Sinee EM100-0R4-1B User manual

User Manual

EM100 Mini Inverter

1

Preface

Thank you for purchasing EM100 series mini inverter.

Document No.: 31010008

Version No.:103

Issue Date: 06/03/2013

EM100 mini inverter is a compact, intuitive, reliable and performing AC variable speed

drive for 3-phase induction motors.

This manual offers the general information of installation, wiring, function parameters,

daily maintenance, and fault diagnosis of EM100 mini inverter.

It is the duty of any user to perform the appropriate, correct installation or configuration

of the optional parameters of the devices. Neither SINEE nor its distributors shall be

responsible or liable for misuse of the information contained herein or mismatching the

inverter with the motor.

In the interests of commitment to a policy of continuous development and improvement,

SINEE reserves the right to update the specification of the product or its performance, or

the content herein without notice.

More updates and information are available at www.sinee.cn.

User Manual

EM100 Mini Inverter

2

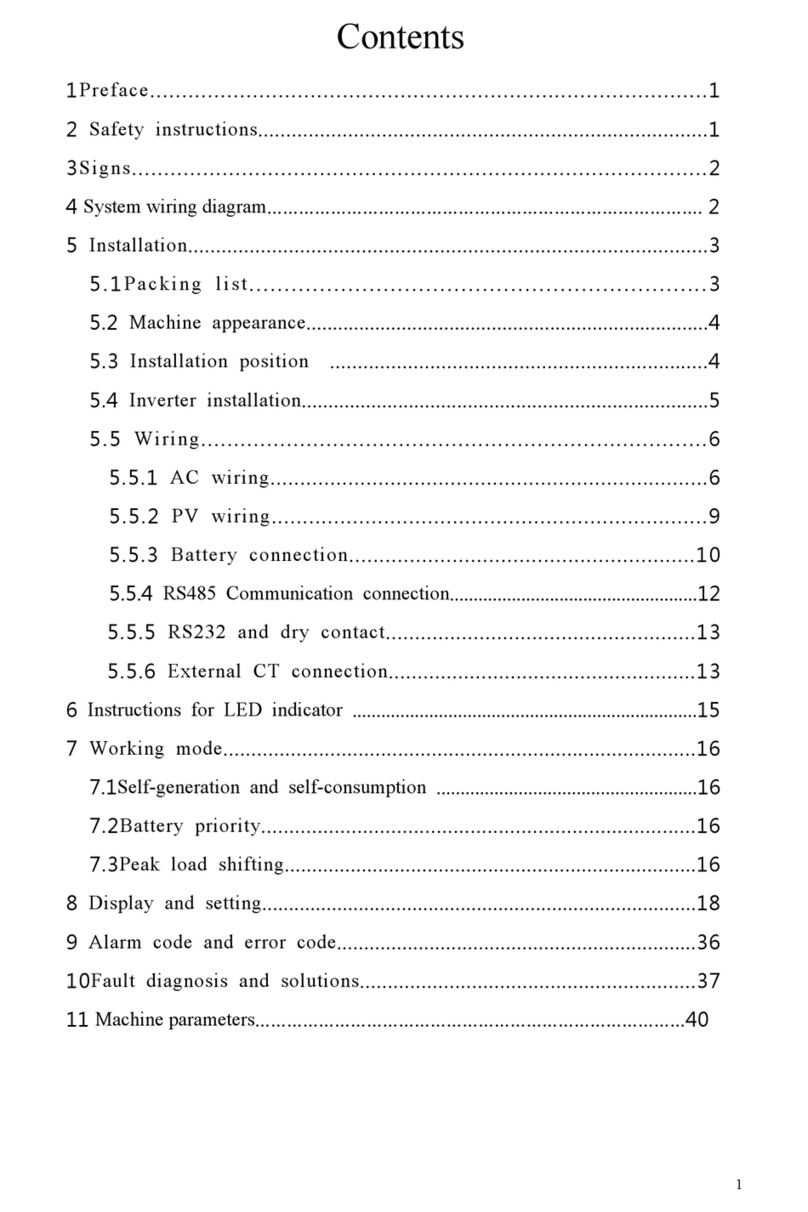

CONTENTS

1. SAFETY INFORMATION ..........................................................................................3

1.1SAFETY PRECAUTIONS............................................................................................3

1.2 PRECUATIONS ...........................................................................................................6

