Simer A5300 User manual

©2016 SIM979 (Rev. 12/31/16)

OWNER’S MANUAL

Battery Backup System

NOTICE D’UTILISATION

Système de secours à batterie

MANUAL DEL USUARIO

Sistema de batería de respaldo

PumpActivity

Activitéde pompe

Actividadde la bomba

SystemAlert

Alertedu système

Alertadel sistema

ACPower

CourantAC

CA

Charging

Recharge

Encarga

BatteryStatus

Étatde batterie

Estadode la batería

AlarmSilenced

Alarmearrêtée

Alarmaapagada

TestSystem

Tester

Probarsistema

SilenceAlarm

Arrêterl’alarme

Apagaralarma

Light

Lumière

Luz

CircuitBreaker

Disjoncteur

Disyuntor

Pump

Pompe

Bomba

FloatSwitch

Interrupteurà flotteur

Interruptordel flotador

Power

Courant

Encendido

ResetSystem

Réinitialise

Restrablecersistema

+

6975 0515

A5300

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance:

Call

800-468-7867

English........................... Pages 2-17

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le

(800)

468-7867

Français .................... Pages 18-32

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 800-

468-7867

Español..................... Paginas 34-49

Device ID Key

Safety 2

Important Safety Instructions

SAVE THESE INSTRUCTIONS - This manual contains

important instructions that should be followed during

installation, operation, and maintenance of the product.

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for one of

the following signal words and be alert to the potential

for personal injury!

indicates a hazard which, if not avoided,

will result in death or serious injury.

indicates a hazard which, if not avoided,

can result in death or serious injury.

indicates a hazard which, if not avoided,

can or may result in minor or moderate injury.

NOTICE addresses practices not related to personal injury.

Carefully read and follow all safety instructions in this

manual and on pump.

Keep safety labels in good condition. Replace missing or

damaged safety labels.

To avoid risk of serious bodily injury due to electrical

shock or burns and property damage due to flooding,

read the safety instructions carefully before installing

pump.

Battery acid is corrosive. Do not spill on

skin, clothing, or battery charger. Wear eye and head

protection when working with battery. Connect and

disconnect DC output terminals only after removing the

charger from the AC outlet. Never allow the DC

terminals to touch each other.

Hazardous Voltage. Can cause severe or

fatal electrical shock. Do not plug in or unplug battery

charger while standing on a wet floor or in water. Be sure

one hand is free when plugging in or unplugging charger.

If basement floor is wet, disconnect power to basement

before walking on floor.

Risk of flooding. Do not run pump dry. To

do so will damage seals and can cause leaking and

property damage.

Follow local and/or national plumbing and electrical

codes when installing the system. A ground fault circuit

interrupter (GFCI) is recommended for use on any

electrical appliance submerged in water.

Use this system only for backup sump pump duty in a

residential application. It is not designed as a primary

sump pump.

Do not lift pump by electrical cord.

Risk of electrical shock. Do not lift the

pump by the electrical cord; lift pump only by the

discharge pipe, lifting ring or handle on the pump. Lifting

by the cord can damage the cord.

Pump clear water only with this pump.

Pump is permanently lubricated at the factory. Do not try

to lubricate it!

Keep battery charger and battery box off of the floor and

in a dry, cool, well ventilated area.

NOTICE: If a Carbon Monoxide (CO) sensor is installed,

it must be at least 15 feet away from battery charger

in order to avoid nuisance CO alarms. Please refer

to your CO detector’s installation guidelines for more

information.

To avoid danger of fire or explosion, keep sparks and

flame (pilot light) away from battery.

Maximum vertical pumping distance is 15 feet (4.6M) for

Model A5300.

Make sure sump is clear of debris. Debris can damage

the pump which can result in flooding.

California Proposition 65 Warning

This product and related accessories contain

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

GENERAL INFORMATION

The battery backup sump system is not a substitute for

your primary sump pump. It is designed to temporarily

backup your primary sump pump during a power outage

or other problem which prevents normal operation of

the primary pump. Do not use this system to pump

flammable liquids or chemicals. Pump clear water only

with this pump.

Keep the battery charger dry and protected from damage.

This system is designed to work with a deep cycle sealed

maintenance free lead-acid AGM battery. It will also

work with a flooded lead acid battery. Gell and Sealed

flooded lead acid batteries are not recommended. In

an emergency (such as an extended power outage)

which depletes the system deep cycle battery, your

automobile battery may be temporarily substituted. Be

sure to replace the system deep cycle battery as soon

as possible. Use of an automobile battery instead of a

deep cycle battery in this system will significantly reduce

the system’s total performance. Automobile batteries

are not designed for this type of application and will be

quickly ruined by the repeated charge/discharge cycling.

NOTICE: This system is not designed for applications

involving salt water, brine, or where fish may be present!

Use with these will void warranty.

Installation 3

BASIC TOOLS AND PARTS NEEDED

(Purchase Separately)

Tongue and groove or

large adjustable pliers

Tape measure

Socket wrench or 5/16”

nut driver

Side cutters

Hacksaw (to cut PVC

pipe)

Medium size pliers

Slotted screwdriver

Phillips head screwdriver

Pencil or marker

PTFE pipe thread sealant

tape

PVC glue (solvent weld)

PVC pipe cleaner

Cloth towel

Plastic fittings

Check valve(s) - 1 or

2 depending on

installation

38-120 Ampere-Hour

Storage or Deep Cycle

Battery

Required Battery Capacity:

For best results, use the following AGM Storage Batteries:

Part Amp-Hour

Gal/Charge

at 10’

Approx Run

Time

BAT40 40 4,800 5 Hours

BAT75 75 11,500 11.5 Hours

• Unit equipped with dual battery capability

• Maximum amp-hour: 120

NOTICE: The charger will not fully charge batteries with

excessive amp hour ratings without resetting system.

BATTERY BACKUP SYSTEM (BBU)

INSTALLATION AND OPERATION

NOTICE:

• Install this system during a time when the primary

pump will not be needed. Gather all supplies before

starting. Read all warnings and installation steps

before you start.

• Be prepared for water to leak from the coupling or

piping when disassembling or cutting the discharge

pipe. Protect system components, tools and supplies

from getting wet. Dry any work areas that get wet.

NOTICE: Determine which installation method will

be best for you. The “Separate Discharge” (Figure 7)

installation is recommended.

NOTICE: Check your local codes and ordinances

regarding waste water disposal (especially when running

the pump discharge outside the house) before you start.

The installation must conform to all legal requirements.

If possible, install the BBU so that the discharge goes

directly outdoors (separate discharge pipe from the

primary sump pump discharge pipe). If this is not a

practical option, see the “Easy Install – Method A” option.

NOTICE: For ALL installations, once the installation is

complete, see page 12 for Link2O setup and complete

the registration and connection process. Run both the

primary sump pump and the BBU through at least one

complete cycle to make sure that everything operates

correctly.

Personal injury and flood hazard. Do not

turn the pump on until all the fittings are glued and the

glue has dried. Loose fittings can explode off of pipes

and cause personal injury and flooding.

Risk of electrical shock. At the circuit breaker

or fuse box, turn off the electrical power to the sump

pump before beginning this installation.

SETUP – COMMON DISCHARGE

1. Locate the high water level in your sump pit (the

water level at which the existing (primary) sump

pump starts - see Figure 1). Turn off power to pump

and mark this point on the discharge pipe with a

pencil or marker.

