Sinee EM500 User manual

EM500 Open-Loop Vector Control Inverter User Manual

1

Preface

Thank you for purchasing EM500 series inverter.

Document No.: 31010076

Issue Date: 2017-03

Version: 102

EM500 inverter is an open-loop vector control inverter that supports: 3-phase AC

induction motor and permanent magnet synchronous motor; multiple internationally

leading drive control technologies, including improved vectored VF control technology

(VVF) and sensorless vector control technology (SVC); speed and torque control; I/O

expansion card, communication bus expansion card and special function expansion card.

EM500 dedicates to any application, so it can be applied to nearly all open-loop

control applications, for example fan, water pump (water supply under constant pressure),

air compressor, winding and unwinding function, and direct wire-drawing machine. For

high-precision closed loop application, please select EM600.

Main features:

Built-in DC reactor starting from 11kW, reducing input current distortion,

improving power factor and enhancing reliability of the product;

High torque control precision: SVC/±8% rated torque;

Wide speed regulation range and high control precision: VF/1:50, SVC/1:200 and

±0.2% rated speed;

Loading capacity at low frequency: VF/1Hz/150% and SVC/0.25Hz/150%;

Multiple types of guarantees: Overvoltage stall, rapid current limit, overload

protection, overheating protection, off-load protection, overspeed protection, etc.;

Support I/O expansion: 4 numeric inputs, 1 numeric output, and one -10V - 10V

voltage input;

Support communication bus expansion and realize various industrial networking:

485 bus, Profibus-DP network, CANopen network and DeviceNet network;

Support special function expansion: constant pressure water supply and so on.

Please read this manual carefully before using EM500 and keep it properly.

Before connecting inverter and a motor for the first time, please select proper

motor type (induction motor or synchronous motor) and configure motor nameplate

parameters including rated power, rated voltage, rated current, rated frequency,

EM500 Open-Loop Vector Control Inverter User Manual

2

rated rotation speed, motor connection and rated power factor.

Since SINEE is committed to the development and improvement of products and

product documents, this manual will be updated without notice.

Latest updates and additional information are available at www.sineedrive.com.

EM500 Open-Loop Vector Control Inverter User Manual

3

Safety Information

In this manual, there are two types of safety information.

Danger: The label indicates that a failure to follow instructions can result in

serious injury or even death.

Caution: The label indicates that a failure to follow instructions can result in

moderate or slight injury and device damage.

Please read this chapter carefully before system installation, debugging and

maintenance and always follow the safety precautions below during operation. SINEE

will not undertake any damage or loss caused by a failure to follow the instructions.

Safety Precautions

Before Installation:

Danger

1. Do not install inverter if its package is wetted or any its component is missing or broken.

2. Do not install inverter if the label information on its package is not identical to that on

inverter.

Caution

1. Be careful when carrying or transporting inverter so as to avoid damage!

2. Do not use inverter if it is damaged or any component is missing so as to avoid injury!

3. Do not touch the parts of control system with bare hands so as to avoid ESD!

During Installation:

Danger

EM500 Open-Loop Vector Control Inverter User Manual

4

1. Installation base shall be metal or other non-flammable material so as to prevent fire

risk.

2. Do not unscrew fixing bolts, especially bolts with red mark.

Caution

1. Ensure that no cable strips or screws are dropped into inverter so as to avoid damage to

inverter.

2. Install inverter at a place with less vibration and no direct sunlight.

3. Consider the installation space for cooling purpose when inverter is installed in a closed

cabinet or space.

Wiring:

Danger

1、Wiring must be performed by authorized and qualified personnel so as to avoid

unexpected accidents.

2、A circuit breaker must be installed between inverter and the mains so as to prevent fire

risk.

3、Ensure that power is off before wiring, and ground inverter in accordance with the

applicable wiring standard so as to avoid electric shock.

4、Grounding terminal must be grounded reliably so as to avoid electric shock and fire

risk.

Danger

1、Never connect input power supply cable to output terminals U, V or W of inverter. Pay

attention to terminal symbols and connect to the terminals correctly so as to prevent risks of

damaging inverter.

2、Be sure that wiring meets EMC requirements and local safety standards. Cable should

be in recommended sizes so as to prevent accident risk.

3、Do not connect braking resistor to DC bus terminals + and – so as to prevent fire risk.

4、Tighten terminals with a screwdriver of specified torque so as to prevent fire risk.

5、Do not connect a phase-shifting capacitor or an LC/RC noise filter to output circuits.

6、Do not connect a solenoid switch or an electromagnetic contactor to output circuits.

Otherwise, it will trigger the action of the overcurrent protection circuit or even damage the

internal parts of inverter.

7、Do not disconnect internal cable of inverter, or else this can possibly damage the

internal parts of inverter.

Caution

1. Ensure the distribution lines accord to EMC requirements and the local area's safety

EM500 Open-Loop Vector Control Inverter User Manual

5

standards. The using wire size refers to the preferred recommendation. Otherwise, an

accident may occur!

2. Never connect the braking resistor directly between the DC bus and the terminals.

Otherwise cause a fire!

3. Tighten the terminal with the specified torque screwdriver, otherwise there is the danger

of fire.

