Sinee BR100 User manual

User Manual

BR100 Braking Unit

1

Preface

Thank you for purchasing BR100 Braking Unit.

Document No.: 31010009

Version No.: 102

Issue Date: 01/2015

BR100 Features:

1. Performance: Stable and reliable

2. Protections: Over-heating and braking resistor short-circuit

3. Real-time detection on DC bus voltage

4. Absorb the motor regenerative energy through braking resistors.

5. Compatible with various inverters

6. Applications: The devices driven by frequency inverter like: hoist,

centrifuges, industrial washer, dryer, crane, elevator, or the load system

which requires quick stop.

It is the duty of any user to perform the appropriate, correct installation and

wiring or selecting the compatible braking resistor of the braking unit.

Neither SINEE nor its distributors shall be responsible or liable for misuse

of the information contained herein.

In the interests of commitment to a policy of continuous development and

improvement, SINEE reserves the right to update the specification of the

product or its performance, or the content herein without notice.

More updates and information available at www.sinee.cn Pictures herein

are for reference only.

User Manual

BR100 Braking Unit

2

Content

Preface...........................................................................................1

Verifying Product..........................................................................3

Safety Information........................................................................3

1.1Model Numbering Scheme......................................................4

1.2Model Specifications................................................................4

2. Technical Specifications ...........................................................5

3. Overall and Installation Dimensions.......................................6

3.1BR100-045 Dimensions ...........................................................6

3.2BR100-160 Dimensions ...........................................................6

3.3BR100-315 Dimensions ...........................................................7

3.4BR100-220-6 Dimensions........................................................7

4. Considerations for Installation Site.........................................8

4.1Considerations for Installation Site........................................8

4.2Installation Space.....................................................................8

5. Installation and Wiring ..........................................................10

5.1Assembly and Disassembly of the Front Panel....................10

5.2Main Circuit Terminals......................................................... 11

5.3 Connecting Cable..................................................................12

6.1 Defining the Peak Brake Current Imax ................................13

7. Braking Resistor.....................................................................14

7.1 Resistance Selection of Braking Resistor............................14

7.2 Power Selection of Braking Resistor...................................14

7.3 Considerations for Installation............................................14

8. Operation Project ...................................................................16

9. Troubleshooting ......................................................................18

User Manual

BR100 Braking Unit

3

Verifying Product

Verify that the device reference marked on the label conforms to the

delivery note corresponding to the purchase order.

Open the packaging and check that the device has not been damaged in

transit.

Contact the distributor or SINEE directly for any quality issue.

Safety Information

The addition of this symbol to a Danger or Warning safety

label indicates that an electrical hazard exists, which will

result in personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

Safety Precautions

Danger

1. Wiring must be performed by authorized and qualified personnel.

2. Wait 5~10 minutes for capacitor discharge after disconnected from

power supply.

3. Electrical hazard exists in the parts of braking unit after power-on.

Failure to follow the instructions will result in fatal injury.

Caution

1. Well connect positive/negative poles of braking unit DC bus.

Otherwise, devices damage and fire may occur.

2. Locate the braking unit in a place with good ventilation, and keep the

ambient temperature lower than 40℃.

Overheating may result in fire or other accidents.

3. Always tighten the screws and gaskets inside the braking unit.

Any loosen may result in devices broken.

4. Be sure that housing is well located.

User Manual

BR100 Braking Unit

4

1. Model Numbering Scheme and Specifications

1.1 Model Numbering Scheme

BR 100 045 3

Product Category

BR: Braking Unit

Product Series

100:General Dynamic Brake

Maximum Applicable Power

160 315

45kW 160kW 315kW

045

2:AC220V

3:AC380V/AC415V

6:AC660V

Inverter Voltage

220

220kW

12:AC1140V

BR100-045 is applicable to the inverter with 3-phase AC220V/

3-phase AC 380V power supply.

For 3-phase AC220V inverter (customization),the braking voltage is

395V or 420V. For 3-phase AC380V inverter (customization),the

braking voltage is 675V or 720V.

BR100-160/BR100-315 is only applicable to the inverter with

3-phase AC380V power supply. the braking voltage is 675V or 720V.

BR100-220-6 is only applicable to the inverter with 3-phase AC660V

power supply,the brake voltage is 1135V.

1.2 Model Specifications

Model No.

