Sinee EM303A-1R1-1CB User manual

User Manual

EM303A General Purpose Inverter

1

Preface

Thank you for purchasing EM303A series inverter.

Document No.: 31010005

Issue Date: 06/06/2013

EM303A is a general purpose inverter (Speed Sensorless Vector Control). It helps an

induction motor to achieve not only the speed regulation standard of a DC motor, but also

the control ability of a torque motor, and the motion control system is optimized with

quick response, precise control and system stability.

The updates of EM303A:

1.Support Modbus RTU standard communication protocol.

2.Support RS485 master-slave communication control mode, numeric synchronized

control achieved.

3.Numeric input terminals support F/R logic control, delay input control, and etc.

4.Numeric output terminals support PWL/pulse output, F/R logic output and delay output,

and etc.

5.Analog input signals VS/IS/VF/IF can be programmed as numeric inputs, numeric

terminals expansion control achieved.

6.With filtering, analog input signals VP/VS/IS/VF/IF can actively avoid analog signals

interference and drift.

7.User can easily define the display of function code menus.

8.Run, stop and parameters setting status can program the displayed parameters

independently.

It is the duty of any user to perform the appropriate, correct installation or configuration

of the optional parameters of the devices. Neither SINEE nor its distributors shall be

responsible or liable for misuse of the information contained herein or mismatching the

inverter with the motor.

In the interests of commitment to a policy of continuous development and improvement,

SINEE reserves the right to update the specification of the product or its performance, or

the content herein without notice.

User Manual

EM303A General Purpose Inverter

2

Safety Information

The addition of this symbol to a Danger or Warning safety label indicates

that an electrical hazard exists, which will result in personal injury if the

instructions are not followed.

Thisisthesafetyalert symbol. It is used to alert you to potential personal

injury. Obey all safety messages that follow this symbol to avoid possible

injury or death.

Safety Precautions

Read and understand these instructions before performing any procedure with this

inverter.

● Verifying Product upon Delivery

Caution

1. Never install an inverter that is damaged or missing components.

Failure to comply can result in injury.

zInstallation

Caution

1. Always hold the case when carrying the inverter.

If the inverter is only held by the front cover, the main body of the inverter may fall, possibly

resulting in injury.

2. Installlation base shall be a metal plate or other non-flammable materials.

Installing the inverter on inflammable material may cause fire.

3. Install a cooling fan when installing more than one inverter in the same

cabinet, the temperature of the air entering the inverter shall be lower than

40℃.

Overheating may result in fire or other accidents.

User Manual

EM303A General Purpose Inverter

3

zWiring

Danger

1.Always turn off the input power supply before wiring.

Otherwise, an electric shock or fire may occur.

2.Wiring must be performed by authorized and qualified personnel.

Otherwise, an electric shock or fire may occur.

3.Be sure the ground terminals earthed.

Otherwise, an electric shock or fire may occur.

4.Always verify the function of emergency stop terminal in work after

connecting.

Otherwise, it may result in injury. (User takes the responsibilities of wiring).

5.Never touch the input or output terminals directly with bare hands, or

connect the terminals of inverter to the housing, or connect the input

terminals to output terminals.

Otherwise, an electric shock or short circuit may occur.

Caution

1.Always confirm if the voltage of AC input power supply satisfies the rated

voltage of inverter.

Otherwise, it may result in injury and fire.

2.Never perform voltage withstanding test.

Otherwise, semi-conductors and other devices can be damaged.

3.Connect braking resistor or braking unit according to required wiring.

Otherwise, a fire may occur.

4.Tighten terminals with screw drivers of specified torque.

Otherwise, a fire may occur.

5.Never connect input power supply cable to output terminals U, V, and W.

The inverter will be damaged if voltage is applied to the output terminals.

6.Never connect phase-shifting capacitor and LC/RC noise filter to output

circuits.

Otherwise, the inverter will be damaged.

7.Never connect the solenoid switch and electromagnetic contactor to output

circuits.

When inverter is with load, surge current, which is produced by the operation of

solenoid switch or electromagnetic contactor, will trigger the overcurrent

protection circuit to act. Sometimes the inverter will be damaged.

8.Never take off the interior wires of inverter.

Otherwise, the inverter will be damaged.

User Manual

EM303A General Purpose Inverter

4

zTrial Operation

Danger

1. Only after the front cover is installed, power can be turned on. Never take

off the front cover when power is on.

An electric shock may occur.

2. Do not come close to the machine at power failure if fault reset function is

active. The inverter will restart automatically when power is on.

An injury may occur.

3. Install an emergency switch for a quick brake in case of abnormal

conditions.

An injury may occur.