4. Do not connect the phase-shift capacitor LC / RC noise filter to the output circuit

5. Do not connect the electromagnetic switch or electromagnetic contactor to the output

circuit. Otherwise, the inverter over-current protection circuit is activated when severe, can

cause damage to the inverter.

6. Do not disassemble the connecting cable inside the inverter. Otherwise, the inverter may

be damaged.

Before Power-on:

Danger

1、Verify that input voltage is identical to the rated voltage of inverter, input terminals R,

S and T and output terminals U, V or W are correctly connected, there are no short circuit

phenomena for the wiring of inverter and its peripheral circuits, and all wires are in good

connection. Otherwise, this may result in inverter damage.

2、Never perform voltage withstanding test on inverter, because it has been done at the

factory. Otherwise, this may result in accident.

Caution

1、The front cover of inverter must be closed before inverter is powered on. Otherwise, it

may result in an electric shock.

2、The wiring of all peripherals must be conducted in accordance with the guidance of

this manual. Otherwise, it may result in an electric hazard.

After Power-on:

Danger

1. Do not touch inverter or its peripheral circuits with wet hands to avoid the electric

shock.

2. If the indicator is off or the keypad does not display any information after power-on,

EM500 Open-Loop Vector Control Inverter User Manual

6

please cut off the power supply immediately. Never touch any terminal of R, S or T of

inverter or the connecting terminals with hands or a screw driver, or else an electric shock

accident may occur. Contact our customer service personnel immediately after cutting off

the power.

3. After being powered on, inverter will automatically check the safety of the external

strong circuit automatically. Therefore, do not touch wiring terminal U, V or W of inverter

or the wiring terminal of the motor with bare hands, otherwise it will result in electric

shock.

Caution

1、If you need to check parameter settings, be careful of personal safety when the motor

is running so as to avoid accidents.

2、Do not change default parameter setting without approval to avoid damage.

During Operation:

Danger

1、Never touch cooling fan, heat sink or discharge resistor with bare hands for checking

temperature, which may result in burning!

2、Only qualified technicians are allowed to detect signal during operation so as to

prevent personal injury or device damage.

Caution

1、Prevent any foreign items from being dropped into the device during operation, so as

to avoid damage to the device.

2、Do not control the start/stop of inverter by ON/OFF of the contactor so as to avoid

damage to the device.

Maintenance:

Danger

1、Maintain and inspect the device only after inverter is powered off for at least 10

minutes to avoid electric shock.

2、Maintain and inspect inverter only after its main circuit is powered off and CHARGE

indicator is off. Otherwise, the residual electric charge of capacitor may result in personal

EM500 Open-Loop Vector Control Inverter User Manual

7

injury.

3、Maintenance and inspection can be performed by well-trained technicians only, so as

to avoid personal injury or device damage.

4、Parameter setting is required if inverter has been replaced. Plug-in & plug-out should

be performed after power-off.

5、For synchronous motor, it will generate power when in rotation, please wait for at least

10 minutes after it stops rotating, and then disconnect the motor from the inverter,

otherwise there is risk of electric shock.

6、

Attentions

Motor Insulation Inspection

Motor insulation inspection shall be performed before using a motor for the first time or

left unused for some time or during routine inspection, in order to avoid damaging

inverter due to failure of insulation performance of motor winding. Make sure to

disconnect motor cable from inverter during inspection; 500V megohmmeter is

recommended. The obtained insulation resistance from test shall not be lower than 5MΩ.

Motor Thermal Protection

If the selected motor does not match with inverter in rated capacity, especially when its

rated power is lower than that of inverter, be sure to adjust motor protection parameters of

inverter or install a thermal relay in front of the motor to protect the motor.

Operation at Power frequency

Output frequency of inverter ranges from 0.00 Hz to 600.00 Hz. To use inverter at over

50.00 Hz, please consider the bearing capacity of mechanical device.

Motor Heat and Noise

Since output voltage of inverter presents a PWM waveform along with some harmonic

waves, the temperature rise, noise and vibration of motor would increase a little in

comparison with the running under power frequency.

Varistor or Power Factor Improvement Capacitor on Inverter Output

Inverter outputs PWM wave. Do not use inverter, if a power factor improvement

capacitor or a lightning varistor is on output side, which may easily result in transient

overcurrent of inverter, or even damage inverter.

Beyond Rated Voltage

Do not use EM500 inverter outside the operating voltage range specified in this manual,

which may easily damage its internal parts. If you have to do so, install a voltage rise or

reduction device for transformation.

EM500 Open-Loop Vector Control Inverter User Manual

8

Surge Protection

A surge protection device is installed in inverter to prevent it from induction lightning

stroke on a certain degree. Additional protection devices are required in front of inverter

in the places where thunder and lightning occur frequently.

Altitude and Derating

When inverter is used in an area at an altitude of over 1,000m, the cooling effect will

degrade, so it must be derated. For details, please consult SINEE.

Attentions at Inverter Scrapping

Burning the electrolytic capacitors of the mains and PCB may result in explosion and

burning plastic parts may generate toxic gas. Please handle them as industrial wastes

when inverter is scrapped.

