Sine Systems RP-8 Owner's manual

www.sinesystems.com

Remote Facilities Controller

– INSTALLATION AND OPERATION –

Remote Facilities Controller firmware version 6.00

Model RFC-1/B

Relay Panel

Model RP-8

•

RFC-1 Table of Contents i

Table of Contents

Section I – Safety Information Page

1.1 Safety Information 1.1

1.2 FCC Compliance 1.2

Section 2 – New Features and System Changes

2.1 Version 6.00 2.1

Section 3 – Installation

3.1 System Includes 3.1

3.2 Installing the System 3.1

Mechanical Installation 3.2

RFC-1/RP-8 Interconnect 3.2

RP-8 Channel Block Assignment 3.3

RP-8 Telemetry Connections 3.3

RP-8 Control Connections 3.4

RP-8 Channel Identification 3.4

Telephone and Telephone Line Connection 3.5

Power Supply 3.5

3.3 Telemetry Source Inputs 3.6

Analog Readings 3.7

Status Readings 3.7

Calibrating Telemetry Readings 3.8

3.4 Control Outputs 3.9

3.5 Telephone Interface 3.9

Wireless Telephone with an RJ-11 Adapter 3.9

Fixed Location Wireless Telephones 3.10

Rural Radiotelephones or Ranch Telephones 3.10

Dedicated Control Port 3.10

3.6 Battery Backup and Clock/Calendar 3.12

Power Failure Alarm 3.12

Uninterruptible Power Supply 3.13

AC Failure Detection on Battery Backup 3.13

3.7 Lightning Protection Tips 3.13

Proper Ground System 3.13

Telephone Line Protection 3.13

SP-8 Surge Protector 3.14

3.8 RF Interference 3.14

Section 4 – Accessories and Miscellaneous Circuit

4.1 Optional Accessories 4.1

SP-8 Surge Protector 4.1

MA-2 Modem Adapter 4.1

PA-2 Printer Adapter 4.1

RAK-2 Intelligent Rack Adapter 4.1

RS-232 Serial Data Adapter 4.1

ACM-2 AC Current Monitor 4.2

AFS-3 Audio Failsafe 4.2

TSN-3 Thermal Sentry III 4.2

TS-1/PS Temperature Sensor (w/Power Supply) 4.2

RFC-1 Table of Contents ii

4.2 Auxiliary Circuits 4.3

Audio Detection 4.3

Latching Relays 4.4

Telemetry Pulse Stretching 4.4

Battery Backup 4.5

Section 5 – Basic Operation

5.1 Overview 5.1

5.2 Operation from the Local Telephone 5.1

Connecting to the RFC-1 5.1

Selecting a Channel 5.1

Reading Telemetry Channels 5.2

Operating the Control Relays 5.2

Issuing other Commands 5.2

Disconnecting from the RFC-1 5.2

5.3 Operating from a Remote Telephone 5.3

Connecting to the RFC-1 5.3

Operating the RFC-1 5.3

Disconnecting from the RFC-1 5.3

5.4 Alarm System 5.4

How the Alarm System Works 5.4

Alarm System Setup 5.4

Programming Alarm Limits 5.5

Programming Telephone Numbers 5.5

Enabling / Disabling the Telemetry Alarm System 5.5

Enabling / Disabling the Power Failure Alarm 5.6

System Limitations 5.6

5.5 Clock and Calendar 5.7

Setting the Calendar 5.7

Setting the Clock 5.7

5.6 Basic Programming 5.7

Security Codes 5.7

Ring Number 5.7

5.7 Operating Commands / Notes 5.8

Section 6 – Advanced Operations

6.1 Introduction 6.1

6.2 Advanced Programming 6.1

Programming Address Table 6.2

Using the Programming Mode 6.3

Restore Factory Settings 6.4

6.3 Telemetry Channels 6.5

Telemetry Channel Programming 6.5

Unit Words 6.5

Status Readings 6.6

Maximum Scale and Decimal Point 6.7

Linear and Logarithmic Scales, Inverted Status and Auto-control Relay 6.7

Indirect Power 6.8

Telemetry Leading Zero Suppression 6.10

Telemetry Settling Time 6.10

Number of Telemetry Channels Available 6.11

RFC-1 Table of Contents ii

6.4 Clock and Calendar 6.12

Setting the Calendar 6.12

Day of the Week 6.12

Setting the Clock 6.12

Automatic Daylight Saving Time Adjustment 6.12

Clock Calibration 6.13

6.5 Action Sequences 6.15

Fixed-programming Action Sequences 6.15

User-programmable Action Sequences 6.16

Control Relay Operation 6.17

Action Sequence Delays 6.18

Alarm Calls 6.19

Logging Telemetry Readings 6.20

Conditional Execution 6.21

Enabling / Disabling Telemetry Alarms 6.24

Extending an Action Sequence 6.24

Testing an Action Sequence 6.25

6.6 Telemetry Alarms 6.26

Telemetry Alarm Programming 6.26

Channel Number 6.26

Trigger Rules 6.27

Action Sequence 6.27

Upper and Lower Limits 6.28

Enabling and Disabling Telemetry Alarms 6.28

Blocking Alarms by Time 6.29

Alarm Scan Interval and Sequence 6.30

6.7 Timed Events 6.31

Enabling Timed Events 6.31

Disabling Timed Events 6.31

Date/Time Triggers and Telemetry Channels—Shared Memory Region 6.31

Programming a Timed Event 6.32

Special Triggering Options 6.33

Programming Examples 6.33

Telemetry Auto-scan Data Interval 6.36

Telemetry Auto-scan Stop Channel 6.36

6.8 Communication 6.37

Programming Telephone Numbers 6.37

Extending Telephone Numbers 6.38

Setting the Call Attempts 6.38

Setting the Call Mode 6.39

Calling Voice Numbers 6.39

Calling Data Numbers 6.39

Calling Pagers in Voice Mode 6.40

Calling Pager in Data Mode 6.41

Tone/Pulse Dialing 6.43

Alarm Call Message Duration 6.43

Alarm Call Pause Duration 6.43

