10

STEP 12

Glazing the Canopy

The glass will be supplied cut to the correct dimensions needed for the installation.

When you push the glazing bar into the wall plate the gasket will have a tendency to fold back. You

need to flick the rubber gasket out so it lips over the glazing bar and glass.

The glass into the glazing should be a nice, tight fit. You will need to apply a suitable lubricant to the

top and bottom gasket prior to inserting the glass. (Not supplied) We suggest fairy liquid.

Always fit the glass into the next glazing bar at floor level before you lift and position into the fixed

bar on the frame.

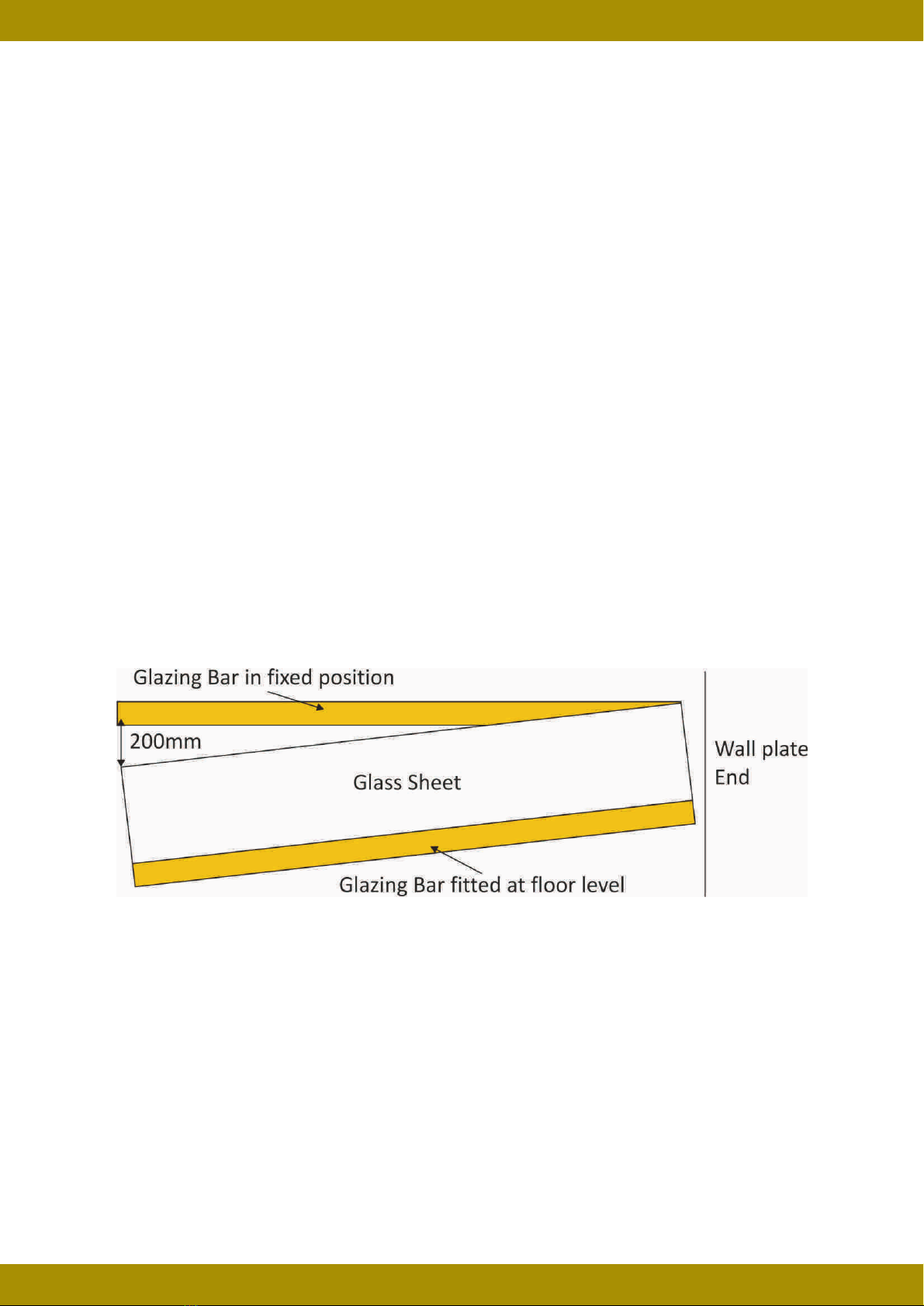

When you are fitting the glass sheet into the fixed glazing bar (with the next bar attached) it is

recommended that you locate the top corner into position first with the other end about 200mm

away from the finished position. When the glass is located in this position it is recommended that

you use a Sach Cramp or rachet straps to ensure the glass stays within the glazing bar and does

not spring out while you are pushing the glass into the bar. Then working from that top corner you

steadily work along pushing the glass into the glazing bar which reduces the gap until the full length

of glass is located into the glazing bar. See illustration below

Secure the glazing bar in place as shown in STEP 9

STEP 13

Fitting of the ‘F’-Section

Secure the glazing bar to the gutter section using M6 X 16MM Pan Pozi Bolts and M6 Nuts.

Ensure the end of the glass is fitting flush with the edge of the glazing bars as shown overleaf.

The glass is 40mm wider than the inside to inside measurement of the roof bars as a rule.

Please refer to your CAD drawing at this stage as this will show you the inside to inside

glazing bar dimension. Measure your glass to ensure it is 40mm wider than this dimension.

The glass is therefor designed to locate 20mm inside each glazing bar. This allows for a 5mm

gap between the centre of the bar and the glass, which is an allowance for any expansion.

The F section is supplied pre cut to the correct width of the inside to inside glazing bar dimension.

Please measure this width and check against your CAD drawing.