EM500 Open-Loop Vector Control Inverter User Manual

9

CONTENTS

PREFACE....................................................................................................... 1

SAFETY PRECAUTIONS..................................................................................................... 3

ATTENTIONS....................................................................................................................7

1. OVERVIEW..............................................................................................14

1.1 EM500 MODEL LIST AND TECHNICAL SPECIFICATIONS.......................................... 14

1.2 EM500 OPERATION STATUS.................................................................................... 17

1.3 DESCRIPTION OF PARTS OF EM500 INVERTER......................................................... 22

2. INSTALLATION......................................................................................24

2.1 PRODUCT VERIFICATION.......................................................................................... 24

2.2 OVERALL AND INSTALLATION DIMENSIONS.............................................................25

2.3 CONSIDERATIONS FOR INSTALLATION SITE..............................................................29

2.4 INSTALLATION DIRECTION AND SPACE....................................................................30

2.5 ASSEMBLY AND DISASSEMBLY OF KEYPAD............................................................. 31

2.6 FLUSH MOUNTING................................................................................................... 32

3. WIRING.................................................................................................... 36

3.1 CONNECTION TO PERIPHERALS................................................................................ 36

3.2 WIRING MAIN CIRCUIT TERMINALS.........................................................................37

3.3 WIRING CONTROL CIRCUIT TERMINALS...................................................................48

3.4 EXTENDING KEYPAD WIRE...................................................................................... 60

3.5 WIRING VERIFICATION............................................................................................. 60

4. KEYPAD OPERATION.......................................................................... 61

4.1 KEYPAD FUNCTION.................................................................................................. 61

4.2 LED KEYPAD OPERATION MODE............................................................................ 63

4.3 FAULT MONITORING................................................................................................ 69

4.4 OPERATION MONITORING........................................................................................ 70

EM500 Open-Loop Vector Control Inverter User Manual

10

4.5 PARAMETER COPY................................................................................................... 70

4.6 FUNCTION OF M.K................................................................................................... 71

4.7 RUN/STOP.................................................................................................................71

5. TRIAL OPERATION...............................................................................72

5.1 TRIAL OPERATION PROCEDURE............................................................................... 72

5.2 ATTENTIONS FOR TRIAL OPERATION........................................................................74

6. FUNCTION CODE TABLE....................................................................76

6.1 PARAMETER DESCRIPTION....................................................................................... 76

6.2 FUNCTION PARAMETER TABLE.................................................................................78

7. PARAMETER DESCRIPTION............................................................154

7.1 F00 GROUP: GENERAL PARAMETER......................................................................154

7.2 F01 GROUP: MOTOR 1 PARAMETER...................................................................... 174

7.3 F02 GROUP: INPUT TERMINAL PARAMETER..........................................................179

7.4 F03 GROUP: OUTPUT TERMINAL FUNCTION PARAMETER.....................................196

7.5 F04 GROUP: START/STOP CONTROL PARAMETER.................................................208

7.6 F05 GROUP: VF CONTROL PARAMETER................................................................215

7.7 F06 GROUP: VECTOR CONTROL PARAMETER....................................................... 221

7.8 F07 GROUP: FAULT PROTECTION PARAMETER..................................................... 229

7.9 F08 GROUP: PRESET SPEED AND SIMPLE PLC PARAMETER................................. 237

7.10 F09 GROUP: PID FUNCTION PARAMETER........................................................... 244

7.11 F10 GROUP: COMMUNICATION FUNCTION PARAMETER...................................... 257

7.12 F11 GROUP: USER-DEFINED PARAMETER........................................................... 266

7.13 F12 GROUP: KEYPAD AND DISPLAY PARAMETER................................................ 268

7.14 F13 GROUP: TORQUE CONTROL PARAMETER...................................................... 278

7.15 F14 GROUP: MOTOR 2 PARAMETER.................................................................... 284

7.16 F15 GROUP: AUXILIARY FUNCTION.................................................................... 285

7.17 F16 GROUP: USER DEFINED FUNCTION PARAMETER..........................................298

7.18 F17 GROUP: VIRTUAL I/O FUNCTION PARAMETER.............................................305

EM500 Open-Loop Vector Control Inverter User Manual

11

7.19 F18 GROUP: MONITORING PARAMETER.............................................................. 310

7.20 F19 GROUP: FAULT RECORD PARAMETER.......................................................... 314

7.21 F25 APPLICATION OF WATER SUPPLY BASIC GROUPS.......................................317

7.22 F26 APPLICATION OF WATER SUPPLY ADVANCED GROUP.....................................327

7.23 F27 WINDING ROLLING APPLICATION..................................................................330

7.24 F28 AIR COMPRESSOR APPLICATION................................................................... 347

8. MOTOR PARAMETER AUTOTUNING............................................ 362

8.1 MOTOR PARAMETER AUTOTUNING........................................................................ 362

8.2 PRECAUTIONS BEFORE AUTOTUNING.....................................................................362

8.3 STEPS OF AUTOTUNING.......................................................................................... 363

9. TROUBLESHOOTING.........................................................................365

9.1 FAULTS...................................................................................................................365

9.2 WARNING ANALYSIS.............................................................................................. 373

9.3 FAULT ANALYSIS................................................................................................... 375

