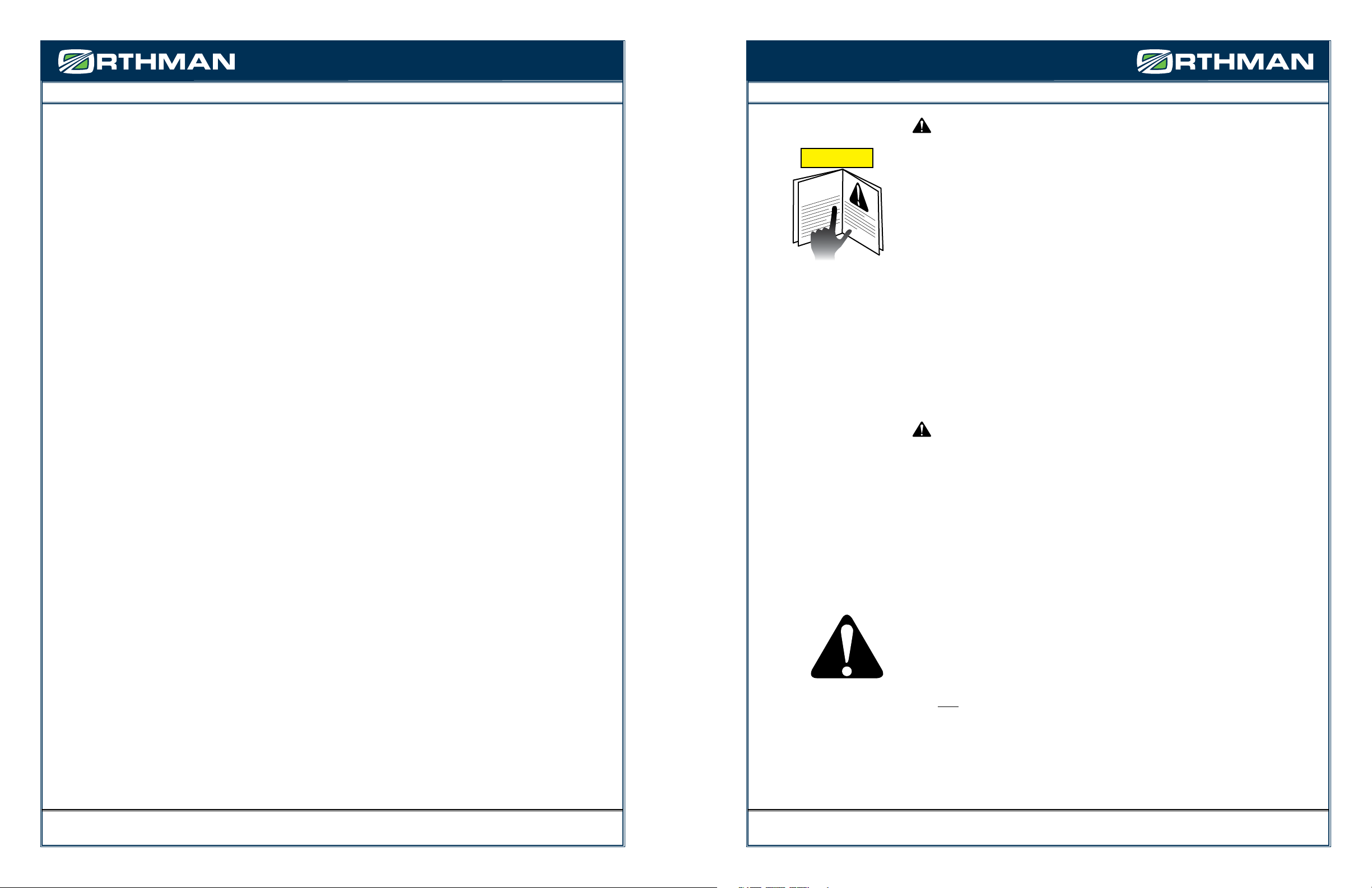

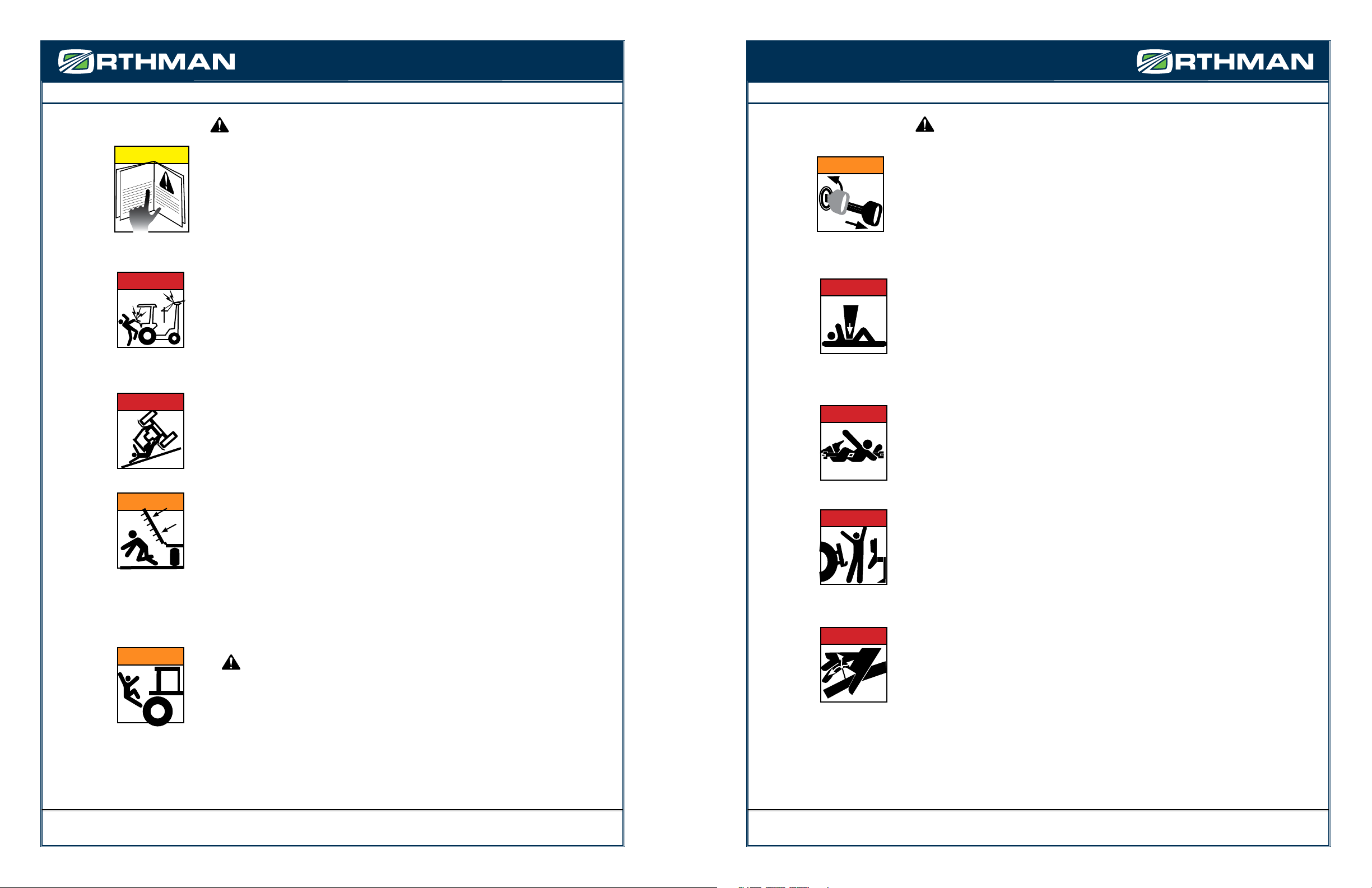

SAFETY INFORMATION

INTRODUCTION

Farm Safety

Contraryto the popular image of fresh air andpeaceful surroundings, a farm is not a hazard-freework setting.