2. OVERVIEW ..................................................................................................................7

2.1 VERIFYING PRODUCT ...............................................................................................7

2.2 MODEL NUMBERING SCHEME AND NAMEPLATE .....................................................7

2.3 MODEL NUMBER ......................................................................................................8

2.4 TECHNICAL SPECIFICATIONS ....................................................................................8

2.5 OUTLOOK ...............................................................................................................11

2.6 OVERALL AND INSTALLATION DIMENSIONS ..........................................................12

3. INSTALLATION ........................................................................................................14

3.1 MECHANICAL INSTALLATION .................................................................................14

3.2 WIRING ...................................................................................................................23

4. KEYPAD OPERATION.............................................................................................38

4.1 KEYPAD ..................................................................................................................38

4.2 FUNCTION CODE CHECK AND EDITING METHOD ...................................................39

5. PARAMETER TABLES ............................................................................................43

5.1 FORMAT OF PARAMETER TABLES...........................................................................43

5.2 PARAMETER TABLES ..............................................................................................43

6. PARAMETER DESCRIPTION ................................................................................59

7. TROUBLESHOOTING ...........................................................................................102

7.1 FAULT AND CORRECTIVE ACTION ........................................................................102

7.2 COMMON FAULT AND TROUBLESHOOTING ..........................................................104

8. EMC(ELECTROMAGNETIC COMPATIBILITY) ............................................107

9. MAINTENANCE AND INSPECTION ..................................................................110

9.1 MAINTENANCE AND INSPECTION..........................................................................110

9.2 OUTLINE OF WARRANTY ......................................................................................111

APPENDIX A: EM100 MODBUS COMMUNICATION PROTOCOL.................112

1. APPLICATION SCOPE...............................................................................................112

2. PHYSICAL INTERFACE.............................................................................................112

3. PROTOCOL FROMAT................................................................................................112

4. EXPLANATION OF COMMAND .................................................................................112

5. DESCRIPTION OF PROTOCOL FORMAT ....................................................................114

6. EXAMPLE ................................................................................................................117

APPENDIX B: ACCESSORIES..................................................................................119

User Manual

EM100 Mini Inv

e

D

l

a

p

C

p

t

h

o

1.1 Safety Preca

u

Before Installat

i

Dange

r

1.

Do not in

broken.

2.

Do not in

inverter.

Dange

r

1.

Be caref

u

2.

Do not u

s

3.

Do not to

Installation:

Dange

r

1.Installati

o

2.Do not u

n

Cautio

1.

Do not le

a

2.

Install the

3.

Consider

t

a cabinet.

e

rter

3

1. Safety I

n

D

anger: The addition of this

a

bel indicates that an electr

i

ersonal injury if the instructi

o

C

aution: This is the safety

otential personal injury haz

a

h

is symbol to avoid possible i

n

r other devices.

u

tions

i

on

r

stall the product if the packa

g

stall the product if the label o

r

u

l of carrying or transportatio

n

s

e damaged product or the in

v

uch the parts of control syste

m

r

o

n base shall be metal or othe

r

n

screw the fixing bolts, espec

i

n

a

ve cable strips or screws in t

h

product at the

p

lace with les

s

t

he installation space for cool

i

n

formation

symbol to a Danger or War

n

i

cal hazard exists, which w

i

o

ns are not followed.

alert symbol. It is used to

a

rds. Obey all safety messag

e

n

jury or

a risk of damage to

g

e is with water, or compone

n

n the package is not identical

n

. Risk of devices damage.

v

erte

r

s missing component. R

i

m

with bare hands. Risk of E

S

r

non-flammable material. Ri

s

i

ally the bolts with red mark.

h

e inverter. Risk of inverter d

a

s

vibration and no direct sunli

g

i

ng

p

urpose when the inverte

r

n

ing safety

i

ll result in

alert you to

e

s that follow

the products

n

t is missing or

to that on the

i

sk of injury.