10. MAINTENANCE AND INSPECTION..............................................379

10.1 ROUTINE MAINTENANCE AND INSPECTION OF INVERTER.....................................379

10.2 WARRANTY INSTRUCTION FOR INVERTER.............................................................381

11. OPTIONS.............................................................................................. 382

11.1 BRAKING RESISTOR..............................................................................................382

11.2 BRAKING UNIT.....................................................................................................383

11.3 OPTIONS OF CABLE.............................................................................................. 383

11.4 OPTION CARD.......................................................................................................384

11.5 BASE.................................................................................................................... 385

11.6 UPPER MOUNTING HOLE......................................................................................388

11.7 COPPER ROW FOR INCOMING AND OUTGOING CABLE SWITCHOVER...................389

12. MODBUS COMMUNICATION PROTOCOL.................................391

12.1 APPLICATION SCOPE............................................................................................ 391

EM500 Open-Loop Vector Control Inverter User Manual

12

12.2 PHYSICAL INTERFACE.......................................................................................... 391

12.3 PROTOCOL FORMAT............................................................................................. 392

12.4 PROTOCOL DESCRIPTION..................................................................................... 414

12.5 EXAMPLE............................................................................................................. 417

13. CANSINEE COMMUNICATION PROTOCOL............................. 422

13.1 APPLICATION SCOPE............................................................................................ 422

13.2 PHYSICAL INTERFACES.........................................................................................422

13.3 PROTOCOL FORMAT............................................................................................. 423

13.4 BROADCAST MESSAGES....................................................................................... 431

13.5 ABNORMAL INFORMATION RESPONSE.................................................................. 432

13.6 ILLUSTRATE..........................................................................................................433

APPENDIX I. MULTI-FUNCTIONAL IO EXPANSION CARD

(EC-IO-A1)..................................................................................................438

I.1 GENERAL............................................................................................................... 438

I.2 INSTALLATION INSTRUCTIONS..............................................................................438

I.3 EXPANSION TERMINAL FUNCTION....................................................................... 439

APPENDIX II MULTI-FUNCTIONAL IO EXPANSION CARD 3

(EC-IO-A3)..................................................................................................441

II.1 GENERAL............................................................................................................. 441

II.2 INSTALLATION INSTRUCTIONS............................................................................ 441

II.3 EXPANSION TERMINAL FUNCTION......................................................................442

APPENDIX III PROFIBUS-DP EXPANSION CARD (EC-CM-P1)...443

III.1 GENERAL............................................................................................................443

III.2 INSTALLATION INSTRUCTIONS...........................................................................443

III.3 EXPANSION TERMINAL FUNCTION.................................................................... 444

APPENDIX IV CANOPEN EXPANSION CARD (EC-CM-C1)..........446

IV.1 GENERAL.............................................................................................................446

EM500 Open-Loop Vector Control Inverter User Manual

13

IV.2 INSTALLATION INSTRUCTIONS........................................................................... 446

IV.3 EXPANSION TERMINAL FUNCTION.....................................................................447

APPENDIX V DEVICENET EXPANSION CARD (EC-CM-D1)........449

V.1 GENERAL.............................................................................................................. 449

V.2 INSTALLATION INSTRUCTIONS.............................................................................449

V.3 EXPANSION TERMINAL FUNCTION...................................................................... 450

APPENDIX ⅥAIR COMPRESSOR EXPANSION CARD

(EC-CM-D1)................................................................................................453

Ⅵ.1 GENERAL.............................................................................................................453

Ⅵ.2 INSTALLATION INSTRUCTIONS........................................................................... 453

Ⅵ.3 EXPANSION TERMINAL FUNCTION.....................................................................454

APPENDIX ⅦCLOCK EXPANSION CARD (EC-TM-A1)..............456

Ⅶ.1 GENERAL.............................................................................................................456

Ⅶ.2 INSTALLATION INSTRUCTIONS........................................................................... 456

Ⅶ.3 EXPANSION TERMINAL FUNCTION....................................................................... 457

APPENDIX ⅧAPPENDIX VII. PHASE SEQUENCE EXPANSION

CARD (EC-PSP-A1).................................................................................. 458

Ⅷ.1 GENERAL.............................................................................................................458

Ⅷ.2 INSTALLATION INSTRUCTIONS........................................................................... 458

Ⅷ.3 EXPANSION TERMINAL FUNCTION....................................................................... 459

EM500 Open-Loop Vector Control Inverter User Manual

14

1. Overview

1.1 EM500 Model List and Technical Specifications

Rated voltage: 3-phase, 380 - 415VAC, 3-phase or single-phase 220 – 230VAC;

Applicable motor: 3-phase AC induction motor and permanent magnet synchronous

motor, power range: 0.75 - 630kW;

Maximum output voltage is identical to input voltage.

