Simpson S664 User manual

S664

Frequency Counter

Operation Manual

www. .com information@itm.com1.800.561.8187

Warranty and Returns

SIMPSON ELECTRIC COMPANY warrants each instrument and other articles manufactured

by it to be free from defects in material and workmanship under normal use and service, its

obligation under this warranty being limited to making good at its factory or other article of

equipment which shall within one (1) year after delivery of such instrument or other article of

equipment to the original purchaser be returned intact to it, or to one of its authorized service

centers, with transportation charges prepaid, and which its examination shall disclose to its

satisfaction to have been thus defective; this warranty being expressly in lieu of all other war-

ranties expressed or implied and of all other obligations or liabilities on its part, and SIMPSON

ELECTRIC COMPANY neither assumes nor authorizes any other persons to assume for it any

other liability in connection with the sales of its products.

This warranty shall not apply to any instrument or other article of equipment which shall have

been repaired or altered outside the SIMPSON ELECTRIC COMPANY factory or authorized

service centers, nor which has been subject to misuse, negligence or accident, incorrect wiring

by others, or installation or use not in accord with instructions furnished by the manufacturer.

Under the normal eld usage there is no need to remove the front bezel of this product. The

front bezel of this product should only be removed by a qualied technician.

About this Manual

To the best of our knowledge and at the time written, the information contained in this

document is technically correct and the procedures accurate and adequate to operate this

instrument in compliance with its original advertised specications.

Notes and Safety Information

This Instruction Manual contains warning headings that alert the user to check for hazardous

conditions. These appear throughout this manual where applicable, and are dened below.

To ensure the safety of operating performance of this instrument, these instructions must be

adhered to.

Warning, refer to accompanying documents.

Caution, risk of electric shock.

Attention, consulter les documents d’accompagnement.

Attention, risque de choc électrique.

www. .com information@itm.com1.800.561.8187

1

Contents

1 Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.1 General Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Part Number Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Option Module Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Hardware Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1 Panel Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Removing / Installing Option Modules. . . . . . . . . . . . . . . . . . . . . 6

2.3 120/240 VAC Power Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Standard Input Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5 Quadrature Input Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.6 Excitation Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3 Display & Rear Panel Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.1 Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 Display Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3 Rate (Frequency) Scaling and Display. . . . . . . . . . . . . . . . . . . . . 15

3.4 A/B Channel Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Appendix A: Technical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . .17

A.1 Functional Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

A.2 Electrical, Environmental and Mech. Specifications. . . . . . . . . . 17

2

www. .com information@itm.com1.800.561.8187

1 Product Description

1.1 General Description

The S664 frequency counter fits a 1/8 DIN standard cutout and is perfect for

tight spaces, extending only 3.24” (82mm) behind the panel.

The unit is UL listed. The unit is for indoor use at altitudes up to 2000m, tem-

peratures between 0° and 40°C, and installation category III, pollution degree 2.

The counter is powered from 120 or 240 VAC.

One of four frequency ranges may be selected to measure from 1Hz to 35KHz.

The counter accepts pulses from different types of sensors, including Quadra-

ture, CMOS or TTL circuits and PNP or NPN devices.

An optional 12 VDC (100mA) excitation output module can provide power for

external sensors.

3

www. .com information@itm.com1.800.561.8187

1.2 Part Number Identification

The following matrix indicates the configuration of your S664 counter.

1.3 Option Module Summary

Figure 1. Option Module Slots (Rear View)

The S664 is a modular product that uses field configuring slide-in modules. The

modules slide easily into the rear of the counter.

Figure 1 displays the functional assignments for each module position. Table 1

describes available option modules for the S664.

