Sinee EA100-2R8-2A User manual

1

Preface

Thank you for purchasing EA100 series servo drive.

EA100 is a high performance general-purpose servo drive, which can be widely used in the numerically controlled machine

tools, printing and packaging machinery, textile machinery, robot automatic production line and other automation fields.

Since SINEE is committed to the development and improvement of products and products documents, this manual will be

updated without notice.

2

Safety Information

Danger: The label indicates that a failure to follow instructions can result in

serious injury or even death.

Caution: The label indicates that a failure to follow instructions can result in moderate or slight injury and device damage.

Please read this chapter carefully before system installation, debugging and maintenance and always follow the safety precautions below during

operation. SINEE will not undertake any damage or loss caused by a failure to follow the instructions.

Safety Precautions

Before Installation:

Danger

1. Do not install servo drive if its package is wetted or any its component is missing or

broken.

2. Do not install servo drive if the label information on its package is not identical to that on

servo drive.

Caution

1. Be careful when carrying or transporting servo drive so as to avoid damage!

2. Do not use servo drive if it is damaged or any component is missing so as to avoid

injury!

3. Do not touch the parts of control system with bare hands so as to avoid ESD!

During Installation:

Danger

1. Installation base shall be metal or other non-flammable material so as to prevent fire risk.

Caution

1. Ensure that no cable strips or screws are dropped servo drive so as to avoid damage to

servo drive.

2. Install servo drive at a place with less vibration and no direct sunlight.

3. Consider the installation space for cooling purpose when servo drive is installed in a

closed cabinet or space.

Wiring:

Danger

1、1.Wiring must be performed by authorized and qualified personnel so as to avoid unexpected

accidents.

2、2.A circuit breaker must be installed between servo drive and the mains so as to prevent fire

risk.

3、3.Ensure that power is off before wiring, and ground inverter in accordance with the

applicable wiring standard so as to avoid electric shock.

4、4.Grounding terminal must be grounded reliably so as to avoid electric shock and fire risk.

Caution

1、1. Never connect input power supply cable to output terminals U, V or W of servo drive. Pay

attention to terminal symbols and connect to the terminals correctly so as to prevent risks of

damaging servo drive.

2、2. Be sure that wiring meets EMC requirements and local safety standards. Cable should be in

recommended sizes so as to prevent accident risk.

3、3.Do not connect braking resistor to DC bus terminals + and –so as to prevent fire risk.

4、4.Tighten terminals with a screwdriver of specified torque so as to prevent fire risk.

5、5.Do not connect a phase-shifting capacitor or an LC/RC noise filter to output circuits.

6、6.Do not connect a solenoid switch or an electromagnetic contactor to output circuits.

Otherwise, it will trigger the action of the overcurrent protection circuit or even damage the

internal parts of servo drive.

7、7.Do not disconnect internal cable of servo drive, or else this can possibly damage the internal

parts of servo drive.

3

Before Power-on:

Danger

1、1.Verify that input voltage is identical to the rated voltage of servo drive, input terminals L1,

L2 and L3 and output terminals U, V or W are correctly connected, there are no short

circuit phenomena for the wiring of servo drive and its peripheral circuits, and all wires are

in good connection. Otherwise, this may result in servo drive damage.

2、2.Never perform voltage withstanding test on servo drive, because it has been done at the

factory. Otherwise, this may result in accident.

Caution

1、1.The front cover of inverter must be closed before inverter is powered on. Otherwise, it

may result in an electric shock.

2、2. The wiring of all peripherals must be conducted in accordance with the guidance of this

manual. Otherwise, it may result in an electric hazard.

After Power-on:

Danger

1. Do not touch servo drive or its peripheral circuits with wet hands to avoid the electric

shock.

2. If the indicator is off or the keypad does not display any information after power-on,

please cut off the power supply immediately. Never touch any terminal of L1, L2 or L3 of

servo drive or the connecting terminals with hands or a screw driver, or else an electric

shock accident may occur. Contact our customer service personnel immediately after

cutting off the power.

3. After being powered on, servo drive will automatically check the safety of the external

strong circuit automatically. Therefore, do not touch wiring terminal U, V or W of servo

drive or the wiring terminal of the motor with bare hands, otherwise it will result in electric

shock.

Caution

1、1.If you need to check parameter settings, be careful of personal safety when the motor is

running so as to avoid accidents.

2、2.Do not change default parameter setting without approval to avoid damage.

During Operation:

Danger

1、1. Never touch cooling fan, heat sink or discharge resistor with bare hands for checking

temperature, which may result in burning!

2、2. Only qualified technicians are allowed to detect signal during operation so as to prevent

personal injury or device damage.

Caution

1、1.Prevent any foreign items from being dropped into the device during operation, so as to

avoid damage to the device.

2、2. Do not control the start/stop of servo drive by ON/OFF of the contactor so as to avoid

damage to the device.

3.Do not contact the rotating shaft of the motor on running so as to prevent personal

injury..

Maintenance:

Danger

1、1.Maintain and inspect the device only after servo drive is powered off to avoid electric

shock.

2、2. Maintain and inspect servo drive only after its main circuit is powered off and CHARGE

indicator is off. Otherwise, the residual electric charge of capacitor may result in personal

injury.

3、3. Maintenance and inspection can be performed by well-trained technicians only, so as to

avoid personal injury or device damage.

4、4. Parameter setting is required if inverter has been replaced. Plug-in & plug-out should be

performed after power-off.

Attentions

4

Varistor or Power Factor Improvement Capacitor on Inverter Output

Servo drive outputs PWM wave. Do not use servo drive, if a power factor improvement capacitor or a lightning varistor is on output side, which

may easily result in transient overcurrent of servo drive, or even damage servo drive.

Surge Protection

A surge protection device is installed in servo drive to prevent it from induction lightning stroke on a certain degree. Additional protection

devices are required in front of servo drive in the places where thunder and lightning occur frequently.

Altitude and Derating

When servo drive is used in an area at an altitude of over 1,000m, the cooling effect will degrade, so it must be derated. For details, please

consult SINEE.

