Read carefully. Most malfunctions in new equipment are the result of improper operation

and/or improper set-up assembly.

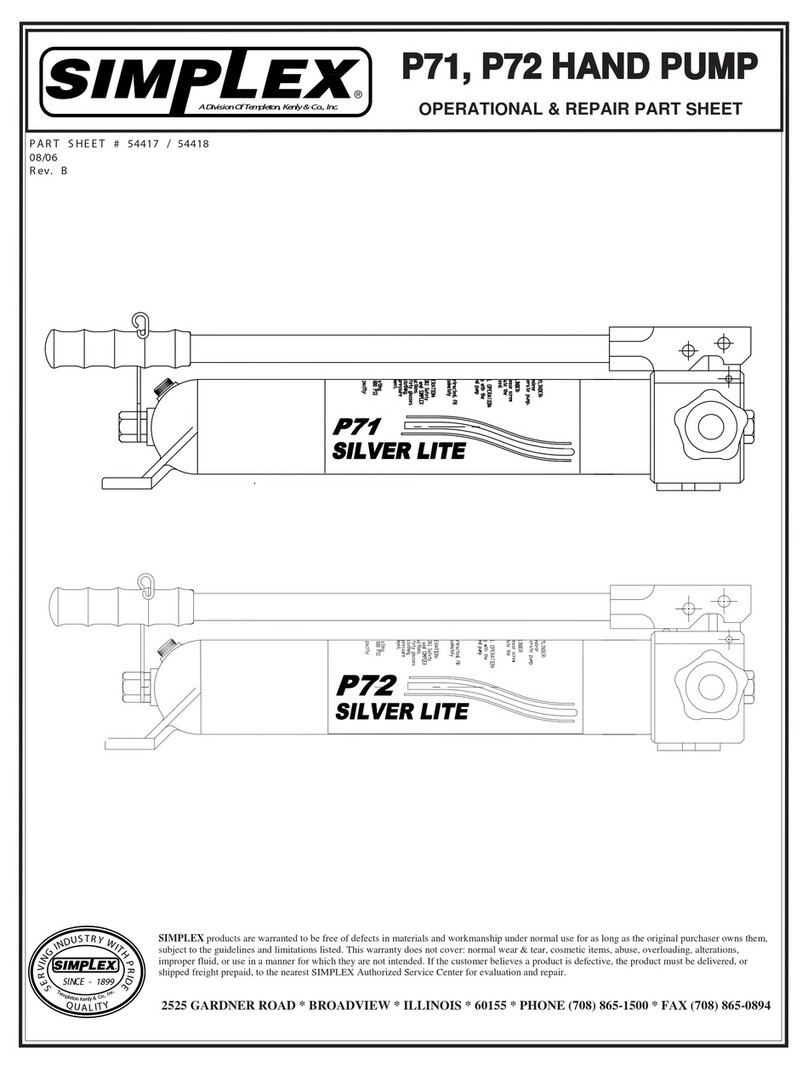

Preparation: Remove pump from shipping container -- but do not remove any plugs or

valves until the unit is ready to be fully assembled to prevent dirt or foreign matter from

contaminating system.

Inspection: Visually inspect all components for shipping damage. If any damage is found,

notify carrier immediately.

2-1. Electrical Connections: Solenoid valves only.

Air Connections for AIR POWER PUMPS: Use only clean, dry, well lubricated air.

Gasoline Motor Oil and Fuel:

1. Above 32 degrees Fahrenheit use S.A.E. 10 W 30 (Motor only )

2. Below 32 degrees Fahrenheit use S.A.E. 5 W 20 (Motor only )

3. Oil sump capacity - -About 1.3 pints or check dip stick

4. Use clean, unleaded automotive gasoline ( without alcohol )

2-2. Hydraulic Connections:

Check hydraulic oil level to prevent possible pump burnout. Open the red plastic fill plug

located on reservoir plate. Oil level should be approximately 2" from top of reservoir

plate -- with cylinders retracted and motor off. Add Simplex oil as necessary. Do not

mix different grades of oil, or types of oil.

Make sure all desired gauge, valve, hose and quick coupler connections are tight and

secure before operating (See Section 1.2). The pumps pressure ports are 3/8 NPTF and are

located just below the control valve. (See Section 3-1).

The use of a pressure gauge is strongly recommended for normal operation of these

pumps and required when the external adjustable relief valve pressures are changed.

Mounted on a gauge adapter between the pump and cylinder, the gauge permits the operator

to monitor loads on cylinders.

Do not exceed rated capacity of equipment connected to pump. Where shock loading

or unsteady loads may cause overloading of cylinders, the operator must use larger capacity

cylinders to provide additional operating margin.

2-3. Starting instructions ( Gasoline Motor )

• Hydraulic control valve in neutral ( center position ): • Throttle to choke position ( extreme

right ): Grasp STARTER HANDLE and pull rope out slowly to engagement: • Pull rope with

a rapid, continuous full stroke and let rewind slowly, and do not allow to snap back. • Move

the control lever to "HIGH SPEED" position then to "RUN" as the engine warms.

INSTRUCTIONS BEFORE USE

- 3 -