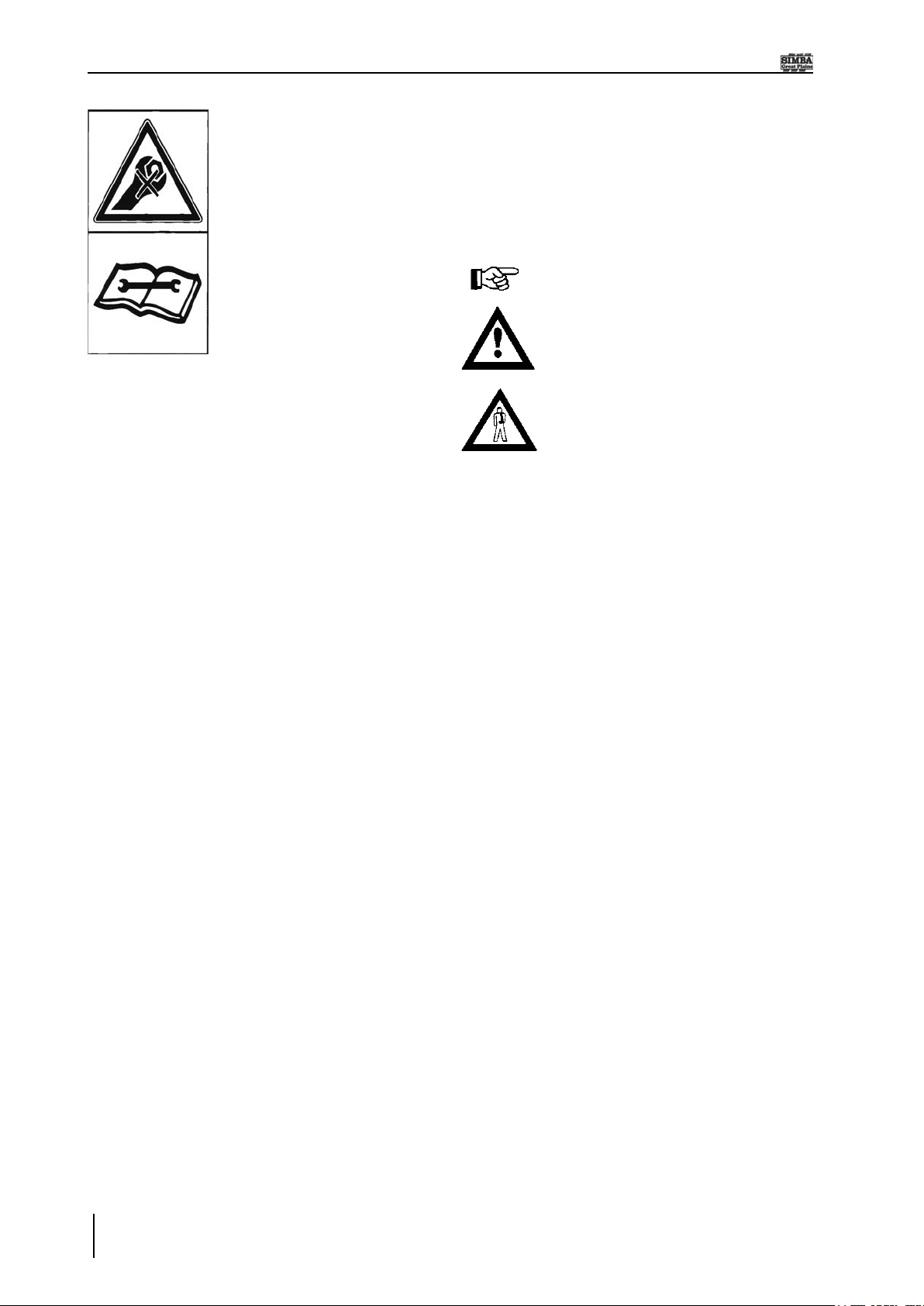

1.SafetyData

Refer to Operating

Instructions before

attemptingmaintenance.

Operating Instructions:

The Operating Instructions distinguish

betweenthreedifferenttypesofwarningand

safety instructions.The following graphic

symbolsareused:

Important!

Riskofinjury!

Riskoffatalandseriousinjuries!

Itisimportantthatallthesafetyinstructions

contained in these Operating Instructions

andall the warning signsonthe machine

arereadcarefully.

Ensurethatthewarningsignsarelegible.

Replace any signs that are missing or

damaged.

Theseinstructionsmustbefollowedinorder

topreventaccidents.Informotherusersof

thewarningsandsafetyinstructions.

