(SERVOS, WHEREOF ONE MODIFIED,

ARE NOT INCLUDED IN THE KIT)

CONSTRUCTION MANUAL

ALTIMETER

*

1

*

2

*

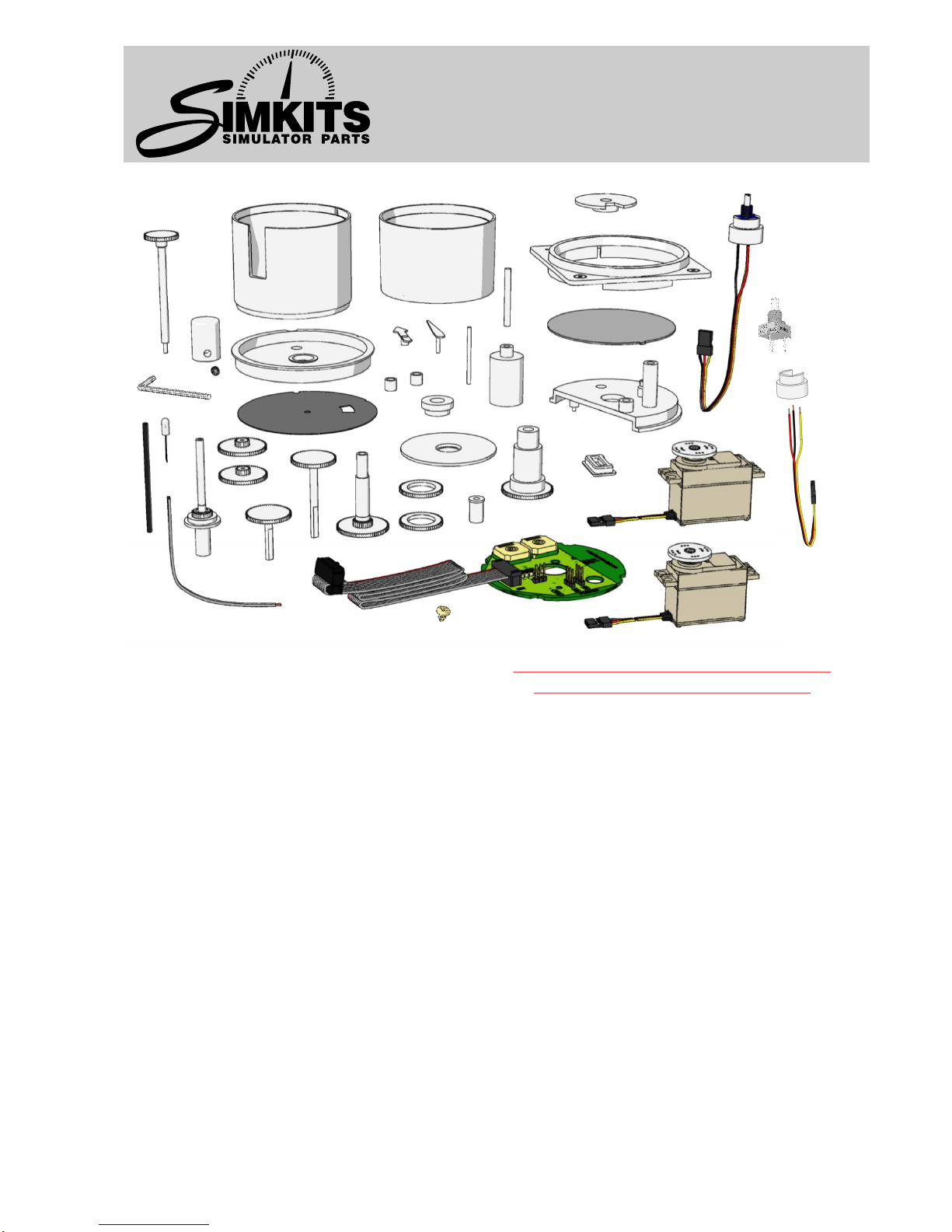

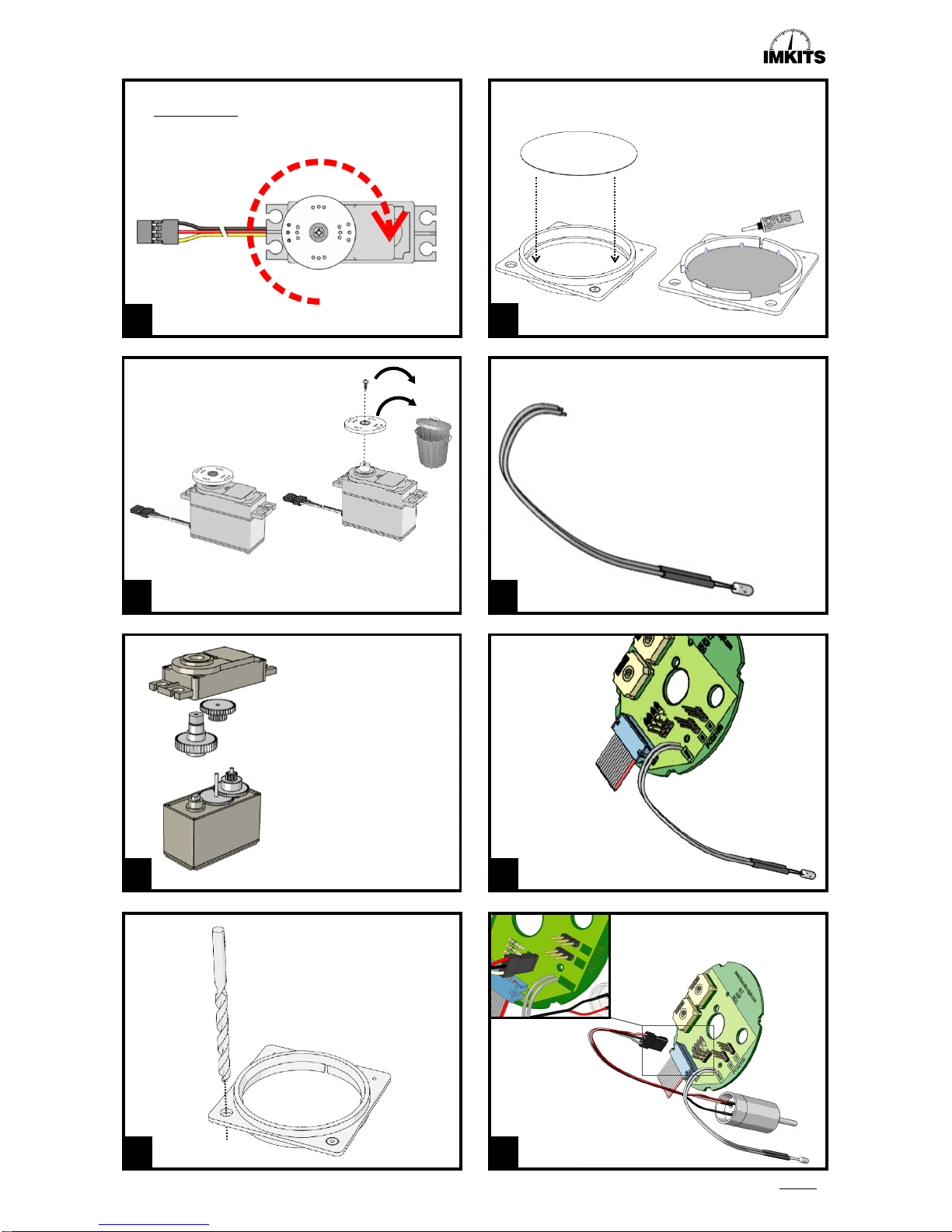

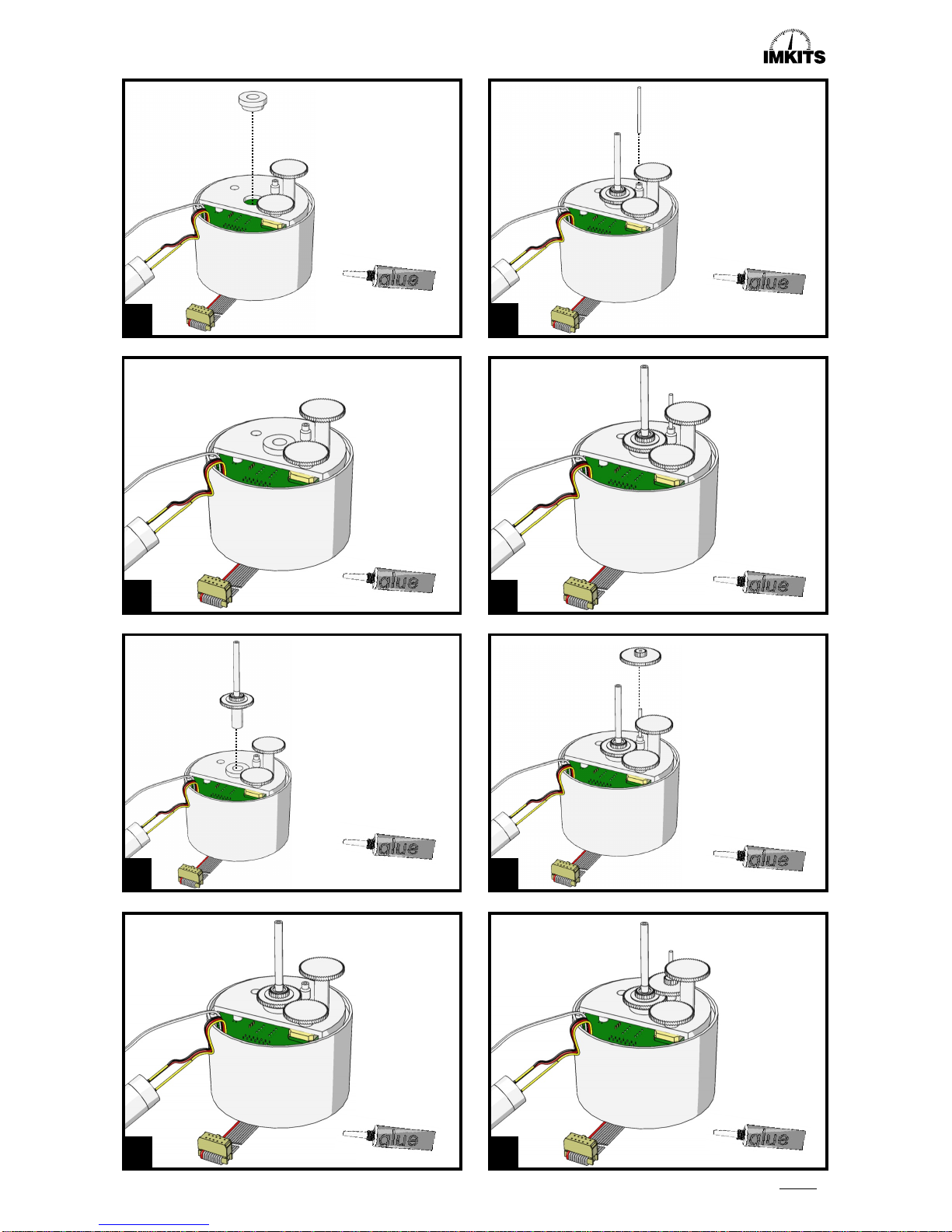

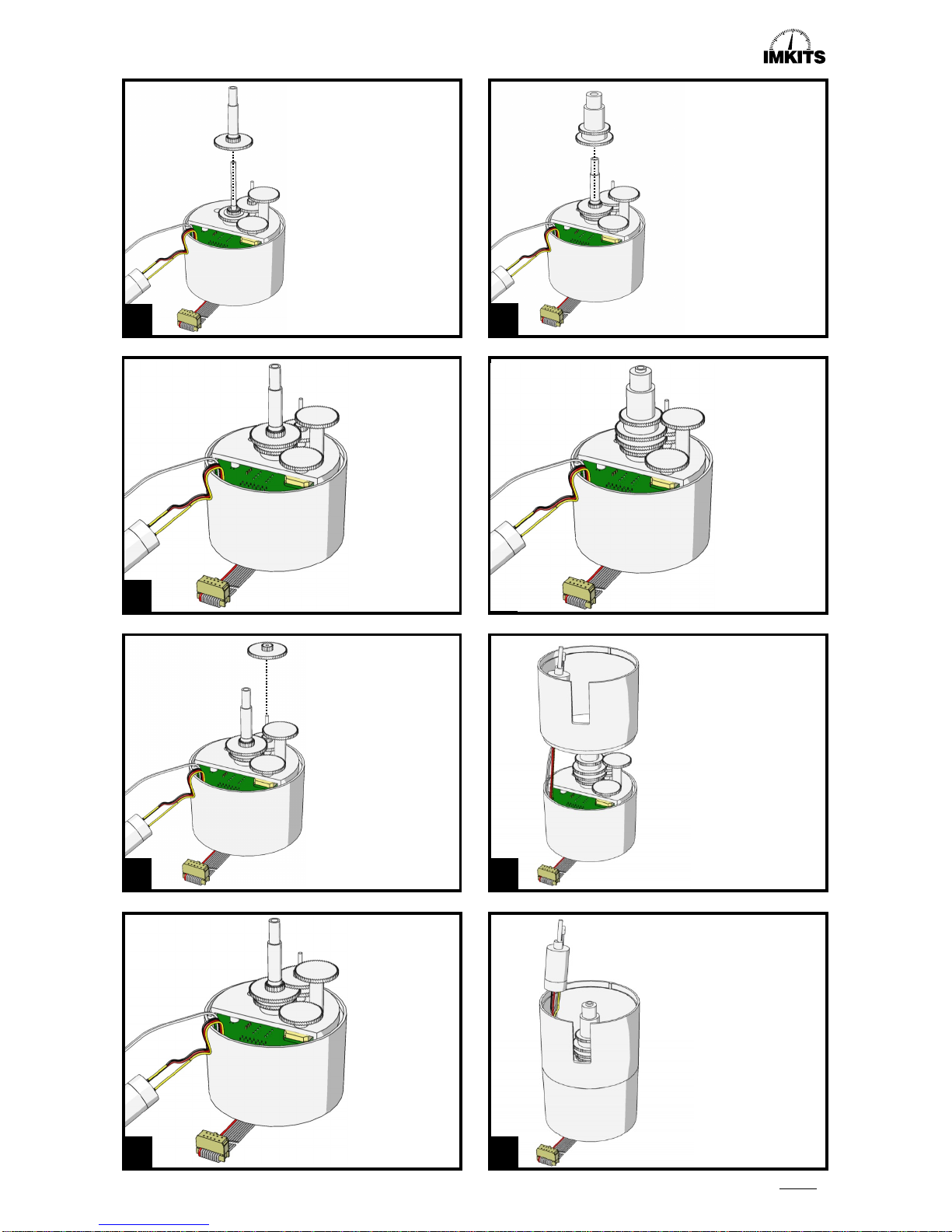

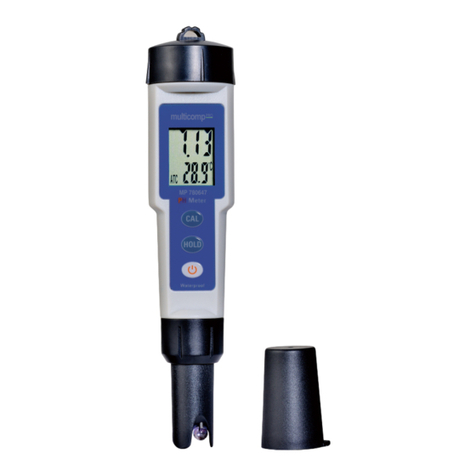

Construction kit “Altimeter” General hints L - Double gearwheel (2 x)

Your kit contains all the necessary Be very careful when using the hobby knife! M - Upper cap rotary encoder

components (except for servomotors) for You can easily hurt yourself when handling N - Propeller shaft

building an “Altimeter”. sharp objects! Take good care of the amount P - Gearwheel with shaft, short

of glue you apply and to which areas you Q - Hollow gearwheel (2 x)

