Ethos 4150 User manual

Operating Instructions

ETHOS 4150

Motor and Phase Rotation Indicator

2

Introduction

The Motor and Phase Rotation indicator is a

handheld, battery-operated instrument

designed to detect the rotary field of

three-phase systems and determine

motor-rotation direction.

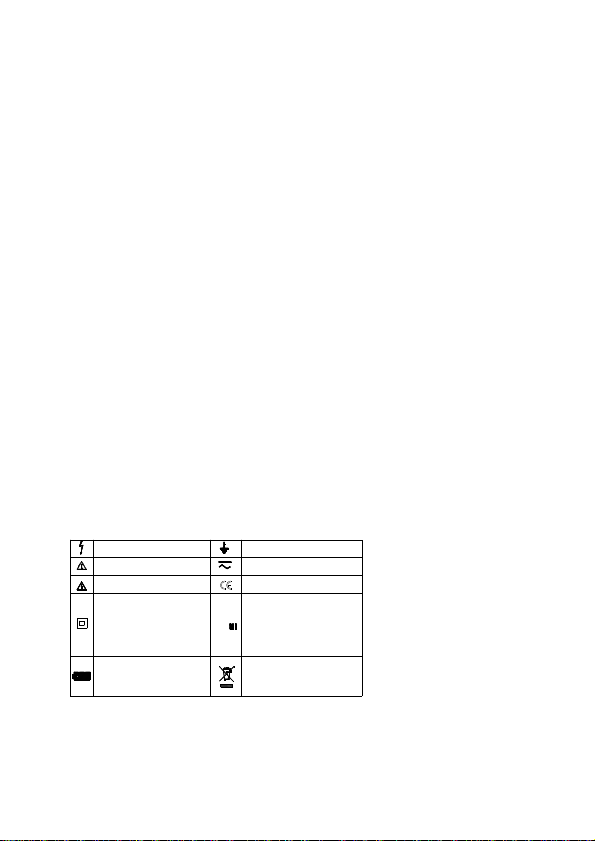

Symbols

The following symbols appear on the Motor

and Phase Rotation indicator or in this manual.

Table 1. Symbols

CAT

Risk of electric shock

Earth

Risk of Danger . Important

information See manual

AC or DC

Hazardous Voltage. Conforms to EU directives.

Equipment protected by

double or reinforced

Insulation

OVERVOLTAGE(Installation)

CATEGORY III,Pollution Degree 2 per IEC

1010-1 refers to the level of Impulse

Wishstand Voltage protection

provided.Equipment of OVERVOLTAGE

CATEGORY III is equipment in fixed

installations (e.g.,electricity meter and

primary over-current protection

equipment.)