2. Drain the sump pit as far as possible without running

the pump dry. Do this by:

A. Piggyback switch: Unplug the pump and switch

from the outlet, then unplug the pump from the

piggyback switch. Reset the circuit breaker or

reinstall the fuse and plug the pump directly into

the outlet. The pump will start. Drain the pit and

unplug the pump. OR

b. Nopiggyback switch: Reset the circuit breaker

or reinstall the fuse and use a non-conducting

broom handle or stick to raise the float switch;

the pump should start. Drain the pit and then

release the switch.

3. When the pit has drained, turn off (open) the circuit

breaker or remove the fuse again to avoid electrical

shock while working on the installation.

'Turn on'

water level of

Primary Pump

Sump Pit

Check

Valve

Remove the

hose coupling

or mark the

1st cut here.

Support the pipe

before cutting.

3547 1016

Mark pipe with

pencil here

(2nd cut).

Figure 1 – Mark and cut pipe as shown

EASY INSTALL – METHOD A

The recommended Easy Install method suggests installing

both of the pumps on the floor of the sump pit. See

Figure 2. The minimum required sump basin diameter at

the bottom of the pit and the recommended depth of the

sump basin is 18”.

Some additional materials you will need are (2) 1-1/4”

NPT 90° elbows and (2) 1-1/4” NPT close pipe nipples.

Second Cut:

at Marked

Water Line

First Cut:

Backup Pump Installation

(Method A)

Not to Scale

Switches and

Wiring omitted

for clarity

1-1/2" x 1-1/4"

Reducer bushing

for 1-1/4" pipe

1-1/2" x 1-1/4"

Reducer bushing

for 1-1/4" pipe

Tee

1-1/2" x 1-1/2"

slip x 1-1/4" FNPT

Short Length

of Discharge Pipe

(may vary)

Primary Sump

Pump Check Valve

to prevent

recirculation

into the sump;

required if not

already installed

on pump

Cut-Off piece of

discharge pipe.

Hose Coupling

with Clamps

1-1/4" Elbow

1-1/4"

Elbow

Close

Pipe

Nipple

(1-1/4"

x 1-1/4")

Back-up Pump

Discharge Port

Primary Pump

Discharge Port

(1 Nipple

is included

with the

back-up

pump

package)

6977 0515

Check Valve

Assembly

Battery

Backup

Switch*

Figure 2 - Installation diagram – Method A

1. Make the second cut in the discharge pipe at the

pencil mark as shown in Figure 1. Clean the pipe

ends with a cloth towel and set the cut-off piece of

discharge pipe aside.

2. Thread a 1-1/4” NPT 90° elbow (purchased locally)

onto the discharge of the back-up pump.

3. Wrap the threads of all 3 of the close pipe nipples

with 2 turns of PTFE pipe thread sealant tape and

thread one of them into the elbow. Set the other 2

aside.

4. Thread the check valve assembly onto the close pipe

nipple.

NOTICE: Make sure the check valve is installed in the

correct direction. See the inset drawing in Figure 3.

Elbow

Back-up Pump

Discharge

Tee

6978 0515

Check

Valve

Assembly

Close

Pipe

Nipple

(The valve

flap opens

away from the

pump outlet)

Water

Flow

through

valve

Check Valve

Primary

required if

not already

installed

on pump

Figure 3 - Installation with close fit

5. Thread a close pipe nipple into the other end of the

check valve.

6 Thread the second 1-1/4” NPT 90° elbow onto the

pipe nipple.

7. Thread the last pipe nipple into the elbow.

8. Thread the tee onto the pipe nipple and set this

assembly aside.

9. Install a short length of pipe into the top of the check

valve in the primary pump discharge. See Figure 4.

NOTICE: There must be a check valve installed in the

Primary Sump Pump discharge pipe between the tee

and the Primary Sump Pump. This will prevent recir-

culation into the Primary Pump when the Backup

Sump Pump comes on.

10. Slip a reducer bushing (if required) onto the end of

the pipe coming from the primary pump discharge.

Do not glue this connection yet.

NOTICE: If your discharge pipe diameter is 1-1/4”,

you will need to glue the reducer bushings into the

tee first and then slip the cut off piece of discharge

pipe into the bushing.

11. Slip the tee and the back-up pump subassembly onto

the reducer bushing.

12. Glue the cut off piece of pipe into the top of the

reducer bushing in the top of the tee.

13. Mount the float switch assembly loosely to the

discharge pipe with the cable ties. See Figure 4.

Do not tighten the cable ties. Adjustments may be

needed later.

Installation 4

Installation 5

Check

valve

6979 0515

Primary

Sump Pump

Discharge Pipe

Tee

Hose

Coupling

and Clamps

Discharge

Pipe

Cable Ties

1-1/4 x 1-1/2”

Reducers

bushings

(if required)

2" Minimum

To the

back-up

pump

discharge

pipe.

Short length of

discharge pipe

(length may vary)

1-1/2"x1-1/2"

Slip Coupling

1-1/2"x1-1/2"

Slip Coupling

Auxiliary

Check Valve

Required

if a check

valve is

not already

installed

on pump

Figure 4 - Back-up pump float switch

METHOD B

1. Make a second cut in the discharge pipe at the

pencil mark made in step 1 and set the cut-off piece

of discharge pipe aside. See Figure 5.

2. Wrap the threads of the close nipple counterclock-

wise with 2 turns of PTFE pipe thread sealant tape

and set aside.

NOTICE: There must be a check valve installed in the

Primary Sump Pump discharge between the tee and

the Primary Sump Pump. This will prevent recircula-

tion into the Primary Pump when the Back Up Sump

Pump comes on. See Figure 5.

3. Thread the check valve onto the backup pump. Make

sure the check flap hinge is up and the flap swings

away from the pump.

4. Thread the close pipe nipple into the check valve

and pump assembly.

5. Thread the close nipple into the tee.

6. Repeat Steps 11, 12 and 13 above

Check

valve

6979 0515

Primary Sump

Pump Discharge

Pipe

Tee

Hose

Coupling

and Clamps

Discharge

Pipe

Cable Ties

2" Minimum

Short length of

discharge pipe

(length may vary)

1-1/2"x1-1/2"

Slip Coupling

1-1/2"x1-1/2"

Slip Coupling

Auxiliary

Check Valve

Required if

a check

valve is not

already

installed

on pump

Close

Nipple

Backup

Sump

Pump

Long End Faces

Pump, Short End

Faces Tee

Figure 5 – Method B – Make the second cut for

installation of the backup pump and check valve

assembly. Install the backup pump. Your installation may

not require the reducer bushings.

Check

Valve

Grounded

Electrical

Outlet

12" Min.

(305mm)

7" Min.

(178mm)

6980 1016

Hose Coupling

with Clamps

Coupling/

Check Valve

Assembly

Figure 6 – Double pump and float switch installation

Installation 6

INSTALLATION (TYPICAL): SEPARATE

DISCHARGE

Risk of electrical shock. Can shock, burn, or

kill. Unplug the primary sump pump before beginning

this procedure.

NOTICE: Allow for overlap when cutting piping and run a

trial (dry) fitting before you glue.

1. Use PTFE pipe thread sealant tape on male ends of

discharge pipe. Thread the 1-1/4” x 1-1/2” elbow

(supplied) onto the discharge. When tight, the elbow

must point up.

2. If possible, install the Battery Backup Unit (BBU) on

the floor of the sump; be sure that the two pumps do

not touch each other and do not interfere with switch

operation.

NOTICE: If debris or gravel is present in the bottom

of the sump pit that could get sucked up into the

pump, set both the primary sump pump and the BBU

up on bricks or cinder blocks to prevent clogging.

3. If the sump is too small to allow both pumps to sit

on the bottom of the sump, install an angle bracket

on the primary sump pump’s discharge pipe with

stainless steel hose clamps. Mount the backup

pump on the angle bracket. See Figure 7, “Separate

Discharge”.

