2 R2 Series Clinic Handout

Table of Contents

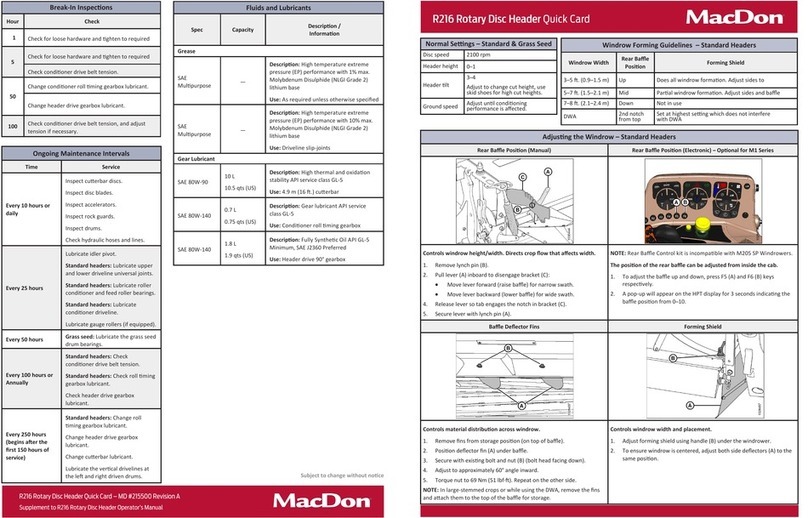

Break-In Inspections..................................................................3