S

D hazard.

s

k of fire.

a

mage.

g

ht.

r

is installed in

User Manual

EM100 Mini Inv

e

Wiring:

Dange

r

1.Wiring

m

2.Circuit-

br

3.Be sure

t

standard

w

4.Groundi

n

5.Dual key

p

Cautio

1.Never c

o

inverter.

P

inverter

d

2.Be sure t

h

should b

e

3.Do not c

o

4.Tighten t

e

5.Do not c

o

6.Do not

c

circuits.

O

7.Do not di

Before Power-o

n

Cautio

1.

Verify th

a

wiring o

f

inverter

a

Risk of i

n

2.

Never pe

r

Risk of a

c

Dange

r

1.

Inverter s

electrical

2.

Wiring o

f

accident.

e

rter

4

r

m

ust be performed by authoriz

e

r

eaker should be installed bet

w

t

hat the power supply is off

w

iring. Risk of electrical haz

a

n

g terminal must be grounded

.

p

ad is not recommended. Ris

k

n

o

nnect input power supply c

P

ay attention to the termina

l

d

amage.

h

at the wiring meets EMC re

q

e

in recommended sizes. Risk

o

nnect braking resistor to DC

e

rminals with screw drivers o

o

nnect phase-shifting capacit

o

c

onnect the solenoid switch

O

therwise, it will trigger over

c

sconnect internal wires of in

v

n

n

a

t the input voltage is identic

a

f

input terminals R, S, and T a

n

a

nd its peripheral circuits, and

n

verter damage.

r

form voltage withstanding te

c

cident.

r

hall be powe

r

-on only after t

h

hazard.

f

all peripherals should abide

b

e

d and qualified personnel. R

i

w

een inverter and the mains.

R

before wiring, and ground

i

a

rd.

.

Risk of electrical hazard an

d

k

of unexpected danger.

able to output terminals U,

l

symbols, connect them cor

r

q

uirements and local safety st

a

of accident.

bus terminal & . Risk o

f

f specified torque. Risk of fir

e

o

r and LC/RC noise filter to o

u

and electromagnetic conta

c

c

urrent protection, o

r

damage

v

erter. Risk of inverter damag

e

a

l to the rated voltage of prod

u

n

d o

u

t

p

ut terminals U, V, an

d

all wires should be in good c

st on inverter, it has been do

n

h

e front cover is assembled.

R

b

y the guide of this manual.

R

i

sk of danger.

R

isk of fire.

i

nverter as per

d

fire.

V, and W of

r

ectly. Risk of

a

ndard. Cables

f

fire.

e

.

u

tput circuits.

c

tor to output

inverter.

e

.

u

ct, correct

d

W, wiring of

onnection.

n

e at ex-works.

R

isk of

R

is

k

of

User Manual

EM100 Mini Inv

e

After Power-o

n

Dange

r

1.

Do not to

electrical

2.

Do not to

electrical

3.

After po

w

automati

c

or wiring

Dange

r

1.

If autotu

n

Risk of a

c

2.

Do not c

h

During Operati

o

Dange

r

1.

Do not to

burning.

2.

Non-

p

ro

fe

injury or

d

Cautio

1.

Prevent a

n

device d

a

2.

Do not c

o

damage.

Maintenance

Dange

r

1.

Maintain

2.

Maintain

b

etween

D

charge o

n

3.

Mainten

a

p

ersonal

i

4.