4. Cut a piece of 1-1/2” PVC pipe to reach from the

backup pump discharge elbow to about one (1) foot

above the basement floor. This is the lower discharge

pipe.

5. To prevent airlocking the pump during operation,

drill a 1/8” hole in the lower discharge pipe about 2”

above the bottom of the pipe (below floor level).

6. Install FP0026-10 check valve (purchase separately)

on the upper end of the pipe. Tighten the hose

clamps securely. BE SURE that the flow arrows point

UP (away from the BBU). If they point down, the

valve will not pass water and the pump will not work.

7. Cut a short length of 1-1/2” PVC pipe for a riser pipe

and clamp it into the top of the check valve.

8. Install a U74-68 Hose and Clamp Assembly on the

top of the riser pipe. For 1-1/2” pipe, remove and

discard the short piece of 1-1/4” hose in the Hose

and Clamp Assembly. Leave the hose clamps loose

and slide the Assembly down below the top of the

riser pipe.

9. Determine where you want the discharge to exit the

basement. At that point, drill the necessary holes

(large enough to have clearance for a 1-1/2” pipe) to

allow you to run the discharge pipe from above the

sump to the outdoors.

10. Install the horizontal discharge pipe. Install a 90°

elbow on the inside end but do not glue.

11. Cut another short piece of 1-1/2” PVC for the Upper

Discharge Pipe to run from the top of the riser pipe

up to the 90° elbow. Be sure to allow enough overlap

for the glue joint in the elbow.

12. Do a trial fit with NO GLUE, installing the 1-1/2”

upper discharge pipe in the 90° elbow and the upper

discharge pipe in the vertical end of the 90° elbow.

The upper discharge pipe should just fit between the

riser pipe and the elbow.

13. Risk of fire and chemical inhalation.

Whenever using PVC primer and PVC cement, follow

the glue manufacturer’s instructions.

14. Make sure that the BBU will clear the primary sump

pump and its switch. If there isn’t room for both

pumps to sit on the floor of the sump, the BBU will

have to be raised (depending on your particular situ-

ation).

15. Clean, prime and glue the upper discharge pipe

into the 90º elbow. When the glue has set, slide the

Hose and Clamp Assembly up to cover the joint and

tighten all the hose clamps.

16. Install the Battery Backup Switch as shown, 1” above

start water level of primary pump. Fasten it to the

pipe with cable ties.

17. Tape the pump cord to the riser pipe so that the plug

cannot fall into the sump.

18. Go to “BBU WIRING AND SETUP” (Page 10) for

wiring instructions.

19. Once all wiring is complete, fill your pit with water

and verify that the PSP removes the water and the

BBU doesn’t run. Then, unplug your PSP and refill

your pit with water. Verify that the BBU pump

removes the water.

20. Make sure that the power is on to both pumps, and

your system is ready to use.

Installation 7

“Separate Discharge”

NOTICE:

Check Valve Flapper(s) must swing AWAY and flow arrow(s) must point

AWAY from pump being protected.

The water level when the switch shuts off must be above the BBU

pump intake.

*Supplied with the Battery Backup System.

Items in italics must be purchased separately.

FLOW

Slope DOWN

to outlet Sill

PTFE pipe thread

sealant tape on all

threaded joints

1-1/2” PVC Riser Pipe

(cut to fit)

1-1/4” FNPTx1-1/2” Slip

Elbow*

Battery Back Up

Sump Pump*

Lower Discharge Pipe

1-1/2” PVC Pipe

(cut to fit)

(2) 1-1/2” PVC

Coupler*

Primary Sump Pump

Check Valve

Check Valve*

Flow Arrow; Must point

AWAY from Pump

being Protected

1-1/2” PVC Upper

Discharge Pipe

(cut to fit)

Battery Backup

Switch*

If the sump is small,

hang the BBU from

the Primary discharge

pipe on an angle bracket.

Floor

Joist

U74-68 Hose and

Clamp Assembly*

Drill 1/8” Anti-Airlock

Hole

6782 1016

Not to scale.

Wiring omitted for clarity.

Figure 7: Typical installation with separate discharge

pipes.

Battery Requirements 8

BATTERY REQUIREMENTS

Hazardous electric current. Can cause

severe burns and start a fire if the battery terminals are

short circuited. Install the battery in the battery case. To

prevent accidental shorting across battery terminals,

close and latch the battery case securely. Do not leave

the battery uncovered.

Do not allow children to play around the battery

backup system installation.

The performance of your backup sump pump depends on

the battery used with it for power. We recommend using

our BAT40 or BAT75. You can also use a group 24M or

27M Deep Cycle battery. They will provide acceptable

performance and will stand up well to long periods of

little or no use.

This system is designed to work with either a sealed

lead-acid AGM battery or a flooded lead-acid battery.

Use of a true Gell Cell (often confused for AGM) or a

standard automotive battery with this charger is not

recommended. An automotive battery may require

charging after only 1-2 hours of continuous use, and the

repeated charging cycles may cause early plate failure in

the battery.

Use only lead-acid batteries. This unit is not designed to

use with Li-Ion, NiMh, NiCAD, Liquid Polymer, etc.

Use only the recommended battery or one of the same

type and size so it will fit in the battery box (maximum

size: 13” long x 7” wide x 10” tall (330.2mm x 177.8mm

x 254mm) including terminals) and supply enough

voltage for full performance.

BATTERY MAINTENANCE

Severe burn hazard. An acid-filled standard

lead-acid battery contains sulfuric acid. Avoid contact with

skin, eyes or clothing.

NOTICE: To protect the battery case from chipping and

gouging, do not let the battery sit on a concrete floor.

Install the battery on a shelf or protective pad (plywood,

2x4s, etc.). Always install the battery in a dry location

that is protected from flooding.

Pre-Qualification Test – 1 and 2

Charger is charging at a very low level to try to bring a

dead battery back to life. If the battery is taking too long,

try resetting the charger once or twice (push the ‘SYSTEM

TEST’ and ‘SILENCE ALARM’ buttons together to reset the

charger).

Special Features:

The charger is equipped with reverse battery, short

circuit, and “runaway charge” protection.