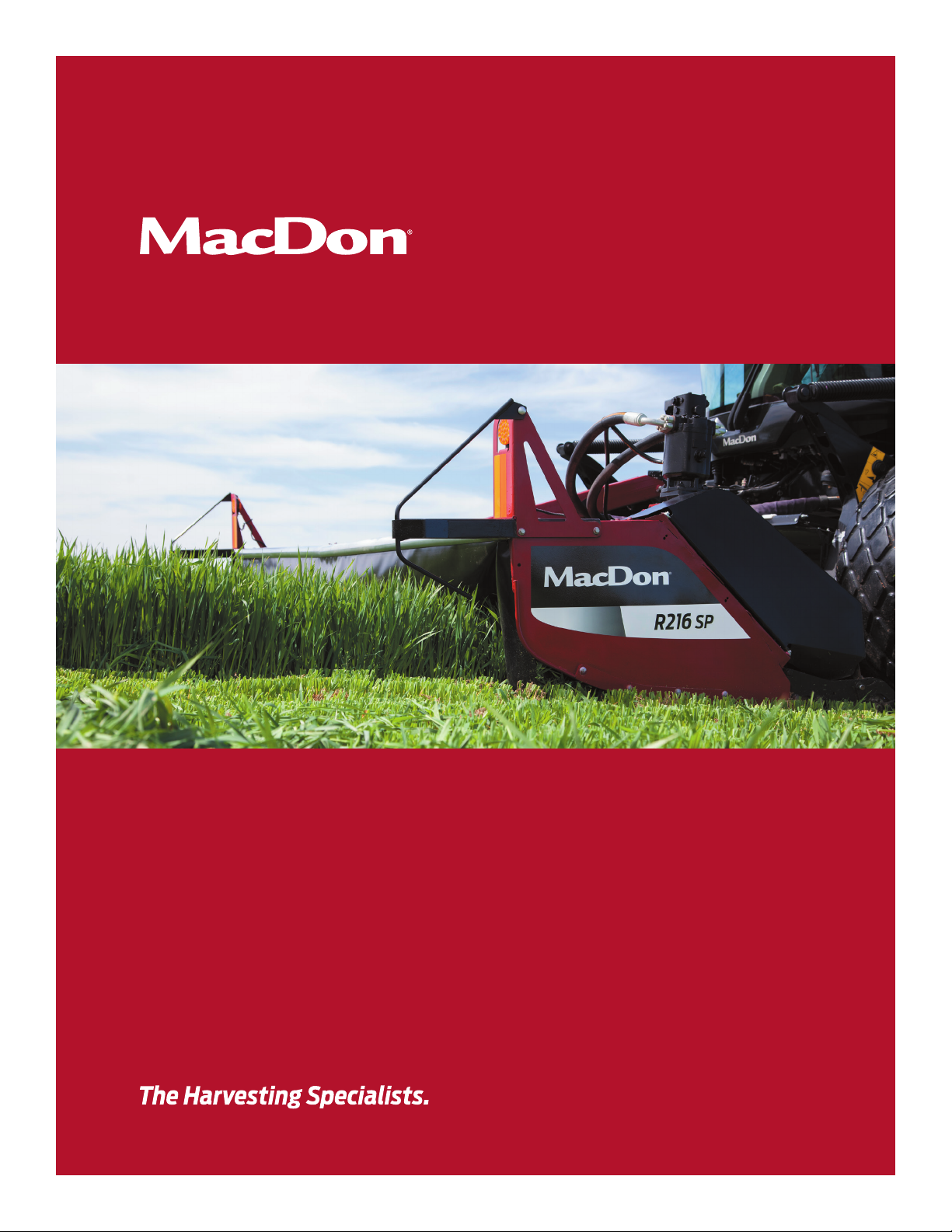

Checking Conditioner Drive Belt Tensioner ...........................................3

Checking Conditioner Drive Gearbox Lubricant .......................................3

Changing Conditioner Drive Gearbox Lubricant.......................................4