Paramete

r

should b

e

e

rter

5

n

r

uch the inverter and its perip

h

hazard.

uch any input/output termina

l

hazard.

w

er is on at the first time, inv

e

c

ally. Meanwhile, do not touc

h

terminal of moto

r

with bare

h

r

n

ing is required, be careful of

c

cident.

h

ange the defaults of paramet

e

o

n

r

uch cooling fans, heatsink or

fe

ssionals shall not detect sig

n

d

evice damage.

n

n

y foreign items from being l

a

mage.

o

ntrol start/stop of inverter by

r

and inspect devices after po

w

and inspect inverter only aft

e

D

C bus terminals & , an

d

n

capacitor may cause

p

erson

a

a

nce and inspection can only

b

i

njury.

r

setting is required if inverte

r

e

performed after powe

r

-off.

h

eral circuits with wet hands.

l

s of inverte

r

with bare hands

.

e

rter will detect external circu

i

h

wiring terminals U, V, and

W

h

ands. Rick of electrical haza

r

personal injury when motor i

s

e

rs. Risk of devices damage.

discharge resisto

r

with bare

h

n

als during operation. Risk of

eft in the devices during ope

r

ON/OFF of contactor. Risk

o

w

er is off. Risk of electric haz

a

e

r the voltage is lower than D

C

d

power is off for 5 minutes.

T

a

l injury.

b

e performed by professional

s

r

has been replaced. Plug-in

&

Rick of

.

Rick of

i

t

W

of inverter,

r

d.

s

running.

h

ands. Risk of

personal

r

ation. Risk of

o

f device

a

rd.

C

36V

T

he residual

s

. Risk of

&

plug-out

User Manual

EM100 Mini Inverter

6

1.2 Precautions

Motor Insulation Inspection

When the motor is used for the first time or when the motor is reused after being kept, or

when periodical inspection is performed, insulation inspection shall be conducted with

motor so as to avoid damaging the inverter because of the insulation failure of the motor

windings. The motor wires must be disconnected from the inverter during the insulation

inspection. It is recommended to use the 500V megameter, and the insulating resistance

measured shall be 5Mat least.

Motor Thermal Protection

If the motor rating does not match that of the inverter, especially when the rated power

of the inverter is higher than that of the motor, adjust motor protection parameters in the

inverter or install thermal relay to protect motor.

Operating with the Frequency Higher than Grid Power Frequency

Output frequency of EM100 is 0.00Hz ~ 320.00Hz. If EM100 is required to operate

above 50.00Hz, please take the endurance of mechanical devices into consideration.

Mechanical Vibrations

Inverter may encounter mechanical resonance point of the load device at certain output

frequencies which can be avoided by setting the skip frequency parameters of the

inverter.

Motor Heat and Noise

Since output voltage of inverter is PWM wave and contains a certain amount of

harmonics, so that the temperature, noise and vibration of the motor will be higher than

those when the inverter runs at grid power frequency.

Piezosistor or the Capacitor Improving Power Factor on Output Side

The inverter outputs PWM wave, do not install capacitor to improve power factor or

piezosistor for lightning protection on output side. Otherwise, it will trigger inverter

instantaneous overcurrent or even damage inverter.

Applied with the Rated Voltage

Apply EM100 with the rated voltage. Failure to comply will damage inverter. If required,

take a transformer to boost or step-down voltage.

Do Not Apply a 3-Phase Input Inverter to 2-Phase Input Applications

Do not apply a 3-phase input EM100 inverter to 2-phase input applications. Otherwise, it

will result in faults or damage inverter.

Lightning Protection

EM100 has integrated lightning over-current protection device which has certain

self-protection capacity against the lightning. Additional protection devices have to be

installed between inverter and power supply in the area where lightning occurs

frequently.

Altitude Derating

In altitudes above 1000m above sea level, the derating is required because of poor

cooling effect due to rare air. Contact SINEE for technical support.

Cautions for Inverter Disposal

The electrolytic capacitors on the main circuit and PCBA may explode when they are

burnt. Emission of toxic gas may be generated when the plastic parts are burnt. Please

dispose inverter as industrial wastes.

User Manual

EM100 Mini Inv

e

2.1 Verifying Pr

o

zNever install

of injury.

Refer to the follo

w

If the products

a

purchase order.