Donotcarryoutanyoperationswhichmay

affectsafeuseofthemachine.

Allreferencestoleftandrightinthismanual

aremadefromtherearofthemachine,facing

the direction of travel (unless otherwise

stated).

11X-Press

Operating Instructions

1.SafetyData

1.3 Operational Safety

The machine is to be put in operation

only after instruction has been provided

by an employee of the authorised dealer

or an employee of SIMBA.The “Machine

Registration”formistobe completedand

returnedtoyourdealer.

All protective and safety equipment, such

as removable protective equipment, must

beinplaceandfunctioningreliablybefore

themachineisputinuse.

Checkscrewsandboltsregularly

for tightness and retighten if

necessary.

In the event of malfunctions,

stop and secure the machine

immediately.

Ensurethatanyfaultsareremedied

immediately.

1.4 No Liability for

Consequential Damage

The X-Press has been manufactured by

SIMBAwithgreatcare.However,problems

may still occur when it is used for the

intendedpurpose.Thesemayinclude:

•Wornwearingparts.

•Damagecausedbyexternalfactors.

•Incorrectdrivingspeeds.

• Incorrect setting of the unit (incorrect

attachment, non-adherence to the Setting

instructions).

Therefore, it is crucial to always

check your machine before and

during operation for correct

operationandadequateapplication

accuracy.

Compensationclaimsfordamagewhichhas

not occurred to the machine is excluded.

This includes any consequential damage

resultingfromincorrectoperation.

1.2 Use for the Intended

Purpose

The SIMBA X-Press is built using the

latest technology and in accordance with

therelevantrecognisedsafetyregulations.

However,risksofinjuryfortheoperatoror

thirdpartiesandimpairmentofthemachine

orothertangibleassetscanariseduringuse.

Themachineisonlytobeoperatedwhen

inatechnicallyperfectconditionandforthe

intendedpurpose,takingintoconsideration

safetyandrisksandfollowingtheOperating

Instructions. In particular, faults that can

impairsafetyaretoberemediedimmediately.

OriginalpartsandaccessoriesfromSIMBA

have been specially designed for this

machine.Sparepartsandaccessoriesnot

supplied by us have not been tested or

authorised.Installationoruseofnon-original

SIMBA products may have a detrimental

effect on specic design features of the

machineandaffectthesafetyof machine

operatorsandthemachineitself.SIMBAwill

acceptnoliabilityfordamageresultingfrom

theuseofnon-originalpartsoraccessories.

TheSIMBAX-Pressisdesignedsolelyas

acultivationimplement.Useforanyother

purpose,e.g.,asameansoftransport,will

bedeemedtobeimproperuse.SIMBAwill

acceptnoliabilityfordamageresultingfrom

improperuse.Theriskwillbebornesolely

bytheoperator.

Use of the X-Press behind high power

tractors (in excess of 40% above the

maximumrecommended)canleadtohigh

loads and stresses which can cause long

termstructuraldamagetothechassisand

key components. Such overloading can

compromisesafetyandistobeavoided.

X-Press

Operating Instructions

12

1.5 Road Trafc Safety

When driving on public roads, tracks and

areas,itisimportanttoobservetherelevant

road traffic laws as well as the specific

regulationsrelatingtothismachine.

Payattentiontothepermittedaxle

loads, tyre carrying capacity, and

total weight in order to maintain

adequatebrakingandsteerability

(these gures are shown on the

serialplate).

Passengers on the machine are

strictlyforbidden!

Max.roadtransportspeed16mph

(25km/h).

1.6 Accident Prevention

InadditiontotheOperatingInstructions,itis

importanttoobservetheaccidentprevention

regulations specied by agricultural trade

associations.ItistheOperator’sresponsibility

toensurethatallotherpersonsareexcluded

fromthedangerzonessurroundingoronthe

machineduringitsoperation.

ItistheOwner’sresponsibilitytoensure:

•theOperatoristrainedandcompetentto

usethemachine

&

tractor,

•thetractorissuitableforthemachine

•adequateRiskandCOSHHassessments

have been undertaken regarding the

machine’s use. Specically, these include

issues concerning contact with the soil,

dust, crop residues, chemicals, lubricants

andother compounds duringoperationor

maintenance,andthepossibilityofstones

beingejectedathighspeedduringwork.

1.6.1 Hitching-up the

machine

There is a risk of injury when hitching/

unhitching the machine. Observe the

following:

•Securethemachineagainstrolling.

• Take special care when reversing the

tractor!

•Thereisariskofbeingcrushedbetween

themachineandthetractor!