Everyyear, thousands of farm workers are injured andhundreds more die in farming accidents. According tothe National Safety Council, agriculture is the

mosthazardous industry in the nation.

How You Can Improve Farm Safety

You can start by increasing your awareness of farming hazards and making a conscious effort to prepare for emergency situations including res, vehicle

accidents,electrical shocks from equipment and wires, and chemicalexposures. Be especially alert to hazards that mayaffect children and the elderly.

Minimizehazards by carefully selecting the products you buyto ensure that you provide good tools andequipment. Always use seat belts when operating

tractors,and establish and maintain good housekeeping practices. Hereare some other steps you can take toreduce illnesses and injuries on the farm:

•Read and follow instructions in equipment operator’s manualsand on product labels.

•Inspect equipment routinely for problems that may causeaccidents.

•Discuss safety hazards and emergency procedures with yourworkers.

•Install approved rollover protective structures, protective enclosures, orprotective frames on tractors.

•Make sure that guards on farm equipment arereplaced after maintenance.

•Review and follow instructions in material safety datasheets (MSDSs) and on labels that come withchemical products

and communicate informationon these hazards to your workers.

Health and Safety Hazards on Farms

Farmworkers including farm families and migrant workers areexposed to hazards such as the following:

Danger Potential Effect or Injury Prevention

Chemicals/Pes-

ticides

Skinand respiratory injury or death MSDS and proper Personal Protective Equipment. Review Manufacturers data sheets

Cold Illness,Frostbite or death Dressproperly for the day.

Dust Respiratoryinjury or explosive combinations Be aware of your surroundings and activity

Electricity Shock, burns, re, death Use a qualied professional for wiring dangerous electrical devices. Never overload a circuit. Replace

damagedelectrical devices or cords. Electrical tape will not insulate you from injury.

Grainbins, Silos Entrapment, Suffocation, Explosion from formation of

dangerousgases and poisoning.

Makesure the bin is properly ventilated and maintained. Never walk the grain.

Handtools Injury including cuts abrasions, electrocution, strains,

sprainsand death

Makesure you hand tools are in good condition. Never leave a damaged tooling accessible forsomeone

elseto use.

Highway trafc Collisionsresulting in injury or death Followregulations, stay alert. Avoid alcohol and use of communication devices while driving

Lifting& lifting

devices

Backinjury, sprains, strains. Falling material resulting

inbeing struck or crushed by heavy material

Useproper lifting technique. Get help when the load is too heavy. Inspect chains, straps or cablesroutine-

lyto make sure they are in good condition.

Livestockhandling Serious injury or death resulting from being pinned

struckor trampled.

Alwaysmake sure you have adequate room and an escape route

Machinery/Equip-

ment

Cuts,abrasions, amputations, death. Thoroughlyread and understand your Owners Equipment Manual. Never operate the equipment without

guardsin place. Make sure the equipment can not be energized or otherwise put into operationwhileyou

areworking on it.

Manurepits Explosionfrom formation of dangerous gases. Suffo-

cation. Poisoning

Propermaintenance.

Mud Sprains,strains, entrapment and suffocation. Eye

injuryand skin irritation.

ProperPersonal Protective Equipment. In some conditions a “Spotter” may be needed.

Noise Hearingdamage PersonalProtective Equipment.

Ponds Drowning Weara life preserver and make sure help is readily available.

Slips/Trips/Falls Sprains,strains, back and neck injury, bone breaks

ordeath

Keepwork area free from clutter and organized. If working on anything elevated make sure youhave

appropriateguarding and/or fall protection such as a harness and lanyard.

Sun/Heat Sunburn, Heat Stroke, shock, death Usecommon sense on excessively hot days, use sun screen, wear a hat and stayhydrated.

Toxicgases Skin and respiratory injury or death. Explosion. MSDSand proper Personal Protective Equipment. Review Manufacturers data sheets

Tractors Cuts,abrasions, amputations, death. Thoroughlyread and understand your Owners Equipment Manual. Never operate the equipment without

guardsin place. Anti-roll over devices.