Attentions at Servo Drive Scrapping

Burning the electrolytic capacitors of the mains and PCB may result in explosion and burning plastic parts may generate toxic gas. Please handle

them as industrial wastes when servo drive is scrapped.

5

CONTENT

1 Product Information ..............................................................................................................6

1.1 Verifying Product ..........................................................................................................6

1.2 Model Numbering Scheme and Nameplate...................................................................6

1.3 Model Number List .......................................................................................................7

1.4 Servo Drive Control Mode............................................................................................ 7

2 Installation..............................................................................................................................8

2.1 Caution..........................................................................................................................8

2.2 Storage ambient conditions ...........................................................................................8

2.3 Installation ambient conditions......................................................................................8

2.4 Servo Drive Installation Direction and Space................................................................8

2.5 Servo Motor Installation Direction and Space...............................................................9

2.6 Circuit breakers and fuse recommendations................................................................10

2.7 Brake resistance selection............................................................................................ 10

2.8 EMI Filters ..................................................................................................................12

3 Display & Operation............................................................................................................ 13

3.1 Display and key operation Exterior............................................................................. 13

3.2 Display and operation mode........................................................................................13

3.3 Parameter setting Description...................................................................................... 13

3.4 Status Display.............................................................................................................. 14

3.5 Monitor display ........................................................................................................... 14

3.6 Fault and alarm display ...............................................................................................14

4 Wiring ...................................................................................................................................15

4.1 Peripheral connection..................................................................................................15

4.2 Main circuit wiring...................................................................................................... 15

4.3 CN5 encoder signal terminal.......................................................................................18

4.4 CN4 Control signal terminal ....................................................................................... 20

4.5 CN2, CN3 communication terminal wiring.................................................................31

4.6 CN1 analog output terminal ........................................................................................31

4.7 Holding brake.............................................................................................................. 32

4.8 Standard wiring diagram for control circuit................................................................. 34

4.9 Control circuit wiring precaution ................................................................................36

4.10 Servo drive main circuit block diagram.....................................................................36

5 Running and debugging.......................................................................................................38

5.1 Drive power on............................................................................................................38

5.2 Trial running................................................................................................................38

5.3 Servo enable method ................................................................................................... 38

5.4 Speed control mode.....................................................................................................39

5.5 Torque control mode debugging steps.........................................................................40

5.6 Gain parameter adjustment strategy ............................................................................40

6 Function Parameters............................................................................................................42

6.1 Function parameters define .........................................................................................42

6.2 Function parameter list................................................................................................42

7 Function parameter details..................................................................................................54

7.1 P0 group - Monitoring parameters............................................................................... 54

7.2 P1-xx Basic control parameters...................................................................................58

7.3 P2-xx Internal multi segment position (Pr) control parameter.....................................74

7.4 P3-xx Internal multi-speed control parameters............................................................76

7.5 P4-xxTorque control parameter...................................................................................76

7.6 P5-xx Gain tuning parameters.....................................................................................77

7.7 P6-xx Input and output(DI/DO)parameter................................................................... 82

7.8 P7-xx Communication parameters ..............................................................................87

7.9 P8-xx Auxiliary check even-parity function parameters..............................................88

7.9 Pb-xx the origin of regression function parameters.....................................................91

8 Communications protocol.................................................................................................... 96

8.1 Application Scope .......................................................................................................96

8.2 Physical interface ........................................................................................................ 96

8.3 Protocol format............................................................................................................96

8.4 Command interpretation..............................................................................................96

8.5 Protocol Format Description .......................................................................................97

8.6 Example....................................................................................................................... 98

9 Fault alarm and Treatment ................................................................................................. 99

9.1Fault Diagnosis and Treatment.....................................................................................99

9.2 Alarm Diagnose and Treatment Measures.................................................................102

10 Specification......................................................................................................................104

10.1 Technical specification............................................................................................ 104

10.2 Dimensions.............................................................................................................. 105

10.3 Motor specification..................................................................................................106

10.4 SER series servo motor dimension.......................................................................... 108

10.5 SER series servo motor overload characteristics..................................................... 110

6

1 Product Information

1.1 Verifying Product

Check and verify the product:

Item

Method

Check if they are identical to the

purchase order.

Check the nameplate at the side of inverter.

Any damage.

Check the overall appearance to see if they are

damaged in transportation.

Any loosened screws or other

fastening parts.

Check with a screw driver if necessary.

If you find any quality problem, please contact SINEE Direct Sale Department or the distributor.

1.2 Model Numbering Scheme and Nameplate

1.2.1 Nameplate

EA100 series servo drive

产品型号

适配电机功率

电源规格

输出规格

产品条码

产品序列号

额定输出电流

SER series servo motor

NOTE:The actual product nameplate may be different from as shown in the figure.

1.2.2 Model Numbering Scheme

Servo drive:

Servo motor:

7

1.3 Model Number List

Servo Drives

Matched Servo Motors

Model of servo

drives

Input voltage

Rated

output

current

Size

Model of servo motors

Motor

power

EA100-2R8-2A

1/3 phase AC

220V

2.8A

SIZE A

SER06-0R4-30-2AAY

400W

EA100-5R5-2A

5.5A

SER08-0R7-30-2AAY

750W

EA100-7R6-2A

7.6A

SIZE B

SER13-1R0-20-2ABY

1000W

EA100-010-2A

3 phase AC

220V

10.0A

SER13-1R5-20-2ABY

1500W

EA100-5R4-3A

3 phase AC

380V

5.4A

SER13-1R5-20-3ABY

1500W

EA100-8R4-3A

8.4A

SER13-2R0-20-3ABY

2000W

EA100-012-3A

12.0A

SER13-3R0-20-3ABY

3000W

EA100-018-3B

18.0A

SIZE C

SER18-4R5-15-3BBZ

4500W

EA100-021-3B

21.0A

SER18-5R6-15-3BBZ

5600W

EA100-030-3B

30.0A

SER18-7R5-15-3BBZ

7500W

1.4 Servo Drive Control Mode

The drive can provide multiple control modes for users, please refers to as follows:

Type

Control mode and

function parameter

Display

Specification

Single

mode

Position mode

P1-00=1

P

Drive accepts position command to control motor

Running at target position.