Ring Sensitivity and Hang-up Detection 6.44

Communication Mode 6.45

Data Communication Settings 6.46

Manual Communication Mode Change 6.46

Saving and Restoring System Settings 6.47

Terminal Emulation Software 6.48

Backing-up System Settings 6.49

Restoring System Settings 6.50

RFC-1 Table of Contents iv

6.9 Security Codes 6.51

Security Code Programming 6.51

Control Security Code Mapping 6.51

Incorrect Code Lockout / Communication Mode Switch Delay 6.52

6.10 Site ID and Other Options 6.53

Site Identification Phrase 6.53

Hardware Version 6.54

Inactive System Timeout 6.54

6.11 Operating Commands / Notes 6.55

Section 7 – Programming Examples

7.1 Telemetry Channel—unit word, full scale, decimal point 7.2

7.2 Site Identification Phrase 7.1

7.3 Action Sequence 7.3

7.4 Date/Time Trigger 7.4

7.5 Alarm Limits—Analog Channel 7.5

7.6 Alarm Limits—Status Channel 7.6

7.7 Voice Mode Telephone Number 7.7

7.8 Text Pager—Voice Mode 7.8

7.9 Logging Readings—Local Printer 7.10

7.10 Tower Light Alarm 7.11

7.11 Tower Light Alarm Block—Daylight Hours 7.12

Section 8 – Troubleshooting and Service

8.1 Common Problems and Possible Solutions 8.1

8.2 Factory Service Policy 8.3

Section 9 – Specifications

9.1 Electrical and Mechanical 9.1

RFC-1 Remote Facilities Controller 9.1

RP-8 Relay Panel 9.1

9.2 Schematic Diagrams 9.2

Appendix A – Programming Address Table

0000 Telemetry Channels A.1

0256 Date/Time Triggers A.6

0640 Telephone Numbers A.14

0724 Action Sequences A.16

0852 Alarms A.18

0948 Security Codes A.20

0984 Site ID Phrase A.21

0996 Operating Parameters A.22

Appendix B – Word Table

Vocabulary List B.1

RFC-1 Safety Information and FCC Compliance page 1.1

Section 1 — Safety Information and FCC Compliance

1.1 Safety Information

Only qualified technical personnel should attempt to install the RFC-1 system. An attempt to

install this device by a person who is not technically qualified could result in a hazardous

condition to the installer or other personnel, and/or damage to the RFC-1 or other equipment.

Ensure that safety precautions are made before installing this device.

The RFC-1 Remote Facilities Controller is registered with the Federal Communications Commission and certified to

meet specific safety requirements. It is extremely important that the RFC-1 not be modified in any way. Modification

of this equipment will void the FCC certification, void the warranty, and perhaps pose a hazard to the user of this

equipment or to maintenance personnel of your local telephone company.

The RFC-1 Remote Facilities Controller should be serviced only by qualified technical personnel who are familiar with

the implications of FCC Part 68 registration. The RFC-1 Remote Facilities Controller and the RP-8 Relay Panels are

designed for indoor use in a dry location. Installation and operation in other locations could be hazardous.

All cables should be disconnected when servicing the RFC-1 system. Extreme caution should be

used when opening the RFC-1 chassis. High voltages may be present on telephone lines.

Although the RFC-1 has a 12-volt AC power transformer, failure of the transformer could cause

dangerous and potentially lethal voltages to become present.

Depending on the installation, the control circuits of the RP-8 Relay Panel may be connected to sources of up to 120

volts AC and/or several amperes of current. Under certain conditions, these voltage sources can be lethal. Always

use caution when working around these circuits. Disconnect all high voltage and high current sources before

servicing the RFC-1 system.

Exercise caution when working near the connectors on the RP-8. The removable connectors used on the RP-8 leave

slightly exposed tips even when the connector is in place. The tips are not dangerous but they are pointed.

Furthermore, the exposed metal provides a very small point where a short could occur. Be careful when using metal

tools near any exposed wiring. Power should be removed form all devices when performing service.

The RFC-1 contains self-resetting "fuses" that protect it from excessive current. If they become damaged,

replacement devices should be of the same type and rating.

The RFC-1, like any electronic device, can fail in unexpected ways and without warning. Do not use the RFC-1 in

applications where a life-threatening condition could result if it were to fail.

RFC-1 Safety Information and FCC Compliance page 1.2

1.2 FCC Compliance

The RFC-1 complies with Part 68 of the FCC rules. On the rear panel of the RFC-1 is a label that contains, among

other information, the FCC registration number and ringer equivalence number (REN) for this equipment. If

requested, this information must be provided to the telephone company.