Caution

1. Never touch braking resistor. It will be very hot and with high-voltage when

running.

Otherwise, an electric shock and a burn injury may occur.

2. Reconfirm the motor and machine are within the applicable ranges before

starting operation.

Otherwise, an injury may occur.

3. Do not check signals while the inverter is running.

Otherwise, the inverter will be damaged.

4. Be careful when editing inverter settings. The inverter is in factory default.

Otherwise, the inverter will be damaged.

zMaintenance and Inspection

Danger

1. Do not touch inverter’s wiring terminals where high voltage exists.

Otherwise, an electric shock may occur.

2. Always keep the front cover in place before power is supplied to the inverter.

Turn off power before taking the front cover off.

Otherwise, an electric shock may occur.

3. Maintenance and check must be performed only after the power supply of

main circuit is turned off, and the indicator of CHARGE is off.

An electric shock may occur due to the residual voltage on electrolytic capacitor

after power is off.

4. Maintenance and inspection must be performed only by authorized

professionals.

Otherwise, an electric shock may occur.

5. Do not change the wiring and disconnect terminal wiring when power is on.

Otherwise, an electric shock may occur and the inverter will be damaged.

User Manual

EM303A General Purpose Inverter

5

Caution

1. CMOS ICs are installed on keypad, control circuit board and drive circuit

board respectively. Handle those parts and CMOS ICs carefully.

The CMOS IC can be destroyed by ESD if touched directly with bare hands.

2.Do not check signals while the inverter is running.

Otherwise, the inverter will be damaged.

zOther

Danger

1. Never attempt to modify or alter the inverter.

Failure to comply can result in electric shock or injury.

2. User shall take full responsibilities for the damages caused by wrong wiring,

improper operation or modifying and altering, and etc.