Table 1. Option Module Summary

124

Input ExitationPower

Supply

Input

Standard

Quadrature

Power Supply

Basic Unit

S664 120 VAC

240 VAC

1

2

1

2

Excitation

None

12VDC

0

1

Other

None 0

Output

None 0

eludoM

tols epyT N/P noitpircseD noitceSeeS

1tupnIeludoMtupnIdradnatS 4.2

1tupnI tupnIlasrevinU/erutardauQ

eludoM 5.2

2.moC/txE46054eludoMnoitaticxECDV21 6.2

4rewoPeludoMrewoPCAV022/021 3.2

4

www. .com information@itm.com1.800.561.8187

2 Hardware Setup

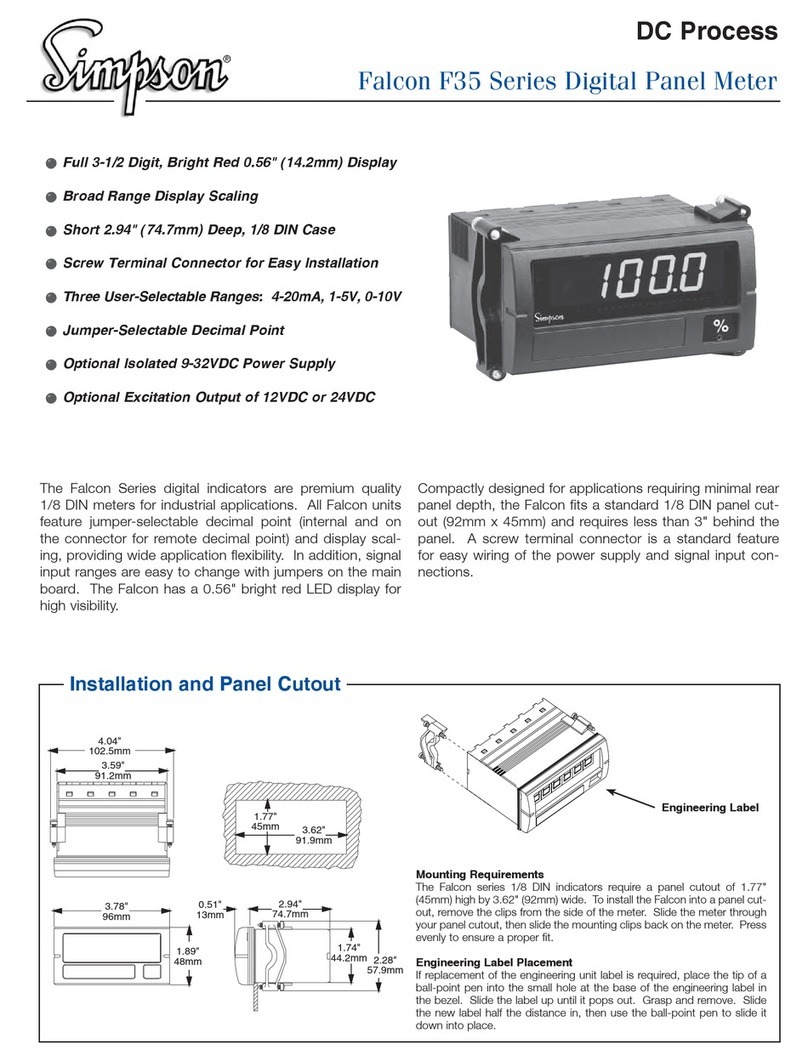

2.1 Panel Installation

The S664 1/8 DIN counter requires a standard 1/8 DIN panel cutout of 1.77”

(45mm) high by 3.62” (92mm) wide. To install the counter into a panel cutout,

remove the clips from the side of the counter. Slide the counter through your

panel cutout, then slide the mounting clips back on. Press evenly to ensure a

proper fit.

Figure 2. Counter and Panel Cut-Out Dimensions

Figure 3. Panel Mounting Clips

2.04"

51.8mm

.52"

13.2 mm

1.8"

45mm

3.24"

82mm

3.62"

92mm

1.74"

44mm

3.93"

99.8 mm

5

www. .com information@itm.com1.800.561.8187

1. Remove module from case by inserting a screwdriver into tab slot opening at top of input

module. Apply pressure to release module from case. Repeat procedure for tab located on

underside of module and then slide module away from the case.

2. Refer to appropriate sections to congure switches or jumpers for proper operation.

Table 1 can be used to identify modules and their associated detail paragraph.

3. Install module by carefully aligning module edges with slots in case and pressing forward

until tabs (on top and bottom) engage.