The REN is used to determine the number of devices that may be connected to the telephone line. Excessive RENs

on the telephone line may result in devices not ringing in response to an incoming call. In most areas, the sum of the

RENs should not exceed 5.0. Contact the local telephone company to determine the maximum REN for the calling

area.

The RFC-1 is designed for use with standard modular (RJ-11C) telephone jacks.

The telephone company may make changes in its facilities, equipment, operations, or procedures that could affect

the operation of the RFC-1. If this happens, the telephone company usually provides advance notice in order for you

to make the necessary modifications to maintain uninterrupted service.

If the RFC-1 causes harm to the telephone network, the telephone company will notify you in advance of service

disconnection. If advance notice isn't practical, the telephone company will notify the customer as soon as possible.

Also, you will be advised of your right to file a complaint with the FCC if you believe it is necessary.

Please contact Sine Systems, Inc., for repair and/or warranty information if you suspect that the RFC-1 has

malfunctioned. If a defective device is causing harm to the telephone network, the telephone company may request

you remove that device from the network until the problem is resolved.

The RFC-1 cannot be used on public coin service telephone lines. Connection to Party Line Service is subject to

state tariffs. Contact your state public utility commission, public service commission, or corporation commission for

information.

The RFC-1 is registered with the Federal Communications Commission and is certified to meet specific safety

requirements. It is important that the RFC-1 not be modified in any way. Modification of this equipment will void the

FCC certification, void the warranty, and perhaps pose a hazard to the user of this equipment or to maintenance

personnel of your local telephone company.

Service should only be performed by qualified technicians that are familiar with the implications of FCC Part 68

registration. Extreme caution should be used if the RFC-1 case is opened while still connected to the telephone line.

High voltages may be present on telephone lines.

RFC-1 New Features and System Changes page 2.1

Section 2 — New Features and System Changes

2.1 Version 6.00

General Feature Updates

The RFC-1 can reset all user programmable settings to their factory default values. A special advanced

programming code has been added to the system that performs this operation.

The system can be manually forced to both data and voice mode with the command 84. Previously it was possible to

force data mode but the system can now be forced back to voice mode too.

The memory dump/print command has additional options. The legacy mode table-style memory dump is included for

backward compatibility. A new annotated memory dump displays the data in logical groups by function and includes

a description on each line of data. The memory restore dump formats the data so that it can be saved to a text file

and used to reprogram the RFC-1 user memory.

Several user prompts have changed. The prompt to enter the main security code changes from “enter” to “enter

security code.” When an incorrect security code is given, the system now says, “error, goodbye” before

disconnecting. The alert that there is an incoming call when user is connected locally changes from “ring-ring” to

“telephone, ring-ring”. The commands to read/reprogram telephone numbers and alarms now identify the item by

letter “A, B, C, etc”.

Clock & Calenear Updates

The real time clock can optionally adjust automatically for Daylight Savings Time as observed in the United States

using rules established in 2007. This feature is disabled by default to avoid issues in areas that do not observe the

seasonal time change. The feature is enabled through a simple adjustment that is stored in non-volatile memory.

The RFC-1 calendar determines the day of the week when the date is set. This operation is automatic and occurs

without user intervention.

The calendar recognizes all four digits for the year.

When appropriate hardware is available, the real time clock synchronizes to the incoming AC power and corrects the

internal time base for better long-term accuracy. The feature works in areas using either 50 Hz or 60 Hz AC power

and operation is completely transparent. It is enabled by default but can be overridden through user programming.

The legacy clock adjustment procedure still exists for sites that are not powered from an AC main supply. This

feature requires hardware support available in systems that shipped after mid 2003.

Systems that are able to perform the automatic clock sync described above also support an internal power failure

alarm. The system is able to recognize the loss of AC power. This feature works in addition to the legacy power

failure alarm that triggers when power is restored after a failure. The power failure alarm is disabled by default and is

enabled with the command 82.

RFC-1 New Features and System Changes page 2.2

Telemetry System Updates

Telemetry channels that are programmed as status channels (“on/off”, “normal/alarm”, etc.) can be individually

programmed to invert the status reading. Typical behavior is a reading of “off” when no voltage is present and “on”

when voltage is present. The readings can be swapped so that no voltage reads “on” and voltage present reads “off”.

This eliminates the need for wiring an external inverter circuit.

There are a couple of changes to the telemetry channel status options. Option 0-4 changes from unused to “normal”

(low) / “failure” (high). Option 0-15 changes from “normal / EAS” to “audio failure” (low) / “normal” (high).

Timed-Event Updates

Timed events can be programmed according to the day of the week. In addition to the previously available options,

time triggers can be programmed to operate only on a specific day of the week, weekdays only or weekends only.

New date/time trigger options are available to repeat an event on specific intervals. The value 15 has always been

used to match all values for month, date and hour. The hour can now be programmed with 15-1, 15-2, 15-3 or 15-4

to repeat an event every 1, 2, 3 or 4 hours. Similarly, minute settings can use 15-1 through 15-5 to repeat an event

every 1 through 5 minutes. Programming of events that repeat on a regular cycle is greatly simplified.