Position command input by terminal, signal is pulse.

Speed mode

P1-00=0

S

Drive accepts speed command to control motor running to

targer speed.

Speed command can be provided by internal register (3

groups) or analog voltage input terminal, and confirm which

use at present based on DI.

Torque mode

P1-00=2

T

Drive accepts torque command to control motor

running to target torque.

Torque command can be provided by internal register (3

groups) or analog voltage input terminal, and confirm which

use at present based on DI.

Mixed

mode

Speed and Position

switch mode

P1-00=3

S-P

S and P can switch by DI terminal.

Torque and Position

Switch mode P1-00=5

T-P

T and P can switch by DI terminal.

Speed and Torque

switch mode

P1-00=4

S-T

S and T can switch by DI terminal.

8

2 Installation

2.1 Caution

Please pay special attention to the following:

The cable between servo drive and servo motor should stay relaxed, not tense.

If the cable between servo drive and servo motor is more than 20 meters, please

Strengthen UVW connection and encoder connection.

When the servo driver is fixed, the installation direction must be in accordance with the regulations, and each fixed screw must be locked.

For the determination of concentric with the servo motor shaft and equipment shaft, to

prevent the radial stress when motor running.

Four fixed screws of the servo motor must be locked according to the prescribed torque.

In order to make the cooling effect better, when install AC servo drives, the upper and lower, left and right and adjacent items and baffle

(wall) must keep enough space, otherwise it will cause fault.

When the servo driver is installed, it can not be dumped. The air suction and exhaust holes are not blocked, otherwise, the fault can be

caused.

2.2 Storage ambient conditions

Please put the product in its packing box before installation. If the drive is not used, in order to enable the product to meet the company's

scope of warranty and future maintenance, be sure to pay attention to the following conditions:

2.3 Installation ambient conditions

2.3.1 EA100 servo drive using ambient conditions:

Item

Description

Dust and gas

No dust, free of corrosive gas or liquid.

Ambient humidity

Relative humidity 20%~90%(no condensation)

Ambient temperature

0℃~+45℃

Vibration

Below 4.9m/s²

Impact

Below 49m/s²

Elevation

Below 1000m,please derating above 1000m

2.3.2 SER series servo motor using ambient conditions:

Item

Description

Ambient humidity

Relative humidity20%~80% (no condensation)

Ambient temperature

0℃~+40℃

Vibration

Below 4.9m/s²

Impact

Below 49m/s²

Elevation

Below 1000m,please derating above 1000m

Do not use motor in closed ambient. Closed ambient will lead to high temperature of motor, shorten the service life.

2.3.3 Other caution

In addition to the above ambient conditions, regardless of the drive or motor, when selecting the installation site, please observe the

following precautions,otherwise, may make the product can not meet the company's warranty coverage and future maintenance:

No high temperature.

No water drops, steam, dust and oil dust.

No corrosive or flammable gas or liquid.

No floating fiber or metal particles.

Installation base shall be solid and free from vibration.

No electromagnetic interference and away from interference source.

2.4 Servo Drive Installation Direction and Space

Servo drive and servo motor appearance size and weight specifications, please refer to the chapter 10.

2.4.1 Method

Please ensure the installation direction and walls are vertical. To use natural convection or fan for cooling of the servo drive. Through the

mounting hole, the servo driver is firmly fixed on the mounting surface.

When installing, please turn the servo drive front (the operator's actual mounting face) to the operator, and make it perpendicular to the wall.

2.4.2 Cooling

Item

Description

Storage temperature

-20℃~+65℃(high temperature: 80℃72hours)

Storage humidity

Relative humidity of 0% to 95% with no condensation

Vibration

Below 49m/s²

Impact

Below 490m/s²

9

In order to ensure the air convection, please refer to Figure 2-1, around the servo drive with enough space.

In order not to make the ambient temperature of the servo drive partial excessive phenomenon, so that to maintain a uniform temperature of

electric cabinet, please install cooling fan above servo drive in electric cabinet.

2.4.3 Ground

Make sure the ground terminal is grounded, otherwise, there may be a risk of electric shock or interference arising from false action.

Figure 2-1 Servo Drive Installation Direction and Space

2.5 Servo Motor Installation Direction and Space

2.5.1 Motor installation

SER series servo motor must be installed in a dry and solid platform, please keep good ventilation and heat radiation effect, and keep a

good grounding.

2.5.2 Installation diagram

Item

Description

Anti-rust

solution

Wipe clean servo motor shaft extension ends of the "anti rust agent" before

installation, and then do the relevant anti rust treatment

Encoder note

Installation to prohibit the impact of the shaft extension end, otherwise it

will cause internal encoder fragmentation.

Pulley

installation

When installing the pulleys in the servo motor shaft with keyway ,please

use screw on the shaft end. In order to install pulley, at first, the double

headed nail is inserted into the screw hole of the shaft, washer is used on

the surface of the coupling end and a nut gradually locked into the

pulley.

About the servo motor shaft with keyway, use the screw holes of shaft

end to install. About the shaft of no keyway, adopt the wear coupling or

similar method.

When removing the pulley, adopt pulley removal device to prevent shaft

subjected to impact.

In order to ensure safety, a protective cover or similar device shall be

installed in the rotating area.

10

Item

Description

Centering

In connection with the machine, please use the coupling, as well as the

axis of the servo motor and mechanical axis to keep in a straight line, the

circumference radial pulsation of the shaft coupling should not be

greater than 0.03mm. If the centering is not sufficient, it will produce

vibration, it can damage the bearings and encoders etc.

Installation

direction

The servo motor can be installed in horizontal direction or vertical

direction, do not install slant, otherwise it may cause motor bearing

wear.