Application

Minimum

Resistance (Ω)

Average Brake

Current Iav(A)

Peak Brake

Current

Imax(A)

Inverter

Power Range

(kW)

BR100-045

Dynamic

Brake

10

45

75

18.5~45

BR100-160

Dynamic

Brake

6

75

150

55~160

BR100-315

Dynamic

Brake

3

120

300

185~315

BR100-220-6

Dynamic

Brake

6

120

200

220~350

Remarks:

When BR100-160 and BR100-220-6 are in minimum resistance, and when

brake duty ratio D≤33%, braking unit can work continuously, it needs to

work discontinuously when brake duty ratio D>33%. Otherwise, braking

unit will trip over-heating protection.

User Manual

BR100 Braking Unit

5

2. Technical Specifications

See Table 2-1 for BR100 technical specifications.

Table 2-1 BR100 Technical Specifications

Item

Specifications

Control

Mode

Output Voltage

Control

Auto-modulated switch-mode

Brake Voltage

Varies with models

395V,420V,675V(Standard),720V,1135V

Protection

Over-heating, short-circuit

Overheating

Trip

80ºC (Heatsink)

Display

LED

POWER indicator, BRAKE Indicator,

FAULT indicator

Application

Conditions

Installation Site

Indoor, with altitude less than 1,000 meters,

free of dust and corrosive gas, and no direct

Ambient

Temperature

-10℃~+40℃. In the temperature range +40

°C…+50 °C, the rated output current is

decreased by 1% for every additional 1°C

20%~90%RH (no condensation)

Vibration

<0.5g

Storage

Temperature

-20ºC ~+65ºC

Installation

Method

Wall mounting

Degree of Protection

IP20

Cooling Method

Self-cooling (BR100-045, BR100-160)

Air cooling (BR100-315,BR100-220-6)

User Manual

BR100 Braking Unit

6

3. Overall and Installation Dimensions

3.1 BR100-045 Dimensions

Figure 3-1 BR100-045 Overall Dimensions

3.2 BR100-160 Dimensions

340

323

2-Ф7

2-7

215

182

184

124

303

Figure 3-2 BR100-160 Overall Dimensions

POWER

BRAKE

86.5

123

90

203

217

230

2-Ф6.5 110

2-6.5

User Manual

BR100 Braking Unit

7

3.3 BR100-315 Dimensions

378

358

2-Ф7

187

215

2-7

184

124

395

Figure 3-3 BR100-315 Overall Dimensions

3.4 BR100-220-6 Dimensions

124

195

323

340

304

194

157

163

2-?7

2-7

Figure 3-4 BR100-220-6 Overall Dimensions

User Manual

BR100 Braking Unit

8

4. Considerations for Installation Site

4.1 Considerations for Installation Site

No water drops

Clean and dry

No corrosive gas and liquid

No dust and metal particles

Ambient temperature: -10C~40C

Humidity: 20% RH~90% RH(no condensation)

Firm and steady installation base

No electromagnetic interference

Install a cooling fan or air-conditioner to keep the ambient

temperature in a maximum of 40ºC if the braking unit is installed in

a cabinet.

4.2 Installation Space

See Figure 4-1 for installation space of the braking unit.

110mm 110mm

30mm 30mm

BR100

Figure 4-1 Installation Dimensions

If multi-braking units are mounted in vertical parallel, the distance should

be in a minimum of 200mm, and a baffle is required for heat resistance

between 2 braking units. See Figure 4-2 for installation.

User Manual

BR100 Braking Unit

9

Figure 4-2 Parallel Installations for 2 Braking Units

Locate the braking unit in a place with good ventilation. A cooling fan

must be fitted at appropriate location in the cabinet for heat

dissipation. The braking resistor must be installed in a separate cabinet and

cannot be installed with the inverter, braking unit or other devices because

it will generate high heat. The distance between braking resistor and other

devices requires more than 2 meters. Otherwise, other devices may be

damaged.