Alarms can be enabled and disabled by commands in an action sequence. This means that timed events can now be

used to enable and disable alarms using all of the date/time trigger options.

Telephone Related Updates

The DTMF tone dialing system is capable of generating the tones associated with the ❊and # keys. These tones are

required by some telephone systems. Previous versions of the RFC-1 could not generate these tones due to

memory limits of the speech processor. Some of the names in the word table were eliminated to create space in

memory for the additional DTMF tones.

The tone dialing system can use a dedicated DTMF tone generator if it is available in hardware. Early hardware

versions use the speech processor to reproduce stored tones. A dedicated tone generator is faster and generates

tones with more accuracy.

Multiple telephone numbers can be chained together to achieve dialing stings longer than the default twelve digits.

Voice calls using tone dialing and data mode calls can utilize this feature. Pulse dialing is limited to 12 digits per

telephone number.

The command 89 now reads and programs telephone number D.

RFC-1 New Features and System Changes page 2.3

Alarm System Updates

The telemetry alarm channel scanning intervals have changed. The factory default scan interval is still one channel

per 10 seconds. Several new intervals have been added including a shorter 5-second interval as well as a very long

240-second interval.

Alarms can be blocked according to the day of the week. As with timed events, the RFC-1 can block an alarm on a

specific day of the week, weekdays only or weekends only.

Alarms can be blocked for a specific month. This allows alarm blocking to “float” from month to month. This will help

stations that operate at multiple power levels.

Action sequences with fixed programming are stored in the system. These action sequences perform common tasks

without occupying any of the user programmable memory space. Pre-programmed action sequences are available to

place telephone calls, print readings to a local printer or print readings to a remote printer. This frees action

sequence 1 and eliminates some potential programming errors that cause the alarm system to not work as expected.

The user programmable action sequences are designated 1 through 8. The factory programmed action sequences

are designated from 9 up.

The factory programming for all alarms is to trigger action sequence 9. If an alarm occurs and the action sequence

that is triggered has no instructions, the system will substitute action sequence 9.

Action sequences can be chained together to achieve sequences longer than eight instructions.

Alarm calls can be made to text based pagers with a site ID number and can optionally include the number of the

channel that triggered the alarm. In previous RFC-1 versions, the message was limited to a single digit repeated ID

digit. This mode is completely DTMF tone driven however some paging systems may not support this feature.

Alarm calls can be made to text based pagers with complete text messages including the channel that triggered the

alarm and the channel reading when the failure occurred. This feature requires the RFC-1 to have a data modem

(MA-1/2 or RAK-1) and data support from the pager service provider. The data communication follows the automatic

messaging mode specified in the TAP protocol that is supported by most paging terminals. Additional data protocols

have been added to the RFC-1 to support standard and non-standard TAP implementations.

RFC-1 Installation page 3.1

Section 3 — Installation

Only qualified technical personnel should attempt to install the RFC-1 system. An attempt to

install this device by a person who is not technically qualified could result in a hazardous

condition to the installer or other personnel, and/or damage to the RFC-1 or other equipment.

Ensure that safety precautions are made before installing this device.

3.1 System Includes

The RFC-1 Remote Facilities Controller package contains these items:

•Remote Facilities Controller model RFC-1

•Rack mounted chassis

•Flat cable with two connectors, 3 ft long

•12 VAC wall plug supply

•Modular telephone cable, 7 ft long

•Flat blade adjustment screwdriver

•Operation manual

All systems are fully tested before leaving the factory but damage may occur in transport. When the RFC-1 and RP-8

panels are unpacked, they should be inspected for obvious signs of mechanical damage or loose parts. Loose parts

should be tightened before installation. If damage is found, save the packing material and report it to the shipping

company and the dealer from which it was purchased. Do not install the system.

3.2 Installing the System

The RFC-1 is easy to install if you are careful, patient and alert. Installation is broken down into a series of logical

steps. Perhaps more importantly, you should have some previous engineering experience in a broadcast transmitter

environment. Having access to the building does not qualify you as an engineer. A transmitter can be extremely

unforgiving to stupid mistakes. We cannot protect you from yourself.

We want to make this point very clear: if you are unfamiliar with this type of equipment, please contact a properly

qualified engineer to handle installation and setup of this system.

RFC-1 Installation page 3.2

3.2.1 Mechanical Installation

The RFC-1 and RP-8 should be mounted in a standard 19-inch equipment rack. The system generates little heat. It

can be mounted in nearly any convenient location. The RP-8 panels should be mounted at a location that is

convenient to the control and metering sources that will be connected to it.

A flat cable is supplied for interconnection between the RFC-1 and the RP-8. The factory supplied cable is three feet

long but it can be replaced with a longer one if the RFC-1 and RP-8 are to be mounted further apart.

Figure 3.1; RFC-1 Remote Facilities Controller and RP-8 Relay Panel

3.2.2 RFC-1 / RP-8 Interconnect

The RFC-1 should be connected to the RP-8 relay panel(s) with the 16 conductor flat (ribbon) cable. This cable is

supplied with the RFC-1. The cable is terminated with one connector at each end. If more than one RP-8 is used in

a system, an extra connector will be supplied with the additional RP-8. The additional connector must be crimped

onto the existing flat cable assembly.

