Sinee EM760 Series User manual

User’s Guide for EM760 series high-performance vector inverter

1

Preface

Thank you for choosing SINEE’s EM760 series high-performance vector inverter.

Document No.: 31010200

Release time: 2022-3

Version: 200

The EM760 series inverter is a high-performance vector control inverter launched by SINEE, which

integrates the synchronous motor drive and asynchronous motor drive. It supports three-phase AC asynchronous

motors and permanent magnet synchronous motors, internationally advanced drive control technologies [such as

the improved vector V/F control technology (VVF), speed sensorless vector control technology (SVC) and speed

sensor vector control technology (FVC)], speed output and torque output, Wi-Fi access and background software

debugging, expansions (such as I/O expansion cards, communication bus expansion cards and PG cards).

The standard EM 760 supports V/F control, SVC control, FVC control of asynchronous motors; it also

supports V/F control and FVC control of permanent magnet synchronous motors. The non-standard version for

synchronous motors also supports V/F control, SVC control, FVC control of asynchronous motors, as well as V/F

control, SVC control and FVC control of permanent magnet synchronous motors.

The EM760 series high-performance vector inverter has the following features:

⚫Equipment of a built-in DC reactor (in case of an inverter of above 18.5kW) can reduce input current

distortion, increase the power factor and promote the product reliability;

⚫High torque control accuracy: SVC/±5% rated torque, FVC/±3% rated torque;

⚫Wide speed range and high control accuracy:SVC/1:200 (±0.2%), FVC/1:1000 (±0.02%) rated speed;

⚫Low-frequency carrier: VVF/3Hz/150%, SVC/0.25Hz/150%, FVC/0Hz/180%;

⚫Protections against overvoltage stall, fast current limit, overload, overheat, off-load, overspeed, and so on;

⚫Support I/O expansion: 3-channel digital inputs, 2-channel relay outputs, 1-channel -10V~10V voltage

input, 1-channel sensor input;

⚫Support communication bus expansion: standard configuration including 485 bus, optional PROFINET,

CANopen and EtherCAT;

⚫Support various encoders: ABZ incremental, UVW incremental, UVW wire saver, rotary transformer and

sine-cosine transformer;

⚫Support debugging by the mobile phoneAPP or monitoring of the inverter status;

⚫Support Wi-Fi module or serial port access;

⚫Rich and convenient PC background software functions.

Before using the EM760 series high-performance vector inverter, please read this guide carefully and

keep it properly.

User’s Guide for EM760 series high-performance vector inverter

2

While connecting the inverter to motor for the first time, please select the motor type (asynchronous or

synchronous) correctly and set the motor nameplate parameters: rated power, rated voltage, rated current,

rated frequency, rated speed, motor connection, rated power factor, etc. In case of FVC drive control mode,

it is required to select the optional PG card and set correct encoder parameters.

We are committed to continuously improving our products and product data, so the data provided by us may

be modified without prior notice.

For the latest changes and contents, please visit www.sinee.cn

User’s Guide for EM760 series high-performance vector inverter

3

Safety precautions

Safety definition: Safety precautions are divided into the following two categories in this manual:

Danger: The dangers caused by nonconforming operations may include serious injuries and even

deaths.

Note: The danger caused by nonconforming operations, including moderate or minor injuries and

equipment damage.

During the installation, commissioning and maintenance, please read this chapter carefully, and follow the

safety precautions herein. Our company will not be liable for any injury or loss arising from nonconforming

operations.

Precautions

Before installation:

Danger

1. Do not install the product in the case of water in the package or missing or damaged components found in

unpacking!

2. Do not install the product in the case of inconsistency between the actual product name and identification on

the outer package.

Warning

1. When opening the wooden case, do wear gloves; to prevent person injuries, do not contact the sealing plate

with hands!

2. When handling the inverter, please hold its bottom. If you hold the front cover, the inverter body may fall

down to cause injuries!

3. Handle the controller with care; otherwise, it may be damaged!

4. Never use the inverter damaged or with some parts missing; otherwise, injuries may be caused!

5. Do not touch components of the control system with your hands; otherwise static charge may be generated to

cause damage to the inverter!