Battery Recycling information

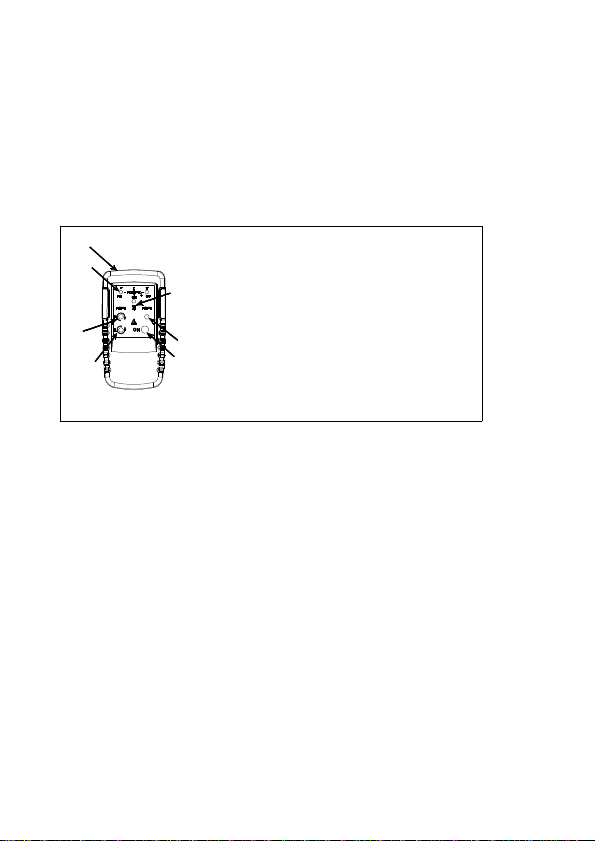

Elements of the Motor and Phase

3

Rotation indicator

Indicators, buttons, and jacks are shown in

Figure 1.

1

2

3

4

MOTOR&PHASE ROTATIONINDICATOR

56

71

2

3

4

5

6

7

Test lead input jack

L1,L2,L3 Indicators

Clockwise Rotation LCD Indicator

Counter-Clockwise Rotation LCD Indicator

ON/OFF button

ON/OFF Indicator

Orientation Symbol

Figure 1. The Motor and phase Rotation

Indicator

Using the Motor & phase Rotation Indicator

Determine Rotary Field Direction

To determine the rotary field direction:

1. Connect one end of the test leads to the

Motor and Phase Rotation indicator.

Make sure the L1, L2, and L3 test leads

4

are connected to the corresponding input

jacks.

2. Connect the Alligator clips to the other end

of the test leads.

3. Connect the Alligator clips to the three

mains phases. Press the ON/OFF button.

The green ON indicator shows that the

instrument is ready for testing.

Either the Clockwise or Counter

Clockwise Rotary indicator illuminates

showing the Type of rotary field

direction present.

4. The rotary indicator lights even if the

neutral conductor, N, is connected

instead of the Test lead input jacks. Refer

to Figure 2 (also shown on the back of

the Motor and Phase Rotation indicator)

for more information.

5

Figure 2. Phase Indication Table (shown

on the rear of the Motor and Phase Rotation

indicator)

Non-contact Rotary Field Indication

For non-contact rotary field indication:

1. Disconnect all test leads from the Motor and

Phase Rotation indicator.

2. Position the Indicator on the motor so that it

is parallel to the length of the motor shaft.

The Indicator should be one inch or close to

the motor. See Figure 3.

3. Press the ON/OFF button. The green ON

indicator shows that the instrument is ready

6

for testing.

Either the Clockwise or Counter Clockwise

Rotary indicator illuminates showing the

type of rotary field direction present.

Note

The indicator will not operate with

engines controlled by frequency converters.

The bottom of the Motor and Phase Rotation

indicator should be oriented towards the

drive shaft. See the Orientation Symbol on

the Motor and Phase Rotation indicator.

Figure 3. Motor Rotation

7

See Table 2 for the minimum motor diameter

and number of pole pair to obtain a reliable test

result.

Table 2. Reliable Motor Test Requirements

3.75

5

6

7.5

10

12

15

20

30

60

85.6

64.2

53.5

42.8

32.1

26.7

21.4

16.0

10.7

5.3

Number of

pole pair

Rotary Number Of Rotary Field (1/min)

at Frequency (HZ)

Angel Between

poles Min. of

Motorcase

16 2/3 50 60 cm

1

2

3

4

5

6

8

10

12

16

1000

500

333

250

200

167

125

100

83

62

3000

1500

1000

750

600

500

375

300

250

188

3600

1800

1200

900

720

600

450

360

300

225

Determine the Motor Connection

1. Connect one end of the test leads to the

Motor and Phase Rotation indicator. Make

sure the L1, L2, and L3 test leads are

connected to the corresponding jack.

2. Connect the alligator clamps to the other end

of the test leads.

8

3. Connect the alligator clamps to the motor

connections, L1 to U, L2 to V, L3 to W.

4. Press the ON/OFF button. The green ON

indicator shows that the instrument is ready

for testing.

5. Turn the motor shaft half a revolution

towards the right.