Adding an extra connector to the flat cable is easy—just be careful and be patient. First, slide the connector over the

end of the ribbon cable. Be sure to check three things:

•The colored stripe (usually red) is on same side of all connectors

•The ribbon cable lines up with the alignment slots in the connector

•The connector is perpendicular to the length of the cable

When you are sure that the connector is aligned properly, squeeze the connector together with a small vice or a pair

of pliers. A couple of small blocks of wood or cardboard will protect the plastic connector from the “gripping teeth” of

the vice or pliers. The latches on the edges of the connector will lock into place when the connector is squeezed

together sufficiently.

Plan your installation cable before you install additional connectors. For multiple RP-8 panels that are mounted next

to each other in the rack, the connectors should be placed about six inches apart on the cable. The supplied cable

should work for the most installations. Longer cables may be used if necessary.

RFC-1 Installation page 3.3

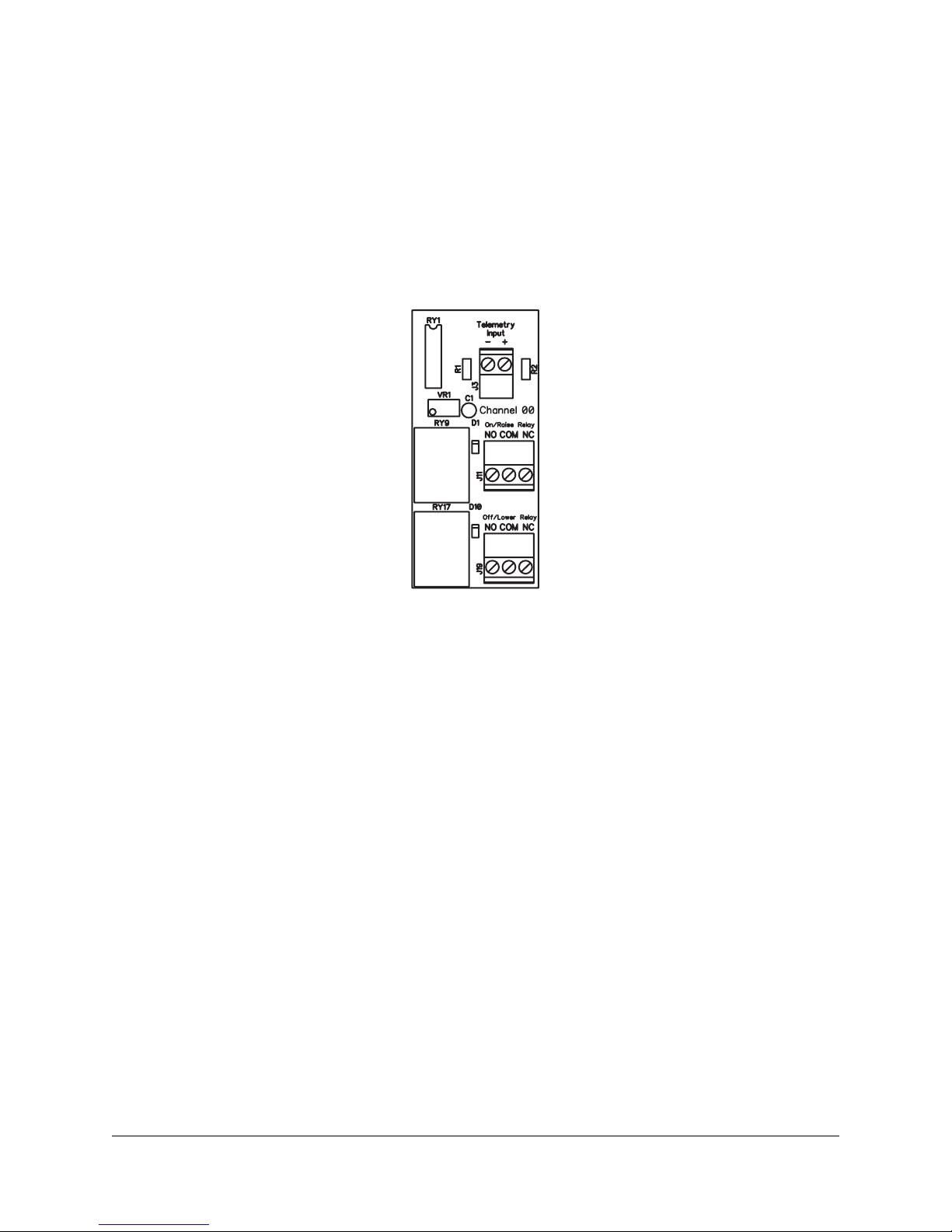

3.2.3 RP-8 Channel Block Assignment

If your system uses only one RP-8 you may skip this section.

Each RP-8 panel in the system should be assigned to a different “block” of eight channels. The channel blocks are:

00-07, 08-15, 16-23, 24-31, 32-39, 40-47, 48-55 and 56-63. Normally, consecutive blocks of channels are used but

this is not necessary.

Channel block assignment is made by moving a selection jumper located at the left end of each RP-8 panel. Simply

move the jumper to the desired block position.

Figure 3.2; RP-8 Channel block select jumper

Be aware that the RFC-1 “rests” on channel 63 during idle conditions (in between telephone calls and not scanning).