User Manual

EM303A General Purpose Inverter

6

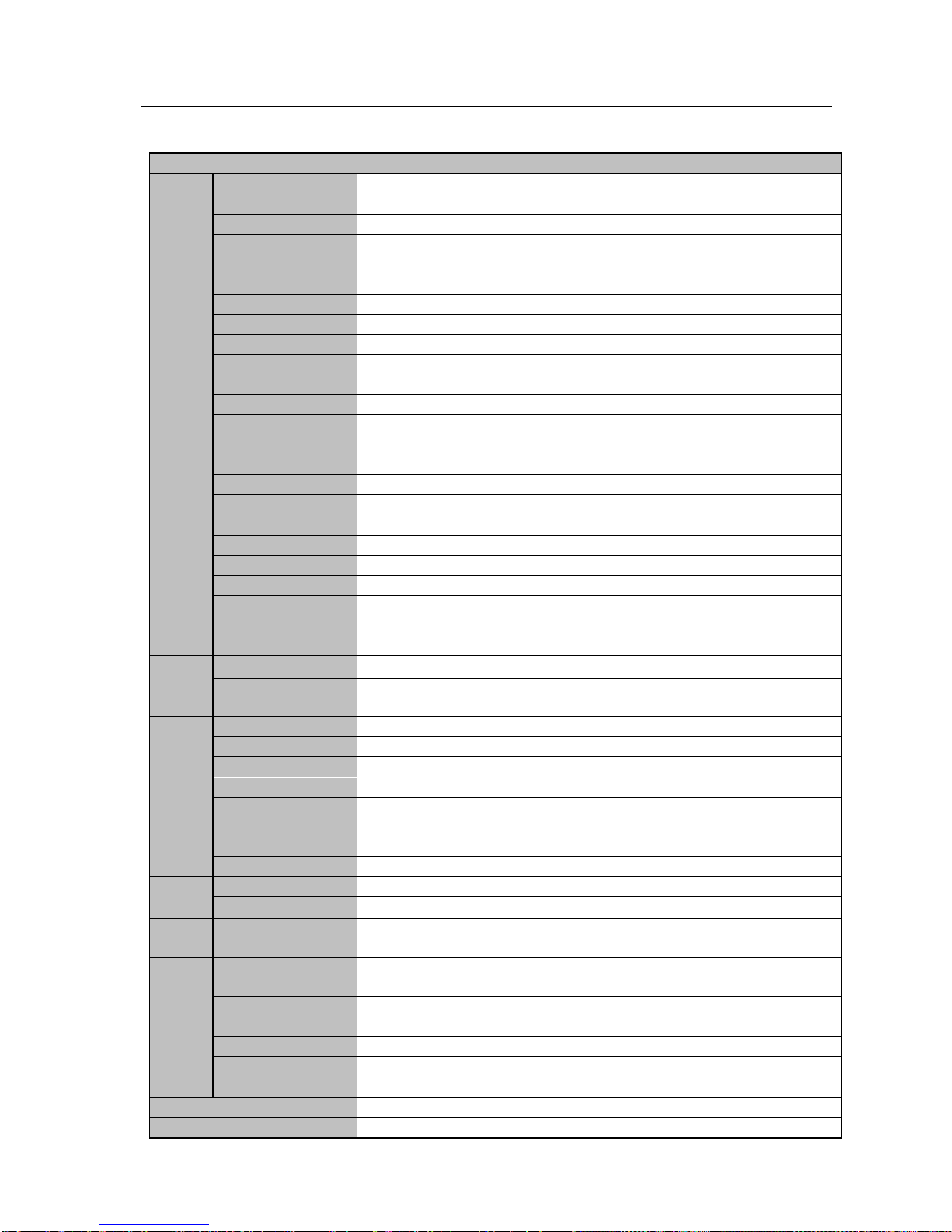

CONTENTS

SUPPLEMENT FOR EM303A-XXX-1C, EM303A-XXX-2C ........... 8

1. OVERVIEW ................................................ 9

1.1EM303A MODEL LIST AND TECHNICAL SPECIFICATIONS .......... 9

1.2BASIC FUNCTIONS OF EM303A ............................ 11

1.3EM303A OPERATION STATUS DEFINITION .................... 13

1.4EM303A OUTLOOK ..................................... 17

2INSTALLATION ......................................... 18

2.1 VERIFYING PRODUCT ....................................... 18

2.2 OVERALL AND INSTALLATION DIMENSIONS ...................... 19

2.3CONSIDERATIONS OF INSTALLATION SITE .................... 21

2.4DIRECTION AND SPACE OF INSTALLATION .................... 21

2.5DISASSEMBLY AND ASSEMBLY OF KEYPAD ................... 22

3WIRING ................................................ 24

3.1CONNECTIONS TO PERIPHERALS ........................... 24

3.2WIRING MAIN CIRCUIT TERMINALS ......................... 25

3.3WIRING CONTROL CIRCUIT TERMINALS ..................... 32

3.4EXTENDING KEYPAD WIRE ............................... 38

3.5WIRING CHECK ........................................ 38

4KEYPAD OPERATION ................................... 39

4.1 TYPE AND FUNCTION OF KEYPAD .............................. 39

4.2LED KEYPAD OPERATION MODE ........................... 40

5TRIAL OPERATION...................................... 41

5.1TRIAL OPERATION PROCEDURES ........................... 41

5.2TRIAL OPERATION PRECAUTIONS ........................... 43

6PARAMETER TABLES ................................... 45

6.1FORMAT OF PARAMETER TABLES ........................... 45

6.2PARAMETERS .......................................... 46

SECTION 1GENERAL PARAMETERS ............................... 46

SECTION 2ADVANCED PARAMETERS .............................. 61

7PARAMETER DESCRIPTION ............................. 77

7.1GROUP F0: GENERAL PARAMETERS ......................... 77

User Manual

EM303A General Purpose Inverter

7

7.2GROUP F1: MOTOR PARAMETERS .......................... 88

7.3GROUP F2: INPUT/OUTPUT TERMINAL PARAMETERS ............ 91

7.4GROUP F3: PRESET SPEED PARAMETERS ..................... 99

7.5GROUP F4: GENERAL PARAMETERS OF PID .................. 104

7.6GROUP F5: GENERAL PARAMETERS OF VECTOR CONTROL ...... 112

7.7GROUP C0: MONITORING PARAMETERS ..................... 117

8 AUTOTUNING MOTOR PARAMETERS ...................... 119

8.1 AUTOTUNING MOTOR PARAMETERS ........................... 119

8.2PRECAUTIONS BEFORE AUTOTUNING ....................... 119

8.3AUTOTUNING PROCEDURE ............................... 120

8.4AUTOMATIC TORQUE BOOST AND SLIP COMPENSATION ......... 121

9 TROUBLESHOOTING ..................................... 123

9.1 FAULTS ................................................. 123

9.2FAULT ANALYSIS ...................................... 125

10 MAINTENANCE AND INSPECTION ........................ 128

10.1 MAINTENANCE AND INSPECTION ............................ 128

10.2DAILY INSPECTION .................................... 128

10.3PERIODIC MAINTENANCE ................................ 128

10.4PERIODIC MAINTENANCE AND REPLACEMENT OF PARTS ........ 129

10.5OUTLINE OF WARRANTY ................................ 129

11ACCESSORIES ......................................... 130

11.1 KEYPAD EXTENSION WIRE ................................. 130

11.2REMOTE OPERATION CASE .............................. 130

11.3 BRAKING RESISTOR ...................................... 131