Fine-tuning apply it. Glue for plastics is essentially a R - Gearwheel with shaft, long

The calibration software allows you to solvent. Excessive use can damage the S - Fastening cap 1

accurately adjust the instrument (once exterior of the instrument. T - Fastening cap 2

connected to the Central Control Unit) to U - Bush rotary encoder

the movement of the needle of the chosen Preparations before beginning construction V - Gearwheel shaft

instrument. Check if all components are included. During W - Shaft

packing, the contents of the construction kit X - Indicator 10.000 foot

Difficulty level have been inspected several times. Nothing Z - Indicator 1.000 foot

This product can be constructed without should be missing. Y - Indicator 100 foot

technical expertise. Knowledge of Use the hobby knife to remove any A1 - Front ring

electronics soldering is required. Care and irregularities. Be careful when using the sharp A2 - Front optical

accuracy are of utmost importance. hobby knife! A3 - Upper casing

A4 - Lower casing

What else do you need? Warranty A5 - Light

A normal and a modified servomotor, types Construction kits come without a warranty! A6 - 2-Wire cable

HS300, HS311 or equivalent, are required A7 - Heat shrink sleeve

to make the instrument fully functional (for List of components A8* - Rotary encoder assembly or R1, R2, R3

modifying a servomotor, see the separate A - Metal knob A9 - Self-tapping screw for mounting PCB

manual). This product can be ordered AA - Inbus key R1* - Rotary encoder

separately through the SimKits webshop or B - Bolt (inbus) R2* - Rotary encoder fitting

bought from any retailer of model kits. C - Strain relief R3* - Rotary encoder wire

Additionally you will need some simple D - Printed Circuit Board

tools, such as a small star-shaped E - Lower faceplate

screwdriver, a hobby knife, some pliers, a E1 - Bearing *(A8 or R1, R2, R3 is included)

small hammer, a 1/16” (4 mm) drill, a 0.26” F - Faceplate

(6.5 mm) drill, a soldering iron (suitable for G - Pressure scale

fine electronics), tin solder, insulating H - Outer shaft

adhesive tape, superglue and glue suitable I - Plate

for plastic model kits. J - Central shaft

K - Inner shaft

A3 A4

A1

A2

A5

A7

A6 D

I

C

A

B

AA

P

R

ST

M

R1

R2

R3

A8

U

A9

X

ZY

W

V

E1

G

Q

Q

L

F

L

KH

J

N

E

Read this manual carefully

before starting construction