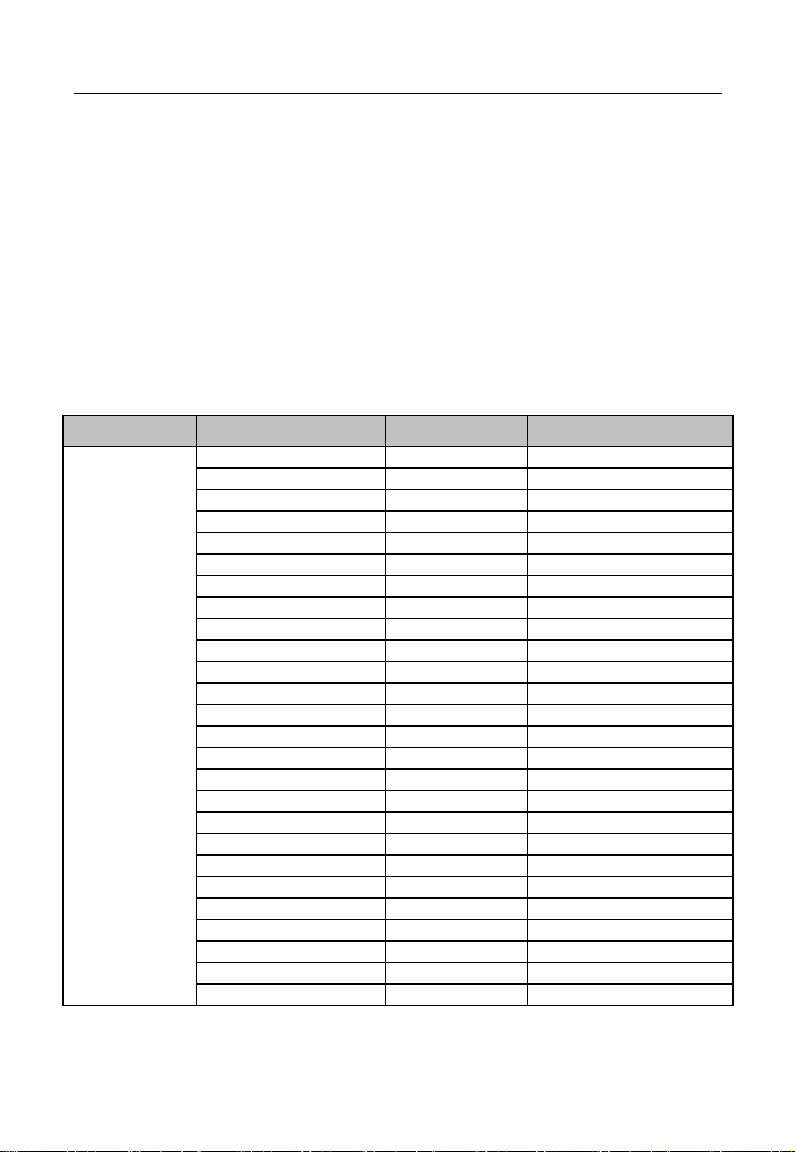

EM500 model and rated output current are shown in Table 1–1.

Table 1-1 EM500 Model List

Rated Voltage

Model

Motor Power (kW)

Rated Output Current (A)

3-phase,

380 - 415V

EM500-0R7G/1R5P-3B

0.75/1.5

2.5/4.2

EM500-1R5G/2R2P-3B

1.5/2.2

4.2/5.6

EM500-2R2G/3R0P-3B

2.2/3.0

5.6/7.2

EM500-4R0G/5R5P-3B

4.0/5.5

9.4/12

EM500-5R5G/7R5P-3B

5.5/7.5

13/17

EM500-7R5G/9R0P-3B

7.5/9

17/20

EM500-011G/015P-3B

11/15

25/32

EM500-015G/018P-3B

15/18.5

32/38

EM500-018G/022P-3B

18.5/22

38/44

EM500-022G/030P-3/3B

22/30

45/59

EM500-030G/037P-3/3B

30/37

60/73

EM500-037G/045P-3/3B

37/45

75/87

EM500-045G/055P-3/3B

45/55

90/106

EM500-055G/075P-3/3B

55/75

110/145

EM500-075G/090P-3/3B

75/90

150/169

EM500-090G/110P-3

90/110

176/208

EM500-110G/132P-3

110/132

210/248

EM500-132G/160P-3

132/160

253/298

EM500-160G/185P-3

160/185

304/350

EM500-185G/200P-3

185/200

357/372

EM500-200G/220P-3

200/220

380/410

EM500-220G/250P-3

220/250

426/456

EM500-250G/280P-3

250/280

465/510

EM500-280G/315P-3

280/315

520/573

EM500-315G/355P-3

315/355

585/640

EM500-355G/400P-3

355/400

650/715

EM500 Open-Loop Vector Control Inverter User Manual

15

EM500-400G/450P-3

400/450

725/810

EM500-450G/500P-3

450/500

820/900

EM500-500G/560P-3

500/560

900/1010

EM500-560G/630P-3

560/630

1010/1140

3-phase,

220~230V

EM500-0R7G/1R5P-2B

0.75/1.5

4.8/8.0

EM500-1R5G/2R2P-2B

1.5/2.2

8.0/10.0

EM500-2R2G/3R0P-2B

2.2/3.0

10.0/13.0

Single-phase

220~230V

EM500-0R7G/1R5P-1B

0.75/1.5

4.8/8.0

EM500-1R5G/2R2P-1B

1.5/2.2

8.0/10.0

EM500-2R2G/3R0P-1B

2.2/3.0

10.0/13.0

★the difference between inverter and motor shall not be more than two power ratings.

Please try to select a motor that matches with inverter in rated current.