•Parkthemachineonrm,levelground.

1.6.2 On the Hydraulic

System

Do not connect the hydraulic lines to the

tractoruntilbothhydraulicsystems(machine

andtractor)aredepressurised.

Anyhydraulicsystemcontaining

an accumulator can remain

under pressure permanently

(even after following manual

depressurisation procedures

with a tractor / implement

combination). It is therefore

importanttocheckalllines,pipes,

andscrewconnectionsregularly

for leaks and any recognisable

externaldamage.

The hydraulic circuit contains

specialisedttingswhichshould

notbetamperedwithunderany

circumstances. Do not attempt

tomodify hoseroutings orhose

clampingarrangements,doingso

mycauseseriousdamagetothe

machineand/orinjury.

1.SafetyData

Bewareoftrappinghazardswhen

manipulating the parking stands

or other moving parts. Ensure

anyheavy componentsare fully

supportedwhenremovingpins/

bolts.

13X-Press

Operating Instructions

Only use appropriate aids when checking

forleaks.Repairanydamageimmediately.

Spurtingoilcancauseinjuriesandres!

Incaseofinjury,contactadoctorimmediately.

The socket and plugs for the hydraulic

connections between the tractor and the

machine should be colour-coded in order

toavoidincorrectuse.

1.6.3 Changing Equipment

• Secure the machine to prevent it from

accidentallyrollingaway!

• Use suitable supports to secure any

raisedframesectionssuspendedabove

you!

• Caution!Riskofinjuryduetoprojecting

parts!

Never climb on to rotating parts

suchastherollunit.Theseparts

mayrotatecausingyoutoslipand

sufferseriousinjury!

Removing components during

maintenance may affect the

stability of the machine. Ensure

it is fully supported in case of

unexpectedweightshifts.

1.6.4 During Operation

Ensurethattheworkingrangeandthearea

around the machine are clear (children!)

beforeoperatingthemachine.

Alwaysensureadequatevisibility!