6. The inverter has undergone withstand voltage testing before delivery. Do not perform withstand voltage

testing on your own; otherwise the inverter may be damaged!

During installation:

Danger

1. Please install the controller on metal or other flame-retardant objects and keep it away from combustible

materials; otherwise, a fire may be caused!

2. Do not loosen the fixing bolts of components, especially those with red marks!

Warning

1. The inverter shall not be installed in a place with conductive dust, corrosive gas, salt spray, oily dirt,

condensation, vibration or direct exposure to sunlight!

2. Never allow wire connectors or screws to fall into the inverter; otherwise, the inverter may be damaged!

3. When the inverter is installed a relatively closed cabinet or space, pay attention to the installation gap to

ensure the effects of heat dissipation.

During wiring:

Danger

1. Observe the instructions in this manual and make wiring done by professional electrical personnel; otherwise,

electric shock may be caused!

2. The inverter must be separated from the power supply by using a circuit breaker (it is recommended to use a

circuit breaker of greater rated current that is the most approximate to twice the rated current of the inverter);

otherwise, a fire may be caused!

User’s Guide for EM760 series high-performance vector inverter

4

3. Before wiring, make sure that the power supply is OFF (zero energy). Do not carry out wiring when the

controller is powered on; otherwise, electric shock may be caused!

4. Never connect the input power supply to the output terminals (U, V, W) of the inverter. Pay attention to the

marks of wiring terminals, and connect wires correctly! Otherwise, the inverter may be damaged and even a

fire may be caused!

5. Ground the controller correctly and reliably as required; otherwise, electric shock may be caused!

Warning

1. Connect the output terminals (U, V, W) of the inverter to corresponding input terminals (U, V, W) of the

motor. An inconsistent phase sequence will cause the motor to reverse.

2. Make sure that the lines meet the EMC requirements and local safety standards. For wire diameters, refer to

the recommendations. Otherwise, an accident may occur!

3. Never connect the braking resistor directly between the DC bus and the terminal; otherwise the

inverter may be damaged and a fire may be caused!

4. Use a screwdriver with the specified torque to tighten main circuit terminals; otherwise, a fire may occur!

5. Never connect the phase-shifting capacitor and LC/RC noise filter to the output circuit.

6. Do not connect the electromagnetic switch and electromagnetic contactor to the output circuit. Otherwise, the

overcurrent protection circuit of the inverter will be enabled, and internal damage of the inverter may be

incurred in severe cases.

7. Do not dismantle the connecting cable inside the inverter; otherwise, internal damage may be caused to the

inverter.

Before power-on:

Danger

1. Check whether the supply voltage is consistent with the rated voltage of the inverter; otherwise, equipment

damage or fire may be incurred.

2. Check whether wiring of power input terminals (R, S and T) and output terminals (U, V and W) is connected

correctly;

3. Check whether there is a short circuit among the peripheral circuits connected to the inverter and whether all

connected lines are tightened; otherwise, the inverter may be damaged!

Warning

1. The inverter must not be powered on until it is properly covered; otherwise, electric shock may be caused!

2. The wiring of all peripheral accessories must be in line with the instructions in this manual. All wires should

be connected correctly according to the circuit connections in this manual. Otherwise, an accident may occur!

After power-on:

Danger

1. Never touch the inverter and surrounding circuits; otherwise, electric shock may occur!

2. If the indicator does not turn on or the keyboard does not display after electrification, immediately turn off the

power switch; 10 minutes later, check if the wiring is connected properly. Do not touch the inverter terminals

R, S and T and any power terminal by hand or with a screwdriver; otherwise, electric shock may occur! After

eliminating the causes of wiring errors, contact our customer service personnel immediately.

3. Never touch any wiring terminals of the inverter after electrification; otherwise, electric shock may occur!

4. Do not disassemble any parts of the inverter while it is powered on.

Warning

1. If parameter identification is required, please pay attention to the danger of injury caused by the rotating

motor. Check the safety before parameter identification; otherwise, an accident may be caused!

2. Do not change the parameters set by the inverter manufacturer without permission; otherwise, the inverter

may be damaged!