User Manual

BR100 Braking Unit

10

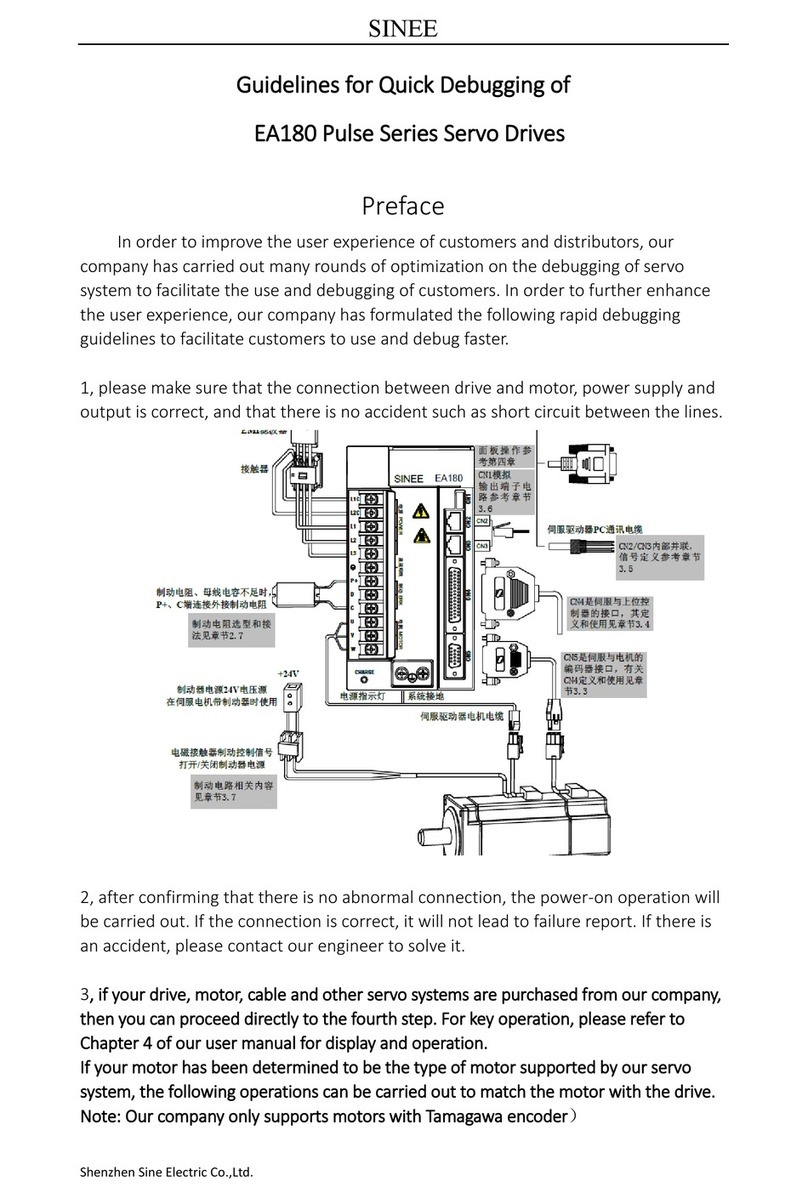

5. Installation and Wiring

5.1 Assembly and Disassembly of the Front Panel

Unscrew the front cover, and disassemble it by following the arrow

direction. See Figure 5-1.

BR100

BR

100

Figure 5-1Front Cover Disassembly

Assemble the cover in opposite direction and by opposite steps, and

tighten the screws after wiring is completed. See Figure 5-2.

BR100

BR

100

Figure 5-2 Front Cover Assembly

User Manual

BR100 Braking Unit

11

5.2 Main Circuit Terminals

BR100-045 Main circuit terminal as shown in Figure 5-3

PB+PB+PB-PB-

Figure 5-3 Main Circuit Terminal Block of BR100-045

BR100-160 Main circuit terminal as shown in Figure 5-4

Figure 5-4 Main Circuit Terminal Block of BR100-160

BR100-315 Main circuit terminal as shown in Figure 5-5

Figure 5-5 Main Circuit Terminal Block of BR100-315

BR100-220-6 Main circuit terminal as shown in Figure 5-6

PB+ PB-

Figure 5-6 Main Circuit Terminal Block of BR100-220-6

NC1 NC2

PB-

PB+

PB+ PB+ PB- PB- NC1 NC2

User Manual

BR100 Braking Unit

12

Table 5-1 Functions of Main Circuit Terminals

Terminal

Symbol

Terminal Name

Function

DC bus

Connect to inverter DC bus

DC bus

Connect to inverter DC bus

PB+

Wiring terminal of

braking resistor

Connect to one end of braking resistor

PB-

Wiring terminal of

braking resistor

Connect to one end of braking resistor

Grounding terminal of

braking resistor

Connect to the ground on-site

EA, EC

Fault output terminal of

relay

Connect to electric system protection circuit, cut

off the power when faults occur.