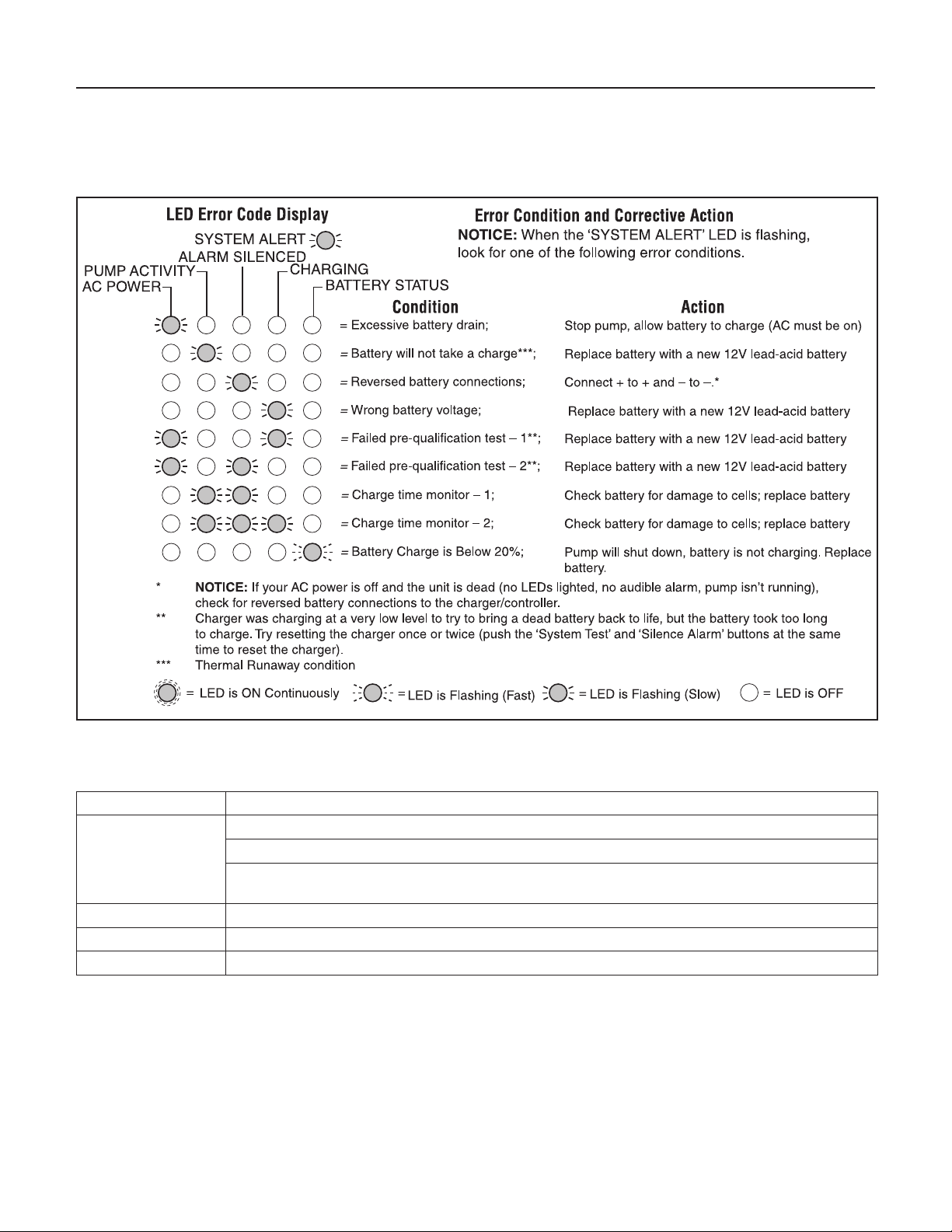

Possible Problems and Remedies

1. Wrong Battery Voltage

Reconnect charger to a 12 volt battery.

2. Reversed Battery Connections

Check all connections. The negative (black) on the

battery must connect to the negative (black) on

the charger, and the positive (red) on the battery

must connect to the positive (red) on the charger.

Reversing the battery connections will cause the

‘SYSTEM ALERT’ and ‘SILENCED AUDIBLE ALARM’

LEDs to flash.

3. Thermal Runaway Condition

“Thermal Runaway” is the technical term for the

condition of the battery when some (or all) of the

cells have deteriorated to the point that they won’t

take a charge. In this case, replace the battery.

4. Charge Time Monitor – 1 and 2

Battery took too long to complete its charge. The

“Charge Time Monitor” will shut down the charger

after 84 hours of continuous charging.

Possible causes are:

A) Pump ran for a long period of time during

charging, or

B) Battery is too large for the charger (including

several batteries connected in a parallel circuit).

Excessive Battery Drain

Pump may have run for a very long time, discharging the

battery. In this case:

1. If 115VAC power is OFF, the charger shuts down

until the power comes back on, but the pump will

run as long as the battery charge lasts. You may need

to replace the battery afterwards.

2. If 115VAC power is ON, the charger/controller

continues to try to charge the battery at a charging

rate of .5 AH until the battery charge is more

than 20%, at which point the charger will resume

charging at a rate of 2 AH.

3. If the pump is running and the AC power is on, you

may need to stop the pump to allow the battery to

charge.

Follow the battery manufacturer’s recommendations for

maintenance and safe use of the battery.

Wiring •Setup 9

6981 1216

BBU WIRING AND SETUP

1. Connect the positive (+) charger/controller lead

wire (red) to the positive (+) battery terminal (red).

Connect the negative (–) charger/controller lead

wire (black) to the negative (–) terminal (black) on

the battery. If you are using two batteries, use the

set of optional terminals and connect the second

battery. Use lead wires (not included) to connect

the positive (+) charger/controller terminal to the

positive (+) battery terminal and the negative (–)

charger/controller terminal to the negative (–) battery

terminal.

2. The backup pump leads are polarity sensitive;

connect the positive pump lead to the terminal

labeled Pump ‘+’ and the negative pump lead to the

terminal labeled Pump ‘–’.

NOTICE: If the leads are reversed, the pump will run

backward and not pump water.

3. The float switch leads are not polarity sensitive;

connect the float switch leads to the ‘Float Switch’

tabs on the charger/controller.

4. Test the float and the pump by lifting and holding

the float. The system alert LED will blink while

the float is up. The ‘PUMP STATUS’ LED will light

continuously and the buzzer will beep steadily. The

pump should start after 3 seconds. If the pump does

not run, check all the connections and remake them

as necessary.

5. To stop the pump, lower the float; after 25 seconds

the pump should stop, the ‘PUMP STATUS’ LED

should flash, and the buzzer should beep.

6. With the pump operating, test the ‘SILENCE ALARM’

button; hold for one second; release. The ‘ALARM

SILENCED’ LED should illuminate and the buzzer

should stop sounding. To reset the buzzer (allow it to

sound) and extinguish the ‘ALARM SILENCED’ LED,

press the ‘SILENCE ALARM’ button again for one

second.

Depress the ‘TEST SYSTEM’ button; hold it for one

second; release. The ‘PUMP STATUS’ LED should stop

flashing.

Wiring •Setup 10

NOTICE: When the unit is first plugged in, or when it first receives power from the battery, the ‘BATTERY STATUS’

LED will flash for 3 seconds.

NOTICE: To activate any Control Button, press and hold it for 1 second.

LED Display and Control Buttons

NOTICE: During normal operation, the flashing

‘PUMP STATUS’ LED indicates that the pump has

run in your absence.

1. Press and hold ‘TEST SYSTEM’ button. All LEDs will

light up, pump will run and buzzer will sound.

Release the button and LEDs should go off, pump

should stop, buzzer should stop.

2. The ‘BATTERY STATUS’ LED indicates the battery

capacity when the A.C. power is off.

A. Continuously ON - the battery voltage is above

10.9 Volts Direct Current (10.9VDC) and

capacity is above 20%.

B. Slow Beep/Slow LED Flash - the battery’s

capacity is between 0 and 20%.

C. Fast Beep/Fast LED Flash - the battery is severely

discharged. The battery will continue to charge

(as long as the 115V AC power to the charger is

on) at the rate of .5 AH until the battery’s charge

is above 20%.

When the first warning occurs (slow beep/slow

flash), you will have approximately 2 hours (or less)

of pump operation left. The actual time of operation

will depend on the condition of the battery and may

be as little as 15 minutes.

4. Connect the Power Supply cable (supplied) to the

Charger/Controller’s Power Input jack.

BATTERY BACKUP INTERNET

CONNECTION AND ALERTS

CONFIGURATION

1. Complete the Battery Backup Registration, Internet

Connection and Alert Configuration BEFORE con-

necting the battery and AC power supply to your

BBU.

NOTICE: If you have already connected the battery

and AC power supply to the BBU before connecting

to to the internet, complete the device registration

process. Then disconnect the battery and remove the

AC power supply from the BBU panel and gateway

for 2 minutes in order to reset the panel. Resume

with Step 8.