During maintenance:

Danger

User’s Guide for EM760 series high-performance vector inverter

5

1. Never carry out repair and maintenance in the live state; otherwise, electric shock may be caused!

2. Maintenance of the inverter must be carried out 10 minutes after the main circuit is powered off and the

display interface of the keyboard is disabled; otherwise, the residual charge in the capacitor will do harm to

the human body!

3. Personnel without professional training are not allowed to repair and maintain the inverter; otherwise,

personal injury or inverter damage may be caused!

4. After replacement of the inverter, it is required to set and check the parameters. Plugging and unplugging

operations must be done with power disconnected!

5. The synchronous motor can rotate to generate electricity. For maintenance and repair of the inverter, it is

required to wait 10 minutes after the motor stops rotation and have safety measures in place before

disconnecting the motor and the inverter; otherwise, electric shock may occur!

During operation:

Danger

1. Do not touch the cooling fan, radiator and discharge resistor to feel the temperature; otherwise, burns may be

caused!

2. Non-professional technicians must not test signals when the controller is in operation; otherwise, personal

injury or equipment damage may be caused!

Warning

1. Prevent any object from falling into the inverter in operation; otherwise, the inverter may be damaged!

2. Do not start or stop the inverter by turning on or off the contactor; otherwise, the inverter may be damaged!

Precautions

Motor insulation inspection

When the motor is used for the first time or after long-term storage or subject to regular inspection, its insulation

should be checked to prevent the inverter from damage caused by failure of the motor winding insulation. During

the insulation inspection, the motor must be disconnected from the inverter. It is recommended to use a 500V

megohmmeter. The measured insulation resistance must not be less than 5MΩ.

Thermal protection of motor

If the motor used does not match the rated capacity of the inverter, especially when the rated power of the inverter

is greater than that of the motor, the motor must be protected by adjusting the motor protection parameters of the

inverter or installing a thermal relay in front of the motor.

Operation above power frequency

Some inverters can provide 0.00Hz~600.00Hz/0.0Hz~3000.0Hz output frequency. When the motor needs to

operate above the rated frequency, please consider the capacity of the mechanical device. Otherwise, equipment

damage or even life-threatening accidents may occur.

Presence of voltage-dependent device or capacitor increasing the power factor on output side

The inverter outputs PWM waves. If there is a capacitor increasing the power factor or voltage-dependent resistor

for lightning protection on the output side, the inverter may be subjected to instantaneous overcurrent and even

damage. Do not use these devices.

Use beyond rated voltage

The inverter should not be used beyond the allowable working voltage range specified in this manual; otherwise,

components inside the inverter are prone to damage. If necessary, use the appropriate step-up or step-down device

for voltage transformation.

Lightning impulse protection

This inverter series is equipped with a surge current protection device for protection against induced lightning. In

lightning-prone places, a lightning protection device should be added before the inverter.

Altitude and derating

In areas with an altitude of more than 1,000m, where heat dissipation of the inverter is poor due to thin air,

derating is required (derating by 1% per 100m altitude increase to maximum 3,000m; for ambient temperature

User’s Guide for EM760 series high-performance vector inverter

6

above 50℃, derating by 1.5% per 1℃ temperature rise to maximum 60℃). Contact us for technical advice.

Precautions for scrapping of inverter

Burning of the electrolytic capacitors of the main circuit and printed circuit board may result in explosion, and

burning of plastic parts may generate toxic gases. Please dispose of the controller as a kind of industrial waste.

Scope of application

This product is not designed and manufactured as a device or system of vital importance. Do not use this product

in these cases.

This product is manufactured under strict quality management. When failure of this product may cause a major

accident or loss, please install a safety device.

Prevention of electric shock

Please read all requirements of safety precautions! Maintenance of the inverter must be carried out 10 min after the

main circuit is powered off and the display interface of the keyboard is disabled; otherwise, the residual charge in

the capacitor will do harm to the human body!

Anti-toppling

The cabinet has an anti-toppling label attached onto it. You may check the label upon receiving the goods to know

transport condition of the goods and reject the goods if the label color has changed.

Transportation

When you select transport of the inverter in a cabinet, it is necessary to protect the whole cabinet with anti-shock

measures.