Normal: Off Fault: On

5.3 Connecting Cable

Since all braking units and braking resistors work at a high voltage

(>400VDC) in a non-continuous working status, please select applicable

cables. See Table 5-2 for specifications of main circuit cable, and take the

cable which meets the insulation and cross-section requirements.

Table 5-2 Cable Selection for Braking Unit and Braking Resistor

Model No.

Average Brake Current

Iav(A)

Peak Brake Current

Imax(A)

Cross-section of Copper

Cable (mm2)

BR100-045

45

75

6

BR100-160

75

150

10

BR100-315

120

300

16

BR100-220-6

120

200

16

Soft cable possesses a better flexibility, so copper cable, soft heat-proof

cable or flame-proof cable is suggested because the cable may contact the

equipment with high temperature. The distance between braking unit and

inverter shall be <2m. Otherwise, the cable on DC side shall be twisted and

shielded with magnetic ring to reduce radiation and induction.

See Figure 5-7 for the cable length between braking unit and braking

resistor, inverter and braking unit.

Inverter Braking

Unit Braking

Resistor

<2m >2m

Figure 5-7 Cable Length

User Manual

BR100 Braking Unit

13

6. Selection of Braking Unit

The braking unit is an electric device designed for short-time and

intermittent work, which is with a limited working capacity when under

big current for a long time. Proper selection can protect braking unit from

damage caused by high heat due to over-current.

The braking unit is selected based on Iav (its average braking current) and

I max (peak braking current). The value of Iav is in direct proportion to the

current of braking unit working continuously for a long time. I max refers to

the maximum current of braking unit. To ensure normal work of braking

unit, the peak current of braking unit<I max, and I max *D < Iav

6.1 Defining the Peak Brake Current Imax

The peak brake current is the brake current of braking unit to ensure

normal work of system and sufficient brake torque of load.

a.Under general circumstances, if the braking torque required is the same

as rated torque of motor, for 380V speed control system:

I max ≈ motor power rating (kW)

b. After braking resistor is selected, the current can be achieved by

following formula: I max ≈ 700 / braking resistor (Ω)

6.2 Defining theAverage Brake Current I av

a. Define the brake duty ratio D, D=brake duration/ brake period* 100%.

Since the brake duty ratio D varies with different loads, D can be

defined based on actual operation of governor. If load cannot be

determined, please take following empirical values as reference:

Elevator D

= 10-15%

Oil Pump D

= 10-20%

Winding D

= 50-60%

Centrifuge D

= 5-20%

Tower crane(>100 meters high) D

= 20-40%

Load with occasional brake D

= 5%

Others D

= 10%

b. Formula for calculating the average brake current Iav,

Iav = D * I max

Thereafter, please refers to the value of Iav and Imax.to select the exact

model of braking unit.

端子标号

线规

(mm²)

制动单元主回路

5.5 ~8

制动电阻回路

(30 欧/2000 瓦)

P+

PB

5.5 ~8

、

User Manual

BR100 Braking Unit

14

7. Braking Resistor

User can choose different resistance and power ratings based on real needs

(But the resistance cannot be less than the minimum brake resistance.) The

braking resistor should be selected based on motor power ratings, and it

could vary with system inertia, deceleration time, and potential energy load.

The greater inertia is, the shorter deceleration time is, and the bigger the

brake duty ratio D will be, then the braking resistor should be with bigger

power rating and smaller resistance.

7.1 Resistance Selection of Braking Resistor

Braking resistor almost absorbs all regenerative energy of motor at brake.

Formula: U2/R=Pb

U—Brake voltage of system stable brake

(Varies with models.For 380V,it is 700V; For 660V,it is 1140V)

Pb—Brake Power

7.2 Power Selection of Braking Resistor

Theoretically, the power of braking resistor and brake power are in

accordance with each other, but it has to derate by70% in practice.