2.2 Removing / Installing Option Modules

Shut power off before removing or installing any option modules

Couper le courant avant de retirer ou d’installer des modules optionnels

6

www. .com information@itm.com1.800.561.8187

2.3 120/240 VAC Power Module

Never connect AC mains (hot or neutral) to the Reset or Common terminals!

2.4 Standard Input Module

NOTE: A fusible link is not provided on this module.

A ½ Amp Time Delay fuse, Bussman MDL ½, or similar is required.

Remove power before wiring option modules.

The AC power module allows the S664 to be

operated from standard 50/60 Hz line power.

The power module will be congured as 120

VAC or 240 VAC per markings on the back

panel. Ensure the input rating of the supply

matches your line voltage. The power supply

module has provisions for a hard-wire Range

Select. This control can be a switch, relay

contact or solid state device. Actuation is

immediate upon an active Low for at least

2.5ms to this terminal. The reset circuit is

independent of the power circuit.

Figure 6. Standard Input Module

Coupez l’alimentation avant de raccorder les modules optionnels.

Ne jamais brancher sur secteur (chaudes ou neutres) pour la réinitialisation

ou terminaux communs!

Denotes module position 1 at rear of counter

Primary Input

Connect the input signal to A INPUT and COMMON

Program Step

Used only in special programming mode

Secondary Input

Direction Control or count pulse input

A INPUT

COMMON

USER

INPUT

B INPUT

IINPUT

COMMON

Denotes modules position 4 at rear

of counter

Power Supply 120 VAC or 240 VAC

power connection

Remote Reset

Active low 0.2V performs primary

reset

~

~VAC

VAC

RESET

COMMON

POWER

Figure 5. AC Power Module

www. .com information@itm.com1.800.561.8187

7

DIP switch SW1, gure 7, is used to set up the counter to conform to the electrical characteristics

of the sensor or signal being detected. Switch positions 1-3 congure channel B, while switches

4-6 congure channel A. These switches select bias (threshold voltages), low pass lter (enable/

disable) and sensor type (Sink or Source). Refer to the documentation that accompanied the

sensor for related information. The sensor can most likely be matched to one of the typical

switch settings shown in gure 8 and gure 8a.

Note: The input boards are designed so that selecting sourcing or sinking is based on the

type of sensor that is being used. If a PNP (sinking) sensor is being used, set the input

board for sinking also (switches 3 and 6 = OFF).

If channel B is not used, default settings for switch positions 1 through 3 should be selected.

Default settings are provided in Table 2.

The Input module also provides for a User input signal. On the S664, this input serves as a

secondary channel (Rate) hard-wired reset. This may be used, for example, to reset latched

alarm outputs that have been assigned to rate.

Figure 7. Standard Input Module Default Settings

8

www. .com information@itm.com1.800.561.8187

The S664 can accept inputs from many different sensors. The A and B chan-

nels may be configured independently as shown in Table 2. Figures 8 and 8a

have examples of some typical sensors and the wiring connections that would be

used.

Table 2. Standard Input Module DIP Switch Settings

* = Factory Default setting

1 B Channel Bias: OFF = Hi* VLT = 5.0 V VUT = 7.0V (+/- 10%)

ON = Low VLT = 1.6 V VUT = 3.6V (+/- 10%)

2 B Channel Frequency: OFF = Hi* (low pass filter disabled)

ON = Lo (low pass filter enabled)

3 B Channel Sensor: OFF = Sinking* (internal pull-up enabled)

ON = Source (internal pull-down enabled)

4 A Channel Bias: OFF = Hi VLT = 5.0 V VUT = 7.0V (+/- 10%)

ON = Low* VLT = 1.6 V VUT = 3.6V (+/-10%)

5 A Channel Frequency: OFF = Hi* (low pass filter disabled)

ON = Lo (low pass filter enabled)

6 A Channel Sensor Type: OFF = Sinking* (internal pull-up enabled)

ON = Source (internal pull-down enabled)

+

9

www. .com information@itm.com1.800.561.8187

The Quadrature / Universal Input Module has two operational modes: Quadrature mode and

Standard mode. Quadrature mode is selected by positioning JP1 and JP2 on pins 1 and 2.