Any part dama

g

Any screw loo

s

2.2 Model Num

b

Model N

u

Product Categ

o

EM: Inverter

Product Series

:

100: Mini Inve

r

Power Ratings

0R4

0.4kW

Namepla

t

e

rter

7

2. Ove

o

duct

C

an inverter that is damaged o

w

ing table, and check and ve

r

Item

a

re identical to the C

h

la

b

g

ed. C

h

s

ened. C

h

b

ering Scheme and Namepl

a

u

mbering Scheme

o

r

y

:

r

te

r

……

……

2R2

2.2kW

……

……

EM 100 –0R

7

t

e

Model No. : E

M

Rated Power : 0.

7

Input Voltage: A

C

Rated Current: 4.

8

Serial No.:

Shenzhe

n

rview

C

aution

r missing components. Other

w

r

ify the product.

Action

h

eck the devices reference ma

r

b

el.

h

eck the outlook if any dama

g

h

eck with a screwdriver if nec

a

te

7

–1 B

B: Integrated Brakin

g

None: No Brakin

g

Voltage Class:

1: 1-phase 220

V

3: 3-phase 380

V

M

100-0R7-1B

75

kW

C

220V

8

A

n

Sine Electric Co., Ltd.

w

ise, a risk

r

ked on the

g

es.

essary.

g

Uni

t

g

Unit

V

V

/415V

User Manual

EM100 Mini Inverter

8

2.3 Model Number List

Table 2-1 EM100 Model Number List

Rated Input

Voltage Model No. Motor

Power(kW)

Rated Output

Current(A)

1-phase AC220V

EM100-0R4-1B 0.4 2.8

EM100-0R7-1B 0.75 4.8

EM100-1R5-1B 1.5 8.0

EM100-2R2-1B 2.2 10.0

3-phase

AC380V/415V

EM100-0R7-3B 0.75 2.8

EM100-1R5-3B 1.5 4.8

EM100-2R2-3B 2.2 6.2

EM100-4R0-3B 4.0 9.2

EM100-5R5-3B 5.5 13

EM100-7R5-3B 7.5 17

EM100-011-3B 11 25

EM100-015-3B 15 32

2.4 Technical Specifications

Table 2-2 EM100 Technical Specifications

Items Specifications

Input

EM100-XXX-1B: 1-phase 220V (±20%)

50~60Hz (±5%)

EM100-XXX-3B:3-phase 380V/415V

(±20%), 50~60Hz (±5%)

Output

Max. Output Voltage 3-phase, from 0 to Usupply.

Rated Output Current 100% rated current non-stop output

Max. Overload Current

150% rated current for 1 minute, 180% rated

current for 10 seconds, 200% rated current

for 2 seconds

Basic

Control

Function

Control Mode V/F, SVC

Speed Setting Mode

Speed setting mode, analog setting, RS485

Communication setting, terminal numeric

setting, keypad setting.

Running Mode Keypad, control terminals (2-wire sequence,

3-wire sequence), RS485

Frequency Control

Range 0.00~320.00Hz

Input Frequency

Resolution

Numeric input:0.01Hz

Analog input: 0.10 Hz

User Manual

EM100 Mini Inverter

9

Governor Deflection 1:50

Speed Control

Accuracy 1.0%

Acceleration/

Deceleration Time 0.01~600.00 seconds

V/F Features Rated output voltage: 5%~100% adjustable

Frequency base:20.00~320.00Hz adjustable

Torque Boost Automatic torque boost, fixed torque boost

curve, customer defined V/F curve scaling

Start Torque 150%/1Hz

AVR

AVR is active while output voltage remains

unchanged if input voltage is varying.

Accuracy: ±10V at rated input voltage

Automatic Current

Limit

Automatically limit output current, avoid

frequent overcurrent trip

DC Brake Brake time:0~30S

Brake current: 150% rated current

Signal Input Source

Numeric, analog voltage, analog current,

preset speed, simple PLC, Modbus

communication, wobbbulation frequency,

and PID. Primary frequency setting and

auxiliary frequency setting integrated and

terminal switch.