Formula: 0.7*Pr=Pb*D

Pr—Resistor Power

D —Brake Duty Ratio

(The ratio of regenerative energy in the whole working process)

Elevator D

= 10-15%

Oil Pump D

= 10-20%

Winding D

= 50-60%

Centrifuge D

= 5-20%

Tower crane(>100 meters high) D

= 20-40%

Load with occasional brake D

= 5%

Others D

= 10%

7.3 Considerations for Installation

Firm and steady installation base

Install a cooling fan or air-conditioner to keep the ambient

temperature in a maximum of 40ºC if the braking unit is installed in a

cabinet.

User Manual

BR100 Braking Unit

15

Install the braking resistor on the top if it is installed with other

devices in the same cabinet.

Choose heat-proof cable since temperature of braking resistor will be

>150℃in the process of brake.

To avoid risk of burn, maintenance can only be conducted after

braking resistor cooled down.

The power of braking resistor should be selected based on

appropriate is calculation on real application needs.

User Manual

BR100 Braking Unit

16

8. Operation Project

User can select braking units with the brake voltage of 395V, 420V, 675V,

720V or 1135V based on real requirement and inverter model. As shown

in Table 8-1. Table 8-1 Brake Voltage Options

Input of Inverter

Brake Voltage Options

3-phase 220VAC

395V(Default), 420V

3-phase 380VAC

675V(Default), 720V

3-phase 660VAC

1140V(Default)

Check the parameters of applicable inverter and motor, and select the

proper braking unit.

Select applicable power cable, and connect two power cables in

parallel when under great current.

Brake indicator is flashing which indicates that the braking unit is in

normal working status.

Wiring of single inverter operation:

Inverter BR100-160

+- - +PB+ PB-

Braking

Resistor Grounding

Inverter

PB

+

Braking Resistor

Grounding

BR100-045

PB

+

PB

-

PB

-

User Manual

BR100 Braking Unit

17

Inverter BR100-315

+-

-

+

PB+ PB-

Braking

Resistor

Grounding

PB+ PB-

+-

Inverter BR100-220-6

+- - +PB+ PB-

Braking

Resistor Grounding

Figure 8-1 Wiring of single inverter operation

User Manual

BR100 Braking Unit

18

9. Troubleshooting

Maintenance, inspection, and replacement of accessories can only be

performed by authorized and qualified personnel.

Table 9-1 Faults and Corrective Actions

Fault

Cause

Corrective Actions

1. Power indicator

does not flash.

Wrong wiring or poor contact

Check wiring

Frequent brake, damages

components overheating.

Select another model of braking

unit

2. Braking unit does

not function.

Braking resistor damaged

Replace braking resistor

Poor contact of resistor wiring

Check resistor wiring

Improper brake voltage

Recalculate brake voltage, and

replace the braking unit

3.Inverter trips

overvoltage

Deceleration time of inverter is

too short.

Prolong the deceleration time

Excessive brake resistance, and

insufficient energy discharge

Replace braking resistor

Wrong selection of braking unit

Change an applicable braking unit

model

Improper wire

Replace wire

4. Brake indicator

flashes before

brake.

Frequent brake, overheating

damages components.

Select a different model of braking

unit

Big grid fluctuation results in

overvoltage of braking unit

input, or brake voltage is

selected too low.

Measure grid voltage, and select

applicable brake voltage

5. Fault indictor

flashes.

High ambient temperature

Install extra cooling fan

Brake resistance exceeds the

minimum brake resistance.

Replace the braking resistor

6. Fault indictor

flashes and buzzer

alarms.

Short circuit of braking resistor.

Turn the power off, check wiring of

braking resistor and braking

resistor

7. Braking resistor

is hot when inverter

stops

Excessive grid voltage

fluctuation which exceeds the

brake voltage of braking unit.

Recalculate brake voltage, and

replace the inverter

Improper selection of brake

voltage

8. Braking resistor

overheating

Resistor power is too small

Uprate power of braking resistor or

install an extra cooling fan for

braking resistor

This manual suits for next models

4

Table of contents

Other Sinee Servo Drive manuals

Popular Servo Drive manuals by other brands

National Instruments

National Instruments NI 9516 Operating instructions and specifications

Festo

Festo EMMB-AS operating instructions

Coolmay

Coolmay MX3G-43C instruction manual

Emerson

Emerson PACMotion IC830DP00307 Accessories guide

Glentek

Glentek Gamma Series Installation & operation manual

Omron

Omron CK5M-CPU 1 Series Startup guide