Oil solution

When using at the place of water droplets drop , please confirm the servo

motor on the basis of the protection level (except the shaft through part).

When using for the site of oil droplets will drop to the shaft through part,

please specify the use of oil seal with the servo motor.

The servo motor operating conditions with oil seal:

Please ensure the oil level is lower than the oil seal lip when

using.

Please use when oil seal can keep oil splash in a good condition.

In the servo motor vertical installation, please pay attention not to use oil

seal.

Shaft through part: Refers to the gap of motor shaft from the end surface of the

protruding part

Stress condition

of cable

Don't make cable excessive bending or tension is applied to it, especially the

core wire of the encoder signal line is 0.12 mm or0.22 mm, very fine, so in

wiring and using, please don't make the stretching tight.

Connector parts

solution

For connector parts, please note the following:

The connector, please confirm there is no garbage or metal debris and

other foreign bodies in connector.

The connector connects to the servo motor please first from one side of

the servo motor circuit cable and cable main grounding wire must

reliable connection. If first connected one side of the encoder cable, the

encoder may be fault caused by the potential difference between the PE.

The connection, please confirm the correct pin arrangement.

The connector is made of resin. Do not apply impact to prevent damage

to the connector.

When cable maintain connection to handle, please hold the servo motor

main body. If only seize the cable handling, may be damaged or broken

cable or connector.

If you need to bend the cable, you should pay full attention to the

wiring , do not make the connector part of the pressure or tension, or

may cause the connector damage or poor contact.

2.6 Circuit breakers and fuse recommendations

If there is a drive to install the leakage circuit breaker to be used as the leakage fault protection, to prevent leakage circuit breakers

malfunction, please select the model about the sense of current in the 200mA above and the action time of 0.1 seconds above.

Fuse, please use the fast fuse model, its rated current should be based on the drive capacity of about 1.5 times.

Strongly recommended: The fuse and circuit breakers recognized by UL/CSA .

2.7 Brake resistance selection

When the motor's output torque and speed in the direction of the opposite, the energy will be transmitted back to the drive from the load.

This energy will be poured into the bus bar so that the voltage value of the bus inside the drive is increased, and the magnitude of the recharge

energy depends on the inertia of the motor and the load. If the system inertia small, may through drive internal capacitors to absorb recharge

energy, but if the system inertia is large, more than the energy that capacity absorb, voltage value may rise too high, causing the drive stop or

even damage, so when the voltage rises to a certain value, recharge energy must by a braking resistor to consume.

The following table 2-1 lists commonly used SER series servo motor rotor inertia and EA100 drive internal capacitive absorption ability, and

retrogradation energy calculation formula.

11

Table 2-1 SER series servo motor rotor inertia and retrogradation capacity absorbed

Model

Motor

rotor inertia

42

( 10 )J kg m

Retrogradation

from rated speed

to motionless

without load

Eo (J)

Capacity

maximum

retrogradatio

n

Ec (j)

EA100-2R8-2□

SER06-0R4-30-2□AY

0.3

1.48

16

EA100-5R5-2□

SER08-0R7-30-2□AY

1.01

4.99

24

EA100-7R6-2□

SER13-1R0-10-2□BY

17.14

9.42

41

EA100-7R6-2□

SER13-1R0-20-2□BY

8.71

19.1

41

EA100-010-2□

SER13-1R5-20-2□BY

12.08

26.5

41

EA100-5R4-3□

SER13-1R5-20-3□BY

12.08

26.5

34

EA100-8R4-3□

SER13-2R0-20-3□BY

17.14

37.67

49.6

EA100-012-3□

SER13-3R0-20-3□BY

25.58

56.22

49.6

EA100-018-3B

SER13-4R5-15-3BBZ

35.37

43.73

61.2

EA100-021-3B

SER13-5R6-15-3BBZ

45.51

56.26

91.8

EA100-026-3B

SER13-7R5-15-3BBZ

79.89

98.76

91.8

retrogradation energy calculation formula:

v:rpm,motor maximum speed

The motor rotor inertia of servo motor with brake is same with servo motor without

brake’s.

2.7.1 Built-in brake resistance

There is brake resistance in EA100 series drive, suitable for the general situation of the load inertia. About EA100 series built-in brake

resistance specifications, please refer to Table 2-2.

Table2-2 EA100 drive built-in brake resistance allowable minimum external brake resistance

Model

Brake resistance(built in)

Retrogradation

treated by built in

brake resistance

Allowable

minimum

external brake

resistance

Resistor(P8-18)

Capacity(P8-19)

EA100-2R8-2□

50Ω

100W

50W

50Ω

EA100-5R5-2□

50Ω

100W

50W

50Ω

EA100-7R6-2□

50Ω

100W

50W

40Ω

EA100-010-2□

50Ω

100W

50W

40Ω

EA100-5R4-3□

50Ω

100W

50W

50Ω

EA100-8R4-3□

50Ω

100W

50W

50Ω

EA100-012-3□

50Ω

100W

50W

45Ω

EA100-018-3B

40Ω

200W

90W

30Ω

EA100-021-3B

40Ω

200W

90W

30Ω

EA100-026-3B

40Ω

200W

90W

25Ω

2.7.2 External brake resistance capacity calculation

When the retrogradation capacity exceeded retrogradation capacity internal brake

resistance can dealt with, should use external braking resistance.

According to the calculation formula of retrogradation , assuming the load inertia is N times the inertia of the rotor of the motor, motor

from the rated speed to 0, retrogradation is (N+1) *Eo, the action cycle is T, then

Power of braking resistance

2.7.3 Note when using external braking resistance

When using external braking resistor, resistor connected to the P+ and C terminal, at the same time must remove the short circuit piece

installing between P+ and D, makes P and D two terminals in the open state.

The external braking resistance cannot be less than reported in table 2-2, otherwise it might damage the drive.

Please make the external resistor braking resistor value and the capacity set to the function parameters of drive correctly, otherwise it will

affect the execution of the function.

P8-18 (brake resistance), P8-19 (brake resistance capacity).