Standard mode is selected by placing JP1 and JP2 on pins 2 and 3 (see Figure 10 for details).

Figure 8. Sensor Connection Examples

Figure 8a. Sensor Input Example

2.5 Quadrature Input Module

123456

HIGH BIAS

HIGH FREQUENCY

SINKING

LOW BIAS

LOW FREQUENCY

SOURCING

ON

123456

HIGH BIAS

HIGH FREQUENCY

SINKING

LOW BIAS

LOW FREQUENCY

SOURCING

ON

NPN SENSOR PNP SENSOR

123456

HIGH BIAS

HIGH FREQUENCY

SINKING

LOW BIAS

LOW FREQUENCY

SOURCING

ON

10

www. .com information@itm.com1.800.561.8187

Figure 10. Quadrature Input Module Default Settings

The Quadrature mode supports a wide range of encoders including the Simpson SE series.

While in Standard mode, this module works similarly to the Standard Input module, with the

added capability to selectively invert the A, B, and User input signals.

NOTE: If B channel is not going to be used, use the default switch settings

for SW1 positions 1 through 3.

Default settings are provided in Table 3. In both modes, the state of the User input signal can

be selected as active high or active low. DIP switch SW1 congures the counter to match the

specications of the accompanying sensor. When shipped from the factory, the counter is set

for X1 quadrature, as shown in Figure 10 and Table 3:

11

Dip Switch

Legend

= ON

= OFF

B Bias Off = Hi On = Lo

B Freq Off = Hi On = Lo

B Off = Sink On = Source

A Bias Off = Hi On = Lo

A Freq Off = Hi On = Lo

A Off = Sink On = Source

B Edge Off = On =

A Edge Off = On =

User pol Off = On =

Quadr Off = X4 On = X1

7

1234569

810

SW1

Dip Switch:

Shown in

Quadrature Mode

(Factory Default)

Figure 9.

Quadrature / Universal Input Module

COMMON

Denotes module position 1 at rear of counter

Primary Input or Quadrature A

Program Step Used only in special program mode

Secondary Input or Quadrature B

A INPUT

COMMON

USER

INPUT

B INPUT

IINPUT

www. .com information@itm.com1.800.561.8187

Table 3. Quadrature Module DIP Switch and Jumper Settings

JP1/2: Count Mode Selector

Jumpered 1-2 = Quadrature mode

Jumpered 2-3 = Standard counter mode

SW1: 10 Position DIP Switch

* = Factory Default setting

1B Channel Bias: OFF = Hi* VLT = 5.0V VUT = 7.0V (+/- 10%)

ON = Low VLT = 1.6V VUT = 3.6V (+/- 10%)

2 B Channel Frequency: OFF = Hi* (low pass lter disabled)

ON = Low (low pass lter enabled)

3 B Channel Sensor: OFF = Sinking* (internal pull-up enabled)

ON = Source (internal pull-down enabled)

4A Channel Bias: OFF = Hi* VLT = 5.0 V VUT = 7.0V (+/- 10%)

ON = Low VLT = 1.6 V VUT = 3.6V (+/- 10%)

5 A Channel Frequency: OFF = Hi* (low pass lter disabled)

ON = Lo (low pass lter enabled)

6 A Channel Sensor Type: OFF = Sinking* (internal pull-up enabled)

ON = Source (internal pull-down enabled)

7B Channel Count Edge: OFF = Rising (standard count mode only)

ON = Falling*

8A Channel Count Edge: OFF = Rising (standard count mode only)

ON = Falling*

9 User Input Polarity: OFF = High/open circuit = Inhibit Count

ON* = Low/closed circuit = Inhibit Count

10 Quadrature Mode: OFF = X4 (quadrature mode only)

ON =X1*

www. .com information@itm.com1.800.561.8187

12

12 VDC Excitation Module

The Excitation Module can supply 12 VDC at up to 100 mA for external sensors or encoders.

This excitation is isolated from the counter internal logic supply.

When using sensors or encoders that do not have a signal return or imply a signal return that

is in common with the supply voltage, a common attachment that ties the excitation supply to

the logic input common may be required.