2. Go to mylink2o.com and select “sign up” (or Login if

you have an existing account).

3. Follow the online instructions and enter the required

personal information to create a new user account.

4. Register your device using the Unique Device ID Key

included on the device and your manual cover.

5. The Alerts will use the e-mail(s) and phone number(s)

entered here.

6. Find an open network connection on your internet

router or other hardwired connection (like an internet

switch).

7. Rotate the Gateway antenna up on the gateway. Us-

ing the supplied 1 meter Ethernet cable (or a longer

cable if necessary) Connect the Gateway to the open

internet port.

NOTICE: We recommend the use of an uninterrupted

power supply for your internet modem, home router,

internet switch (if applicable), and the gateway power

supply.

8. Connect the Gateway power supply to a 115 VAC

outlet, plug the cord into the back of the Gateway.

• The Gateway will blink red for a few seconds.

• When the LED becomes solid Green or solid

Green with an occasional blink – your Gateway

is communicating with the Link2O server. If not,

refer to Gateway Trouble in the manual.

9. Connect the red positive (+) charger/controller lead

wire to the positive (+) (red) battery terminal. Con-

nect the black negative (-)charger/controller lead wire

to the negative (-) (black) battery terminal.

10. Connect the Charger Power Supply cable (supplied)

to the Charger/Controller’s Power input jack. Plug

the other end into a 115 VAC outlet.

11. Check the AC power LED on the Controller – if it is

solid green the unit is communicating with the WEB

site.

12. Verify the system is operational by pressing the ‘TEST

SYSTEM’ button and observing the test sequence.

13. Test communication by clicking the “Test” icon on

the web page and verify the unit has run the test.

14. Using the drop down menu configure the desired

method of Alerts you want to receive (Text or E-mail).

15. Alerts can be tested by activating the pump with the

float switch.

Link2O™Setup 11

IF GATEWAY LED LIGHT IS NOT GREEN (GREEN, SLOW BLINK) FIRST TRY TO “POWER CYCLE” THE GATEWAY (UNPLUG THE

POWER CORD, WAIT 15+ SECONDS, THEN RE-APPLY POWER).

Gateway Status

Indicator (LED Color)

Definition Action Needed

Green Power on: gateway connected to servers. OK - Connection complete and operational

Green, quick blink Power on: data traffic to servers. OK - Operating, data is moving between BBU and

Server

Green, slow blink

(1-2 blinks per second)

Power on: gateway connected to local router, but

not connected to Internet or servers.

System is online and scanning for destination/server

(add a network switch inline to help define unit).

Red Power on: gateway has no local connection to

router. The gateway does not "recognize/see" that it

is connected to the router.

Check Ethernet cable connections and/or quality or

cable. Try a different router port. Is the router turned

on.

Red, slow blink

(1-2 blinks per second)

Power on: gateway communicating with router, but

router cannot assign Dynamic Host Configuration

Protocol (DHCP) or Domain Name System (DNS) to

gateway.

Router is not permitting the gateway to access the

internet (add a network switch inline to help define

unit).

Off Power off or product fault. Check power source, verify power adapter is

functioning. Defective gateway.

GATEWAY TROUBLESHOOTING

Link2O™Setup Setup 12

Charger/Controller LED Display 13

LED Operating Code Display System Operating Condition

CHARGING

BATTERY STATUS

PUMP ACTIVITY

AC POWER

ALARM SILENCED

SYSTEM ALERT

Indicates 115V AC Power is connected / Unit online

NOTICE: All of the situations listed above indicate normal system operation; no action is required.

However, if the BBU pump is running or has run, check the primary pump and actively monitor the

charger status for battery life. Always reset the charger after the pump runs.

During normal system operation, the ‘SYSTEM ALERT’ LED blinks while the float switch is on,

indicating the pump should start within 3 seconds. The “AC POWER” LED is lighted

(solid or blinking) as long as the system is plugged in to an operating AC power circuit.

Indicates Pump is running (continuous LED)

Indicates Audible alarm is switched off

Indicates Battery is charging normally

Indicates Continuous LED: battery charge is above 20%,

system is maintaining charge

Indicates Slow flashing LED: battery charge is below 20%

6790 0313

LED is Flashing (Slow)

=LED is OFF

LED is ON Continuously

= =

LED is Flashing (Fast)

=

Indicates Fast flashing LED: Pump has run

Indicates Fast flashing LED: Battery pre-qualification test is running

Indicates 115V AC Power is connected / Unit offline

NOTE: When the System Alert light IS NOT flashing, refer to Table II. When the System Alert light

IS flashing, refer to Table IV

TABLE II – Operating Code Displays (LEDs Lighted Continuously or Flashing)

TABLE III – LED Function Displays (LEDs Lighted Continuously)

Control LED: Continuous Illumination Indicates Normal Operation:

AC Power AC power is present. Unit is online.

Pump Status

The float switch has been activated. The LED remains on (flashing) after the pump

has stopped. Depress the ‘SYSTEM TEST’ button to reset it.

Silenced Audible Alarm Audible Alarm has been silenced. Press and release the ‘SILENCE ALARM’ button

to reset (activate) the audible alarm and turn OFF the LED.

Charging

Indicates that the battery is charging – see Table II, above.

Battery Status A. Continuous ON - the battery voltage is above 10.9 Volts DC and capacity is

above 20%.

B. Slow Beep/Slow LED Flash - the battery’s capacity is below 20%, and voltage is

between 8.2VDC and 10.9VDC.

C. Fast Beep/Fast LED Flash - the battery has been discharged to less than 8.2VDC.

System Alert Flashing (in unison with the buzzer) indicates that the charger has entered ‘Failure

Mode’. Press the ‘SYSTEM TEST’ and ‘SILENCE ALARM’ buttons to reset it.

NOTICE: If the source of the failure is not corrected, the charger will reenter

“Failure Mode”. See Table IV for error code information.

Charger/Controller LED Display 14

NOTE: When the System Alert light IS NOT flashing, refer to Table II. When the System Alert light

IS flashing, refer to Table IV

TABLE IV – Error Code Displays (LEDs Flashing)

TABLE V – Control Button Functions

Control Button: Result of Pushing Button:

System Test Pump starts and all LEDs light up.

Will reset the ‘PUMP ACTIVITY’ LED.

When pushed with the ‘SILENCE ALARM’ button, the Charger/Controller microprocessor resets

and error code resets.

Silence Alarm Toggle; Prevents the audible alarm sounding. Press and release to reset.

Light Toggles the light on the Charger/Controller on and off.

System Reset Press and release ‘TEST SYSTEM’ and ‘SILENCE ALARM’ to reset system.

Pump won’t run: Check all the wiring connections.

Check for a low or defective battery.

Check that the automatic switch is free to move up and down.

Press the circuit breaker reset button on the control panel.

Motor hums but pump won’t run: Check for low or defective battery.

Pump runs but pumps very little or no water: Make sure a check valve is installed and functioning between the

primary pump discharge and the Battery Backup wye.

Check for an obstruction in the discharge pipe.

The discharge pipe length and/or height exceeds the capacity of the

pump.

Check for a low or defective battery.

The Positive (+) and negative (–) pump wires are reversed.

Disconnect them and reconnect correctly.

Pump cycles too frequently: The check valve located between the discharge of the primary

pump and the Battery Backup wye is not installed or is not

working properly. Install an auxiliary check valve or replace the

existing check valve as required.