In the natural environment, when the braking resistor can handle retrogradation capacity (average) below the rated capacity, resistance

temperature will rise to 120℃above(in the continuous braking condition). For security, please use the forced cooling system, to reduce

the temperature of the brake resistor; or recommend the use of braking resistor with thermo switch. The load characteristics on braking

resistance, please refer to the manufacturer.

Note:

1) Please make the external braking resistor same with the internal braking resistor, otherwise,

may lead to drive damaged.

)(182/

2

0JJ v

E

T

NEE C))1((20

12

2) When using external braking resistance, if don‘t remove the short circuit piece which is

between P and D, it may lea to drive damaged.

2.8 EMI Filters

All of the electronic equipment (including servo drives) in normal operation, will produce some high frequency or low frequency noise, and

through the conduction or radiation interference peripheral equipment. If you can match the appropriate EMI filter and the correct installation

method, the interference will be reduced to a minimum.

When the servo driver and EMI filter are installed, we can follow the installation and wiring of the contents of the manual, we can be sure that it

can meet the following specifications:

1. EN61000-6-4(2001)

2. EN61800-3 (2004)PDS of category C2

3. EN55011+A2(2007)Class A Group 1

2.8.1 EMI Filter installation caution

In order to ensure that the EMI filter can achieve maximum effect of inhibit the servo drive interference, in addition to the servo drive

according to the contents of the manual installation and wiring, still need to pay attention to the followings:

1) Servo drive and EMI filter must be installed on the same piece of well grounded metal plane.

2) Servo drive and EMI filter, please try to install the servo drive above the EMI filter .

3) All wiring will be as short as possible.

4) Metal shell of servo drive and EMI filter must be reliably connected with the metal ,surface, and the contact area between the two should be

as large as possible.

2.8.2 Selection of motor cable and installation notes

The selection and installation of the motor line is correct or not, it’s related to the EMI filter can play the greatest effect of servo drive

interference suppression.

Please note the followings:

1) The cable with isolation copper mesh (Double isolation layer is preferred).

2) The isolated copper mesh on both ends of motor line to ground in the shortest distance and the maximum contact area.

3) Motor line isolation copper mesh connects metal plane correctly, isolated copper mesh on both sides of motor line should be fixed with

U-shaped metal piping supports and metal plane.

13

3 Display & Operation

3.1 Display and key operation Exterior

Mode key UP key DOWN key Left key Set key

Digital display

EA100-8R4-3A

01020052111410280001

MOD SET

88888 Drive model

and serial

number

3.2 Display and operation mode

There are 5 display and operation mode for EA100 servo drive

Mode

Function

Monitor mode

Monitoring the value of parameter code

Parameter group

selection mode

Choose parameter group to be monitored or set

Parameter code

selection mode

Choose parameter code to be monitored or set

Setting Mode

Setting the value of the selected parameter code

Fault and alarm mode

Display fault and alarm information

3.3 Parameter setting Description

1) When the drive is powered on, the digital tube display the default monitor code for one second, then work in monitor mode.

2) In monitor mode, pressing UP or DOWN key to change the monitored parameter code, then press the SET key to monitor selected

parameter code. If there is no key operation, it will monitor selected parameter code automatically after one minute.

3) In monitor mode, if the monitored parameter is 32 bit or displaying a more than 5 digits binary number, press the left key to switch the

display for high bit and low bit. When displaying high bit, the digital tube decimal point of the highest bit is lit.

4) In monitor mode, press MOD to enter the parameter set selection mode, then press UP / DOWN key to switch the parameter set, press the

MOD key to exit the parameter set selection mode back to monitor mode.

5) In parameter group selection mode, pressing left key, the flashing character shift left. It is easy to choose parameter group number. Press

SET key to enter parameter code selection mode, press MOD key to exit parameter code selection mode and back to parameter group

selection mode.

6) In parameter code selection mode, pressing UP or DOWN key can change the value of last two code to change parameter code, then press

the SET key immediately to enter the parameter setting mode and display the value of the parameter code.

7) In the parameter setting mode, use UP / DOWN key to set parameter. When pressing left key the blinking character will shift left, it is

easily and quickly to modify the value of the parameter high bit.

8) After setting the value, press SET key to store or execute a command.

9) After setting the value, the digital tube will display the status information of the parameter, for example, displaying -End-. Then

automatically back to parameter code selection mode.

10) In parameter setting mode, press MODE key or no key operation in one minute will cancel the modification of parameter value, and back

to parameter code selection mode.

11) When servo alarm, pressing MODE key for one second, it will show the current alarm code; pressing any key again to exit the alarm code

displayed.

Alarm display Monitoring

parameter Basic control

parameter Internal multi-

location parameters Auxiliary function

parameter

...

Or

MOD MOD

SET Display parameter settings

SET Storage Parameters

MOD

Double-click

or Shift Left

Fault

Fault

Fault

Fault

Fault

MOD MOD

MOD

Double-click

MOD

Double-click

AL00

1

P0-00

P0-01

P0-02

P1-00

P1-01

P1-02

P2-00

P2-01

P2-02

P8-00

P8-01

P8-02

10000

10001

-EnD-

14

Figure 3-1 Panel Operation flowchart

3.4 Status Display

There are following states:

Display symbol

Content note

-End-

The set value is stored correctly.

Po-0n

This parameter must be rebooting to be effective.

Sru0n

Parameter cannot be set when servo starting

Err-r

Read - only parameters, which cannot be modified

EESud

This parameter is reserved and cannot be modified.

3.5 Monitor display

Press the MOD key twice or no key operation more than one minute, servo drive will automatically enter monitor display group function code

P0---, in monitor mode, you can press UP or DOWN key to change the monitoring code.

Example

Describe

P0-00

Press SET key to display the motor speed

P0-01

Press SET key to display the motor load rate

P0-02

Press SET key to display current electric angle

P0-30

Press SET key to display received external pulse frequency

3.6 Fault and alarm display

Example

Describe

AL0nn

When there is a fault in the drive, it will be shown in the panel and

displaying fault code "Al0" and "NN". "NN" ranges from 01 to FFH.