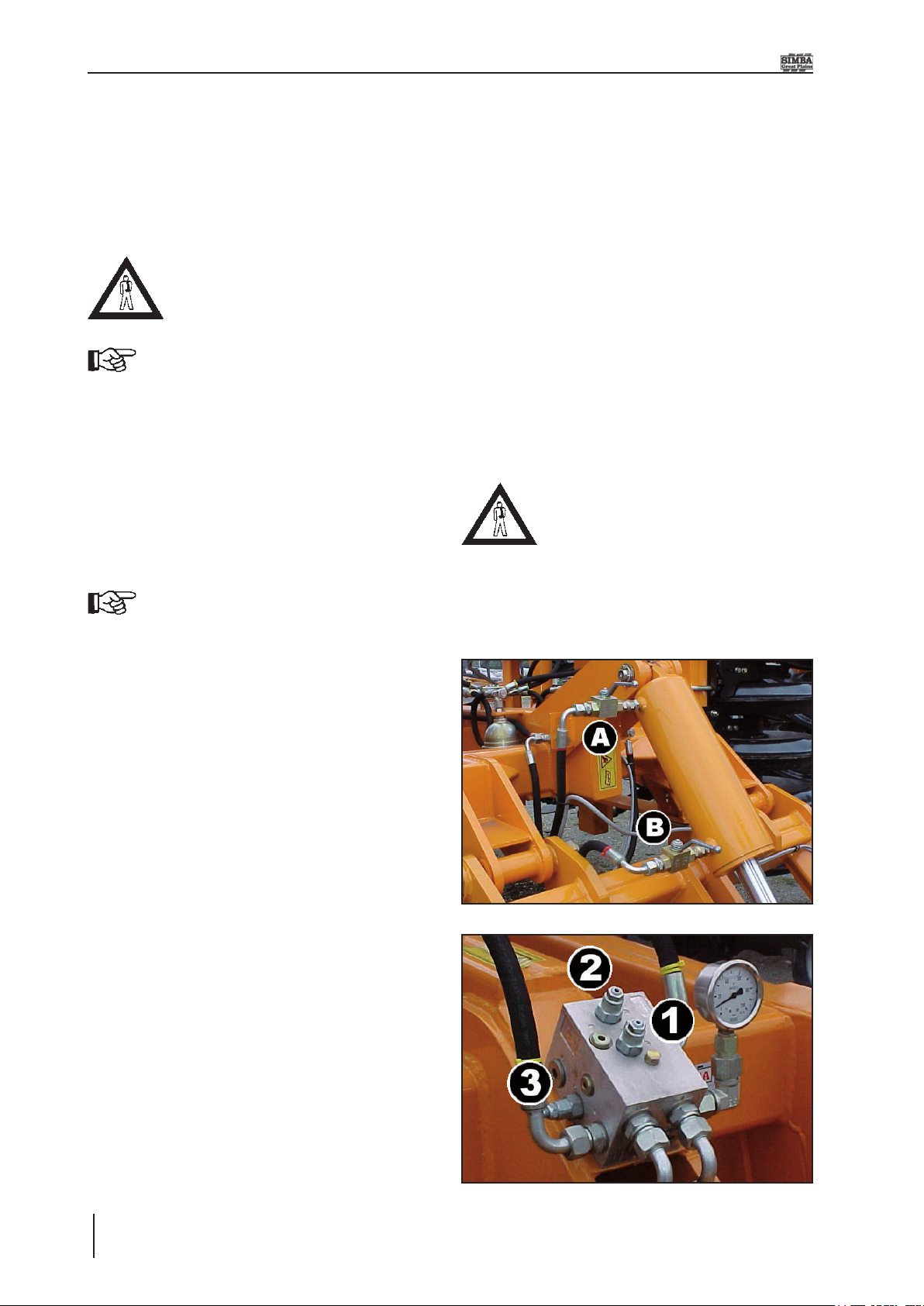

Fig. 1.01: HydraulicTaps

Donotstandonthemachinewhileitisin

operation!

Operatorsmusthaveavaliddrivinglicence

in order to drive on public roads. In the

operatingarea,theoperatorisresponsible

forthirdparties.

Thepersoninchargemust:

•provide the operatorwitha copyof the

OperatingInstructions,and

• ensure that the operator has read and

understoodtheinstructions.

•makesurethattheoperatorisawareofthe

specicregulationsrelatingtothemachine

whendrivingonpublicroads.

1.7 Servicing &

Maintenance

Ensurethatregularchecksandinspections

are always carried out within the periods

required by law or specified in these

OperatingInstructions.

Whencarryingoutserviceandmaintenance

workalways:

• switchoffthetractorengineandremove

theignitionkey.

• wait until all the machine parts have

stoppedmoving.

• depressurisethehydraulicsystem.

Many hydraulic circuits contain lock or

overcentrevalveswhichcanretainpressure

in the lines even after depressurising the

tractor side of these circuits. If in doubt,

consult trained personnel (such as your

localSimbaDealer)toensuresuchvalves

aredepressurisedtothecorrectprocedure

before removing or servicing any parts

connecteddownstreamofthesevalves.

1.SafetyData

X-Press

Operating Instructions

14

1.8 Operating Areas

The operating areas include the drawbar,

hydraulicconnectionsanddepthadjustment

equipmentaswellasalloperatingpoints

requiringmaintenance.

All operating areas will be specied and

describedindetailinthefollowingchapters

onservicingandmaintenance.

Observe all safety regulations included in

thesectiondealingwithSafety,andinthe

subsequentsections.

1.9 Authorised Operators

Only those persons who have been

authorised and instructed by the operator

may operate the machine. The operator

mustbeatleast16yearsofage.

1.10 Protective

Equipment

Foroperationandmaintenance,yourequire:

•Tightttingclothing.

• Strong protective gloves (to provide

protection against sharp-edged machine

components).

•Protectivegoggles(tostopdirtgettinginto

youreyes).

Check all hydraulic lines for leaks, loose

connections, chafe marks and damage.

Remedyanydecienciesimmediately!Pay

particularattentiontohoserenewalintervals

as outlined in the specic sections which

follow.ALL hydraulic hoses have a safe

maximumworkinglifeof6(SIX)yearsfrom

dateofinstallation,providedtheyremainina

safecondition.Hoseswhichexceed6years

ofageshouldbereplaced,orinspectedand

certied by a suitably qualied person to

haveanextendedlifeperiodwhichshould

berecorded.

Payparticularattentiontothoseitemswhich

require specialist service tools or training

tobecarriedoutbyqualiedpersonnel.Do

notattempttoservicetheseitemsyourself!

Theseincludeitemsretainingpressure(e.g.

accumulatorcircuits),orforce(e.g.spring

tines),andDDRollsofanytype.

Prior to performing maintenance and ser-

vicingwork,ensurethatthemachineisposi-

tionedonsolid,levelgroundandissecured

topreventit rolling away.Donotuseany

partstoclimbontothemachineunlessthey

arespecicallydesignedforthispurpose.