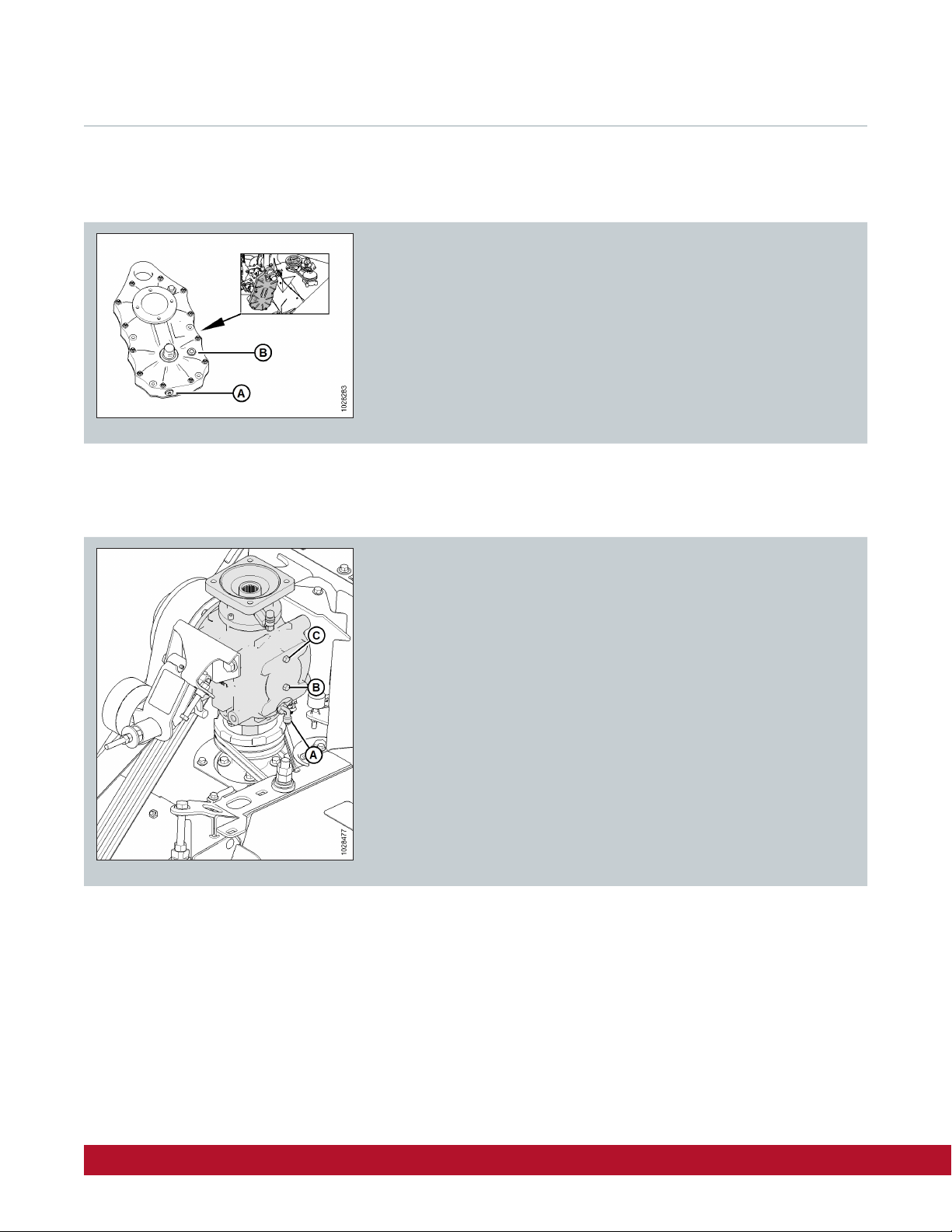

Changing Header Drive Gearbox Lubricant ...........................................4

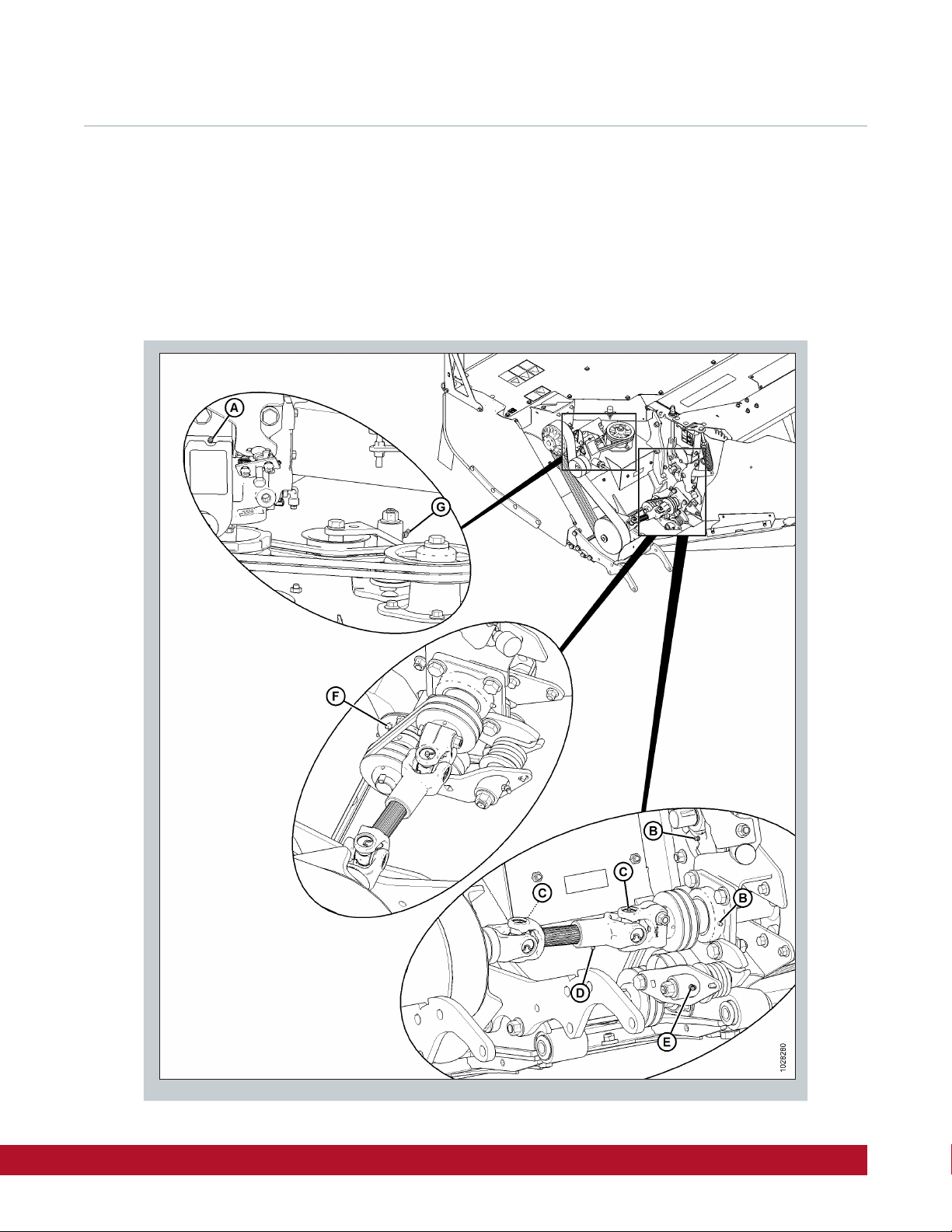

Lubrication Locations ................................................................5