User’s Guide for EM760 series high-performance vector inverter

7

TABLE OF CONTENTS

Preface........................................................................................................................................1

Safety precautions.....................................................................................................................3

Chapter 1 Overview ..................................................................................................................8

Chapter 2 Installation............................................................................................................. 11

Chapter 3 Wiring.....................................................................................................................21

Chapter 4 Keyboard Operations............................................................................................30

Chapter 5 Trial Run................................................................................................................ 34

Chapter 6 Solution ..................................................................................................................41

Chapter 7 Maintenance........................................................................................................... 46

Chapter 8 Select Accessories...................................................................................................48

Chapter 9 Function Code Table .............................................................................................51

User’s Guide for EM760 series high-performance vector inverter

8

Chapter 1 Overview

1.1 Model and Specification of EM760 Series Inverter

Rated voltage of power supply: Three-phaseAC 340V~460V

Applicable motor: Three-phaseAC asynchronous motor and permanent magnet synchronous motor.

Rated voltage of

power supply

Model

Applicable motor power

(kW)

Rated output current (A)

Three-phaseAC

340~460V

EM760-0R7G/1R5P-3B

0.75/1.5

2.5/4.2

EM760-1R5G/2R2P-3B

1.5/2.2

4.2/5.6

EM760-2R2G/3R0P-3B

2.2/3.0

5.6/7.2

EM760-4R0G/5R5P-3B

4.0/5.5

9.4/12

EM760-5R5G/7R5P-3B

5.5/7.5

13/17

EM760-7R5G/9R0P-3B

7.5/9.0

17/20

EM760-011G/015P-3B

11/15

25/32

EM760-015G/018P-3B

15/18.5

32/38

EM760-018G/022P-3B

18.5/22

38/44

EM760-022G/030P-3B

22/30

45/59

EM760-030G/037P-3/3B

30/37

60/73

EM760-037G/045P-3/3B

37/45

75/87

EM760-045G/055P-3/3B

45/55

90/106

EM760-055G/075P-3/3B

55/75

110/145

EM760-075G/090P-3/3B

75/90

150/169

EM760-090G/110P-3