Before cleaning the machine with water,

steam jets (high-pressure cleaning appa-

ratus) or other cleaning agents, cover all

openingsintowhich,forreasonsofsafety

or operation, no water, steam or cleaning

agents are to penetrate (bearings, for in-

stance).

Lubricateallthelubricatingpointstoforce

outanytrappedwater.

When carrying out servicing and main-

tenance work, retighten any loose screw

connections.

Whenservicingthemachinetakeprecauti-

onsagainstsoil,dust,seedcoatings,oilor

any other hazardous substances that you

mightencounter.

1.SafetyData

On a new machine tighten all nuts and

boltsafter5hoursworkandagainafter15

hours.Thisalsoappliestopartsthathave

beenmovedorreplaced.Aftertheinitial15

hoursofworkaonceaweekcheckshould

besufcientdependingondailyworkrates.

15X-Press

Operating Instructions

2.3 Installation

Whencarryingoutinstallationandmainte-

nanceworkthereisahigherriskofinjury.

Itisimportantthatyoufamiliariseyourself

with the machine and read the Operating

Instructionsbeforehand.

Operatorinstructionandinitialinstallationof

themachinearecarriedoutbyourservice

techniciansorauthoriseddistributors.

Themachinemustnotbeusedinanyway

beforehand!The machinecan onlybere-

leasedforoperationafterinstructionshave

beenprovidedbyourservicetechniciansor

authoriseddistributors.

•Ifanymodulesorpartshavebeenremoved

fortransportation,theseshallbemountedby

ourservicetechnicians/authoriseddealers

beforetheinstructiontakesplace.

•Checkallimportantscrewconnections!

•Lubricateallnipplesandjoints!

•Checkallhydraulicconnectionsandlines

fordamage.

2. Transportation and

Installation

Transportationandinitialinstallationofthe

machinearedescribedinthischapter.

2.1 Delivery

The machine is normally delivered, fully

assembled.

•Themachinecanbeliftedoffwithacrane

orothersuitableliftingequipment.

•Themachineshouldbehitchedtoatractor

anddrivenoffalow-loader.

2.2 Transportation

TheX-Presscanbetransportedonpublic

roadsbyhitchingituptoatractororona

low-loader.

• It is important to observe the permitted

dimensionsandweightswhentransporting

themachine.

•Ifthemachineistransportedonatraileror

alow-loader,itmustbesecuredusingstraps

orotherdevices.

• Before transporting the machine on

public roads, it must be adjusted to its

transportationpositionandthestipulations

relatingtoroadtransportationfullled.

The transportation width can

varyaccordingtotheadjustment

of working parts (eg. discs, roll,

etc). It may be necessary to

adjusttheseelementsinorderto

achieve the minimum transport

width.

Adjustments, including the

attachmentoftransportdevices,

shouldbemadeatgroundlevel;

lowering the machine may be

necessarytoachievethis.

• The maximum permissible speed is 25

km/h.

2.Transportation/Installation

X-Press

Operating Instructions

16

2.4 Hitching Up

2.4.1 Hitching up a Tractor

to the X-Press / Preparing for

Transport

When hitching-up the machine,

ensurethatno-oneisbetweenthe

tractorandthemachine.

When the X-Press is parked for

extendedperiodsoftimeitshould

ideally be left in the unfolded,

i.e. work, position for stability,

safety and ease of access for

maintenance. However, parking

theX-Pressinthefoldedposition

(usingtheparkingstandsprovided)

isacceptableinthenormalcourse

ofoperation.

Tractor Oil Flow Adjustment:

Asageneralrulethetractoroilow

rateshouldbesetinthelowestset-

tingbeforestarting.Thiscanthen

beincreasedtoallowthedesired

rate of operation as applicable.

Thiswillminimiseexcessiveoilow

andconsequentpowerusageand

heatgeneration.

1. Ensure the tractor hydraulics are

depressurised and in the locked or

closed(notoat)setting.

2. Ensuretherearaxletapsarelocked

to avoid high pressure at the quick

releasecouplings.

3. Couple the hydraulic hoses to the

tractor ensuring that the two wing

hoses (yellow) are together and the

twodrawbarcylinderhoses(red)are

together.

4. Connect the tractor to the drawbar

usingthehydraulicstoraiseorlower

theheightoftheshackle.

5. Opentherearaxletaps

6. Carefully operate the hydraulics to

lowerthedrawbarandtilttheX-Press

ontotheroadtransportwheels.Fully

extendthedrawbarandaxlecylinders.

7. Ifthemachineisunfoldedthenoperate

thefoldcircuitandfoldthemachine.

Fitthewingstraptotiethetwowing

sectionstogether.