Examples of this appear in gures 8, 8a, 11 and 12.

Figure 11. Wiring Encoder w/Excitaion Supply

Figure 12. Wiring Encoder with External Supply

Figure 2.6 Excitation Module

www. .com information@itm.com1.800.561.8187

13

3 Display & Rear Panel Controls

3.1 Display

Figure 14. Display Layout

• 6-digit 0.56” high red LED display.

• Units Window for supplied label or legend.

• Upon power up, the S664 will identify its model and version.

Figure 13. Excitation Module

14

EXCITATION

ISO+12V

ISOCOM

+

_

__

---

12 VDC, 100 mA max

Denotes module

position 2 at rear of

counter

Numeric & Message Display

Units Window

www. .com information@itm.com1.800.561.8187

3.2 Display Error Messages

Display Description Action

Required

9999 or

-999

(Flashing)

Display Over Range: The displayed count is too

large for the counter to display. Since the internal

count buffer is much larger than the display, the

counter will maintain accurate frequency well

beyond the display value.

Reset

Counter

E3

(Outputs

deactivate, count

stops)

Watchdog Fault: The counter did not experience

an orderly power-down. This can happen by

exceeding the maximum allowable count speed for

a sustained period of time.

Reset

Counter

3.3 Rate (Frequency) Scaling and Display

The S664 can measure frequencies ranging from 1.00 Hz to 35 KHz. The fre-

quency scale is selected according to Table 4. The frequency range is selected

by using a wire or switch across the RESET and COMMON terminals on the

rear of the counter. The range prompt (scl 1) will toggle each time the contact is

made.

Table 4. Frequency Scale Selection

Frequency can also be displayed as a signed entity and will be negative accord-

ing to the direction control. (See section 3.4.)

Range

Typical

Update

Period

Max

Update

Period

Min.

Input

Frequency

Max.

Input

Frequency

Comments / Typical Application

scl1 1.0 sec 3.0 sec 1.00 Hz 99.99 Hz 1/100 Hz resolution / measure

signals less than 100 Hz.

scl2 1.0 sec 2.0 sec 1.6 Hz 999.9 Hz 1/10 Hz resolution / measure

signals less that 1 KHz

scl3 0.5 sec 1.0 sec 4 Hz 9999 Hz 1 Hz resolution / measure signals

less than 10 KHz

scl4 0.5 sec 1.0 sec 0.01 KHz 35.00 KHz 0.01 KHz resolution / measure

signals in KHz

15

www. .com information@itm.com1.800.561.8187

3.4 A/B Channel Inputs

The A channel input is a pulse source. This signal must be limited to under 35

KHz. This corresponds to a minimum pulse width of 28.57 microseconds. The

signal does not need an even duty cycle (On vs. Off time) as long as a minimum

(high or low) of 1 microsecond is maintained (See figure 15).

Figure 15. Input Pulse Definition

The B Channel acts as a direction control. If the B input is in the active state,

frequency will be displayed as a negative number. When using the quadrature

input card (in quadrature mode), A and B encoder signals are translated to Pulse

and Direction signals internally.

1 us 1 us

Tp (Minimum)

16

www. .com information@itm.com1.800.561.8187

Appendix A: Technical Specifications

A.1 Functional Specifications

Frequency modes Scale 1 1.00 to 99.99 Hz 1 update / sec

Scale 2 2.0 to 999.99 Hz 1 update / sec

Scale 3 4 to 9999 Hz 2 updates / sec

Scale 4 0.01 to 35.00 KHz 2 updates / sec

Frequency Inputs Channel A and Channel B

Miscellaneous inputs Reset (Scale Select) and B (Direction Control)

Maximum count rate 35 KHz (Standard and Quadrature X1 modes)

8.75 KHz (Quadrature X4 mode)

Min pulse width 2 uS (Standard mode)

Frequency range

(internal)

-2,147,483,648 Hz to +2,147,483,648

Frequency accuracy

(instantaneous)

> ± 0.001% of reading

Frequency vs

temperature

+ 0.0001% of reading per °C

Frequency vs time

(aging)

