Simplex, Inc., 5300 Rising Moon Road, Springfield, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2007 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

®

LOAD BANK MANUAL • Saturn 3000 DV • W.O. 63798/2 • page 4 of 20

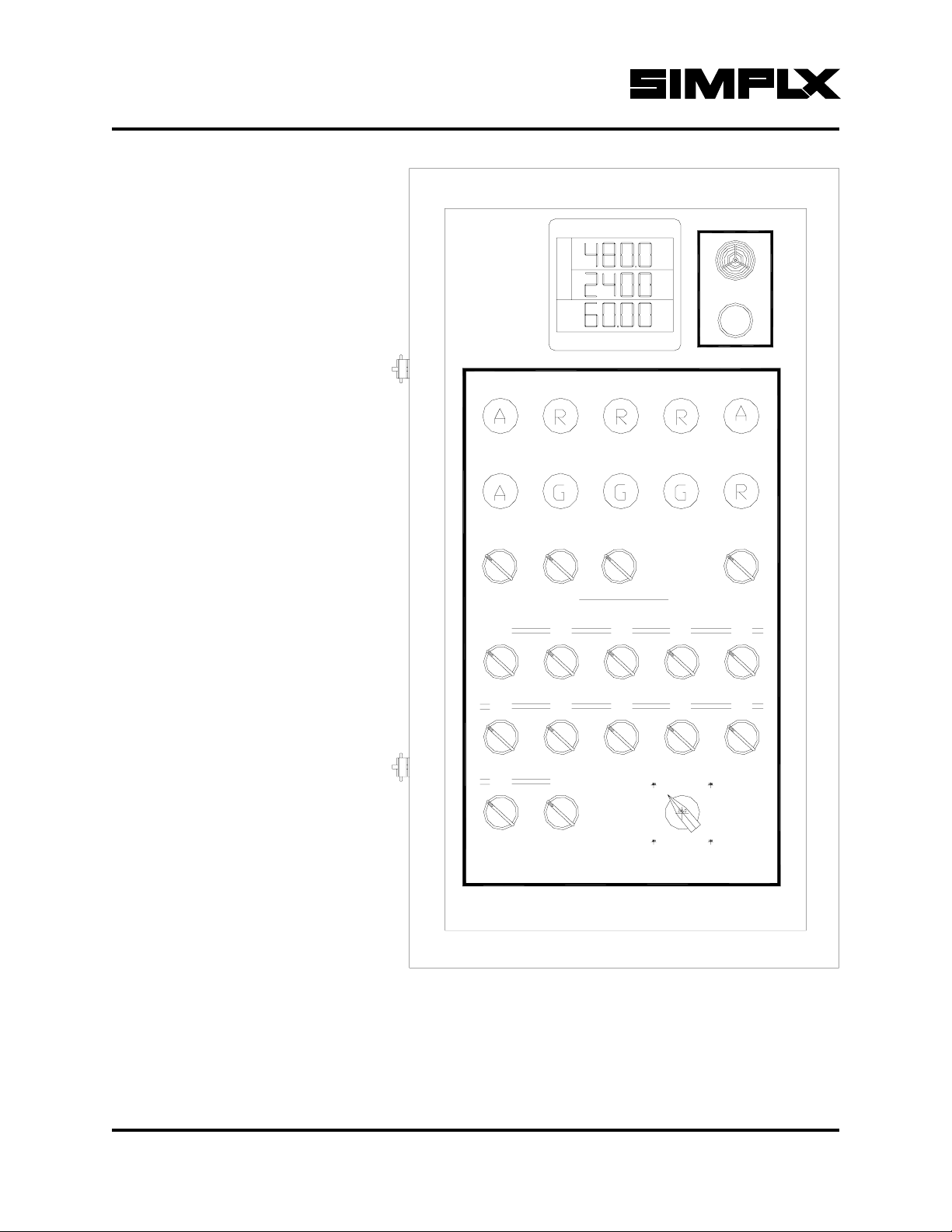

CONTROL SYSTEM

The Control System allows the operator

to apply a desired load to the test source

and measure the response of the test

source to the load. This system also

contains the circuitry utilized to discon-

nect the load from the test source in the

event of cooling failures and/or improp-

erly positioned operating controls.

Fan power is applied to the Fan Motor

(MOT) through the Fan Circuit Breaker

(FCB 1A or FCB 1B), the Disconnect

Switch (DSW), the Fan/Control Voltage

Selector swtich (S1), the Auto Trans-

former, and the Fan Motor Contactor

(FMC) contacts. An Overload Relay

(OVR) is used to protect the motor.

COOLING SYSTEM

Resistive Load Elements are cooled by

a forced air system consisting of a 60"

fan blade belt driven by a 30HP, TEFC

motor, creating a 50,000 CFM. The fan

motor is energized by a 60A, 600V, 3

pole contactor (FMC) and protected by

a 100A frame, 60A trip, 3 pole, 600V

circuit breaker (FCB).

LOAD SYSTEM

The Load System consists of indepen-

dently controlled resistive and/or reac-

tive load elements specifically designed

for Load Bank systems. They are pro-

tected by 200,000AIC, 600VAC fuses.

Simplex Resistive Load Elements con-

servatively operate at approximately half

the maximum temperature rating of the

alloy (1080°F vs. 1920°F). For example:

Alloy: FeCrAl

See Parts Legend Drawing for specific

elements used.

These elements are rigidly supported

by high-temperature, ceramic-clad,

stainless-steel supports. Element-to-

element short circuits are virtually elimi-

nated. The elements are assembled in

discrete trays which are assembled in a

vertical “stack”. Each tray is independ-

ently serviceable without disturbing ad-

jacent trays.

PRIMARY INSPECTION

Preventative visual inspections of the

shipping crate and Load Bank is ad-

vised. Physical or electrical problems

due to handling and vibration may oc-

cur. Never apply power to a Load Bank

before performing this procedure. The

following Nine Point/30 Minute Inspec-

tion is recommended before installa-

tion, as part of the 50 hour / 6 month

maintenance schedule and whenever

the Load Bank is relocated:

1. If crate shows any signs of damage

examine the Load Bank in the corre-

sponding areas for signs of initial

problems.

2. Check the entire outside of the cabi-

net for any visual damage which could

cause internal electrical or mechani-

cal problems due to reduced clear-

ance.

3. Inspect all hinged panels and doors

for smooth and safe operation, try all

latches and knobs.

4. Rotate and push all switches through

all positions to ensure smooth opera-

tion.

5. Check cooling system by inspecting

fan motor and blade. Slowly rotate

blade by hand and note clearance of

blade tip through its rotation near the

housing. Observe free rotation of mo-

tor shaft.