90/110

176/208

EM760-110G/132P-3

110/132

210/248

EM760-132G/160P-3

132/160

253/298

EM760-160G/185P-3

160/185

304/350

EM760-200G/220P-3

200/220

380/410

EM760-220G/250P-3

220/250

426/456

EM760-250G/280P-3

250/280

465/510

EM760-280G/315P-3

280/315

520/573

EM760-315G/355P-3

315/355

585/640

EM760-355G/400P-3

355/400

650/715

EM760-400G/450P-3

400/450

725/810

EM760C-450G/500P-3

450/500

820/900

EM760C-500G/560P-3

500/560

900/1010

EM760C-560G/630P-3

560/630

1010/1140

Table 1–1 Technical Specifications of EM760 Series Inverter

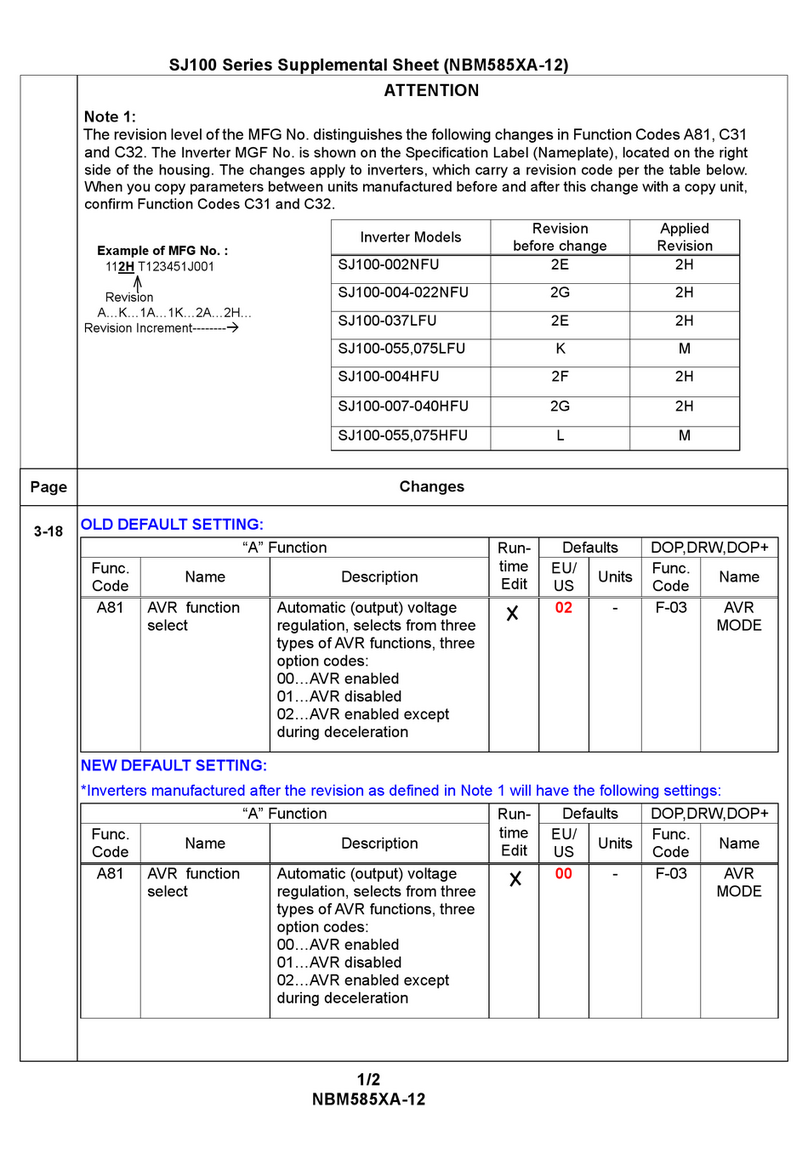

Item

Specification

Power

supply

Rated voltage of

power supply

Three-phase 340V-10% to 460V+10%

50-60Hz ±5%; voltage unbalance rate: <3%

Output

Maximum output

voltage

The maximum output voltage is the same as the input power voltage.

Rated output current

Continuous output of 100% rated current

Maximum overload

current

G model: 150% rated current for 60s

P model: 120% rated current for 60s (2kHz carrier; please derate for carriers

above this level)

Basic

control

functions

Driving mode

V/F control (VVF);

Speed sensorless vector control (SVC)

Speed sensor vector control (FVC)

Input mode

Frequency (speed) input, torque input

Start and stop

Keyboard, control terminal (two-line control and three-line control),

User’s Guide for EM760 series high-performance vector inverter

9

control mode

communication

Frequency control

range

0.00~600.00Hz/0.0~3000.0Hz

Input frequency

resolution

Digital input: 0.01HzAnalog input: 0.1% of maximum frequency

Speed control range

1:50 (VVF), 1:200 (SVC), 1:1000 (FVC)

Speed control

accuracy

±0.5% (VVF), ±0.2% (SVC), ±0.02% (FVC)

Acceleration and

deceleration time

0.01s~600.00s/0.1s~6000.0s/1s~60000s

Voltage/frequency

characteristics

Rated output voltage 20%~100% adjustable, reference frequency

1Hz~600Hz/3000Hz adjustable

Torque boost

Fixed torque boost curve, any V/F curve optional

Starting torque

150%/3Hz (VVF), 150%/0.25Hz (SVC), 180%/0Hz (FVC)

Torque control

accuracy

±5% rated torque (SVC), ±3% rated torque (FVC)

Self-adjustment of

output voltage

When the input voltage changes, the output voltage will basically remain

unchanged.

Automatic current

limit

Output current is automatically limited to avoid frequent overcurrent trips.

DC braking

Braking frequency: 0.01 to maximum frequency Braking time: 0~30S

Braking current: 0%~150% rated current

Signal input source

Communication, multi-speed, analog, high-speed pulse, etc.

