Page1

Table of Contents

I. Warnings and Cautions ..................................................................................... 4

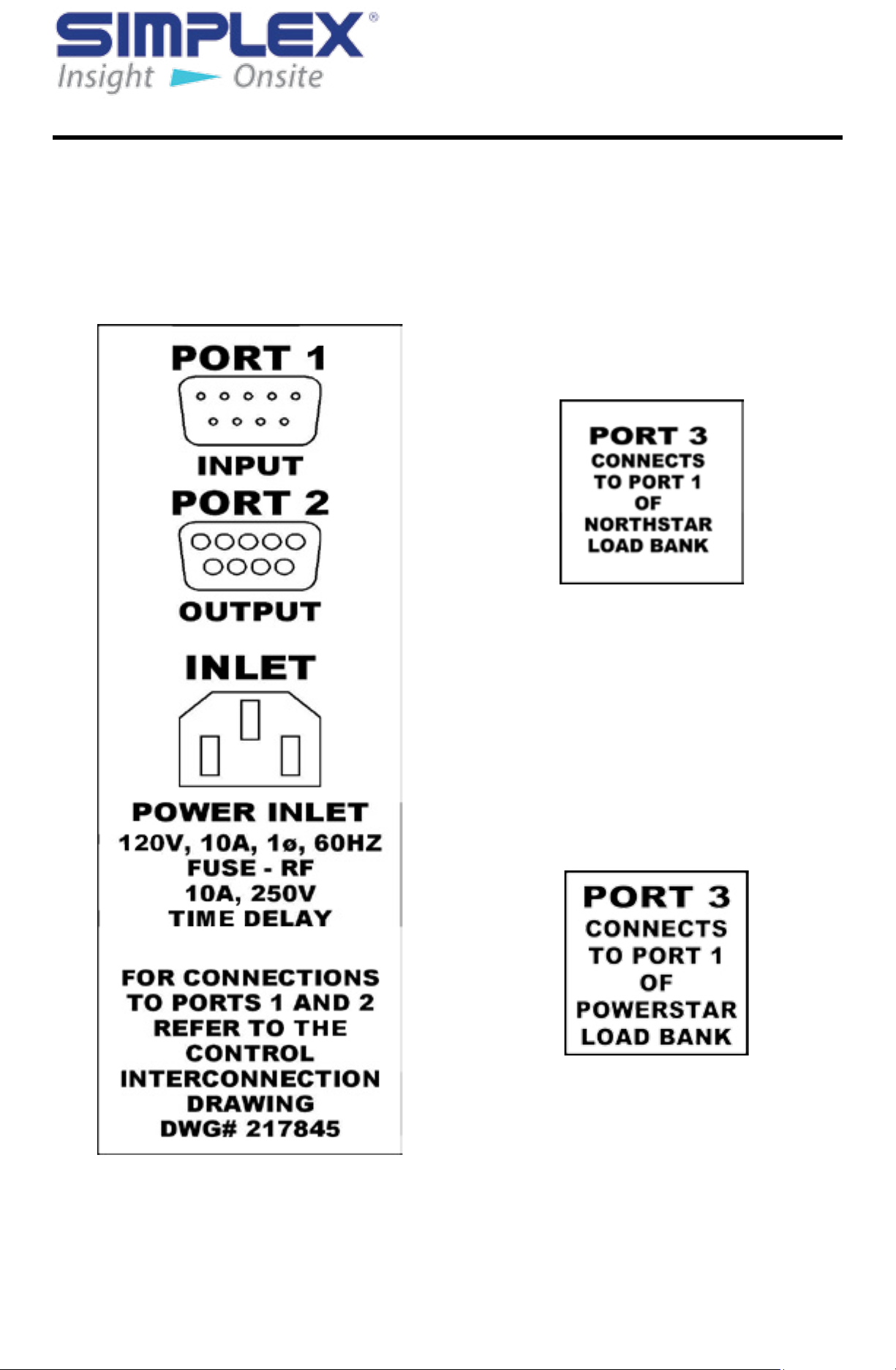

II. Nameplates and Placards.................................................................................. 6

1. Introduction......................................................................................................................... 6

2. Instruction Placards ........................................................................................................... 6

III. Description and Specication..........................................................................11

1. Introduction....................................................................................................................... 11

2. Overview of Use................................................................................................................ 11

3. Capabilities ....................................................................................................................... 11

4. Safety ................................................................................................................................ 12

5. Specications ................................................................................................................... 12

IV. Unpacking ......................................................................................................... 13

1. Introduction....................................................................................................................... 13

2. Included Components and Parts .................................................................................... 13

3. Primary Inspection ........................................................................................................... 13

V. Installation......................................................................................................... 14

1. Introduction....................................................................................................................... 14

2. Load Bank Location ......................................................................................................... 14

VI. Operating Instructions..................................................................................... 16

1. Introduction....................................................................................................................... 16

2. Overview of Load Bank HMI Software ............................................................................ 16

3. Handling ............................................................................................................................ 18

4. Basic Operations .............................................................................................................. 18

5. Shutdown .......................................................................................................................... 20

6. Additional Screens and Programming Information ...................................................... 20

VII. Alarms and Warnings....................................................................................... 23

1. Introduction....................................................................................................................... 23

2. Over-temperature Alarm .................................................................................................. 23

VIII. Supplemental Equipment ................................................................................ 24

1. Introduction....................................................................................................................... 24

2. Cam-Lok Cables ............................................................................................................... 24

IX. Diagnostics and Troubleshooting................................................................... 25

1. Introduction....................................................................................................................... 25

2. General Maintenance ...................................................................................................... 25

3. Failure Subsystem............................................................................................................ 26

4. Parts Breakdown .............................................................................................................. 27

X. Ordering Information........................................................................................ 29

1. Powerstar or NorthStar ................................................................................................... 29

2. Covering ............................................................................................................................ 29

APPENDIX A — ABBREVIATIONS IN THIS MANUAL.................................................................. 31

APPENDIX B — IMPORTANT FORMULA......................................................................................32