Left Side Every 25 hours .............................................................5

Right Side Every 25 hours............................................................6

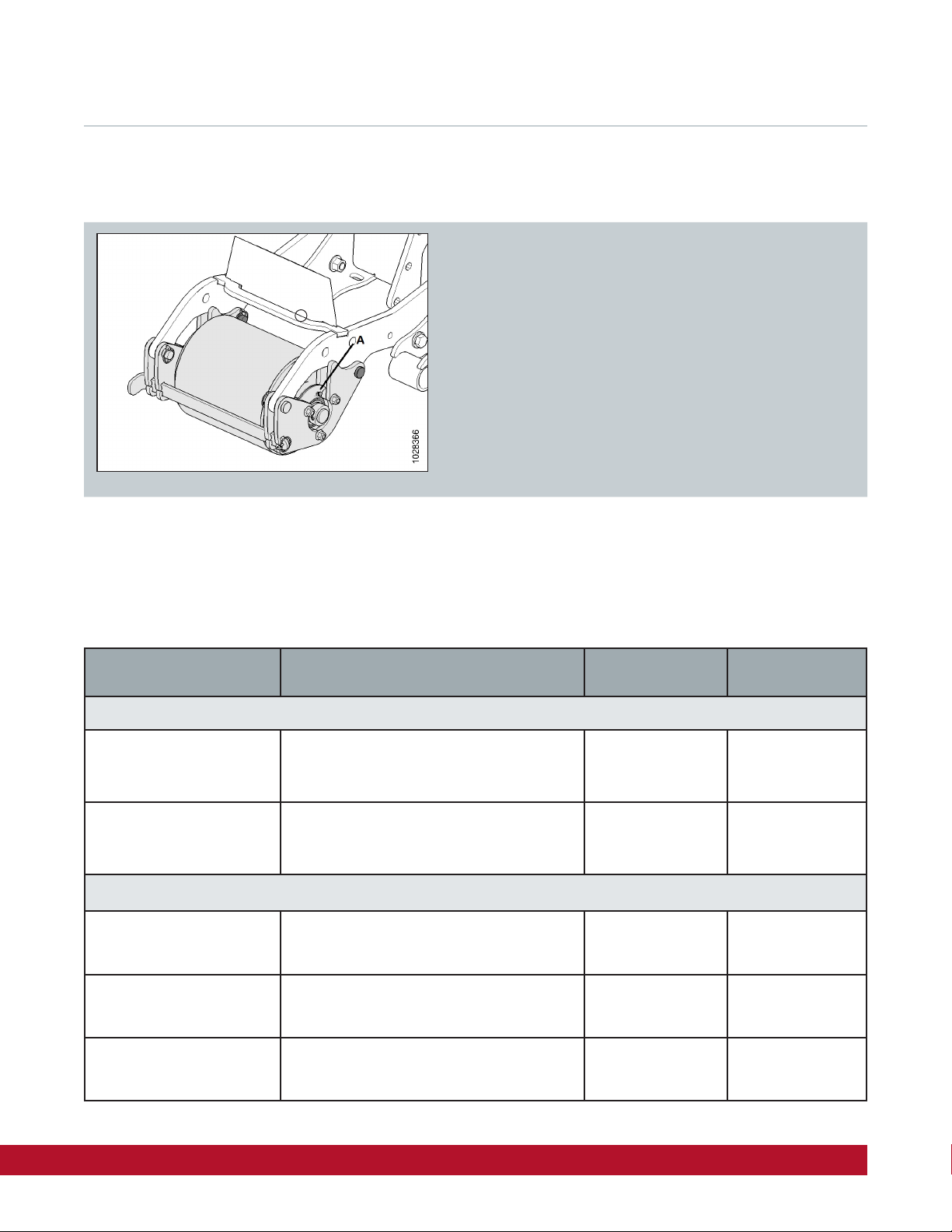

Lubrication Locations (Gauge Rollers) ...............................................7