Pressing operation key for other display, but the decimal point of the

lowest digital tube will be flashing, until it is cleared, there are no fault or

displaying AL--- when warning

ALEnn

When the drive alarms, it will be shown in the panel and displaying

warning code "AlE" and "NN". Pressing operation key for other display,

but the decimal point of the lowest digital tube will be flashing, until the

alarm is cleared.

15

4 Wiring

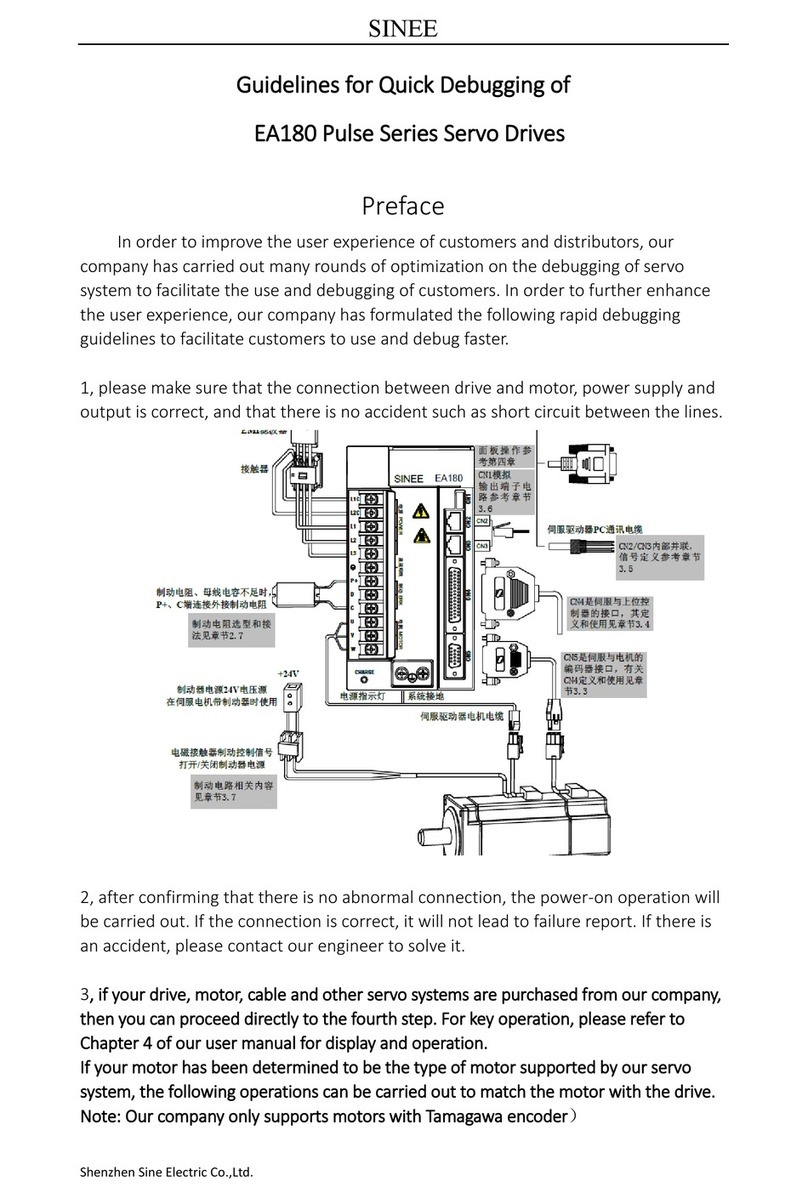

4.1 Peripheral connection

CN2

CN3

When braking resistance or bus

capacitance is insufficient, an

external braking resistor should

connect to P+ terminal and C

terminal

+24V

Electromagnetic contactor

brake control signal.

Open / Close brake power

supply

EMI filter

24V power supply for

brake (only for servo

motor with brake)

System ground

PC communication cable

of servo drive

Servo motor cable

Contactor

Servo motor

3-phae 220V AC / 380V AC

Breaker

CN1 analog

output terminal.

Please see

section 3.6 for

the circuit.

CN2 / CN3 internal

connected in parallel.

Please see section 3.5

for signal definition

Please see section 4

for panel operation

CN4 is connected to the

upper computer.

Please see section 3.4 for

definition and use of CN4

CN5 is connected to servo

motor encoder.

Please see section 3.3 for

definition and use of CN5

Please see section 2.8 for

selection and wiring of

braking resistor

Please see section 3.7

for braking circuit

Power indicator

SINEE EA100

L1C

L2C

L1

L2

L3

P+

D

C

U

V

W

CHARGE

CN1CN2CN3CN4CN5

电源 POWER 电机 MOTOR

制动 BRK

直流母线

Remark:

1) The servo drive is connected to the industry power supply directly, and there is no power isolation like transformer. To prevent electric

shock of servo system, please put a fuse or molded case circuit breaker in the input power supply.

2) Do not install electromagnetic contactor between the drive and the motor, which can damage the drive.

3) Please note the power supply capacity when connect to external control power supply or 24V power supply, especially when the power

supply is connected to several drives or brakes. If power supply capacity is not enough, the output current will also be not enough,

which can lead to the damage of drive or brake. Please note that the brake power supply is 24V DC, whose capacity should be

consistent brake power. Please refer to describe of servo motor for related brake power.

4) Check the servo motor output U, V, W terminal wiring phase. The motor will not run or run out of control and then alarm, or even

damaged by incorrect wiring.

5) When using external resistor, P+ and D terminal should be open, and the external brake resistor should be connected to P+, C terminal.

When using internal brake resistor, P+ and D terminal should be shorted and P+ and C terminal should be open.

6) In 1-phase 220V wiring, the main power supply terminal is L1, L2 terminal, and L3 should be empty.

7) CN2 and CN3 are same defined communication terminals, so that you can use any one of them.