TROUBLESHOOTING - PUMP

Troubleshooting 15

Repair Parts 16

6982 0916

3

9

7

4

5

1

6

8 – Gateway Kit

2

10B

10C

10D 10F

10E

10B

10

10G

10A

Key No. Part Description Part Number

1DC Backup Pump PS17-2005*

21-1/4 FNPT x 1-1/2 Slip Elbow U78-1012

3Float Switch PS17-2003

4 Charger/Controller PS217-1522

5Battery Case Base

Battery Case Cover

PS17-2044

PS17-2045

6AC Adaptor PS17-2008

7Cable Ties - 11” **

8Gateway Kit (Gateway, Power Supply, 1m RJ45 Cable) U117-1568

9Switch Bracket PS17-2004

* If pump fails, replace entire system.

** Purchase at local hardware store.

NOTICE: All check valves must be installed as described in the installation instructions or the warranty is void. This

includes the check valve for the primary sump pump in a Common Discharge installation.

Part Description

Part

Number

AGM 75A-Hour BAT75

AGM 40A-Hour BAT40

Optional Battery Supplies

Sold Separately

Key Part Description Part Number

10 Hardware Replacement Kit (Includes Key Nos. 1A through 1G) PS198-270

10A Rubber Hose Coupling with Inserts (2) and Clamps (2) U74-68

10B 1-1/2 x 1-1/4 PVC Slip Reducer Bushing (2) †

10C PVC Tee 1-1/2 x 1-1/2 Slip x 1-1/4 FNP †

10D Auxiliary Check Valve †

10E 1-1/2 x 1-1/2 PVC Slip Coupling †

10F PVC Pipe Nipple, 1-1/4 NP x Close †

10G Check Valve Assembly, 1-1/4 FNP x 1-1/4 FNP †

†Included in Hardware Replacement Kit, Key No. 1.

NOTICE Key No. 10G Check Valve Assembly must be correctly installed or warranty is void. If primary sump pump has no check

valve installed below the Battery Backup Tee, Key No. 10D Auxiliary Check Valve must be correctly installed or warranty is void.

Optional Battery Supplies

Sold Separately

Warranty 17

Retain Original Receipt for Warranty Eligibility

Limited Warranty

This Limited Warranty is effective June 1, 2011 and replaces all undated warranties and warranties dated before June 1, 2011.

SIMER warrants to the original consumer purchaser (“Purchaser” or “You”) that its products are free from defects in material and

workmanship for a period of twelve (12) months from the date of the original consumer purchase. If, within twelve (12) months

from the original consumer purchase, any such product shall prove to be defective, it shall be repaired or replaced at SIMER’s

option, subject to the terms and conditions set forth herein. Note that this limited warranty applies to manufacturing defects only

and not to ordinary wear and tear. All mechanical devices need periodic parts and service to perform well. This limited warranty

does not cover repair when normal use has exhausted the life of a part or the equipment.

The original purchase receipt and product warranty information label are required to determine warranty eligibility. Eligibility

is based on purchase date of original product – not the date of replacement under warranty. The warranty is limited to repair or

replacement of original purchased product only, not replacement product (i.e. one warranty replacement allowed per purchase).

Purchaser pays all removal, installation, labor, shipping, and incidental charges.

For parts or troubleshooting assistance, DO NOT return product to your retail store. Contact SIMER Customer Service at

800-468-7867.

Claims made under this warranty shall be made by returning the product (except sewage pumps, see below) to the retail outlet

where it was purchased immediately after the discovery of any alleged defect. SIMER will subsequently take corrective action

as promptly as reasonably possible. No requests for service will be accepted if received more than 30 days after the warranty

expires. Warranty is not transferable and does not apply to products used in commercial/rentalapplications.

Sewage Pumps

DO NOT return a sewage pump (that has been installed) to your retail store. Contact SIMER Customer Service. Sewage pumps

that have seen service and been removed carry a contamination hazard with them.

If your sewage pump has failed:

• Wear rubber gloves when handling the pump;

• For warranty purposes, return the pump’s cord tag and original receipt of purchase to the retail store;

• Dispose of the pump according to local disposal ordinances.

Exceptions to the Twelve (12) Month Limited Warranty

Product Warranty Period

BW85P, M40P 90 days

2115, 2300, 2310, 2330, 2883, 2886, 2943, 2955, 2956, 2957, A5300, A5500 2 Years

4” Submersible Well Pumps, 2945, 2958, 2975PC, 3075SS, 3963, 3984, 3995,

4185, 4185P, 4186, 4188, 4190

3 Years

Pre-Charged Pressure Tanks, 3985, 3986, 3988, 3989, 5910, 5950, 5955, 5965, 5975 5 Years

General Terms and Conditions; Limitation of Remedies

You must pay all labor and shipping charges necessary to replace product covered by this warranty. This warranty does not

apply to the following: (1) acts of God; (2) products which, in SIMER’s sole judgement, have been subject to negligence, abuse,

accident, misapplication, tampering, or alteration; (3) failures due to improper installation, operation, maintenance or storage; (4)

atypical or unapproved application, use or service; (5)failures caused by corrosion, rust or other foreign materials in the system,

or operation at pressures in excess of recommended maximums.

This warranty sets forth SIMER’s sole obligation and purchaser’s exclusive remedy for defective products.

SIMER SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES,

INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. THE FOREGOING WARRANTIES SHALL NOT EXTEND BEYOND THE DURATION PROVIDEDHEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long an

implied warranty lasts, so the above limitations or exclusions may not apply to You. This warranty gives You specific legal rights

and You may also have other rights which vary from state to state.

SIMER • 293 Wright Street • Delavan, WI U.S.A. 53115

Phone: 800-468-7867 • Fax: 800-390-5351 • www.simerpump.com

Sécurité 18

Consignes de sécurité importantes

CONSERVER CES DIRECTIVES - Ce manuel contient

des directives importantes devant être respectées lors de

l’installation, de l’utilisation et de l’entretien de ce produit.

Il s’agit du symbole d’alerte à la sécurité. Ce symbole,

lorsqu’il se trouve sur votre pompe ou votre manuel, signale

qu’il faut chercher la présence de l’un de ces mots indicateurs

et être conscient des risques de blessure!

indique un risque qui, s’il n’est pas évité, causera

des blessures graves, voire la mort.

indique un risque qui, s’il n’est pas évité, peut

causer des blessures graves, voire la mort.

indique un risque qui, s’il n’est pas évité, peut

causer des blessures mineures, voire modérées.

AVIS vise des pratiques qui ne concernent pas les blessures.

Lire soigneusement et respecter toutes les consignes de

sécurité contenues dans ce manuel ou placées sur la pompe.

Faire en sorte que les étiquettes de sécurité demeurent en

bon état. Remplacer les étiquettes de sécurité manquantes ou

endommagées.

Pour éviter tout risque de blessures graves causées par un

choc électrique ou des brûlures de même que tout risque de

dommage à cause d’une inondation, prendre le temps de bien

lire les consignes de sécurité avant d’installer la pompe.

L’acide de batterie est une matière corrosive.

Ne pas mettre en contact avec la peau, les vêtements ou le

chargeur de batterie. Porter une protection oculaire et à la tête

lorsqu’il est nécessaire de manipuler des batteries. Brancher et

débrancher les bornes de sortie CC uniquement après avoir

débranché le chargeur de la prise CA. Ne jamais laisser les

bornes CC se toucher.

Tension dangereuse. Peut causer des chocs

électriques graves, voire mortels. Ne pas brancher ou

débrancher le chargeur de batterie lorsque vous vous tenez sur

une surface mouillée ou inondée. S’assurer qu’une main

demeure libre au moment de brancher ou de débrancher le

chargeur. Si le plancher du sous-sol est mouillé, couper

l’alimentation électrique vers le sous-sol avant de marcher sur

le plancher.