Themachineshouldbelowered

so that the transport strap can

bettedfromtheground.Donot

climbonthemachine.

8. Ensurethatparkingstandsarelocked

upintheirworkpositions.

Fig. 2.01: Rear Axle Cylinder

Fig. 2.02: Manifold Block

2.Transportation/Installation

17X-Press

Operating Instructions

2.5 Folding and Unfolding

2.5.1 Unfolding into the Work

Position

1. Ensurethatthetapsontherearaxle

cylinder(Fig.2.01,tapsAandB)arein

theopenposition(ie.inlinewithow).

2. Removethetransportstrapfromthe

rearwingcylinders.Donotclimbon

themachinetoremovethetransport

strap.

3. Lift the machine clear of the ground

readyforunfolding.

4. Operatethehydraulicstofullyunfold

thewings.

When wings are fully lowered

they will appear to be lower at

the wingtips. This is to enable

themachineto‘oat’overuneven

groundinworkandisnormal.

5. Ensurethattheparkingstandsarein

thefullyraisedposition.

6. Lowerthemachinetothegrounduntil

thedrawbarcylinderstouchthedepth

stops.

7. Retract the rear axle cylinders

completely.

8. Closethetapsontherearaxletolock

thewheelsclearofthegroundduring

work.

9. Check the wing pressure on the

gauge(showninFig.2.02).Ifthisis

aboveorbelowthedesiredvaluethen

pressurisethewingstofoldwhichwill

zerothesetting.Increasethepressure

onthe cylindersidebyadjustingthe

valve (Fig.2.02, valve 3) clockwise.

Byrotatinganticlockwisethepressure

willbereduced(seepage34formore

details).Pressurisetounfolduntilthe

requiredpressureisachieved.

10. Draw the X-Press into work then

set the desired pitch of the machine

by adding or removing shims from

the drawbar cylinder or disc frame

adjusters.Thechassisshouldideally

besettorunslightlynosehigh.The

drawbarhydraulicsmaybeworkedin

oatifdesired.

2.5.2 Folding into the

Transport Position

1. Opentheaxletaps(Fig.2.01,tapsA

andB).

2. Operatethehydraulicstofullyraisethe

machine.

3. Foldthemachinefully.

4. Lower the machine to maximise

stability while ensuring adequate

clearanceforroadtransport.

5. Close the taps on the rear axle. Fit

thetransportstrapfortransportsafety.

The strap should be tted from the

ground.Donotclimbonthemachine.

6. Themachineisreadyfortransport.If

the X-Press is to be unhitched from

the tractor in the folded position the

parkingstandsshouldbelowered.

Fig. 2.03 Folded Machine

2.Transportation/Installation

X-Press

Operating Instructions

18

2.5.3 Following Harrow

Operation

Into Work:

1. Arrive in field and unfold machine

accordingtooperatinginstructions

2. Whilstatrearofmachineclosingaxle

tapsmovePins(qty2)fromfrontmost

holes(bylug)torearhole.

3. Removepinonouterquadrantplate

andre-positioninthehighestpossible

holeforstorage.

4. Drivingforwardwilliptheharrowout

intoaworkposition

5. Whenturninginwork,tipthemachine

rearwards into the roll. Reversing

the machine in this position allows

theharrowtoiptemporarilyintothe

transport position. Driving forwards

againipstheharrowbackintowork.

Turninginworkmustonlybeon

theDD700rearroll.Attemptingto

lowerthetransportaxlewiththe

harrow in the work position will

seriously damage the following

harrowcomponents.

Into Transport:

1. TilttheX-Pressontotherearrolland

reverse the machine slightly as if

performingaheadlandturn.

2. Whilst at the rear of the machine

openingthetransportaxletaps,move

theharrowclamppins(qty2)fromthe

frontholestotherearholesbythelugs.

3. Usethepinintheouterquadrantplate

tothelowestpositionpermittedthatit

willlocktheharrowarmdown.

4. Continue folding the X-Press in

accordance with the operating

instructions.

2.6 Air Brake Coupling

Procedure

Pleaserefertothefollowingprocedurewhen

couplingordecouplinganyitemofSIMBA

machineryttedwithanAIRbrakeorAIR

and HYDRAULIC brake system. Please

notethatthisproceduredoesnotapplyto

any machines tted with a HYDRAULIC

systemONLY.

2.6.1 When Coupling

1. Reverse up to the machine and

connectthemachinetothetractoras

instructedtoinSection2.4.1.

2. With the machine connected couple

theairlines.Whencouplingensurethe

yellowlineisattachedrstfollowedby

theredline.