Recommended Lubricants ..........................................................7

Cutterbar Components ...............................................................8

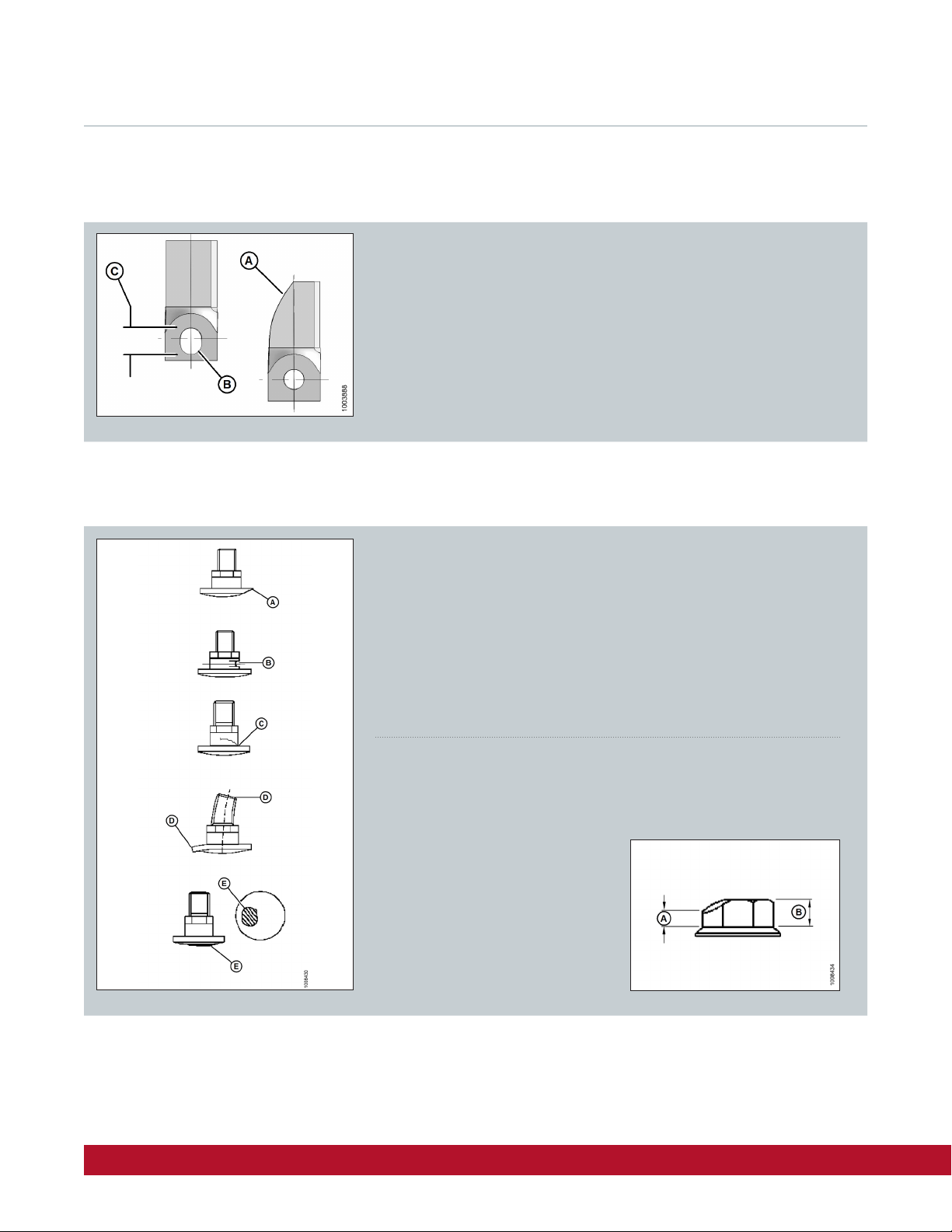

Disc Blades..........................................................................8

Disc Blade Hardware ................................................................8