Input/

Output

Function

Auxiliary Power

Supply 10V/10mA , 24V/50mA

Numeric Input

Terminal

Internal electrical impedance: 27k

Acceptable external input:0~20V, the

terminal is on at low level.

Maximum input frequency: 1kHz

6 numeric programmable input terminals,

user can define terminal functions via

function code.

Analog Input

Terminals

1 voltage input:0~10V, and another input

can be configurated as a current input: 4~

User Manual

EM100 Mini Inverter

10

20mA or a voltage input:0~10V

Input impedance:

voltage input: 1M, current input: 250

Accuracy: 0.2%

Numeric Output

Terminal

1 programmable OC output

Max. load capacity: 50mA/24V

Output frequency range:0~1kHz

1 programmable relay output, EA-NO,

EB-NC, EC-Common port

Contact capacity: 3A/AC250V

Power factor:>0.4 or 1A/DC30V

Analog Output

Terminal

1 programmable analog output terminal,

output: 0~10V

Max. load capacity: 2mA

Accuracy: 0.1V

Display LED 5-bit display, 8 input keys

Protection Protections

Overcurrent, overvoltage, input/output phase

loss, output short-circuit, overheating, and

etc.

Application

Conditions

Installation Site

Indoor, with altitude less than1,000 meters,

free from dust and corrosive gas, and direct

sunlight

Ambient Temperature

-10℃~+40℃. In the temperature range +40

°C…+50 °C, the rated output current is

decreased by 1% for every additional 1 °C.

20%~90%RH (no condensation)

Vibration ﹤0.5g

Storage Temperature -20°C~+65°C

Installation Method Wall mounting

Protection Grade IP20

Cooling Method Forced air cooling

Noise 38-62dB/A(See 3.1.4.3 for detail.)

Safety Standard IEC61800-5-1:2007

EMC Standard IEC61800-3: 2004

User Manual

EM100 Mini Inv

e

2.5 EM100 Outl

o

Housin

g

Keyp

a

Term

i

Cove

r

Contr

o

e

rter

11

o

ok

g

Uppe

r

a

d

i

nal

r

o

l Terminal Power

Terminal

DIN Rail Release

B

EM10

0

Main Air In

l

Namepl

a

Air Outl

e

Housi

n

B

a

Main Air Ou

t

B

utton

0

ID

l

e

t

a

te

e

ts

n

g

a

se

t

le

t

User Manual

EM100 Mini Inverter

12

2.6 Overall and Installation Dimensions

2.6.1 Overall Dimensions

Model

No.

Unit

(mm)

EM100-0R4-1B

EM100-0R7-1B

EM100-1R5-1B

EM100-2R2-1B

EM100-0R7-3B

EM100-1R5-3B

EM100-2R2-3B

EM100-4R0-3B

EM100-5R5-3B

EM100-7R5-3B

EM100-011-3B

EM100-015-3B

W 95 110 130 150

W1 85 100 118 138

W2 11 11 / /

H 152 163 220 289.5

H1 142 153 209 272

H2 159 170 / /

H3 130.5 140.5 / /

H4 110.5 121.5 / /

D 117 132 152.5 173

D1 130 145 165.2 185.7

D2 74 84 104.7 125

d1 4.5 4.5 5.5 5.5

d2 4.5 5 / /

N.W./Kg 1 1.5 2.8 5.0

Frame SIZE1 SIZE2 SIZE3 SIZE4

Remarks:

D2:The distance between the entrance hole of power cable and the installation plate.

Symbol / indicates that the size is not available.

2.6.2 Diagram of Overall and Installation Dimensions

User Manual

EM100 Mini Inverter

13

2.6.3 Keypad Dimensions

2.6.4 Dimensions of Keypad Chassis (Accessories) and Mounting Holes

Remarks: Please contact distributors or SINEE for keypad chassis if needed.