If the last block of channels is used (56-63), the telemetry relay for channel 63 will be energized during idle periods.

This is not normally an issue.

RFC-1 Installation page 3.4

3.2.4 RP-8 Telemetry Connections

Telemetry connections to the RP-8 are made through two-conductor screw terminal connectors. The screw terminal

connectors can be removed for easier installation. There are no locks or catches, grasp the connector firmly and pull

it away from the panel.

The connector can be plugged onto the terminal posts in several directions: horizontal or vertical and left or right

facing. You may choose the position that is most convenient. Any connector orientation is acceptable but be sure to

observe proper signal polarity.

Figure 3.3; RP-8 Telemetry input connection point

Telemetry samples should conform to the following rules:

•For a full scale voltage reading a minimum of 1.0 volt DC is necessary

•Telemetry samples significantly over 5 volts DC should be dropped with an external attenuator

•Absolute maximum telemetry sample is 10 volts DC

•Telemetry samples can be offset from ground up to 30 volts DC

•Positive or negative DC voltages can be metered but not both on the same channel

More information on telemetry sources is provided later in this section.

RFC-1 Installation page 3.5

3.2.5 RP-8 Control Connections

Control connections to the RP-8 are made through three-conductor screw terminal connectors. The screw terminal

connectors can be removed for easier installation. There are no locks or catches, grasp the connector firmly and pull

it away from the panel. In addition, the connector can be plugged onto the terminal posts in several directions:

horizontal or vertical and left or right facing. You may choose the position that is most convenient.

Figure 3.4; RP-8 Control output connection point

The control relays are SPDT with both normally open and normally closed contacts available. Observe proper

orientation between the NO, NC and common terminals when making these connections. Detailed information on

control outputs is given later in this section.

3.2.6 RP-8 Channel Identification

The front of the RP-8 includes a place to record pertinent data regarding each channel. Remember, the channels

read in the correct order from the back of the panel when wiring. Channels read right to left as viewed from the front

of the panel—the lowest channel number is on the far right.

Ch. 00Ch. 07 Ch. 01Ch. 02Ch. 03Ch. 04Ch. 05Ch. 06

Figure 3.5; Order of RP-8 channels as viewed from front

It is often desirable to write the channel number in the space indicated as well as any other information pertinent to

that channel. A grease pencil works well for this task. A permanent marker can be used but it will be difficult to

remove the ink without damaging the painted panel if it becomes necessary to do so.

RFC-1 Installation page 3.6

3.2.7 Telephone and Telephone Line Connection

The RFC-1 should be connected to a standard (POTS) telephone line with the modular (RJ11C) jack on the rear

panel labeled "Line". A telephone cable is supplied with the RFC-1 for this purpose. A telephone may be connected

to the jack labeled "Phone". This telephone will be used to control the RFC-1 locally (on-site) and will function

normally when the RFC-1 is not online.

Line Phone

Power

Sine Systems, inc

Relay Panels

Remote Facilities Controller model RFC-1/B • Sine Systems, Inc. • Nashville,Tennessee

Figure 3.6; RFC-1/B rear panel I/O connectors

3.2.8 Power Supply

Power to operate the RFC-1 and up to eight RP-8 panels is supplied by a 12 volt AC wall-plug transformer that is

supplied with the RFC-1. This transformer is designed for 120 volts AC at 50-60 Hz and is rated at 1 amp. The leads

of this transformer should be stripped and connected to the screw terminal connector marked “12 VAC” on the RP-8.

If more than one RP-8 is used, connect to any one of the RP-8 panels. If the supplied transformer has a connector

on the end of the power cord, simply cut the connector off and discard it.

Figure 3.7; RP-8 Power and I/O connections

In installations where 120 volts AC is not available, the RFC-1 may be powered by any source delivering 12.0 to 14.2

volts AC at 50-60 Hz or 16 to 18 volts DC. The RFC-1 draws a maximum of approximately 0.50 amps when a control

relay is engaged. A 12.6-volt filament transformer makes a good substitute power source. The power source must

be floating. Neither side of the power source should be connected to ground (earth) nor should the power source be

connected to any other equipment. Failure to observe this precaution will result in inaccurate telemetry indications.

RFC-1 Installation page 3.7

3.3 Telemetry Source Inputs

Telemetry samples may be elevated several hundred volts above ground on some equipment.

Permanent damage may occur to the RFC-1 and/or external equipment if a high voltage telemetry

source is connected to the RP-8! Failure to observe this warning may also cause injury to the

installer or other personnel.

Telemetry inputs are located across the top of the RP-8 panel through the 8 two conductor terminal blocks marked

“Telemetry”. The channels are identified as “00” through “07”. In situations where more than one RP-8 is used,

channel numbers increase by 8 on each successive relay panel.

The RFC-1 will accept either a positive or negative DC voltage source as a telemetry input. One volt DC is the

minimum voltage required for a full-scale reading. A lower input voltage can be used but the maximum reading will

not reach full scale. Low sample voltages can be calibrated initially but changing readings will have steps instead of

being smooth and continuous.

Telemetry samples over 5 volts may be used but calibration accuracy suffers on analog readings. Telemetry sample

voltage is less critical for status on/off channels. Samples for status channels may be up to 10 volts DC. Telemetry

sample voltage should never exceed 16 volts DC.