11.4 BRAKING UNIT .......................................... 132

11.5 CONNECTING CABLE ..................................... 132

12 COMMUNICATION PROTOCOL OF EM303A ................ 133

12.1 APPLICATION SCOPE ...................................... 133

12.2 PHYSICAL INTERFACE ..................................... 133

12.3 PROTOCOL FORMAT ...................................... 133

12.4 DESCRIPTION OF PROTOCOL FORMAT ......................... 136

APPENDIX 1 ............................................... 139

User Manual

EM303A General Purpose Inverter

8

PBWUVL2L1

Supplement for EM303A-XXX-1C,

EM303A-XXX-2C

Except input voltage, applicable motor and power wire size, EM303A-XXX-1C and

EM303A-XXX-2C are the same as EM303A-XXX-3C in terms of installation, wiring,

operation and function codes, and etc.

1. Model and Specifications of EM303A-XXX-1C and EM303A-XXX-2C Inverter

(Open Loop Vector Control)

zRated voltage: 1-phase AC220V, 3-phase AC220V

zApplicable motor: 3-phase AC induction motor. Power ratings: 0.4~4.0 kW.

Rated voltage: AC220V

zOutput voltage: 3-phase, from 0 to Usupply.

Model and rated output current of EM303A-XXX-1C are shown in Table 0-1.

Table 0-1 Model List of EM303A-XXX-1C

Rated Input

Voltage Model No. Motor

Power(kW)

Rated Output

Current

(A)

Overall

Dimensions

Wire Size

(m2)

1-Phase

AC220V

EM303A-1R1-1CB 1.1 6.2 The same as

EM303A-2R2G

/3R0P-3CB

2.5

EM303A-1R5-1CB 1.5 8.0 4

EM303A-2R2-1CB 2.2 10.0 4

EM303A-3R0-1CB 3.0 13 The same as

EM303A-7R5G

/9R0P-3CB

6

EM303A-4R0-1CB 4.0 17 6

See Table 0-2 for model number and rated output current of EM303A-XXX-2C.

Table 0-2 Model List of EM303A-XXX-2C

Rated Input

Voltage Model No. Motor Power

(kW)

Rated Output

Current

(A)

Overall

Dimensions

Wire Size

(m2)

3-Phase

AC220V

EM303A-0R4-2CB 0.4 3.0

The same as

EM303A-2R2G

/3R0P-3CB

1.5

EM303A-0R5-2CB 0.55 3.7 1.5

EM303A-0R7-2CB 0.75 4.8 1.5

EM303A-1R1-2CB 1.1 6.2 2.5

EM303A-1R5-2CB 1.5 8.0 4

EM303A-2R2-2CB 2.2 10.0 4

EM303A-3R0-2CB 3.0 13 The same as

EM303A-7R5G

/9R0P-3CB

6

EM303A-4R0-2CB 4.0 17 6

2. Terminal Block of EM303A-XXX-1C and EM303A-XXX-2C

Terminal block of EM303A-XXX-1A is shown as below.

Terminal block of EM303A-XXX-2C is the same as that of EM303A-XXX-1C.

User Manual

EM303A General Purpose Inverter

9

1. Overview

1.1 EM303A Model List and Technical Specifications

zRated voltage: 3-phase, AC380V/415V

zApplicable motor: 3-phase induction motor, power range: 0.75~400kW.

Rated voltage: AC380V/415V

zOutput voltage: 3-phase, from 0 to Usupply.

1.1.1 EM303A Model and Rated Output Current

Table 1-1 Model List of EM303A

Rated Voltage Model No. Motor Power(kW) Rated Output

Current(A)

3-phase,

AC380V±20

%/415V±20%

EM303A-0R7G/1R1P-3CB 0.75 2.8

EM303A-1R1G/1R5P-3CB 1.1 3.7

EM303A-1R5G/2R2P-3CB 1.5 4.8

EM303A-2R2G/3R0P-3CB 2.2 6.2

EM303A-3R0G/4R0P-3CB 3.0 8

EM303A-4R0G/5R5P-3CB 4.0 10

EM303A-5R5G/7R5P-3CB 5.5 13

EM303A-7R5G/9R0P-3CB 7.5 17

EM303A-9R0G/011P-3CB 9.0 20

EM303A-011G/015P-3CB 11 26

EM303A-015G/018P-3CB 15 34

EM303A-018G/022P-3C 18.5 41

EM303A-022G/030P-3C 22 48

EM303A-030G/037P-3C 30 60

EM303A-037G/045P-3C 37 75

EM303A-045G/055P-3C 45 90

EM303A-055G/075P-3C 55 115

EM303A-075G/090P-3C 75 150

EM303A-090G/110P-3C 90 180

EM303A-110G/132P-3C 110 220

EM303A-132G/160P-3C 132 265

EM303A-160G/185P-3C 160 310

EM303A-185G/200P-3C 185 360

EM303A-200G/220P-3C 200 380

EM303A-220G/250P-3C 220 420

EM303A-250G/280P-3C 250 470

EM303A-280G/315P-3C 280 530

EM303A-315G/355P-3C 315 600

EM303A-355G/400P-3C 355 660

EM303A-400G/450P-3C 400 740

Remarks:

1.EM303A is an integrated model with G (Fixed torque) and P (square torque) in one.

The data listed above is of Model G. When applied to square torque like blower, water

pump and etc., the power ratings of applicable motor can be one grade higher. See the

details of inverter’s nameplate.

2.See 2.1 for the model numbering scheme.

User Manual

EM303A General Purpose Inverter

10

1.1.2 EM303A Technical Specifications

Table 1-2 EM303A Technical specifications

Items S

p

ecifications

Input

Rated Voltage 3-phase AC380V~415V±20%, 50~60Hz±5%, voltage imbalance rate <3%

Output

Output Voltage 3-phase, from 0 to Usu

pp

l

y

.

Rated Output Current 100% rated current non-stop output

Max. Overload Current Model G: 150% rated current for 1 minutes, 180% rated current for 2 seconds

Model P: 120% rated current for 1 minutes, 150% rated current for 2 seconds

Basic Control Functions

Control Mode V/F, SVC

Input Mode Frequency (Speed) input, torque input

Running Mode Keypad, control terminals (2-wire sequence, 3-wire sequence), RS485

Frequency Control Range 0.00~600.00Hz

Input Frequency

Resolution Numeric input:0.01Hz, analog input: 0.1% of maximum frequency

Governor Deflection 1:50(V/F), 1:100(SVC)

Speed Control Accuracy ±0.5% rated synchronous speed

Acceleration/Deceleration

Time 0.01~600.00 seconds/minutes

V/F Features Rated output voltage: 20%~100% adjustable, frequency base :20Hz~600Hz adjustable

Torque Boost Automatic torque boost, fixed torque boost curve, customer defined V/F curve scaling

Start Torque 150%/1Hz(V/F),150%/0.5Hz(SVC)

Torque Control Accuracy ±15% rated torque (SVC1)

AV R AVR is active while output voltage remains unchanged if input voltage is varying.

Automatic Current Limit Automatically limit output current, avoid frequent overcurrent tripping

DC Brake Brake frequency:0.1~60Hz, brake time:0~30S, brake current:0~100% rated current

Signal Input Source Communication, analog voltage, analog current, preset speed, simple PLC and their

combinations

Special

Function

Control

Textile Wobbulation Realize textile wobbulation functions like wobbulation range, time and jump

Droop Control With increase of load, the speed droops, suitable for one machine driven by multi-motor

Function of Input and

Output

Reference Power 10V/20mA

Terminal Control Power 24V/150mA

Numeric Input Terminals 7 programmable numeric input terminals

Analog Input Terminals 4 analog inputs:2 voltage inputs (0~10V), and 2 current inputs(0~20mA)

Numeric Output Terminal

s

2 OC outputs and 1 relay output are programmable. Maximum output current of OC:

50mA. Relay contact capacity: 250VAC/3A or 30VDC/1A. When relay acts, EA-EC is

NO, and EB-EC is NC.

Analog output Terminals 2 programmable analog output terminals can output 0~10V or 0~20mA

Keypad

Display

LED Human interactions with displays and control actuators

Parameter Copy Upload and download parameter information of the inverter, copy parameters rapidly.

Protections Protections Short circuit, overcurrent, overload, overvoltage, undervoltage, phase loss, overheating,

external fault, and etc.

Applica-tion

Conditions

Installation Site Indoor, with altitude less than1,000 meters, free from dust,corrosive gas, and direct

sunlight

Ambient Temperature -10℃~+40℃. In the temperature range +40 °C…+50 °C, the rated output current is

decreased by 1% for every additional 1 °C. 20%~90%RH (no condensation)

Vibration <0.5g

Storage Temperature -25℃~+65℃

Installation Method Wall mounting, or floor mounting

Degree of Protection IP20

Cooling Method Forced air cooling

User Manual

EM303A General Purpose Inverter

11

1.2 Basic Functions of EM303A

1.2.1 Process PID Control

2 process PID control modes: Speed process PID control and torque process PID

control. When output of process PID control is taken as inverter’s speed input, it

is speed process PID control. When output of process PID control is taken as

inverter’s torque input, it is torque process PID control. Speed process PID

control is applicable to all drive modes, while torque process PID control is only

active in SVC1.