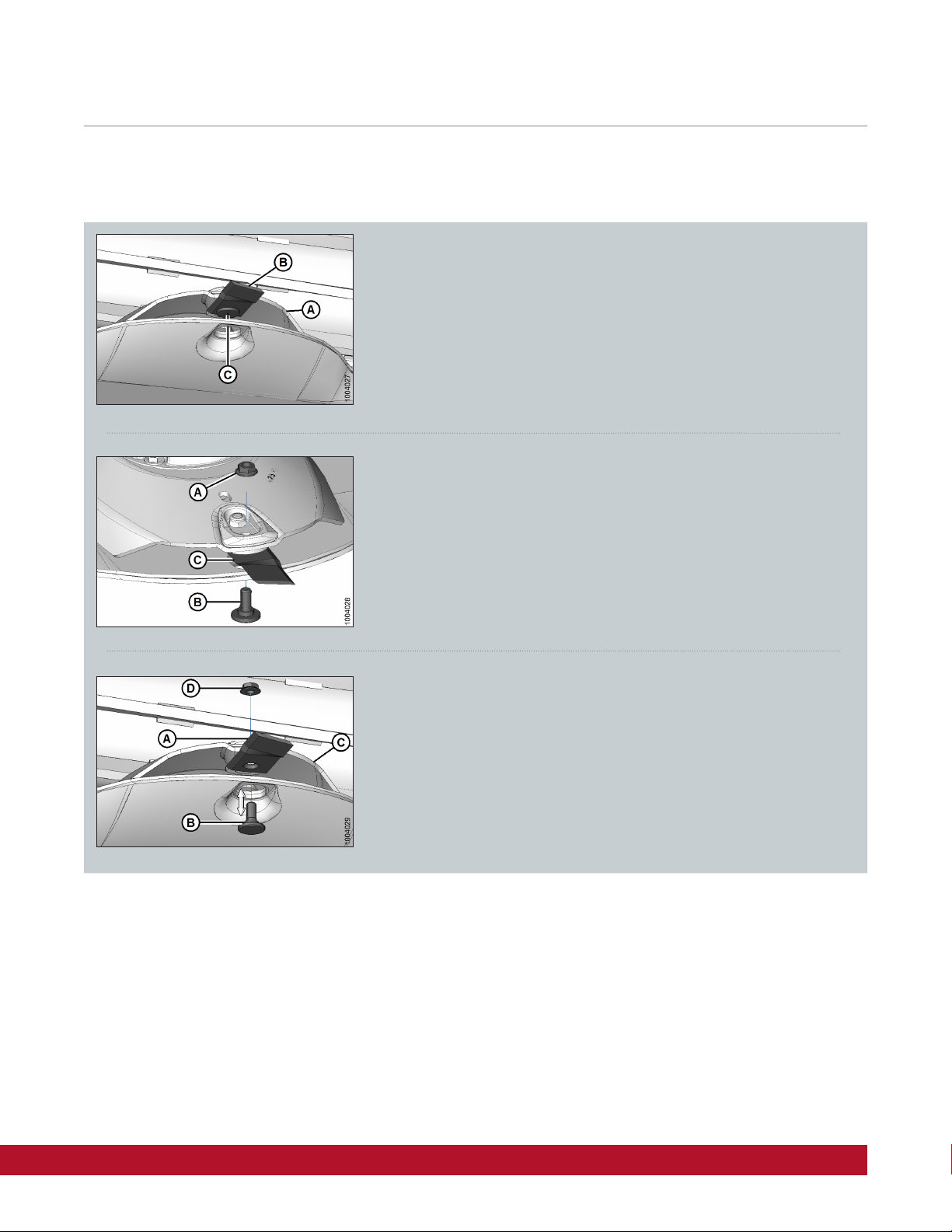

Removing / Installing Disc Blades....................................................9

Settings .............................................................................10

Conditioner Roll Gap ...............................................................10

Forming Shields ....................................................................10

Manual Rear Bae..................................................................11

Positioning Rear Bae Deflector Fins ................................................11

In-Cab Electric Remote Bae ......................................................12

Recommended Starting Settings with a DWA .......................................12

Setting Header Float ...............................................................13

Performance Options................................................................14

Tall Crop Divider Kit ................................................................14

Adjustable Gauge Roller Kit.........................................................14

Adjustable Skid Shoes Kit ..........................................................15

In-Cab Electric Remote Bae Kit ...................................................15

R2 Maintenance Schedule...........................................................16

M1240 Windrower ................................................................... 17

Break-in Inspection................................................................. 17

M1240 Maintenance Chart...........................................................18