Excessive telemetry sample voltage reduces the useful range of the 22 turn calibration pots to the last few turns. The

result is an overly sensitive calibration that is “touchy”—a small change of the calibration pot causes a large change

in the telemetry reading.

Telemetry samples that are significantly over 5 volts should be reduced with an external attenuator. One solution is

to add a 2.2 KΩshunt resistor across the telemetry input terminals and a series resistor in the telemetry sample. The

series resistor should be about 2200 Ωper volt in excess of two volts. For example, to attenuate a telemetry voltage

of 10 volts, use a 2.2 KΩshunt resistor and an 18 KΩseries resistor. The values are not critical.

The telemetry terminal blocks are polarity specific. Connect the positive (high) side of the telemetry source to the “+”

terminal and the negative (low) side to the “-” terminal. Either side may be ground referenced if necessary.

Telemetry sources may be offset from ground up to 30 volts.

Shielded wire is not normally necessary for short runs to the telemetry inputs since a considerable amount of RFI

filtering is built into the RFC-1. However, long cable runs or lines from AM sampling loops may contain a very large

amount of RF energy which can cause telemetry linearity or other problems. Excessive RF energy can burn the

telemetry input components on the RP-8. This problem can usually be eliminated by inserting 2.5 mH chokes in

series with each telemetry lead.

It makes sense for the telemetry and control on a channel to be related. If the relays on a channel are wired to

control transmitter power, then the telemetry sample on that channel should indicate transmitter power too.

There is no internal hardware connection between the telemetry input and the control I/O. It is entirely possible for a

single channel to control a function that is completely unrelated to the telemetry. System operation is not intuitive in

such a case but the RFC-1 allows this.

Channel readings do not change just because a control function is given. A sample voltage is required to indicate

any change of state. In other words, if you activate the control relay on a channel to turn on a device and there is no

telemetry sample from that device to indicate that the device turned on, the channel reading will still be “status off”.

RFC-1 Installation page 3.8

3.3.1 Analog Readings

Any telemetry channel can be a status channel on the RFC-1. Explained briefly, the RFC-1 has the capability to read

telemetry over a range of 0000 to 2040. If the reading is:

•Between 0003 and 2039 the telemetry is spoken as four digits

•Lower than 0003 the words "status off" are spoken

•Higher than 2037 the words "status on" are spoken

Thus, any channel can act as either an analog input or a status channel with no specific programming changes. A

voltage must be applied to a telemetry input indicate a change of status. The voltage will be interpreted as a logic

level signal by the RFC-1 using the rules listed above.

3.3.2 Status Readings

The diagram below shows how to wire a telemetry input for a status output. When the external contact is closed, the

channel will read "status on" and when the contacts are open the telemetry will read "status off".

Figure 3.8; Typical wiring for a normally open status channel

The power supply shown in the illustration can be a simple wall-plug transformer that supplies anywhere from 6 to 12

volts DC. A single power supply can be used for many status contacts. The external 1 KΩresistor is added to

discharge the input smoothing capacitor on the RP-8 more quickly. Without this resistor it takes about 5 seconds to

reach a “status off” reading after the external contacts open. Adjust the telemetry calibration pot so that the system

reads "status on" when the external contact closes.

This example illustrates one method of generating a status indication. There are many others. For example, to read

a closed contact as "status off", connect the voltage source through a 1 KΩresistor to the positive telemetry terminal

and bridge the contact across the positive and negative telemetry terminals. A closed contact will short the voltage

and produce a "status off" indication.

Figure 3.9; Typical wiring for a normally closed status channel

RFC-1 Installation page 3.9

In some cases it is necessary to use an externally generated voltage to indicate status. Suppose, for example, that a

large AC contactor that does not have auxiliary contacts is to be metered. A small step-down transformer can be

placed across the coil of the contactor to generate a low voltage AC sample. The low voltage AC can then be routed

through a series diode and resistor (approximately 1 KΩ) to the telemetry input. The 10 µF capacitor on the RP-8

should provide sufficient filtering. Do not apply more than 16 volts DC to the telemetry input terminals!

3.3.3 Calibrating Telemetry Readings

Calibrating the telemetry inputs requires basic operational skills with the RFC-1 in local mode. Skip ahead and read

the section that covers operation from the local phone if you have no previous experience with the RFC-1.

Calibrating the telemetry inputs involves adjusting the channel readings so that they correspond to the readings given

from front panel meters. The process is to adjust the calibration pot just behind the front panel for a given channel

while checking the value with the local phone. Tweak the calibration pot until the RFC-1 reads the same reading that

is shown on the corresponding front channel meter. Channels read right to left as viewed from the front of the

panel—the lowest channel number is on the far right. Make sure that you adjust the correct pot for the channel that

you are calibrating.

Figure 3.10; Telemetry calibration point

The calibration pots are 22-turn trimmer resistors that allow precise adjustment. The pots have a clutch at each

extreme to protect the internal mechanism from traveling too far but the pot will turn indefinitely. It does make a faint

clicking sound at each end of travel.

As you adjust the pot, the RFC-1 will read new values automatically if the change is very large. However, as you

close in on the proper value, you will need to reselect the channel to get an updated reading. Take advantage of as

much of the scale as possible. If the normal reading is 100, calibrate the channel to 1000. This is still well within the

upper limit of 2040 and offers much higher resolution than if the channel was calibrated to 0100.