User Manual

EM100 Mini Inv

e

3.1 Mechanical

I

3.1.1 Installatio

n

Caution

1. Always h

o

Risk of i

n

2. Installati

o

Risk of fi

r

3. Install a

temperat

u

Overheati

n

3.1 .2 Installatio

n

Consideratio

n

zGood ventil

a

zAmbient te

m

zNo high te

m

other liquid

d

zNever instal

l

zNo direct su

n

zNo flammab

zNo dust, flo

a

zFirm and ste

3.1.3 Precaution

Take protective

p

articles or dust

objects after inst

a

3.1.4 Installatio

n

A fan is integrat

e

for the purpose

o

EM100 and its

pe

and vertically. S

e

and mass airflow

e

rter

14

3. Inst

a

I

nstallation

n

Recommendations

o

ld the case when carrying

t

n

jury if only holding the termi

o

n base shall be metal or ot

h

r

e if installing the inverter on

cooling fan when instal

l

u

re shall be lower than 40℃

n

g may result in fire or other

a

n

Site

n

s for installation site:

a

tion indoo

r

m

perature: -10°C~+40°C, 20

%

m

perature and high moisture,

h

d

rops

l

on flammable materials

n

light

le, corrosive gas or liqui

d

a

ting fiber or metal particles

ady installation base

s

measures during installatio

n

from entering the inverter w

h

a

llation.

n

Direction, Space and Cool

i

e

d in EM100 for forced air co

o

f good cooling circulation.

e

ripheral objects. Multi-EM1

e

e followings for specific sp

a

.

a

llation

t

he inverter.

nal cover.

h

er non-flammable material

inflammable materials.

l

ing inverter in a cabin

e

at air inlet.

a

ccidents.

%

~90%RH(No condensatio

n

h

umidity:<90%RH, no wate

r

n

to prevent foreign matte

r

h

en drilling. Please take off

t

i

ng

oling. EM100 has to be insta

l

Sufficient spaces have to be

00 can be installed in parall

e

a

ce requirement, heat dissip

a

.

e

t, and air

n

)

r

drops or any

r

s like metal

t

he protective

l

led vertically

left between

e

l horizontally

a

ting capacity

User Manual

EM100 Mini Inverter

15

3.1.4.1 Installation Space of Single EM100

3.1.4.2 Vertical Installation of Multi-EM100

User Manual

EM100 Mini Inverter

16

3.1.4.3 Table of Heat Dissipating Capacity (HDC), Mass Airflow(MAF) and Noise

of Single EM100

Model No. Frame MAF

(CFM)

MAF

(m3/h)

HDC

(W)

Noise

(dB/A)

EM100-0R4-1B SIZE1 8 13.6 42 38

EM100-0R7-1B 8 13.6 70 38

EM100-1R5-1B

SIZE2

13 22 90 40

EM100-2R2-1B 13 22 120 40

EM100-0R7-3B 13 22 75 40

EM100-1R5-3B 13 22 85 40

EM100-2R2-3B 13 22 105 40

EM100-4R0-3B 13 22 150 40

EM100-5R5-3B

SIZE3

31.2 53 174 45

EM100-7R5-3B 31.2 53 252 45

EM100-011-3B 31.2 53 362 45

EM100-015-3B SIZE4 106 180 520 55

Remarks:

1. The values listed in the table refer to that the HDC and the MAF required when single

EM100 is mounted in an enclosed space.

2. The HDC is calculated based on the rated voltage, rated current and preset carrier

frequency of each model.

3. If multi-EM100 has to be installed in an enclosed space, please add HDC and MAF.

3.1.4.4 Load Shedding Curve

User Manual

EM100 Mini Inverter

17

3.1.5 Installing with Screws

a. 4-hole Installation

See Overall and Installation Dimensions for the dimensions of 4-hole (Hole a). Refer to

Figure a, and punch 4 holes on the installation panel. Put the inverter against the panel

and mate 4 holes, and then tighten screws in the 4 holes (Tighten any of the 2 screws in

diagonal position, tighten 4 holes with screws for strengthened installation. Screw size:

M4xL, L>12mm, tightening torque: 1N.m±10%)

Figurea Figureb

Do not take the sunk screws as shown in the

picture. Otherwise, inverter may be damaged.