3. Your brake hoses are now attached

andarereadyforoperation.

4. Continuewiththecouplingprocessas

instructedinSection2.4.1.

2.6.2 When De-coupling

1. Bring the machine to the parking

positionasinstructedtoinSection2.9.

2. With the machine still connected to

thetractorremovetheredbrakeline

followedbytheyellowline.

2.Transportation/Installation

19X-Press

Operating Instructions

2.7 Preceding & Trailing

Implements

2.7.1 Hitching a Disc Harrow

to the X-Press

1. Removethetransportstrapsfromthe

disc harrow, exercise great CARE

whenextendingtheaxlecylinder.

2. Reverse the disc harrow up to the

X-Pressdrawbarensuringthatthetwo

drawbarsarealignedallowingaslight

clearancetoenablethemachinesto

becoupledtogether.

3. Lowerthedischarrowtotheground.

4. Connect the four hydraulic hoses

fromtheX-Pressintothedischarrow

rear outlets ensuring that the two

winghosesaretogetherandthetwo

drawbarcylinderhosesaretogether.

Ensurethatthefoldingcircuitsandlift

drawbarcircuitsarecoupledcorrectly.

3. YourbrakeswillnowbeONandwill

hold,ensuringtheyhavebeenadjusted

andmaintainedcorrectly,themachine

inposition.(note:ifthemachine‘stank

is drained of air once all lines have

beendetachedthebrakeswillcomeoff

(samesituationaspushingtheshunt

valve).

4. Continuede-couplingthemachineuntil

itisfullydisconnected.

Byfollowingtheaboveinstructions

you will see that at NO point

in the coupling or decoupling

process has the red line been

left in the tractor on its own.

Thisisintentionalandshouldbe

consideredthe‘rule’to coupling

thehoses.

5. RaisetheX-Pressdrawbarabovethe

discdrawbar(200mmapprox.).

6. Raise the disc harrow to the same

height as the X-Press drawbar then

reverse the disc harrow to couple

the two machines together. A pair

of additional taps (P00774) may be

required in the lift circuit of the disc

harrowortheX-Press.Thiswillisolate

thedrawbarcircuit.

7. Operatethehydraulicstolowertherear

axleand drawbar,tiltingthe X-Press

ontotheroadtransportwheels.Fully

extendthedrawbarcylinders.

8. Operate the hydraulics to fold the

wings.

9. Operatethehydraulicstoliftthedisc

harrowintothetransportposition.

10. Fitthedischarrowtransportstraps.

11. FittheX-Presswingtransportstrapto

tiethetwowingsectionstogether.

12. Ensurethatparkingstandsarelocked

upintheirworkposition.

WhentheX-Pressisusedintandemwith

a disc harrow the disc should be set to

the operators manual i.e. front disc gang

tobe50mmclosertothegroundthanthe

correspondingdiscbladeonthereargang.

Withbothmachinesinthetransportposition

i.e.raisedandfolded,thetopframeofthe

disc harrow should be slightly nose down

orhorizontalevenwhenthedownwardload

fromtheX-Pressisappliedtothedrawbar

ofthedischarrow.

Theframemaybelevelledbyalteringthe

rearwardtiltoftheX-Presstoincreaseor

reducetheloadingonthediscreardrawbar.

2.Transportation/Installation

X-Press

Operating Instructions

20

2.7.4 Hitching a Rear Roll to

the X-Press

Followprocedure2.4(page16)tocouplea

tractortotheX-Press.Oncethetractoris

safelyconnectedtotheimplementandinits

foldedsetting,raisethemachinefullyclear

oftheground.

1. ReversetheX-Pressuptotheroller.

2. AligntheX-Pressandrollerdrawbars,

lowertheX-Presstothegroundand

depressurisethelifthydraulics.

3. Raise / lower the axle as required

to align the respective machines‘

drawbarsandcoupletogether.

4. Coupletherearrolltotheliftcircuitof

theX-Press,ensuringthatthehoses

are connected to the corresponding

circuitonthetrailingmachine.

5. Coupletherearrollwing(fold)circuit

tothewing(fold)circuitoftheX-Press.

6. Fully raise the X-Press and the roll

clearoftheground.

7. Checkthatalltransportstraps/devices

aretted.

2.7.2 Transporting an X-Press

Towed Behind a Disc Harrow

Withbothmachinesinthetransportposition

i.e.raisedandfolded,thetopframeofthe

disc harrow should be slightly nose down

orhorizontalevenwhenthedownwardload

fromtheX-Pressisappliedtothedrawbar

of the disc harrow. The top frame should

NEVERbetaillowintransportasthiswill

giveahighnegativeloadingonthetractor

whichcouldlead to lossoftraction to the

rearwheels.

