Table of Contents

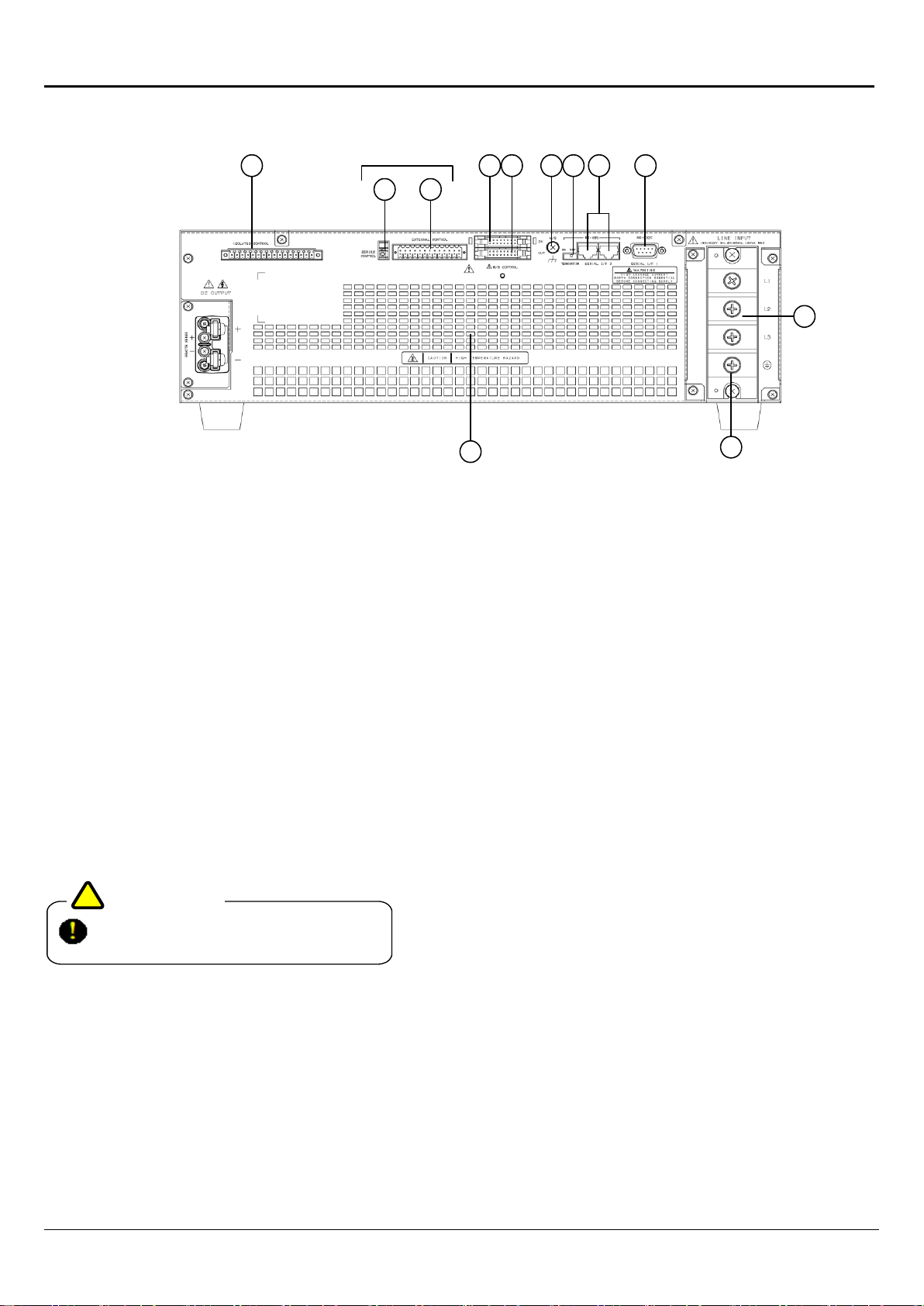

Controlling with External Analog & Contact

Signals ......................................................135

Using External Control Terminals...................... 135

External Control Connector Terminal List.......... 136

Isolated Control Connector Terminal List ..........136

Uses of Terminals ..............................................136

Toggling Output ON/OFF with External Contacts

............................................................................... 137