Input and

output

function

Reference power

supply

10.5V±0.5V/20mA

Terminal control

power

24V/200mA

Digital input

terminal

7 (standard configuration X1~X7) + 3 (extension card X8~X10)-channel

digital multi-function inputs:

X7 can be used as a high-speed pulse input terminal (F02.06 = 35/38/40);

X1~X6 and X8~X10, totally 9 terminals that can only serve as ordinary digital

input terminals

Analog input

terminal

3 (standard configurationAI1 ~ AI3) + 1 (extension cardAI4)-channel analog

input:

1-channelAI1: support 0 ~ 10V or -10~ 10V, optional for selection by using

function code F02.62;

2-channelAI2/AI3: support 0 ~ 10V or 0~ 20mAor 4~ 20mA, optional for

selection by using function code F02.63 and

F02.64 is optional;

1-channelAI4: support 0 ~ 10V or -10~ 10V, optional for selection by using

function code F02.65

Digital output

terminal

2 (standardY1/Y2) open-collector multi-function outputs +

2 (R1: EA/EB/EC and R2: RA/RB/RC) relay multi-function outputs +

2 (extension card) (R3: RA3/RC3 and R4: RA4/RC4) relay multi-function

outputs

Maximum output current of the collector: 50 mA;

Relay contact capacity 250VAC/3A or 30VDC/1A, with EA-EC and RA-RC

normally open, EB-EC and RB-RC normally closed; RA3-RC3, RA4-RC4

normally open

Analog output

terminal

2-channel (M1/M2) multi-function analog output terminals to output 0~10V or

0~20mA or 4~20mA, optional for selection by using function codes F03.34

and F03.35

V

LCD display

The LCD digital tube displays relevant information about the inverter.

Parameter copying

Parameter settings of the inverter can be uploaded and downloaded for fast

User’s Guide for EM760 series high-performance vector inverter

10

parameter copying.

Protectio

n

Protective Function

Short circuit, overcurrent, overvoltage, undervoltage, phase loss, overload,

overheat, overspeed, load loss, external fault, etc.

Use

condition

s

Location

Indoor, at an altitude of less than 1 km, free of dust, corrosive gases and direct

sunlight

Applicable

environment

-10℃ to +50℃, derating by 5% per 1℃ increase above 40℃, 20% to 90%RH

(non-condensing)

Vibration

Less than 0.5g

Storage environment

-40℃~+70℃

Installation method

Wall-mounted, floor-standing electrical control cabinet, through-wall

Protection level

Standard IP21/IP20 (remove the plastic cover at the top of the plastic case)

Cooling method

Forced air cooling

User’s Guide for EM760 series high-performance vector inverter

11

Chapter 2 Installation

2.1 Product check

Warning

⚫Never install the inverter damaged or with some parts missing.

Otherwise, injuries may be caused.

When you receive the product, please check it against the table below.

Item to be confirmed

Confirming methods

Check whether the product is consistent

with the order.

Check the nameplate on the side face of the inverter.

Check whether any part is damaged.

Check the overall appearance for damage caused in transportation.

Check whether the fastened parts (e.g.

screws) are loose.

If necessary, check the product with a screwdriver.

In the case of any defect, contact the agent or our Marketing Department.

⚫Nameplate

⚫Description of inverter model

User’s Guide for EM760 series high-performance vector inverter

12

EM760:高性能系列

空:柜内安装型

C:柜机

适配负载功率:

0R7

0.75kW 4R0

4.0kW

……

……

018

18.5kW

……

……

EM 760 –4R0G/5R5P –3 B

B:内置制动单元

无:不含制动单元

电压等级:

2:三相220V

3:三相380V

6:三相660V

标识

G

P

适配电机类型

通用机型

风机水泵型

2.2 Outline dimensions and installation dimensions

EM760 inverters have 3 types of appearance and 13 installation sizes, and may be connected with external

keyboards and trays. As shown in Fig. 2-1 and Table 2-1.