Take screws combined with springs and plain

gaskets to install inverter.

User Manual

EM100 Mini Inverter

18

b. 3-hole Installation

See Overall and Installation Dimensions for the dimensions of 3-hole (Hole b). Refer to

Figure b, and punch 3 holes on the installation panel with screws in each of them. Do not

tighten the screws, leave a distance of 7.5~9mm between the gaskets and installation

panel, hung the inverter onto the 3 screws from top to bottom (Screw size: M4xL,

L>16mm, tightening torque: 1N.m±10%), and then tighten the 2 screws at the bottom.

3.1.6 DIN Rail Installation (DIN Rail Width: 35mm)

See Overall and Installation Dimensions for the dimensions of DIN rail. Refer to the

following Figure, install and remove the inverter by pushing the DIN rail release button.

DIN

Rail

Mount multi-inverter in parallel with DIN rail:

3.1.7 Flange Mounting (For the Models with Frame SIZE3&4 )

Unit

(mm)

Frame

W L W1 W2 W3 L1 L2 L3 d H1 H2

SIZE3 138 223 170 157 37 261 249 99 5.5 84 81

SIZE4 156 290 190 177 37 329 317 142 5.5 131 70

Remarks Size of

mounting hole

Size of depth

User Manual

EM100 Mini Inverter

19

Remarks:

Instruction of assembling the flange: Assemble the flange left and right on the left and

right sides of EM100 first, fasten the screws on the top and at the buttom, locate the

inverter with flange into the mounting hole, and tighten the screws to finish the

assembly.

User Manual

EM100 Mini Inverter

20

3.1.8 Disassembly and Assembly of Keypad

a. Disassemble keypad. See following Figure: Push the buckle on the keypad in

Direction 1 first, and then lift up the keypad in Direction 2.

b. Assemble keypad. See following Figure: Place keypad in the slot in Direction 1, and

then press the keypad in Direction 2 until it clicks into right place.

This manual suits for next models

11

Table of contents

Other Sinee Inverter manuals

Popular Inverter manuals by other brands

Tripp Lite

Tripp Lite PowerVerter RV1250ULHW Specifications

Centech

Centech 64867 owner's manual

Tripp Lite

Tripp Lite APSWX Series owner's manual

DualLite

DualLite LG125S Installation instructions and user manual

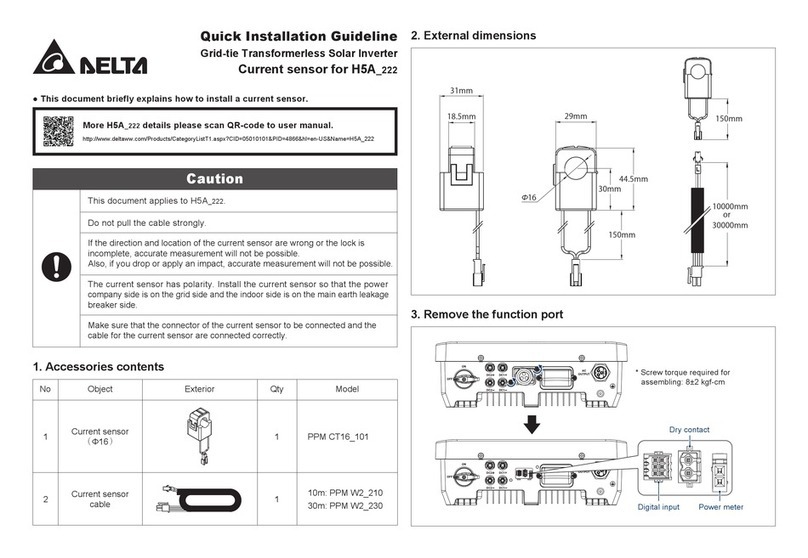

Delta

Delta PPM CT16 101 Quick Installation Guideline

APsystems

APsystems QS1 Installation and user manual