4.2 Main circuit wiring

Main circuit (strong electric part) terminals and screw size are shown below.

16

L1C

L2C

L1

L2

L3

P+

D

C

U

V

W

SIZE

Main circuit terminal

Screw Size

Tightening

torque

SIZE A

M4

2.5N.m

SIZE B

M4

2.5N.m

SIZE C

M4

2.5N.m

SIZE

PE ground terminal

Screw Size

Tightening

torque

SIZE A

M4

2.5N.m

SIZE B

M4

2.5N.m

SIZE C

M4

2.5N.m

4.2.1 Main circuit (strong electric) terminal Introduction

Table 4-1 servo drive main circuit terminal

Terminals

markings

Terminal name

Terminal Function

L1C, L2C

Control power supply

input terminals

1-phase input which is consistent with the main circuit

power supply voltage level

L1, L2, L3

Main circuit AC

power input terminals

EA100-2R8-2□

EA100-5R5-2□

EA100-7R6-2□

L1, L2 1-phase 220V input

L1, L2, L3 3-phase 220V input

EA100-010-2□

L1, L2, L3 3-phase 220V input

EA100-5R4-3□

EA100-□□□-3□

EA100-026-3□

3-phase 380V input

P+,D,C

External braking

resistor connection

terminals

Default connection between D and P +.

When the braking is insufficient, please keep P +, D

circuit open, and connect an external braking resistor

between the P + and C.

P+,

DC bus terminal

DC bus terminal of servo drive. It can be shared when

multi-parallel.

U,V,W

Servo motor

terminals

Connection terminals of the servo motor and they are

connected to U, V, W of the motor

PE

Ground

One ground terminal for EA100-2R8-2A and

EA100-5R5-2A; Two ground terminals for other power

drives. It is connected to the ground terminal of power

supply and the ground terminal of motor.

4.2.2 Power Wiring

Servo drive power connection is divided into 1-phase and 2-phase. 1-phase only for the drives with output current 7.6Aand less than 7.6A

1-phase power supply wiring (rated output current ≤7.6A)

Figure 4-1 1-phase power supply wiring diagram

3-phase power supply wiring (all series are applicable)

17

Figure 4-2 3-phase power supply wiring diagram

Remark:

1: If you do not want to cut off the main circuit power supply when a failure occurs, RA relay is

not necessary.

2: L1C, L2C can be connected to P +, - terminals instead of external power supply.

Power on timing

Control circuit power

supply

Mains supply

Servo ready output

(S-RDY)

Servo enable

(S-ON )

Servo motor

excitation

Unpowered

Powered

Unpowered

Powered

Not ready Ready

Enable invalid

Not receive

instruction

Motor

Unpowered

Motor

powered

Not receive

instruction

Receive instruction

Position / speed /

Torque command

Delay1.5S

Delay as P1-54 set

Servo enable signal

(S-ON signal) Invalid Valid Invalid

Enable invalid

Motor

Unpowered

Enable valid

Figure 4-3 power-on timing chart

Please refer to figure 3-1 and 3-2 for power wiring and wire as followed sequence.

1) Control power circuit L1C, L2C must be powered on before the main circuit or at the same time as the main circuit power supply. If only

the power control circuit is powered on, the servo ready signal (S-RDY) will be invalid.

2) The main circuit power input terminals should be connected to the mains supply by electromagnetic contactor (3-phase: L1, L2, L3, 1

phase: L1, L2).

3) After the main circuit power supply is powered on and a 1.5-second delay, servo ready signal (SRDY) will be valid, then it can accept the

servo enable (S-ON) signal. When detecting the servo enable signal is valid, the motor will be activated, and running. When detecting the

servo enable is invalid or alarmed, output of drive will be off, and the motor is in a free state.

4) When the servo enable and the mains supply are powered on at the same time, the motor will be activated after 1.5 second.

5) Frequently turning on or off of the main circuit power supply may damage the soft start circuit and dynamic braking circuit. The frequency

of tuning on or off should be less than 5 times one hour, and 30 times one day. When the drive or motor is overheating, after the solving

the problem, the main circuit should be powered on again after 30 minutes cooling.

6) The input power cable cannot connect to the output terminals U, V, W, which can damage the servo drive.

7) The braking resistor is absolutely prohibited to be connected to the DC bus P +, terminals, which may lead a fire.

8) After the power is turned off, there may be residual voltage in the servo drive internal capacitance, confirm the CHARGE indicator on the

servo drive panel is off before other operation.

4.2.3 Connector specification of motor power cables

Table 4-2 motor servo motor power cable connection terminals

Connector shape and model

Terminal pinout

Motor

flange size

12

34

Shell model:C4140HM-2X2P

4PIN AMP Plug(without brake)

Pin

Define

1

U

2

V

3

W

4

PE

60

80

86

18

Connector shape and model

Terminal pinout

Motor

flange size

Plug model:C4140F-TP-H

1

23

4

Model:YD28K4TS

Aviation plug(without brake)

Pin

Define

1

PE

2

U

3

V

4

W

130

1

23

4

56

7

Model:YD28K7TS

Aviation plug(with brake)

Pin

Define

1

PE

2

24V(brake)

3

0V(brake)

4

not used

5

U

6

V

7

W

130

Note: Due to the product improvement, the aviation plug model may be changed.