安装键盘托架开孔尺寸:

143×105mm

146.6

23.7

110.6

Reference size of keyboard bracket opening

(a) Dimension of keyboard tray

EM760:

High-performance series

Null: Installation in cabinet

TC: Cabinet type

Identification

G

P

Compatible motor type

Universal model

Fan pump type

B: Built-in braking unit

None: Without braking unit

Voltage class:

2: Three-phase 220V

3: Three-phase 380V

6: Three-phase 660V

Compatible load power:

Dimension of opening for

keyboard tray:

143 ×105mm

User’s Guide for EM760 series high-performance vector inverter

13

W

H

W1

H1

D

D2

D1

d

H2

(b) Appearance of EM760-0R7G/1R5P~022G/030P inverters

D1

D2

H

H1

H2

D

W1

W

d

(c) Appearance of EM760-030G/037P~400G/450P inverters

User’s Guide for EM760 series high-performance vector inverter

14

W

H2

H

H1

D

D2

W1

D1

d

(d) Appearance of EM760- 450G/500P~560G/630P inverters

Fig. 2-1 Overall dimensions of EM760 Series Keyboard and Inverter

User’s Guide for EM760 series high-performance vector inverter

15

Table 2-1 Outer and installation dimensions of EM760 inverters

Specifications

W

W1

H

H1

H2

D

D1

D2

d

appear

ance

EM760-0R7G/1R5P-3

B

95

82

230

222

218

171

132

96

4.5

(b)

EM760-1R5G/2R2P-3

B

EM760-2R2G/3R0P-3

B

EM760-4R0G/5R5P-3

B

EM760-5R5G/7R5P-3

B

110

95

275

267

260

187

146

105

5.5

EM760-7R5G/9R0P-3

B

EM760-011G/015P-3B

140

124

297

289

280

207

163

120

5.5

EM760-015G/018P-3B

EM760-018G/022P-3B

190

171

350

340

330

220

173

128

7

EM760-022G/030P-3B

EM760-030G/037P-3/

3B

254

200

484

465

440

221

180.5

158

9.5

(c)

EM760-037G/045P-3/

3B

EM760-045G/055P-3/

3B

304

210

540

519

480

263

217

197

9.5

EM760-055G/075P-3/

3B

EM760-075G/090P-3/

3B

324

230

638

613

570

264

220

181

11.5

EM760-090G/110P-3

339

270

623

600

578

296

243

243

11.5

EM760-110G/132P-3

EM760-132G/160P-3

422

320

786

758

709

335

271

256.4

11.5

EM760-160G/185P-3

EM760-200G/220P-3

441

320

1025

989

942

357

/

285

11.5

EM760-220G/250P-3

EM760-250G/280P-3

560

450

1204

1170.5

1100

400

/

333

13

EM760-280G/315P-3

EM760-315G/355P-3

660

443

1597

1567

1504

430

375.5

323.5

13

EM760-355G/400P-3

EM760-400G/450P-3

EM760C-450G/500P-3

805

756

2145

1945

1804

700

440

165

13

(d)

EM760C-500G/560P-3

EM760C-560G/630P-3

2.3 Installation Site Requirements and Management

Installation site

The installation site should meet the following conditions:

⚫The room is well ventilated.

⚫The ambient temperature is -10C to 50C.

⚫The controller should be free from high temperature and humidity (less than 90% RH) or rainwater

and other liquid droplets.

User’s Guide for EM760 series high-performance vector inverter

16

⚫Please install the inverter on a fire-retardant object (e.g. metal). Never install it on flammable objects

(e.g. wood).

⚫No direct sunlight.

⚫No flammable or corrosive gas and liquid, dust, oily dust, floating fibers or conductive dust.

⚫The installation foundation should be secured and vibration-free. Do not pose any obstacle within

1m behind the inverter cabinet, so as to provide some space for maintenance.

⚫Avoid electromagnetic interference and keep the controller away from interference sources.

Preventive measures

Take protective measures to the inverter during installation to prevent metal fragments or dust generated in

drilling and other processes from falling into the inverter. Remove the protection after installation.

2.4 Installation Direction and Space

The EM760 inverters are equipped with cooling fans for forced air cooling. To ensure good cyclic cooling

effects, the inverter must be installed in a vertical direction, and sufficient spaces must be reserved between the

inverter and adjacent objects or baffles (walls). Refer to Fig. 2-2.

大于120mm

大于120mm

对流口

大于50mm大于50mm

Fig. 2-2 Inverter installation direction and space

2.5 Panel removal and installation

Wiring of the main circuit, control circuit and expansion card for the EM760 Series requires removal of the

top cover. When wiring is completed, install the wiring ducts and top cover in the reverse order of removal.