Speed process PID control is used for:

zPressure control: Regulate motor speed by taking pressure signal as a feedback

to keep pressure constant.

zFlow control: Regulate motor speed by taking flow signal as a feedback to keep

flow constant.

zTemperature control: Regular motor speed by taking temperature signal as a

feedback, to keep temperature constant.

Torque process PID control is used for:

zTension control: Regulate motor’s torque current by taking tension signal as a

feedback to keep tension constant.

1.2.2 Program Operation (Simple PLC)

Program operation is that inverter finishes specified control logic according to the

mode and time set in the program. Program operation is categorized as speed

program operation, torque program operation and process PID program operation

(including speed and torque process PID program operation). The program

operation mode can be further categorized as: Single-cycle (stop after

completion), run at the 7th preset speed after single-cycle, limited continuous

cycle (stop after completion), and unlimited continuous cycle.

1.2.3 Wobbulation Operation (Textile only)

Wobbulation is applied to textile and chemical fiber industry that needs for

traverse and winding.

1.2.4 Stepping Mode Operation

Provide 5 stepping input modes for speed, torque and process PID input control

modes.

1.2.5 Droop Control

When the machine is driven by multi-motor, setting function of droop control can

evenly assign the output power of each inverter.

1.2.6 Stop Control at Power-off

When driving load with big inertia, the inverter will automatically enter stop

control status in case of power failure, and convert the rotational kinetic energy

into electrical energy to stop the motor quickly. It prevents the system from free

revolving with big inertia for a long time.

User Manual

EM303A General Purpose Inverter

12

1.2.7 Low Noise Design

Due to the high frequency harmonic wave with the output of inverter, the motor

generates the electromagnetic noise inevitably. Usually, electromagnetic noise can

be lowered by increasing carrier frequency, which, however, in turn makes the

inverter overheat, and the rated output current is required to be decreased by 5%

for every additional 1 kHz in carrier frequency. EM303A achieves low noise

operation with low carrier frequency by carrier frequency regulation.

1.2.8 Current Limit

When inverter is running, if acceleration/deceleration time is too short or the load

becomes heavier, the output current of inverter may exceed the permitted limit. If

current limit is enabled, inverter will automatically decrease its output frequency

to keep the output current limit unchanged. When output current is less than the

current limit, it runs as per regular input command. This function is applied to

V/F control mode only. For other control modes, the current is automatically

regulated.

1.2.9 Energy Autosaving

When motor is idling or with light load, EM303A will properly regulate its output

voltage for energy saving purpose.

1.2.10 Constant Power Output

With the same load, output current will increase as the input voltage of inverter

decreases. Meanwhile, if constant power output is active, the inverter will

automatically calculate its real-time output power and work at maximum power

permitted.

1.2.11 Automatic Voltage Regulation (AVR)

When the input voltage fluctuates, the output voltage remains unchanged

basically, and V/F value keeps constant.

1.2.12 Dynamic Overvoltage Stall

Effectively avoid bus voltage accumulation by real-time detecting voltage of DC

bus and regulate overvoltage points dynamically.

1.2.13 Dynamic Brake

When motor decelerates or runs with potential energy load, the voltage of DC bus

will rise due to energy feedback, and such voltage is called as rebounding

overvoltage. In order to make motor brake quickly within given deceleration time

while the inverter will not perform overvoltage protection, and rebounding

braking resistor or braking unit can be used to consume this energy, such brake is

called as dynamic brake.

1.2.14 Fault Autoretry

During operation of inverter, faults such as undervoltage (instant power failure

but resume immediately), overvoltage, overcurrent, and overload may occur. If

faults autoretry is active, inverter will automatically try to restart after a setting

User Manual

EM303A General Purpose Inverter

13

interval. Meanwhile, if speed search is active, inverter will automatically detect

motor speed and direction to make it return the setting input frequency smoothly.

1.2.15 Multi-function Numeric Input Terminals

7 multi-function numeric input terminals X1 ~X7 of EM303A can be

programmed based on real needs.

1.2.16 Multi-function Analog Output Terminals

Multi-function analog output terminals M0~M1 of EM303A can be defined as

different information, or as signals of 0~10V or 0~20mA.

1.2.17 Multi-function Numeric Output Terminals

The output of multi-function numeric output terminals Y1 and Y2, and relays of

EM303A can be programmed based on real needs.