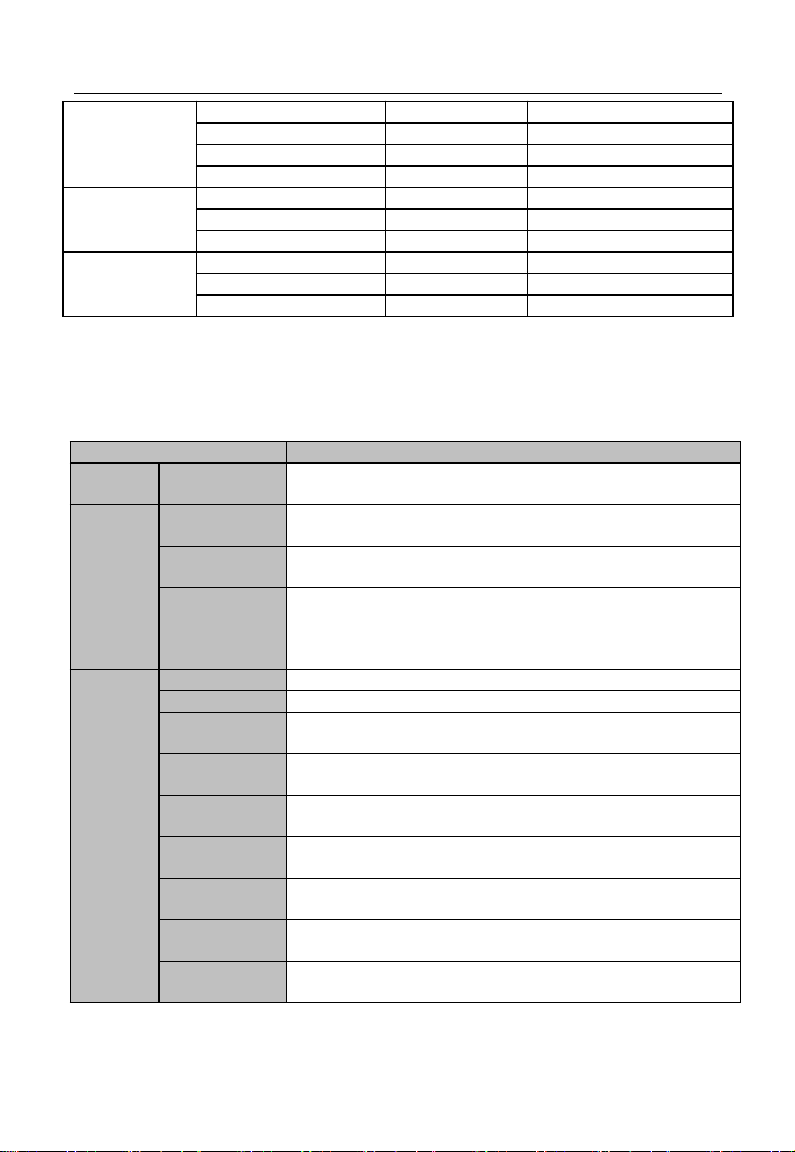

EM500 technical specifications are shown in Table 1–2.

Table 1-2 EM500 Technical Specifications

Items

Specifications

Input

Rate Voltage

Range

3-phase 380V-20% - 415V+20%, 3-phase or single-phase 220

– 230VAC; 50 - 60 Hz±5%, voltage unbalance <3%

Output

Maximum

Output Voltage

Maximum output voltage is identical to input voltage.

Rated Output

Current

100% non-stop rated current output

Maximum

Overload

Current

Model G: 150% rated current for 60s, 180% rated current for

10s and 200% rated current for 2s

Model P: 120% rated current for 60s, 150% rated current for

10s and 180% rated current for 2s

Basic

Control

Functions

Control Mode

V/F(VVF) and SVC

Input Mode

Frequency (speed) input and torque input

Start/Stop

Control Mode

Keypad, control terminals (2-wire sequence, 3-wire

sequence) and communication

Frequency

Control Range

0.00 - 600.00 Hz /0.0 – 3000Hz

Input Frequency

Resolution

Numeric input: 0.01 Hz/ 0.1Hz, analog input: 0.1% of

maximum frequency

Governor

Deflection

1: 50 (VVF), 1:200 (SVC)

Speed Control

Accuracy

±0.2% rated synchronous speed

Acceleration/De

celeration Time

0.01-600.00 seconds/0.1 - 6000.0 seconds/1 - 60000 seconds

V/F Features

Rated output voltage: 20% - 100% adjustable; frequency

base: 1 Hz - 600 Hz/3000Hz adjustable

EM500 Open-Loop Vector Control Inverter User Manual

16

Torque Boost

Fixed torque boost curve, customer defined V/F curve scaling

Start Torque

150%/ 1 Hz (VVF), 150%/ 0.25 Hz (SVC)

Torque Control

Accuracy

±8% rated torque (SVC)

AVR

Output voltage remains unchanged basically and input

voltage varies when AVR is active

Automatic

Current Limit

Automatically limit output current to avoid frequently

overcurrent trip.