Risque d’inondation. Ne pas faire fonctionner

la pompe à sec. Ce faisait, les joints de la pompe seront

endommagés, créant potentiellement une fuite et des

dommages à la propriété.

Suivre les consignes des codes de plomberie et d’électricité

locaux et nationaux au moment d’installer le système. Il est

recommandé d’utiliser un disjoncteur de fuite de terre (GFCI)

avec tout appareil électrique submergé dans l’eau.

N’utiliser ce système que comme pompe de puisard de secours

dans un milieu résidentiel. Il n’a pas été conçu pour servir de

pompe de puisard principale.

Ne pas soulever la pompe à partir de son cordon électrique.

Risque de choc électrique. Ne pas soulever la

pompe par son cordon électrique; plutôt, la soulever par le

tuyau de décharge, l’anneau de levage ou la poignée qui se

trouve dessus. Le cordon pourrait être endommagé s’il est

utilisé pour soulever la pompe.

Ne pomper que de l’eau propre avec cette pompe.

La pompe a été lubrifiée de manière permanente en usine. Ne

pas essayer de la lubrifier!

Garder le chargeur de batterie et le boîtier de batterie en

hauteur, dans un endroit sec, frais et bien aéré.

AVIS : si un détecteur de monoxyde de carbone (CO) est

installé, il doit se trouver à au moins 4,6 m (15 pi) du chargeur

de batterie, ce afin d’éviter l’occurrence de fausses alarmes. Se

reporter aux directives d’installation du détecteur de CO pour

en apprendre davantage.

Pour éviter les risques d’incendie ou d’explosion, assurer que

les sources d’étincelles ou de flammes (pilote) se trouvent à

l’écart de la batterie.

La distance de pompage verticale maximale de la pompe est de

4,3 m (14 pi), dans le cas du modèle A5300.

S’assurer qu’il n’y a pas de débris encombrant la pompe de

puisard. Les débris peuvent endommager la pompe et ainsi

entraîner une inondation.

Avertissement lié à la Proposition 65 de la Californie

Ce produit et les accessoires connexes

contiennent des produits chimiques reconnus dans l’État

de la Californie comme pouvant provoquer des cancers,

des anomalies congénitales ou d’autres dangers relatifs à la

reproduction.

RENSEIGNEMENTS GÉNÉRAUX

La pompe de puisard à batterie de secours ne peut pas se

substituer à votre pompe de puisard principale. Elle a été

conçue pour agir en tant que support pour votre pompe

principale en cas de panne d’électricité ou de tout autre

problème nuisant au fonctionnement normal de la pompe

primaire. Ne pas utiliser ce système pour pomper des liquides

inflammables ou des produits chimiques. Ne pomper que de

l’eau propre avec cette pompe.

Assurer que le chargeur de batterie demeure au sec et bien

protégé contre tout dommage.

Ce système a été conçu pour fonctionner avec une batterie

AGM (plomb-gel et feutre) scellée et sans entretien. Il peut aussi

fonctionner avec une batterie plomb-acide à électrolyte liquide

à décharge poussée. Les batteries à électrolyte gélifié et scellées

plomb-acide à électrolyte liquide ne sont pas recommandées.

En cas d’urgence (comme une panne de courant prolongée),

si la batterie à décharge poussée est complètement déchargée,

il est possible d’utiliser une batterie automobile à la place.

Prendre soins de remettre la batterie à décharge poussée en

place aussi rapidement que possible. Utiliser une batterie

automobile à la place d’une batterie à décharge poussée réduira

significativement la performance totale du système. Les batteries

automobiles ne sont pas conçues pour ce type d’application;

elles seront rapidement rendues inutiles par les cycles répétés de

charge/décharge. AVIS: ce système n’a pas été conçu pour les

applications impliquant l’eau salée, la saumure ou la présence

de poissons; l’utiliser dans ces conditions entraînera l’annulation

de la garantie!.

Installation 19

OUTILS DE BASE ET PIÈCES

NÉCESSAIRES (vendus séparément)

Pince multiprise à crémaillère ou autre pince réglable de

grande taille

Ruban à mesurer

Clé à douille ou tourne-écrou de 7,9 mm (5/16 po)

Couteau latéral

Scie à métaux (pour couper du tuyau de PVC)

Pinces de taille moyenne

Tournevis à lame plate

Tournevis cruciforme

Crayon ou marqueur

Ruban scellant pour filets de tuyau en PTFE

Colle pour PVC (soudure par solvant)

Nettoyant à tuyau de PVC

Chiffon

Raccords de plastique

Clapet(s) de non-retour - 1 ou 2, selon l’installation

Batterie à stockage de 38-120 ampères-heures ou à décharge

poussée

Capacité de batterie requise :

Pour obtenir de meilleurs résultats, se servir des batteries à

stockage AGM suivantes :

Pièce Amp-Heure

Gal/Charge à 3

m (10 pi)

Temps de

fonctionnement

approx

BAT40 40 4800 5 heures

BAT75 75 11500 11,5 heures

• Unité pouvant être équipée d’une batterie double

• Amp-heure maximum : 120

AVIS : Le chargeur ne parviendra pas à charger complètement

les batteries dont la cote d’ampères-heure est excessive sans

procéder à la réinitialisation du système.

SYSTÈME DE SECOURS À

BATTERIE (SSB) INSTALLATION ET

FONCTIONNEMENT

AVIS :

• Installer ce système à un moment où il n’est pas nécessaire

de faire fonctionner la pompe principale. Rassembler

tout le matériel nécessaire avant de commencer. Lire tous

les avertissements et les étapes d’installation avant de

commencer.

• Prendre en considération que l’eau pourrait couler des

raccords ou de la tuyauterie lors du démontage ou de la

coupe du tuyau de décharge. Protéger les composantes du

système, les outils et le matériel pour ne pas les mouiller.

Sécher la surface de travail à mesure qu’elle elle mouillée.

AVIS : lire attentivement les pages 4 à 6 pour déterminer la

méthode d’installation la plus appropriée. L’installation de type

« décharge distincte » (figure 2, page 4) est recommandée.

AVIS : vérifier les codes et les règlements locaux concernant

l’élimination des eaux usées (particulièrement lorsque la

pompe se décharge hors de la maison) avant de commencer.

L’installation doit se conformer à toutes les exigences légales.

Si possible, installer le SSB de manière à ce que la décharge soit

évacuée directement à l’extérieur (tuyau de décharge distinct

du tuyau de décharge de la pompe de puisard principale). Si

cette option n’est pas envisageable, passer à l’option « décharge

commune » (figure 3, page 4).

AVIS : Applicable pour TOUTES les installations une fois

terminées, il faut faire fonctionner en même temps les deux

pompes de puisard (la pompe principale et la pompe de

secours) pendant un cycle complet pour vérifier que tout

fonctionne correctement.

Risque de blessure et d’inondation. Ne pas mettre la

pompe en marche tant que tous les raccords n’ont pas été collés et que

la colle n’a pas eu le temps de sécher. Les raccords lâches peuvent

exploser et causer des blessures ou une inondation.

Risque de choc électrique. Sur le panneau électrique ou

la boîte de fusibles, couper l’alimentation électrique se rendant vers la

pompe de puisard avant de commencer l’installation.

Mise en place

1. Déterminer le niveau d’eau élevé dans le puits de puisard (le

niveau d’eau auquel la pompe de puisard en place (principale) se

met en marche - se reporter à la figure 1). Couper l’alimentation

vers la pompe et indiquer ce niveau sur le tuyau de décharge à

l’aide d’un crayon ou d’un marqueur.