1.2.18 Autotuning Motor Parameter

When autotuning motor parameters is enabled, the inverter will autotune and save

the motor parameters. (Autotuning motor parameter is categorized as stationary

autotuning and rotational autotuning. Please make motor in idling status by

separating motor and load if taking rotational autotuning mode. )

1.2.19 Parameter Copy

All function parameters of EM303A can be copied through keypad.

1.2.20 Programmable Displayed Information

Monitoring codes C0-00 ~C0-31 of EM303A can be displayed by setting

program.

1.2.21 RS-485 Interface

Through RS-485 interface and computer monitoring software, multi-inverter

operation can be easily achieved with computer network.

1.2.22 User Password

User can set password to protect function codes from unauthorized editing.

1.2.23 Overmodulated Output

When the load is heavy, overmodulation can raise the output voltage of inverter

and lower motor current, and then lower motor temperature rising.

1.2.24 Oscillation Suppression

Mechanical load may have mechanical resonance point, and motor may have

electromagnetic resonance point. Oscillation suppression can eliminate resonance

and enable system to operate stably and to be free from failures.

1.3 EM303A Operation Status Definition

1.3.1 Operation Status of Inverter

zParameters setting status: After power is on, inverter finishes initialization

enters standby status without fault or start-up command, and does not output.

zNormal running status: After receiving active start command through

keypad, control terminal or RS485, the inverter drives motor in accordance

User Manual

EM303A General Purpose Inverter

14

with the requirements of setting input.

zJOG running status: Set by keypad, external terminal or RS485 to make

motor run per JOG input speed.

zJOG stop status: Refer to the process that the output frequency drops to zero

in JOG deceleration time after JOG running command is not active.

zAutotuning status: Set by keypad to autotune motor’s parameters in

stationary or rotational autotuning.

zStop status: Refer to the process that the output frequency drops to zero in

given deceleration time after running command is not active.

zFault status: Status of inverter at protections, all kinds of faults and failures.

1.3.2 Control Modes of Inverter

The control modes of inverter refer to that the inverter controls motor rotation as

per required speed and torque with open loop or close-loop control mode. The

control modes include:

zGeneral open loop space vector control——V/F control

Applicable to the applications of slow speed changes and low speed stability

accuracy demand, and meet needs of most of AC motor drives.

zSVC 0—— Open-loop vector control without PG feedback

Only estimate speed in real-time, but no feedback control. Output current is

under real-time close-loop control, output of motor reaches 150% of rated

torque at 0.5Hz, and inverter automatically traces load variables and limit

output current to make it not exceed the maximum value. Even if there is

sudden load change, quick acceleration or deceleration, inverter will not trip

overcurrent, short-circuit, and etc., and keeps high performance and reliability.

zSVC1—— Torque control(Close-loop vector control without PG feedback)

Not only estimate speed in real-time, but also conduct feedback control. Speed

and current are under real-time close-loop control. Not only speed control but

also torque control can be realized. A regular AC induction motor can be

converted to AC variable speed motor and AC torque motor by adopting this

control mode. It is a genuine speed sensorless vector control.

1.3.3 Setting Modes of Inverter

The setting mode of inverter refers to that what kind of physical quantity inverter

is taken as control object when driving motor.

zSpeed setting mode is to take motor speed as the control object

zTorque setting mode is to take motor torque as the control object.

Set through various and flexible methods such as numeric setting, analog voltage,

and analog current or other mathematical combinations. Jog speed setting mode

is prior to other setting modes, i.e. when pressing JOG button on keypad or

making control terminals FJOG and RJOG on, no matter what the present setting

mode is, the inverter will automatically switch to jog speed setting. See Figure

1-1 and Figure 1-2 for the details of all speed setting modes of EM303A.

User Manual

EM303A General Purpose Inverter

15

Figure 1-1 Speed Setting Modes

User Manual

EM303A General Purpose Inverter

16

Figure 1-2 Torque Input Modes

User Manual

EM303A General Purpose Inverter

17

1.3.4 Operation Control Mode of Inverter

The operation control mode of inverter refers to the action conditions when

inverter enters operation status, which includes 3 modes as controlled by keypad

operation, terminal operation, and RS485 communication. Terminal operation

mode is categorized as 2-wire sequence, and 3-wire sequence. The setting details

and control logic of these three modes are shown in the description of function

parameters F0-04 and F0-05 in 7.1.

1.4 EM303A Outlook

See Figure 1-3 for the outlook of EM303A (Instance: EM303A- 4.0kW).