(1) EM760 0R7G/1R5P~022G/030P panel removal

>50mm

>50mm

>120mm

Convect

ion

opening

大于 l20mm

User’s Guide for EM760 series high-performance vector inverter

17

按压

①用工具将下盖板

螺钉拆出 ②向内按压两侧卡扣,

将下盖板倾斜向外拉出

③如使用扩展卡,则先将上

盖板固定螺钉拆出,再将键

盘网口拔出即可拆卸上盖板

Fig. 2-3 EM760-0R7G/1R5P~022G/030P panel removal diagram

(2) EM760 030G/037P~400G/450P panel removal

①用工具将面板上下两

侧螺钉取下

②用手转动面盖右侧即

可打开面盖

③转动面盖,面盖最终可转

到110°左右

Fig. 2-4 EM760-030G/037P~400G/450P panel removal diagram

2.6 Through-wall installation

EM760 0R7G/1R5P~160G/185P support through-wall installation, which can realize dissipating 70% of the

total heat generated out of the device (cabinet), so as to reduce heat accumulation. Besides, through-wall

installation may also prevent entry of wood chips, paper scraps, dust, metal dust and other debris into the inverter

and improve reliability of the inverter.

①Use a tool to remove

screws on the top and

bottom sides of the panel

②Turn the right side of the

panel by hand to open the

panel

③Turn the panel, and it can be

turned finally to around 110°

Press

①Use a tool to remove

the screws fixing the

bottom cover

②Press the side clips inwards,

and pull the bottom cover aslant

outward

③When an expansion card is used,

the top cover can be removed after

the screws fixing the top cover are

removed and the keyboard is

unplugged from the network access

port

User’s Guide for EM760 series high-performance vector inverter

18

The bracket for through-wall installation is available as an optional part for purchase. If it is needed, please contact

us.

Fig. 2-5 Through-wall installation

风扇

独立风道

外部散热

外部进气

内部进气

内部散热

Internal heat

dissipation

External heat

dissipation

Fan

Independent

air duct

Internal air supply

External air supply

User’s Guide for EM760 series high-performance vector inverter

19

Table 2-2 Number of screws and opening dimension for EM760 0R7G/1R5P~160G/185P

through-wall installation

Frequency converter model

Bracket

installation

screws

Through-wall

installation

screws

Opening size (L×W)

EM760-0R7G/1R5P~4R0G/5R5P-3B

2×M4

6×M6

235mm×100mm

EM760-5R5G/7R5P~7R5G/9R0P-3B

2×M4

6×M6

280mm×115mm

EM760-011G/015P~015G/018P-3B

2×M4

6×M6

300mm×145mm

EM760-018G/022P~022G/030P-3B

4×M4

6×M6

355mm×195mm

EM760-030G/037P~037G/045P-3/3B

14×M5

6×M8

500mm×265mm

EM760-045G/055P~055G/075P-3/3B

14×M5

6×M8

550mm×320mm

EM760-075G/090P-3/3B

14×M5

6×M10

645mm×340mm

EM760-090G/110P~110G/132P-3

14×M5

6×M10

630mm×350mm

EM760-132G/160P~160G/185P-3

13×M6

6×M10

715mm×440mm

支架安装螺钉

透壁安装支架

透壁安装螺钉

Fig. 2-6 Through-wall installation diagram of EM760-0R7G/1R5P~022G/030P

Bracket installation

screws

Through-wall

installation bracket

Through-wall

installation

screws

User’s Guide for EM760 series high-performance vector inverter

20

透壁安装支架

支架安装螺钉

支架安装螺钉

Fig. 2-7 Through-wall installation diagram of EM760-030G/037P~110G/132P

透壁安装支架

支架安装螺钉

透壁安装螺钉

Fig. 2-8 Through-wall installation diagram of EM760-132G/160P~160G/185P

Through-wall installation

bracket

Bracket installation screws

Bracket

installation

screws

Through-wall installation

bracket

Bracket installation

screws

Through-wall installation

screws

Other manuals for EM760 Series

1

This manual suits for next models

34

Table of contents

Other Sinee Inverter manuals