Wells Electrocution,amputation, death Avoidcontact with water while working on an electrical device. Always be sure the equipment can/willnot

beenergized during repair or maintenance. Make sure all guarding is in place.

SevereWeather Electrocution,“struck by” injuries, death Moveto a safe place. Lightening, hail and tornadoes are unpredictable.

OrthmanManufacturing, Inc. does not limit the potential effects or injuries nor prevention measures to those listed above. Theyare providedsolely

as a guideline to making your farm life safer. Always consult your Owner/Operators Manual for specic tool and equipment safety requirements.

2-1

TABLE OF CONTENTS

HYDRAULICS

Standard Manifold Block Identication...........................................................................................................................................7 - 1

NT Manifold Block Identication.....................................................................................................................................................7 - 2

Standard Machine Fold Hydraulic Hose Routing .............................................................................................................................7 - 3

Machine Lift Hydraulic Hose Routing..............................................................................................................................................7 - 4

NT Machine Fold Hydraulic Hose Routing........................................................................................................................................7 - 5

TROUBLESHOOTING

Toolbar will not fold or unfold.........................................................................................................................................................8 - 1

Removal of internal cylinder assembly ...........................................................................................................................................8 - 3

Machine will not raise or lower.......................................................................................................................................................8 - 5

MAINTENANCE

Practice Safe Maintenance..............................................................................................................................................................9 - 1

Torque Specications......................................................................................................................................................................9 - 2

Lubrication .....................................................................................................................................................................................9 - 3

Implement Inspection ....................................................................................................................................................................9 - 6

Implement Storage.........................................................................................................................................................................9 - 7

PARTS IDENTIFICATION

Tongue Assembly ..........................................................................................................................................................................10 - 1

Toolbar Hinge Assembly................................................................................................................................................................10 - 3

Toolbar Center Section Assembly..................................................................................................................................................10 - 4

Narrow Transport Toolbar Center Section Assembly .....................................................................................................................10 - 5

Carrier Assembly ...........................................................................................................................................................................10 - 7

NT Outer Wing Hinge Assembly ....................................................................................................................................................10 - 9

Small Wheel and Axle Package ...................................................................................................................................................10 - 11

Large Wheel and Axle Package ...................................................................................................................................................10 - 12

Camoplast TTS 30-1601 Track Package........................................................................................................................................10 - 13

Camoplast TTS 45-1811 Track Package........................................................................................................................................10 - 14

Standard Internal Fold Assembly ................................................................................................................................................10 - 15

NT Mid-Wing Internal Fold Assembly..........................................................................................................................................10 - 16

NT Outer Wing Fold Linkage Assembly........................................................................................................................................10 - 17

Hydraulic Cylinder (Wing Fold)....................................................................................................................................................10 - 19

Hydraulic Cylinder (Machine Lift)................................................................................................................................................10 - 20

Standard Hydraulic Manifold Assembly ......................................................................................................................................10 - 21

NT Hydraulic Manifold/Gear Flow Divider Assembly ...................................................................................................................10 - 22

Hydraulic Hose Identication - Standard Wing Fold ...................................................................................................................10 - 23

Hydraulic Hose Identication - Narrow Transport Wing Fold......................................................................................................10 - 25

Hydraulic Hose Identication - Machine Lift...............................................................................................................................10 - 27

Smart Implement Guidance Steering Components.....................................................................................................................10 - 29

Smart Implement Guidance Steering Components.....................................................................................................................10 - 30

Steerable Wheel and Axle Assembly (Small Wheel)....................................................................................................................10 - 31

Steerable Wheel and Axle Assembly (Large Wheel) ...................................................................................................................10 - 32

Light Bracket Assembly...............................................................................................................................................................10 - 33

Light Kit Assembly ......................................................................................................................................................................10 - 34

Liquid Fertilizer Package Assembly.............................................................................................................................................10 - 35

Dry Fertilizer Package Assembly .................................................................................................................................................10 - 36

1-5