Seetru G27 User manual

Other Seetru Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Digital Monitoring Products

Digital Monitoring Products 1154 installation guide

Lutron Electronics

Lutron Electronics PDO-519 Operation manual

Hama

Hama TH-130 operating instructions

LEGRAND

LEGRAND Raritan PM Series Quick setup guide

M-system

M-system R1MS-GH3 instruction manual

Dremel

Dremel 3Z Laser Measurer Operating/safety instructions

INTEGRA Merering

INTEGRA Merering Calec energy master Installation and operating instructions

Morris Products

Morris Products 57262 Operator's instruction manual

Hioki

Hioki PW3336-01 instruction manual

Nuvair

Nuvair PRO TRIMIX quick start guide

Teledyne

Teledyne 4220 Installation and operation guide

Keysight

Keysight M9614A Quick Startup Poster

Megasat

Megasat HD 5 Combo user manual

Elma Instruments

Elma Instruments Elma 35 user manual

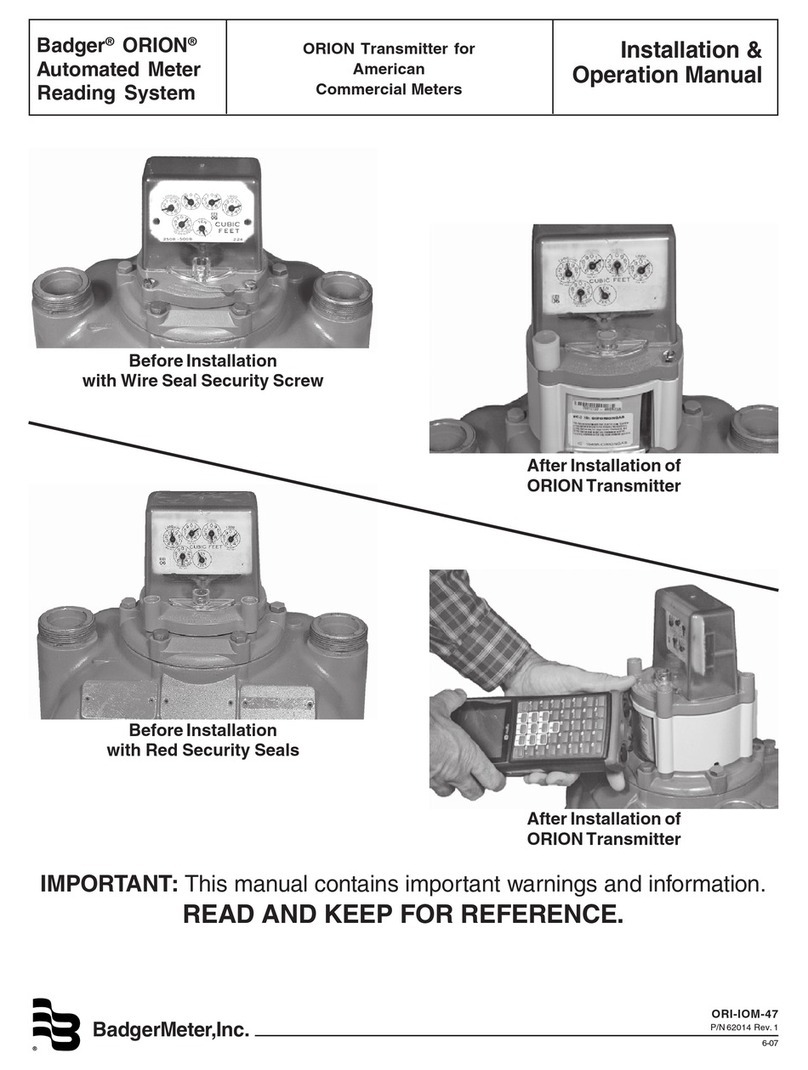

Badger Meter

Badger Meter Orion 64989-002 Installation & operation manual

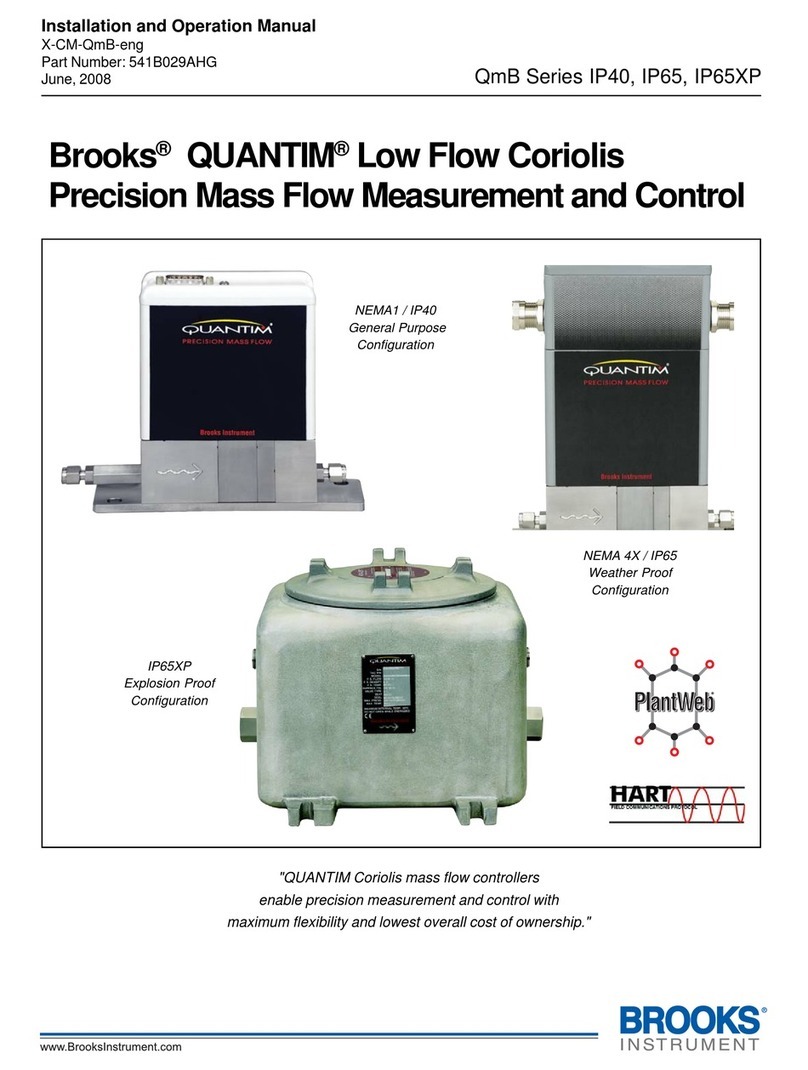

Brooks Instrument

Brooks Instrument QUANTIM QmB IP40 Series Installation and operation manual

scigiene

scigiene SP-850055 instruction manual

Baylan

Baylan BT.11 user manual