Note

The bottom of the Motor and Phase Rotation

indicator should be oriented towards the drive

shaft. See the Orientation Symbol on the Motor

and Phase Rotation indicator.

Either the Clockwise or Counter Clockwise

Rotary indicator illuminates showing the type of

rotary field direction present.

Magnetic Field Detection

To detect a magnetic field, place the Motor

9

and Phase Rotation indicator to a solenoid valve.

A magnetic field is present if either the

Clockwise or the Counter Clockwise Rotary

indicator illuminate.

Note

The Motor and Phase Rotation indicator

contains alkaline batteries. Do not dispose of

these batteries with other solid waste. Used

batteries should be disposed of by a qualified

recycler or hazardous materials handler.

The Motor and Phase Rotation indicator

uses a 9V battery (supplied). To replace the

battery, follow these steps.

1. Place the Motor and Phase Rotation

indicator face down on a nonabrasive

surface and loosen the battery-door

10

screw with a screwdriver.

2. Life the battery access lid away from the

Motor and Phase Rotation indicator.

3. Observe the battery polarity shown in the

battery compartment.

4. Secure the battery access lid back in

position with the screw.

Unpacking the Motor and Phase

Rotation indicator

The Motor and Phase Rotation indicator ships

with the following items:

3 test leads

3 alligator clips

9 V battery

Users Manual

11

Safety Information

C a u tio n id e n tifie s c o n d itio n s a n d

a c tio n s th a t m a y d a m a g e th e D T -9 0 2

W a rn in g id e n tifie s c o n d itio n s a n d

a c tio n s th a t p o s e h a z a rd to the u s e r.

Read First: Safety Information

To avoid possible electric shock or fire, do the

following:

Read the following safety information

carefully before using or servicing the

instrument.

Adhere to local and national safety codes.

Individual protective equipment must be

used to prevent shock and injury.

Use of instrument in a manner not specified

by the manufacturer may impair safety

12

features/protection provided by the equipment.

Avoid working alone. Damage leads must be

replaced. Do not use the Motor and Phase

Rotation indicator if it looks damaged.

Be careful when working above 30V ac rms,

42V ac peak and 60V dc. Such voltages pose a

shock hazard.

Measurements can be adversely affected by

impedances of additional operating cir

connected in parallel or by transient currents.

Verify operation prior to measuring

hazardous voltages (voltages above 30V ac rms,

42V ac peak and 60V dc).

Do not use the Motor and Phase Rotation

indicator with any of the parts removed.

Do not use the Motor and Phase Rotation

indicator around explosive gas, vapor, or dust.

13

Do not use the Motor and Phase Rotation

indicator in a wet environment. cuits

Specifications

Environmental

Operating Temperature

0℃ to +40℃

Operating Altitude

2000 m

Pollution Degree

2

Type of protection

IP 40

Mechanical Specifications

Size (H x W x D): 130mm x 69mm x 32mm.

Weight: 130g

Humidity

14

15% to 80%

Safety Specifications

Electrical Safety

Meets DIN VDE 0411,IEC 61010 DIN, VDE

0413-7,

IEC 61557-7/EN 61557-7

Maximum Operating Voltage (Ume)

400 V AC for all ranges

Protection Levels

CAT lll, 300V

Electrical Specifications

Battery

9 V alkaline, IEC 6LR61

Current Consumption

Max 20 mA

Battery life

Minimum 1 year for average use

15

Determine Rotary Field Direction

Nominal Voltage Rotary Direction

1 to 400 V AC

Nominal Voltage phase indirection

120 to 400 V AC

Frequency Range (fn)

Inspect the test leads for damaged

insulation or exposed metal. Check test

lead continuity.