From the factory, the RFC-1 will read a four-digit value between 0003 and 2039 with no decimal point. Programming

options include different scales, a decimal point, unit words and lead zero suppression. The Advanced Operation

section of this manual contains more information.

RFC-1 Installation page 3.10

3.4 Control Outputs

While the control relay contacts are rated for 120 volts AC, only low voltage AC or DC sources

should be connected to the RP-8. The large number of exposed terminals on this panel could

result in a hazardous condition to the installer or other personnel if high voltage were present.

Each RP-8 relay panel has eight “On/Raise” relay contacts and eight “Off/Lower” relay contacts. The output relay

contacts are form C (SPDT), floating, and rated at 120 volts AC, 5 amperes resistive, 2 amperes inductive. Both

normally open (NO) and normally closed (NC) contacts are available on the three conductor terminal block for each

relay.

The control relays on the RP-8 are momentary relays that operate as long as the control commands (* or #) are sent

to the RFC-1. An external latching relay must be used if maintained outputs are required. The appropriate output

relay of the RP-8 can be used to provide a control signal to the latching relay. Electrical or mechanical latching relays

can be used but electrical latching relays may chatter if there is a power supply glitch.

3.5 Telephone Interface

The RFC-1 should be connected to an ordinary (POTS) telephone line. In some cases a telephone line is either not

available or is prohibitively expensive. There are several alternatives to a regular telephone line that are compatible

with the RFC-1.

3.5.1 Cellular Telephone with an RJ-11 Adapter

It is possible to connect a cellular telephone to the RFC-1 in place of a telephone line. Some phone manufacturers

offer docking-station devices that equip an off-the-shelf cellular telephone with a standard RJ-11 jack. There are also

stand-alone devices that combine the radio and emulation hardware in one device. Both types of devices emulate a

standard telephone line including dial tone, ring voltage and battery.

Most devices of this type operate better in a typical transmitter environment with an external antenna and a constant

power supply. Some manufacturers offer these items as part of their product line. There are also many aftermarket

devices that may be useful. The best approach is to discuss your needs with your supplier to find a solution that

meets the needs of the specific site.

Most devices that emulate a telephone line generate a functional but non-standard ring signal on incoming calls. The

RFC-1 has a firmware adjustment to help it recognize the non-standard ring signal. The Advanced Programming

section of the RFC-1 documentation provides details on making this adjustment.

3.5.2 Fixed Location Cellular Telephones

An alternative to using a mobile cell phone with an RJ-11 adapter is to use a phone designed specifically for fixed

locations. These devices combine the wireless radio and line emulation hardware into one device.

Fixed location devices tend to cost more than docking stations but they are typically more flexible and more robust

then their low-cost counterparts. For instance, most fixed-location devices easily support an external antenna.

This manual suits for next models

1

Table of contents

Popular Remote Control manuals by other brands

Universal Electronics

Universal Electronics Apple TV Remote for Video Service Providers user manual

Tripp Lite

Tripp Lite Keyspan URM-15T quick start guide

Comfortaire

Comfortaire B-SMA owner's manual

WhisperPower

WhisperPower WP-BC Instructions for use

Icom

Icom IC-RM2 instruction manual

Fly Sky

Fly Sky FS-T6 instruction manual

Microtech

Microtech e-Trap quick start guide

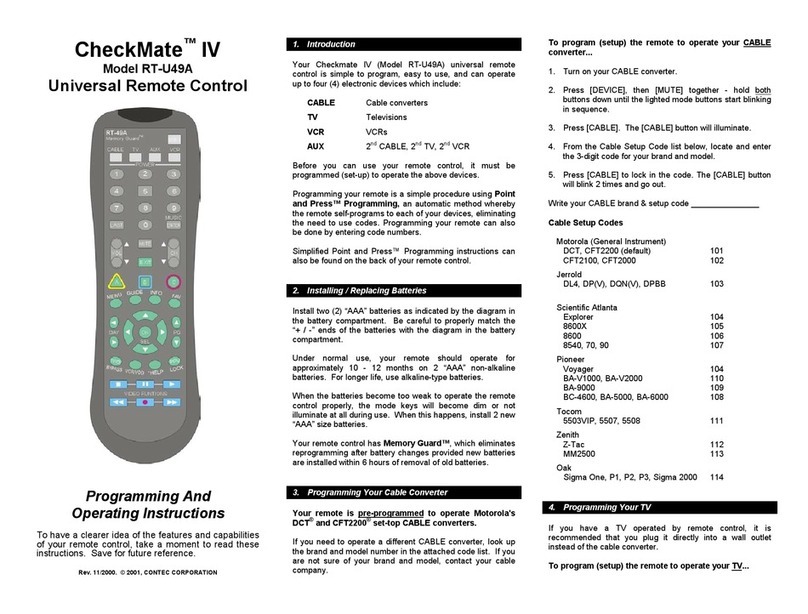

Contec

Contec CheckMate IV RT-U49A Programming and operating instructions

Contro l4

Contro l4 C4-SR260 manual

Sky Master

Sky Master Universal Remote Control user manual

mundoclima

mundoclima KJRH-120K/BMKO-E Owners & installation manual

One Forall

One Forall URC-7140 user manual