Toggling Output ON/OFF with Isolated External

Contacts ............................................................... 139

Toggling Output ON/OFF with External Contacts in

Series Operation.................................................. 141

TRIP Operation with External Contacts ............ 143

TRIP Operation with Isolated External Contacts

............................................................................... 144

Output Voltage Control ....................................... 145

Output Voltage Control with External Resistance

........................................................................... 145

Output Voltage Control with External Voltage ...149

Output Voltage Control with Isolated External

Voltage...............................................................150

Output Current Control....................................... 151

Output Current Control with External Resistance

........................................................................... 151

Output Current Control with External Voltage ... 155

Output Current Control with Isolated External

Voltage...............................................................156

Analog Output Monitor ....................................... 157

Output Voltage Monitor......................................157

Output Current Monitor......................................157

Isolated Analog Output Monitor......................... 158

Isolated, Output Voltage Monitor ....................... 158

Isolated, Output Current Monitor ....................... 158

Status Output....................................................... 159

Output Circuit..................................................... 159

LEVEL1_ALM, OUTPUT ON/OFF_STS ...........160

LEVEL1_ALM, ...................................................161

Special Loads...........................................162

Loads with Reverse Current .............................. 162

Pulse Current Loads ........................................... 163

Connection to Secondary Battery ..................... 164

Maintenance .............................................166

Warranty Period................................................... 166

Maintenance Service........................................... 166

Daily Maintenance and Inspection .................... 166

Lifespan of Parts ................................................. 166

Cleaning the outer of this equipment................ 166

Periodical check and replacement of air filter.. 167

Calibration ................................................170

Calibrating Output Settings................................ 170

Offset/Full Scale Calibration of Output Voltage

Settings..............................................................170

Offset/Full-Scale Calibration of Output Current

Settings..............................................................172

Offset/Full-Scale Calibration of Output Voltage

with External Analog Input ................................. 174

Output Voltage Control with External Voltage

(Isolated External Voltage) ................................ 174

Output Voltage Control with External Resistance(A)

...........................................................................176

Output Voltage Control with External Resistance(B)

...........................................................................178

Output Voltage Control with External Resistance(C)

...........................................................................180

Offset/Full-Scale Calibration of Output Current

with External Analog Input..................................182

Output Current Control with External Voltage

(Isolated External Voltage).................................182

Output Current Control with External Resistance (A)

...........................................................................184

Output Current Control with External Resistance (B)

...........................................................................186

Output Current Control with External Resistance (C)

...........................................................................188

Calibrating Meters................................................190

Voltmeter Offset/Full-Scale Calibration ..............190

Ammeter Offset/Full-Scale Calibration...............192

Offset/Full Scale Calibration of Output Voltage

Monitor (Isolated Output Voltage Monitor)........194

Offset/Full Scale Calibration of Output Current

Monitor (Isolated Output Current Monitor)........196

Specifications ..........................................198

Output Specifications..........................................198

Input Specifications.............................................199

Constant Voltage Characteristics ......................200

Constant Current Characteristics ......................201

Measurement and Display ..................................202

Protection Functions...........................................204

Remote Sensing...................................................204

Other Functions ...................................................205

Applied Standard (30V,60V,500V,1000V)............207

Applied Standard (120V,400V) Since 1 April 2021

...............................................................................207

External Control ...................................................207

Isolation/ Withstanding Voltage..........................209

Cooling..................................................................209

Operational Environment....................................209

Dimensions/Weight..............................................210

External Diagrams ...............................................211

Appendix ..................................................224

Appendix 1 Output Current vs Input Current....224

Appendix 2 Output Current vs Efficiency..........230

Appendix 3 Rush Current Wave Form ...............236

Appendix 4 Loaded Current vs Recommended

Conductor Area ....................................................237

Appendix 5 Circuit Block Diagram.....................238