2 to 400HZ

Test Currents (In per phase)

Less than 3.5 m A

Non-Contact Rotary Field Indication

Frequency Range (fn)

2 to 400HZ

Determine the Motor Connection

Nominal Test Voltage (U me)

16

1 to 400 V AC

Nominal Test Currents (In per phase)

Less than 3.5 m A

Frequency Range (fn)

2 to 400 HZ

Distributed by MTi

Unit 12, Access 18, Kings Weston Lane,

Bristol BS11 8HT

Tel: 0117 938 6400

Fax: 0117 923 5374

Email: enquiries.ethos@adivision.co.uk

Web: www.ethos-instruments.co.uk

Table of contents

Other Ethos Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

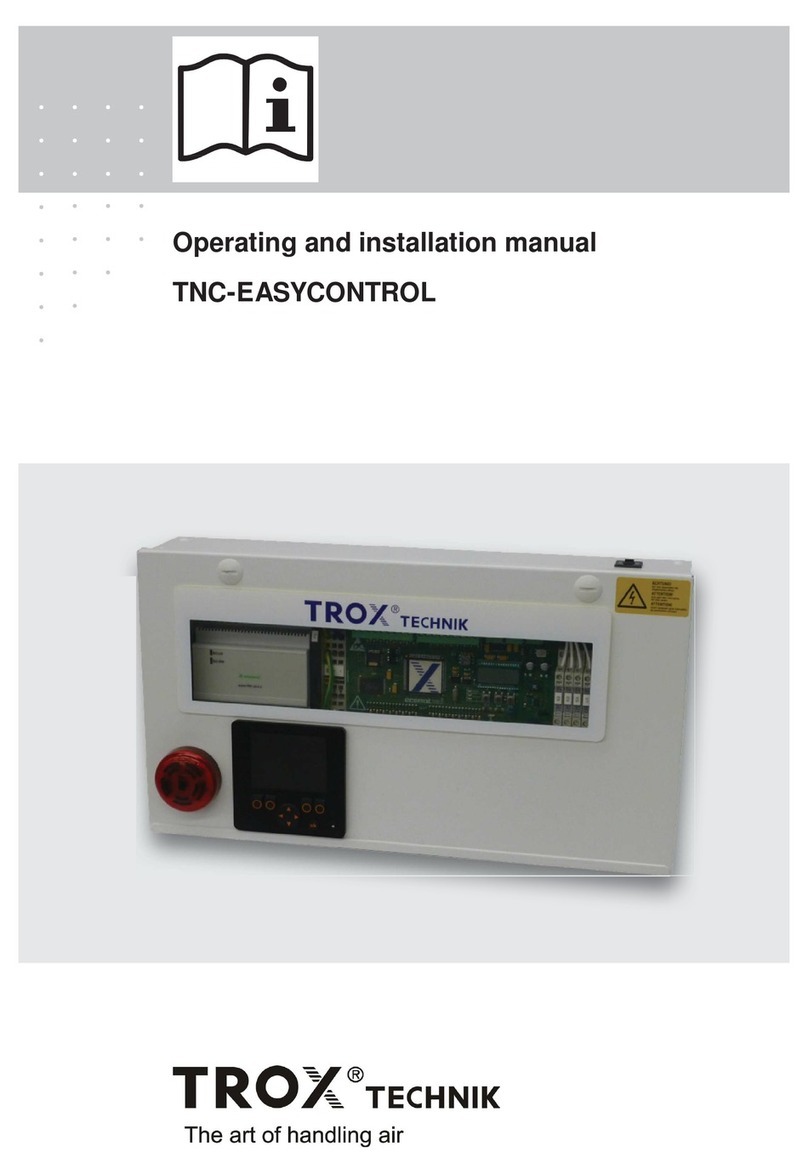

Trox Technik

Trox Technik TNC-EASYCONTROL OPERATING AND INSTALLATION Manual

Siko

Siko DE04 User information

Apera Instruments

Apera Instruments EC700 instruction manual

TSI Instruments

TSI Instruments AIRASSURE 8144 Operation and maintenance manual

Universal Biosensors

Universal Biosensors SENTIA user guide

E Instruments

E Instruments AQ 200 instructions