DC Brake

Brake frequency: 0.01 - Maximum frequency, brake time: 0 -

30S

Brake current: 0% - 100% rated current

Signal Input

Source

Communication, preset speed, analog, high-speed impulse

Function

of Input

and Output

Reference

Power Supply

10V/20mA

Terminal

Control Power

Supply

24V/200mA

Numeric Input

Terminal

7 (standard X1 - X7) + 4 (expansion card X8 - X11) numeric

multi-functional input terminals:

X7 can be selected as high-speed impulse input terminal

(F02.06=35/38/40);

X1 - X6 and X8 - X11 (10 in total) can be used as common

digital input terminals.

Analog Input

Terminal

3 (standard AI1 -AI3) + 1 (expansion card AI4) analog

input terminals:

1 (AI1) voltage source 0 - 10 input;

2 (AI2/AI3) voltage source 0 - 10V inputs or current

source 0 - 20mA input;

1 (AI4) voltage source -10V - 10V input

Numeric Output

Terminal

2 (standard Y1/Y2) + 1 (expansion card Y3) OC

multi-functional outputs and 2 (R1: EA/EB/EC and R2:

RA/RB/RC) relay multi-functional outputs.

Maximum output current of OC: 50mA; relay contact

capacity: 250VAC/3A or 30VDC/1A. When the relay works,

EA-EC and RA-RC are on, but EB-EC and RB-RC are off.

Analog Output

Terminal

M1 is with output 0 - 10V only.

M2 is with output 0 - 10V or 0 – 20 mA.

Keypad

Display

LED

LED displays relevant information about inverter.

Parameter Copy

Upload and download parameter setting information of

inverter to realize rapid copy.

Protection

Protection

Short circuit, overcurrent, overvoltage, undervoltage, phase

loss, overload, overheating, overspeed, offload, external fault,

etc.

EM500 Open-Loop Vector Control Inverter User Manual

17

Working

Condition

Installation Site

To be installed indoor with an altitude less than 1,000 meters,

free from dust, corrosive gas and direct sunlight.

Ambient

Temperature

-10℃- +40℃, 20% - 90%RH (no condensation)

Vibration

< 0.5g

Storage

Temperature

-25℃~ +65℃

Installation

Method

Wall mounting, floor mounting (electrical cabinet) and flush

mounting

Protection Degree

IP20/IP21 (450kW and above)

Cooling Method

Forced air cooling

1.2 EM500 Operation Status

1.2.1Operating Status of Inverter

EM500 inverter operating status: Parameter setting status, normal running status,

JOG running status, autotuning status, stop status, JOG stop status and fault status.

Parameter setting status: After it is powered on and initialized and is standby

without a fault or a start-up command, inverter has no output.

Normal running status: Having received an active start command through

keypad, control terminal or communication, inverter drives motor as per the

setting input.

JOG running status: Drives motor at JOG input speed through setting of keypad,

external terminal or communication.

Autotuning status: Set through keypad to autotune the parameters of motor in

stationary or rotational autotuning.

Stop status: When a running command is inactive, output frequency drops to zero

as per set deceleration time.

JOG stop status: When JOG running command is inactive, output frequency

drops to zero as per JOG deceleration time.

Fault status: Status of inverter under protection, and all kinds of faults and

failures.

EM500 Open-Loop Vector Control Inverter User Manual

18

1.2.2Control Modes of Inverter

Control modes of inverter refer to what kind of method is adopted to drive motor at

desired speed or torque. These modes include:

VVF (Vector decoupling based VF control): The steady performance is the same as

that in SVC. Suitable for occasions of low speed change and low speed stability

accuracy and meet the needs of most AC motor drives.

SVC (Sensorless Vector Control): Advanced speed estimate algorithm, no need for

encoder, open loop vector control and high control accuracy.

1.2.3Setting Modes of Inverter

Setting mode of inverter refers to what kind of physical quantity is taken as the

control object when inverter drives motor.

Speed setting mode: Motor speed is taken as the control object;

This mode can be realized by numeric setting, analog input setting, high-speed pulse

input setting, communication setting, digital potentiometer setting, process PID, simple

