Simplicity 796 User manual

Other Simplicity Snow Blower manuals

Simplicity

Simplicity 760 User manual

Simplicity

Simplicity 1690048 User manual

Simplicity

Simplicity Signature Series User manual

Simplicity

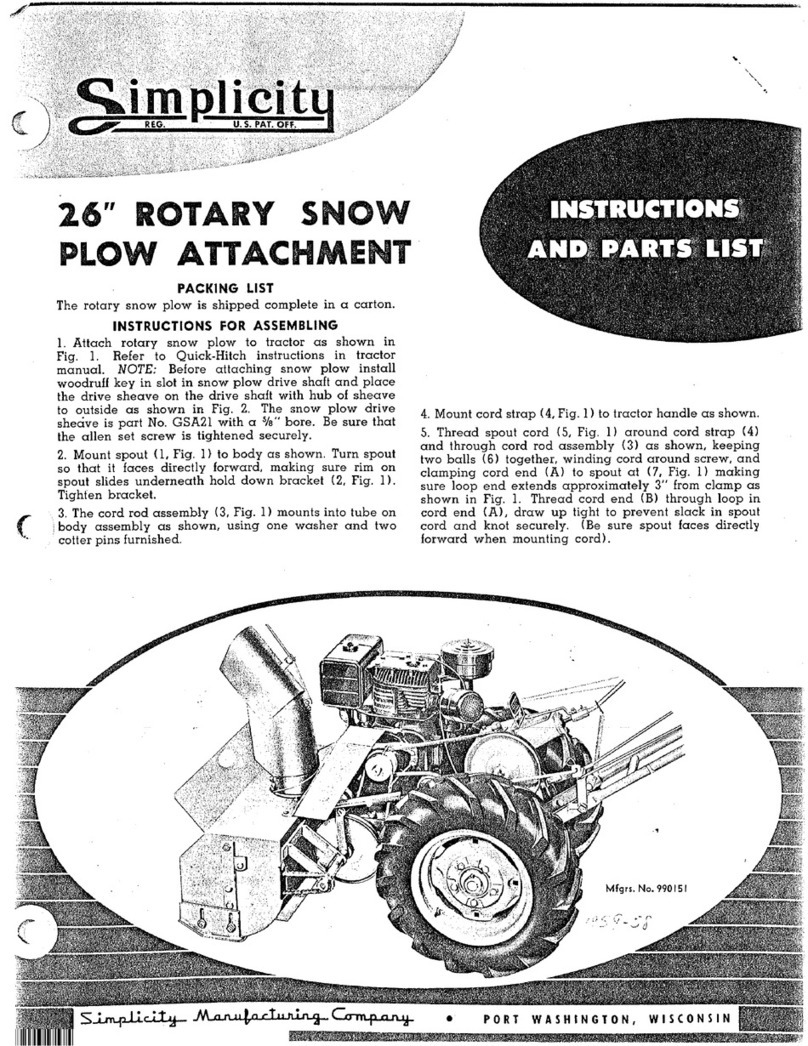

Simplicity 990151 Datasheet

Simplicity

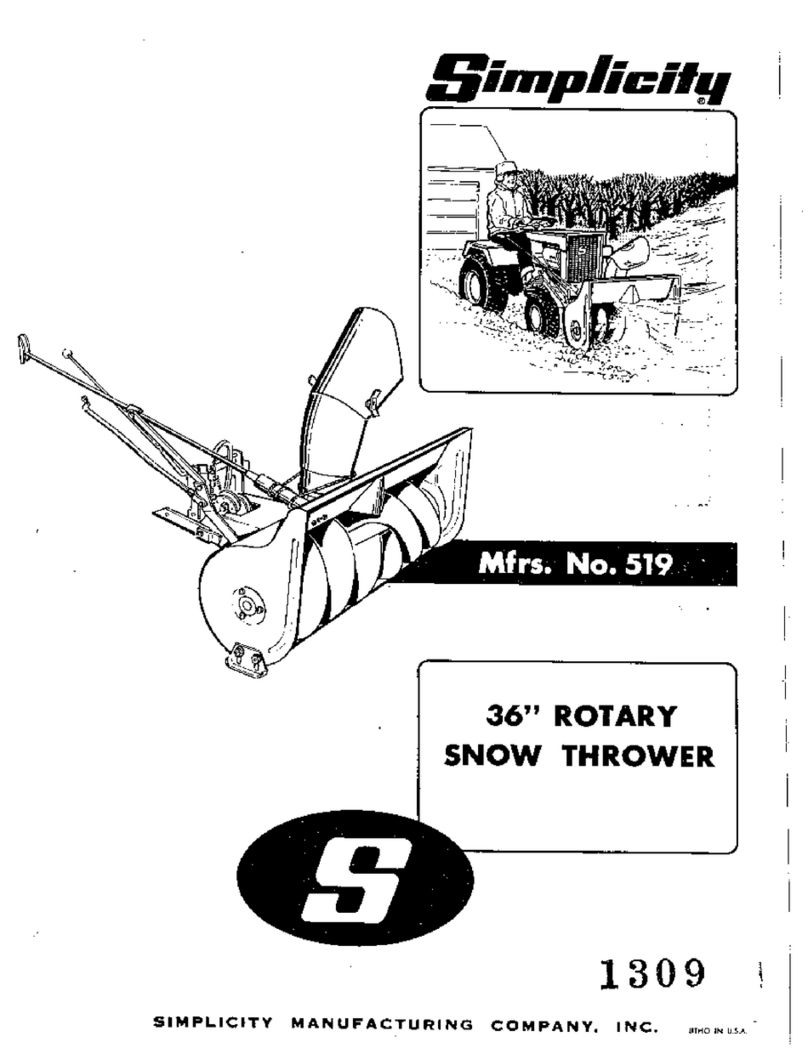

Simplicity 519 User manual

Simplicity

Simplicity 1690034 User manual

Simplicity

Simplicity 560S User manual

Simplicity

Simplicity 882 User manual

Simplicity

Simplicity 421 User manual