± 0.001% of reading per year

Display Digits 4-digit, 7-segment with leading zero blanking

Display Decimal Point Position according to selected scale

Display LEDs Red 0.56" (14.2mm), high efficiency

Display Range - 999 to + 9999

(Independent of decimal position)

A.2 Electrical, Environmental and Mechanical

Specifications

Power Requirements AC Supply: 120 or 240 VAC, ±10%

Power Consumption 3VA

Reset Input Signal Active Low: 0.2 VDC = active

Storage Temperature -10 to 60°C

Operating Temperature 0 to 40°C

Relative Humidity

0 to 80% for temperatures less than 32°C,

decreasing linearly to 50% at 40°C. (Non-

condensing)

Bezel 3.93" x 2.04" x 0.52" (99.8 x 51.8 x 13.3mm)

Panel Cutout 3.62" x 1.77" (92 x 45 mm) 1/8 DIN

Case Depth 3.24" (82mm)

Weight 9.0 oz. (255.1 g)

17

www. .com information@itm.com1.800.561.8187

!

Quadrature / Universal input module

tupnI

slennahC resUdnaB,A

tupnI

noisrevnI

lennahcBdnaA.elbatcelesytiraloptupniresU

.ylnoedomdradnatsnievitcelesytiralop

noitarepO

sedom 4XerutardauQdna1XerutardauQ,dradnatS

tupnI

secruoS

NPNroPNP,scigolLTTroSOMC,tcatnochctiwS

sredocne)dedne-elgnis(erutardauqsecived

tupnI

ecnadepmI

%01±)CDV61-0.9(otpu-lluP.seR%5,K01:gnikniS

nommocotnwod-lluP.seR%5,K1.5:gnicruoS

sdlohserhTtupnI

B&A

slennahc

%01±V6.3=TUV%01±V6.1=TLV:edomsaiBwoL

%01±V0.7=TUV%01±V0.5=TLV:edomsaiBhgiH

resU

lennahC )xam(V51.3=TUV)nim(V9.0=TLV

ssapwoL

retlif

taevawerauqstupniV01ot0(zH002<ycneuqerF

)elcycytud%05

egatlovxaM deniatsusmumixamCDV03slennahcresUdnaB,A

Isolated 12V Excitation Module

tuptuOnoitatixE%5±CDV21taAm001

noitalosInoitatixEV0051

Standard input module

Input Channels A, B and User

Count edge High to low transition (A and B channels)

Input Sources Switch contact, CMOS or TTL logics, PNP or NPN

devices

Input Impedance Sinking: 10K, 5% Res. Pull-up to (9.0 - 16 VDC) ±10%

Sourcing: 5.1K, 5% Res. Pull-down to common

Input Thresholds

A & B channels Low Bias mode:VLT = 1.6V ±10% VUT = 3.6V ±10%

High Bias mode:VLT = 5.0V ±10% VUT = 7.0V ±10%

User Channel VLT = 0.2V (min) VUT = 3.0V (max)

Low pass filter Frequency < 200Hz (0 to 10V input square wave at

50% duty cycle)

Max voltage A, B and User channels 30VDC maximum sustained

18

www. .com information@itm.com1.800.561.8187

Table of contents

Other Simpson Measuring Instrument manuals

Simpson

Simpson S663 User manual

Simpson

Simpson 2865 User manual

Simpson

Simpson Mini-Max series User manual

Simpson

Simpson 260 series 5M User manual

Simpson

Simpson Gima User manual

Simpson

Simpson 884-2 User manual

Simpson

Simpson 260-6XLPM User manual

Simpson

Simpson 444 User manual

Simpson

Simpson 897 User manual

Simpson

Simpson S662 User manual

Simpson

Simpson 260-8XPI User manual

Simpson

Simpson SPEEDMULLER User manual

Simpson

Simpson 260 series 5M User manual

Simpson

Simpson 260 series 5M User manual

Simpson

Simpson 260-8XI User manual

Simpson

Simpson 160 User manual

Simpson

Simpson 886-2 User manual

Simpson

Simpson 260-8P User manual

Simpson

Simpson Amik 301 User manual

Simpson

Simpson 260-8PRT User manual