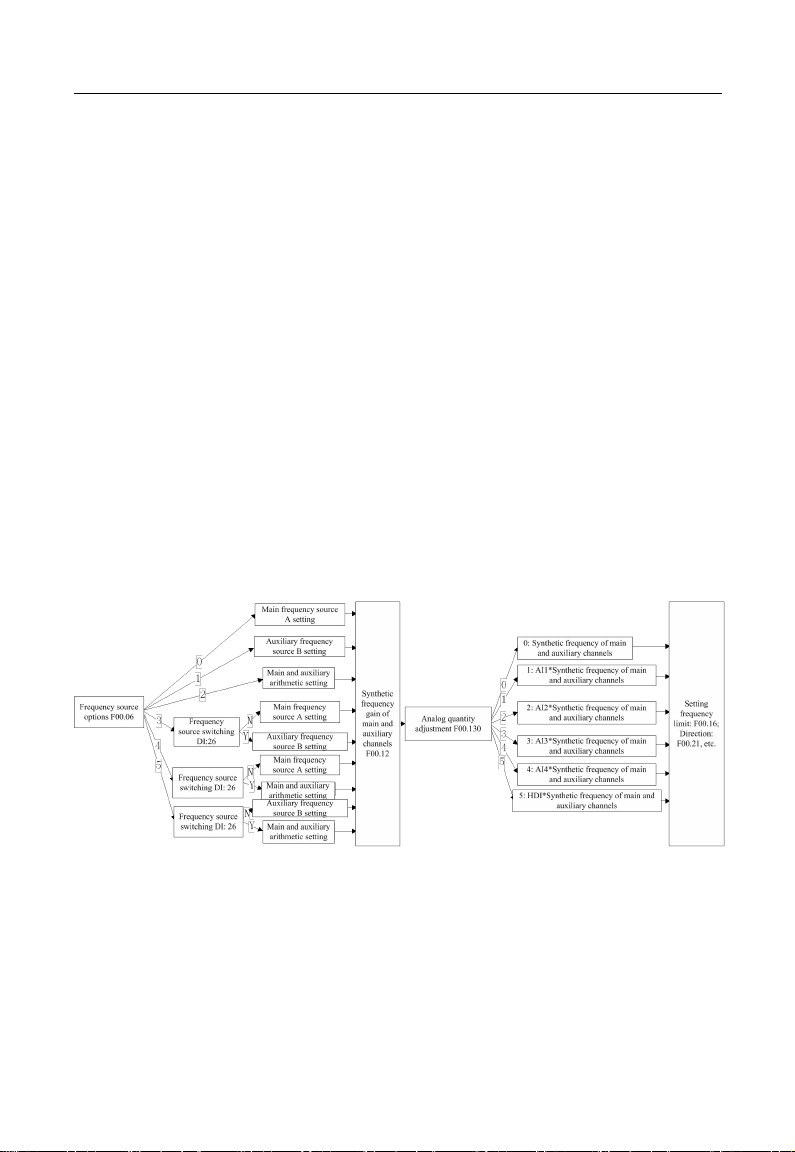

PLC or preset speed, individually or jointly. In Figure 1-1 to Figure 1-4, various input

modes under the speed setting mode of EM500 are described:

Figure 1-1 Speed Input Mode

As indicated in Figure 1-1, there are mainly three speed setting modes of EM500,

respectively main frequency source A setting (referred to as “Main A” for short),

auxiliary frequency source B setting (referred to as “Auxiliary B” for short) and main &

auxiliary arithmetic setting. The speed setting mode is finalized by simple regulation and

EM500 Open-Loop Vector Control Inverter User Manual

19

limit (upper limit frequency limit, maximum frequency limit, direction limit and

frequency hopping limit). The setting descriptions are given in Figure 1-2 to Figure 1-4.

主频率切换

DI:51~56

0:数字频率给定F00.07

1:AI1*F00.16

2:AI2*F00.16

3:AI3*F00.16

4:AI4*F00.16

5:HDI*F00.16

0

1

2

3

4

5

主

频率源

增益

F00.10

多段速端子

DI:14~11 0

n=1,2,…,15

第n段速

F08.00~F08.14

无

有效 F00.07

AI1

AI2

AI3

HDI(脉冲)

通讯

+

+

6:SCI*F00.16

6

UP/DOWN给定

+

+

Preset speed terminal

DI: 14 - 11

Main frequency

switching

DI: 51 – 56

Disabled

Enabled

Preset speed n

F08.00 – F08.14

Main frequency

source A

F00.04

HDI (pulse)

Communication

0: Numeric frequency setting

F00.07

1: AI1 * F00.16

2: AI2 * F00.16

3: AI3 * F00.16

4: AI4 * F00.16

5: HDI * F00.16

6: SCI * F00.16

UP/DOWN setting

Main

frequency

source gain

F00.10

Figure 1-2 Main Frequency Source A Setting

As indicated in Figure 1-2, when setting main frequency source A, user needs to

consider settings and status of numeric terminals comprehensively. According to terminal

settings, inverter can run at a preset speed or at a speed determined through numeric

setting, analog input, pulse or communication.

If all the numeric terminals are disabled, function code F00.04 is used to set present

channel and is in arithmetic together with UP/DOWN to get the final setting.

Figure 1-3 Auxiliary Frequency Source B Setting

EM500 Open-Loop Vector Control Inverter User Manual

20

As indicated in Figure 1-3, when auxiliary frequency source B is being set, the

setting of F00.05 will be based upon to determine present setting channel. Process PID

and Simple PLC can participate in the setting.

Figure 1-4 Main and Auxiliary Arithmetic Setting

As indicated in Figure 1-4, main and auxiliary arithmetic can be classified into four

categories. At this time, both main and auxiliary settings are enabled.

Torque setting mode: Motor current is taken as the control object.

Torque setting mode can be set by multiple ways, which include numeric setting,

analog input setting, high-speed pulse input setting, communication setting, digital

potentiometer setting and preset torque setting. In Figure 1-5, various input modes for

torque setting of EM500 are described.

Figure 1-5 Torque Setting Mode

Table of contents

Other Sinee Inverter manuals

Popular Inverter manuals by other brands

Berges

Berges ACM-D2 Series operating manual

Resol

Resol DeltaSol AL E Manual for the specialised craftsman

Chelion

Chelion iHome-B5-HD02 Series user manual

SolarEdge

SolarEdge StorEdge SE7600A-USS installation guide

Siemens

Siemens SINAMICS V20 Inverter Compact operating instructions

PNI

PNI L1200W user manual