Extreme caution must be taken when the

X-Pressistransported upsteepgradients

andacrosssideslopes.Onthewidemodels,

higherdrawbarloadingcanbeachievedby

shorteningthedrawbarcylinder.

Priortoleavingtheeldtotravelonapublic

highway ensure that any clods of soil are

removedfromthemachinetopreventthem

fromfoulingtheroad.

MAXIMUMROADTRANSPORTSPEED16

MPH(25KPH).

2.7.3 Changing from Work

to Road Transport (X-Press

Towed Behind a Disc Harrow)

1. Removethedischarrowwinglocking

bolts.

2. Operatethehydraulicstoraisethedisc

andX-Press.

3. Operate the hydraulics to fold the

wingsonboththedischarrowandthe

X-Press.

4. Fit the transport straps to both

machines.

Itmaybenecessarytoshortenthelevelling

springsuntilthetopframeofthedischarrow

is horizontal or slightly nose down before

movingthemachines.

Shortening the X-Press drawbar

cylinder will increase the loading

on the rear of the disc frame. If

necessary this can be used to

level the disc top frame for road

transport.

2.Transportation/Installation

Other manuals for X-Press

1

Table of contents

Other Simba Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Maschio

Maschio GIRAFFONA F07010484 Use and maintenance / spare parts

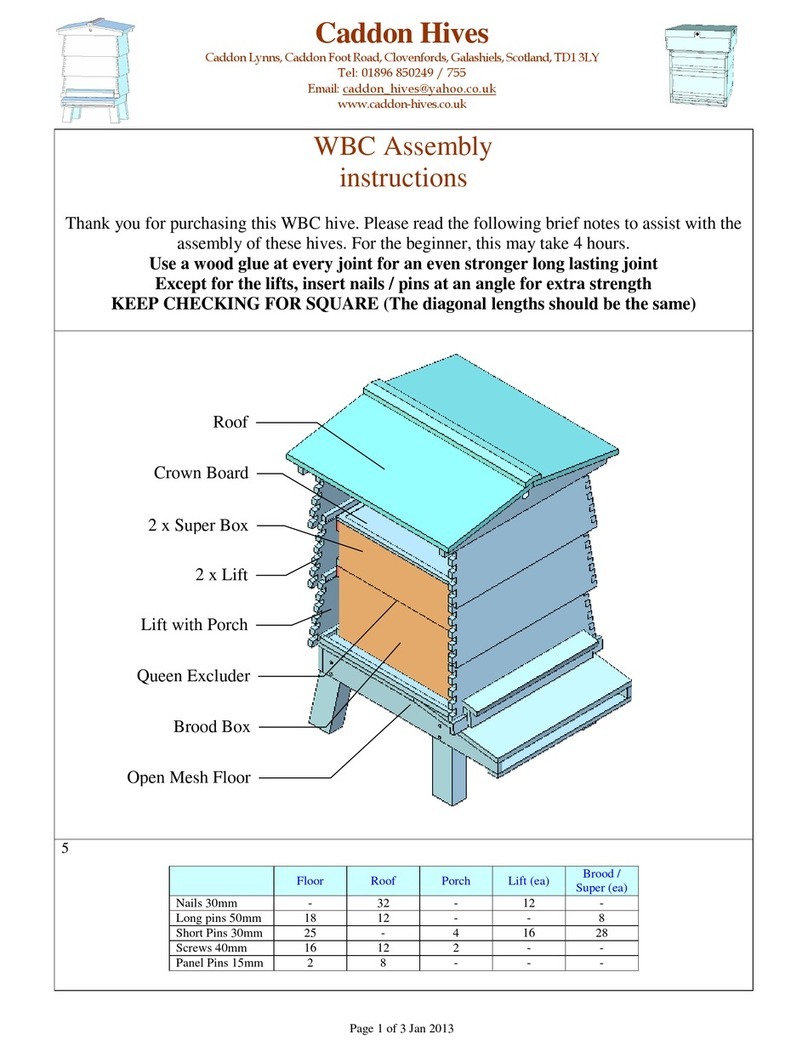

Caddon Hives

Caddon Hives WBC Assembly instructions

LANDY

LANDY S-SMB Operator's manual

Bomford Turner

Bomford Turner TL150 Instruction & parts manual

Samon

Samon SU2M Manual & Parts list

Wessex

Wessex FLC125 Operations manual and parts book