4.2.4 Specifications of recommended cable for main circuit connection

Model

L1C,L2C

L1,L2,L3

P+,C

U,V,W

PE

EA100-2R8-2□

0.5mm2

1.0mm2

1.0mm2

1.0mm2

2.5mm2

above

EA100-5R5-2□

EA100-7R6-2□

2.0mm2

2.0mm2

2.0mm2

EA100-010-2□

EA100-5R4-3□

1.0mm2

1.0mm2

1.0mm2

EA100-8R4-3□

2.0mm2

2.0mm2

2.0mm2

EA100-012-3□

EA100-018-3B

4.0mm2

4.0mm2

4.0mm2

EA100-021-3B

EA100-026-3B

6.0mm2

6.0mm2

6.0mm2

4.3 CN5 encoder signal terminal

CN5 is encoder signal terminal (DB15 socket), its position is shown in Figure 3-4:

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

SINEE EA100

L1C

L2C

L1

L2

L3

P+

D

C

U

V

W

CHARGE

电源 POWER 直流母线 制动 BRK 电机 MOTOR

CN1CN2CN3CN4CN5

Figure 4-4 CN5 terminal positions

4.3.1 Encoder terminal definition drive-side

19

5

10

4

9

3

8

2

7

1

15

14

13

12

11

6

Encoder B+ signal

Encoder B- signal

Encoder A+ signal

Encoder A- signal

Shielded layer

connect to PE

Encoder Z- signal

Encoder U- signal

Encoder V- signal

Encoder W- signal

Encoder power

supply 5V

Encoder Z+ signal

Encoder U+ signal

Encoder V+ signal

Encoder W+ signal

GND 5

10

4

9

3

8

2

7

1

15

14

13

12

11

6

Shielded layer

connect to PE

Encoder power

supply 5V

SD+

SD-

GND

CN5 2500ppr incremental encoder terminal definition CN5 17-bit encoder terminal definition

It indicates that the

terminal Is Left,

and do not connect

Note: When connected to

the wire-saving encoder, U

+ / U-, V + / V-, W + / W-,

Need not to be connected.

Figure 4-5 CN5 terminal pinout

2KΩ

100Ω

100Ω

1

33

34

上位机装置

100Ω

100Ω

31

32

14

16

PULSE+

PULSE-

SIGN+

SIGN-

GND

PE

GND

GND

伺服驱动器

普通脉冲位置指令

最小脉冲宽度1us

最大输入频率为500kpps

PULHIP

PULHIS

1

6

11

5

10

15

Figure 4-6 CN 5 terminal welding pinout

4.3.2 Encoder terminal definition of servo motor side

There are two shapes encoder terminal in the servo motor side.

AMP plug,for motor with 60, 80 flange, the pin defined in Table 4-3a, 3b, 3c

Plugs in motor side

Shape

2500ppr incremental encoder

17 bit encoder

4 532

1

9 107

6

14 151312

11

8

Motor side

321

64

987

5

Motor side

Encoder cable connector

15

610

11

15

234

9 7

12

1314

8

123

6 4

7

89

5

Shell model:

C4140-HM-3*5P

Plug model:

C4140F-TP-L

Shell model:

C4140-HM-3*3P

Plug model:

C4140F-TP-L

Aviation plug: for motor with 110 flange and above, the pin defined in Table 4-3a, 3b, 3c

2500ppr incremental encoder

17 bit encoder

2

5

14

13

15

11

10

6

3

1

Terminal type:YD28K15TS

Note: Due to the product improvement, the aviation plug model may be changed.

Table 4-3a 17-bit incremental encoder cable connection

Function

Description

Drive side DB15

Servo motor side

AMP plug

Aviation plug

Signal name

Pin

Pin

Pin

Encoder power

supply

+5V

5

1

2

Encoder power

GND

10

2

3

20

Function

Description

Drive side DB15

Servo motor side

AMP plug

Aviation plug

Signal name

Pin

Pin

Pin

supply ground

Positive terminal

of serial signal

SD+

1

5

4

Negative terminal

of serial signal

SD-

3

6

7

Shield layer PE

PE

Shell

9

1

Table 4-3b 17-bit absolute encoder cable connection

Function

Description

Drive side DB15

Servo motor side

AMP plug

Aviation plug

Signal name

Pin

Pin

Pin

Encoder power

supply

+5V

5

1

2

Encoder power

supply ground

GND

10

2

3

Positive terminal

of serial signal

SD+

1

5

4

Negative terminal

of serial signal

SD-

3

6

7

Positive terminal

of external battery

VB+

7

14

Negative terminal

of external battery

VB-

8

15

Shield layer PE

PE

Shell

9

1

Table 4-3c 2500ppr non-wire-saving encoder cable connection

Function

Description

Drive side DB15

Servo motor side

AMP plug

Aviation plug

Signal name

Pin

Pin

Pin

Encoder signal Z +

Z+

1

7

6

Encoder signal U +

U+

2

6

10

Encoder signal V +

V+

3

10

11

Encoder signal W +

W+

4

11

12

Encoder supply 5V

+5V

5

2

2

Encoder signal Z-

Z-

6

5

9

Encoder signal U-

U-

7

8

13

Encoder signal V-

V-

8

12

14

Encoder signal W-

W-

9

15

15

Encoder power

supply ground

GND

10

3

3

Encoder signal B +

B+

11

4

5

Encoder signal B-

B-

12

14

8

Encoder signal A +

A+

13

9

4

Encoder signal A-

A-

14

13

7

Shielding layer PE

PE

Shell

1

1

Remark for servo wiring:

1) Make sure the drive and the motor shielded layer are grounded; otherwise it will cause the drive error.

2) Do not confuse GND and PE.

3) Be sure that the differential signal can match the two cables of a twisted pair. For example, A + and A- is a set of differential signal, you

should use a twisted pair.

4) Encoder cable routing must be separated from the power cable routing by at least 30cm or more.

4.4 CN4 Control signal terminal

Using the DB44 socket, CN4 signal terminal provides signals for communication with upper computer.

Signals include:

8 programmable digital inputs

4 programmable digital differential output

This manual suits for next models

19

Table of contents

Other Sinee Servo Drive manuals

Popular Servo Drive manuals by other brands

RHINO MOTION CONTROLS

RHINO MOTION CONTROLS RMCS-1110 Installation Manual and Datasheet

Omron

Omron R88D-KTA5L user manual

Kollmorgen Seidel

Kollmorgen Seidel 6SM56 Series Technical description

Siemens

Siemens SIMOTICS S-1FL6 Compact operating instructions

Minimotors

Minimotors DBS 55 Series Installation, use and maintenance manual

Omron

Omron OMNUC G Series user manual