Figure1-3 EM303A Outlook

The face terminal cover can be taken away by following the arrow shown in

Figure1-3. See Figure 1-4 for control circuit terminals and main circuit terminals.

a. Control Circuit Terminal Block

PBWUVSTR

b. Main Circuit Terminal Block

Figure 1-4 Control Circuit Terminals and Main Circuit Terminals

User Manual

EM303A General Purpose Inverter

18

2Installation

2.1 Verifying Product

Refer to Table 2-1, and check and verify the EM303A.

Table 2-1 Check List

Item Action

If the products are identical to the

purchase order.

Check the devices reference marked on

the label.

Any part damaged. Check the outlook if any damages.

Any screw loosened. Check with a screwdriver if necessary.

Contact the distributor or SINEE directly for quality issue.

zNameplate

zModel Numbering Scheme

User Manual

EM303A General Purpose Inverter

19

2.2 Overall and Installation Dimensions

Classified to 10 sizes for total 30 models of EM303A, installation dimensions as

shown in Figure 2-1 and Table 2-2.

The keypad can be installed on the metal panel separately with a hole size of

116.5±0.1(L)*71.5±0.1 (W)mm, and applicable panel thickness:1.2~2.0mm

71

74

118

26

34

116

8

58

77

16

-R

2-M3

(a)Keypad Dimensions for Installation

W

W1

4-

d

H1

H

D

D1

D2

-R

D1

H2

H1

H

W

W1

2-d

D

-R

D2

(b) (c)

Figure 2-1 Overall and Keypad Dimensions of EM303A for Installation

User Manual

EM303A General Purpose Inverter

20

Table 2-2 Overall and Installation Dimensions of EM303A

Model No. WW1 H H1 H2 D D1 D2 dFrame

EM303A-0R7G/1R1P-3CB

140 125 220 205 -- 152 120 161 6 (b)

EM303A-1R1G/1R5P-3CB

EM303A-1R5G/2R2P-3CB

EM303A-2R2G/3R0P-3CB

EM303A-3R0G/4R0P-3CB

EM303A-4R0G/5R5P-3CB

EM303A-5R5G/7R5P-3CB

165 148 250 235 -- 161 126 170 6 (b)

EM303A-7R5G/9R0P-3CB

EM303A-9R0G/011P-3CB

215 150 352 335 317 215 172 224 7 (c)

EM303A-011G/015P-3CB

EM303A-015G/018P-3CB

EM303A-018G/022P-3C

270 200 470 450 424 245 187 254 10 (c)

EM303A-022G/030P-3C

EM303A-030G/037P-3C

EM303A-037G/045P-3C

335 240 550 530 500 245 190 254 10 (c)

EM303A-045G/055P-3C

EM303A-055G/075P-3C

390 300 695 665 635 250 200 259 12 (c)

EM303A-075G/090P-3C

EM303A-090G/110P-3C

560 400 828 803 775 355 255 364 12 (c)

EM303A-110G/132P-3C

EM303A-132G/160P-3C

EM303A-160G/185P-3C

650 400 1060 1034 1000 400 325 409 13 (c)

EM303A-185G/200P-3C

EM303A-200G/220P-3C

EM303A-220G/250P-3C

825 660 1200 1170 1137 400 320 409 13 (c)

EM303A-250G/280P-3C

EM303A-280G/315P-3C

EM303A-315G/355P-3C

1068 870 1213 1183 1150 410 330 419 13 (c)

EM303A-355G/400P-3C

EM303A-400G/450P-3C

Remarks:

z5 models: EM303A-055~075, EM303A-090~132, EM303A-160~200,

EM303A-220~280, and EM303A-315~400 can be floor-mounted with a chassis

which is in the same width as the inverter. Heights of optional chassis: 120mm,

250mm, 300mm, 300mm and 350mm.

zEM303A-090 or above: power input terminals are on the top, and power output

terminals are at the bottom of the inverter.

This manual suits for next models

42

Table of contents

Other Sinee Inverter manuals

Popular Inverter manuals by other brands

Federal Signal Corporation

Federal Signal Corporation PVS220W-24 installation manual

Greatwatt Energy

Greatwatt Energy S-700 owner's manual

Guardian

Guardian 4389 Diagnostic repair manual

CyberPower

CyberPower CPSHB300ETR user manual

Hitachi

Hitachi SJ Series Safety function Guide

Toyotomi

Toyotomi UTN-17AP user manual

Briggs & Stratton

Briggs & Stratton 40213 Installation and start-up manual

TOOLINE

TOOLINE HY70i user manual

brennenstuhl

brennenstuhl SES P1307 Instructions & user's manual

Stanley

Stanley PC1000S instruction manual

Berges

Berges ACM-D2 Series operating manual

Siemens

Siemens SINAMICS G180 Installation and operating instructions