2. Vider le puits de puisard aussi profondément que possible sans

que la pompe se mette à fonctionner à vide. Pour ce faire :

A. INTERRUPTEUR DE SORTIE CONJOINTE : débrancher

la pompe et l’interrupteur de la prise puis débrancher la

pompe de l’interrupteur de sortie conjointe. Réinitialiser le

disjoncteur de circuit ou remettre le fusible en place puis

brancher la pompe directement dans la prise. La pompe va

démarrer. Vidanger le puits et débrancher la pompe. OU

B. SANS INTERRUPTEUR DE SORTIE CONJOINTE : réinitialiser

le disjoncteur de circuit ou remettre le fusible en place et

se servir d’un manche à balai ou d’un bâton pour soulever

l’interrupteur à flotteur, ce qui devrait faire fonctionner la

pompe. Vidanger le puits puis relâcher l’interrupteur.

3. Une fois le puits vidangé, couper (ouvrir) le disjoncteur de circuit

ou enlever le fusible à nouveau pour éviter tout choc électrique

pendant l’installation.

'Turn on'

water level of

Primary Pump

Sump Pit

Check

Valve

Remove the

hose coupling

or mark the

1st cut here.

Support the pipe

before cutting.

3547 1016

Mark pipe with

pencil here

(2nd cut).

Fig 1 : faire une marque au niveau d’eau de «

démarrage »

Clapet de non

retour

Puits de puisard

Niveau de demarrage

de la pompe principlae

Débrancher

le raccord en

caoutchouc ou

repérer la première

coupe ici.

Supporter le tuyau

avant de le couper.

Installation 20

INSTALLATION FACILE – MÉTHODE A

La méthode installation facile recommandée suggère d’installer

les deux pompes sur le fond du puisard. Se reporter à la Figure

2. Le diamètre minimum requis du puisard à sa partie inférieure

et sa profondeur recommandée doivent être de 18 po.

Les autres fournitures dont on aura besoin seront 2 coudes à

90° de 1 1/4 po et 2 mamelons courts de 1 1/4 po.

Second Cut:

at Marked

Water Line

First Cut:

Backup Pump Installation

(Method A)

Not to Scale

Switches and

Wiring omitted

for clarity

1-1/2" x 1-1/4"

Reducer bushing

for 1-1/4" pipe

1-1/2" x 1-1/4"

Reducer bushing

for 1-1/4" pipe

Tee

1-1/2" x 1-1/2"

slip x 1-1/4" FNPT

Short Length

of Discharge Pipe

(may vary)

Primary Sump

Pump Check Valve

to prevent

recirculation

into the sump;

required if not

already installed

on pump

Cut-Off piece of

discharge pipe.

Hose Coupling

with Clamps

1-1/4" Elbow

1-1/4"

Elbow

Close

Pipe

Nipple

(1-1/4"

x 1-1/4")

Back-up Pump

Discharge Port

Primary Pump

Discharge Port

(1 Nipple

is included

with the

back-up

pump

package)

6977 0515

Check Valve

Assembly

Battery

Backup

Switch*

Figure 2 – Schéma de l’installation – Méthode A

1. Procéder à une deuxième coupe du tuyau de refoulement

au repère fait au crayon. Avec un chiffon propre, nettoyer

les extrémités du tuyau, puis mettre de côté le morceau de

tuyau de refoulement coupé.

2. Glisser un coude à 90° (à acheter localement) sur le

refoulement de la pompe de secours.

3. Enrouler les filets des 3 mamelons courts de deux tours

du ruban d’étanchéité en PTFE pour filetage (Réf. 3), puis

visser un mamelon sur le coude. Mettre les deux autres de

côté.

4. Revisser le clapet de non retour sur le mamelon court.

REMARQUE: S’assurer que le clapet de non retour est

installé dans le bon sens. Se reporter à l’encadré de la

Figure 3.

Elbow

Back-up Pump

Discharge

Tee

6978 0515

Check

Valve

Assembly

Close

Pipe

Nipple

(The valve

flap opens

away from the

pump outlet)

Water

Flow

through

valve

Check Valve

Primary

required if

not already

installed

on pump

Figure 3 - Installation à ajustement serré

5. Visser un mamelon court sur l’autre extrémité du clapet de

non retour.

6. Visser le deuxième coude à 90° sur le mamelon.

1 ¼ po NPT

7. Visser le dernier mamelon sur le coude.

8. Visser le té sur le mamelon, puis mettre cet ensemble de

côté.

9. Brancher une petite longueur de tuyau sur le clapet de non

retour du refoulement de la pompe principale. Se reporter

à la Figure 4.

REMARQUE: Un clapet de non retour doit être installé sur

ce tuyau de refoulement de la pompe principale, entre le

té et la pompe principale. Ceci empêchera la recirculation

dans la pompe principale lorsque la pompe de secours se

mettra en marche.

10. Glisser une bague de réduction (si requise) sur l’extrémité

du tuyau provenant du refoulement de la pompe

principale. Ne pas coller ce raccord pour le moment.

REMARQUE: Si le diamètre du tuyau de refoulement est

de 1 1/4 po, il faudra coller les bagues de réduction dans

le premier té, puis glisser le morceau coupé du tuyau de

refoulement dans la bague.

11. Glisser le té et le sous-ensemble de la patte de la pompe

de secours sur la bague de réduction.

12. Coller le morceau de tuyau coupé sur la bague de

réduction qui se trouve en haut du té.

13. Poser l’interrupteur à flotteur sur le tuyau de refoulement

avec les colliers, sans les serrer. Se reporter à la Figure 4.

Ne pas serrer les colliers. Il faudra peut-être procéder à des

réglages plus tard.

Pas à l’échelle

Les interrupteurs et

le câblage ne sont

pas montrés pour

plus de clarté.

Raccord en

caoutchouc et

colliers

Morceau coupé

du tuyau de

refoulement

Première coupe

Petite longueur de

tuyau de refoulement

(peut varier)

Clapet de non retour

de la pompe de puisard

principale; empêche

la recirculation dans le

puisard; requis si pas déjà

installé sur la pompe

Orifice de

refoulement de la

pompe principale

Mamelon

court

(1 1/4 po

x 1 1/4 po)

(1 mamelon

est livré

avec la

pompe de

secours)

Coude de

1 1/4 po

Orifice de

refoulement de la

pompe de secours

clapet de

non retour

coude de

1 1/4 po

Bague de

réduction de 1

1/2 po x 1 1/4

po pour tuyau

de 1 ¼ po

Té de 1 1/2 po x 1 1/2

po à glissement x 1 1/4

po FNPT

Bague de réduc-

tion de

1 1/2 po x 1 1/4

po pour tuyau

de 1 ¼ po

Interrupteur

de batterie de

secours*

Deuxième

coupe à la

ligne d’eau

repérée

Té Mamelon

court

Coude

Clapet de

non retour

L’eau

circule

dans le

clapet

(L’obturateur

du clapet de

non retour s’ouvre à

l’opposé du refoulement

de la pompe) Refoulement de la

pompe de secours

Clapet antiretour

primaire requis si

pas déjà installé

sur la pompe

Installation de la pompe de secours

(Méthode A)

Table of contents

Languages:

Popular Power Supply manuals by other brands

Rockwell Automation

Rockwell Automation Allen-Bradley 1606-XLE120EL installation instructions

VOLTCRAFT

VOLTCRAFT PLC-2400C operating instructions

Fisher Scientific

Fisher Scientific FB1000-2 Operator's manual

Sanela

Sanela SLZ 08 Mounting instructions

Optimal Power

Optimal Power OPR200-05S user manual

Et system

Et system LAB-SMS/E Series manual