Simplicity

Simplicity 1691899 User manual

Simplicity

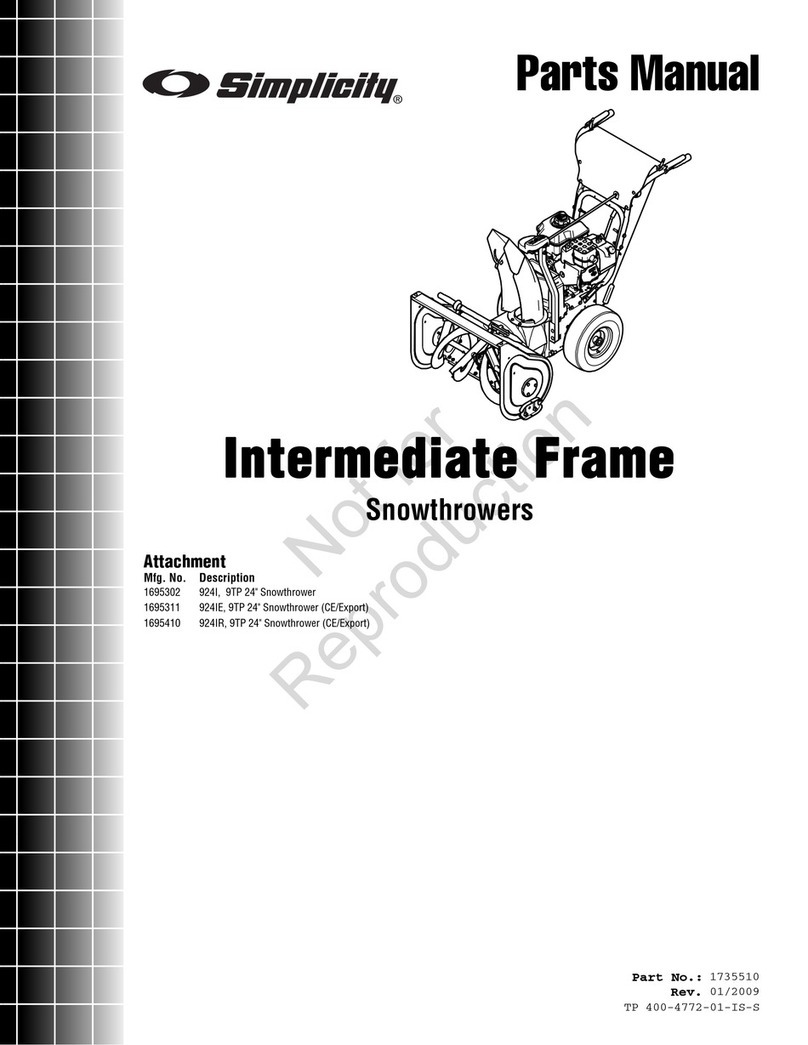

Simplicity 1696302 User manual

Simplicity

Simplicity 551E User manual

Simplicity

Simplicity Signature Series User manual

Simplicity

Simplicity 1696326 User manual

Simplicity

Simplicity 476 User manual

Simplicity

Simplicity 1694238 Setup guide

Simplicity

Simplicity 1604 User manual

Simplicity

Simplicity 1695846 User manual

Simplicity

Simplicity 1695856 User manual

Simplicity

Simplicity 1695875 User manual