Sinexcel PDS1-750K-H User manual

PDS1-750K-H DC converter

Manual

1

Sinexcel

PDS1-750K-H DC converter

User Manual

Data Version V1.0

Filed on 2022-06

Shenzhen Sinexcel Electric Co., Ltd.

All rights reserved. In case of any content change, it shall be without prior notice.

Shenzhen Sinexcel Electric Co., Ltd.

Website: http://sinexcel.us/ or www.sinexcel.com

Add: Building 6, Area 2, Baiwangxin High-tech Industrial Park, No. 1002, Songbai Road, Nanshan District,

Shenzhen

Postcode: 518055

Hotline: +86 0755-8651-1588

2

Table of Contents

1 OVERVIEW.................................................................................................................................................................5

1.1APPLICABLE MODELS.......................................................................................................................................................5

1.2 TARGET GROUP ...............................................................................................................................................................5

1.3 NOMENCLATURE TERMS AND ABBREVIATIONS ................................................................................................................6

2 SAFETY PRECAUTIONS...........................................................................................................................................7

2.1 SYMBOLS.........................................................................................................................................................................7

2.2 IMPORTANT SAFETY INSTRUCTIONS.................................................................................................................................7

2.3ADDITIONAL INFORMATION .............................................................................................................................................8

3 PRODUCT INTRODUCTION ....................................................................................................................................9

3.1 SYSTEM INTRODUCTION..................................................................................................................................................9

3.2 BIDIRECTIONAL DC CONVERTER APPEARANCE...............................................................................................................9

3.3 SYSTEM SCHEMATIC ......................................................................................................................................................10

3.4 MODULE INTRODUCTION...............................................................................................................................................11

3.5 DIMENSIONS AND WEIGHT ............................................................................................................................................12

3.6 HEAT DISSIPATION AND FIRE PROTECTION......................................................................................................................13

3.7 SWITCH STATUS .............................................................................................................................................................13

4 SPECIFICATIONS ....................................................................................................................................................14

5 STORING、LIFTING AND TRANSPORTING.......................................................................................................15

5.1 TRANSPORTAND STORAGE.............................................................................................................................................15

5.2 TRANSFER .....................................................................................................................................................................16

5.3 OUT OF THE BOX INSPECTION.........................................................................................................................................18

5.3.1 Unpacking .............................................................................................................................................................18

5.3.2 Test.........................................................................................................................................................................18

6 DEVICE INSTALLATION........................................................................................................................................20

6.1 INSTALLATION REQUIREMENTS ......................................................................................................................................20

6.1.1 Basic requirements ................................................................................................................................................20

6.1.2 Outdoor requirements............................................................................................................................................20

6.1.3 Foundation Support Requirements........................................................................................................................21

6.1.4 Space requirements................................................................................................................................................21

6.1.5 Ventilation Requirements.......................................................................................................................................22

6.2 ON-SITE INSTALLATION..................................................................................................................................................23

6.2.1 Trunking design.....................................................................................................................................................23

6.2.2 Fixed DC Converter ..............................................................................................................................................24

6.3 ELECTRICAL CONNECTIONS ...........................................................................................................................................25

6.3.1 General Safety.......................................................................................................................................................25

6.3.2 Installation tool .....................................................................................................................................................25

6.3.3 Wiring Parts ..........................................................................................................................................................26

6.3.4 Preparation before wiring .....................................................................................................................................26

6.3.5 Cable Requirements...............................................................................................................................................27

3

6.3.6 Wiring Precautions................................................................................................................................................28

6.3.7 Overview of the wiring area ..................................................................................................................................28

6.3.8 Power line wiring..................................................................................................................................................30

6.3.9 Ground connection................................................................................................................................................31

6.3.10 Installation Checklist...........................................................................................................................................32

7 PRODUCT RUNS ......................................................................................................................................................33

7.1 CHECK BEFORE RUNNING ..............................................................................................................................................33

7.1.1 Check cable connections .......................................................................................................................................33

7.2.2 Check the DC converter ........................................................................................................................................33

7.2.3 Check battery/bus side voltage..............................................................................................................................34

7.2 START AND STOP............................................................................................................................................................34

7.2.1 Start.......................................................................................................................................................................34

7.2.2 Stop........................................................................................................................................................................35

7.3 OPERATING MODE..........................................................................................................................................................36

7.3.1 Main function ........................................................................................................................................................36

7.3.2 Introduction to work status....................................................................................................................................37

7.4 PROTECTIVE FUNCTION .................................................................................................................................................38

8 LCD TOUCH SCREEN OPERATION GUIDE ........................................................................................................39

8.1 LCD TOUCH SCREEN FUNCTION AND MENU INTRODUCTION ..........................................................................................39

8.2 MAIN PAGE INTRODUCTION ...........................................................................................................................................40

8.2.1 Start page ..............................................................................................................................................................40

8.2.2 Home page.............................................................................................................................................................40

8.3 OPERATION INFORMATION MENU INTRODUCTIO.............................................................................................................41

8.4 INTRODUCING THE EVENT LOG MENU...........................................................................................................................42

8.5 CONTROL SCHEDULING MENU INTRODUCTION...............................................................................................................44

8.6 SYSTEM SETTINGS MENU INTRODUCTION ......................................................................................................................46

8.7 OPERATION MODE MENU INTRODUCTION .....................................................................................................................47

8.8 OPERATION STRATEGY MENU INTRODUCTION ................................................................................................................48

8.9ABOUT THIS MACHINE'S MENU INTRODUCTION..............................................................................................................49

9 INTRODUCTION TO WEB MONITORING...........................................................................................................50

9.1 WIFI WEBPAGE BACKGROUND FUNCTIONAND MENU INTRODUCTION ...........................................................................50

9.2 NETWORK MONITORING INITIAL STATE DESCRIPTION.....................................................................................................50

9.3 LAN PORT LAN CONNECTION:......................................................................................................................................51

9.4 OPERATION INFORMATION MENU INTRODUCTION ..........................................................................................................52

9.5 INTRODUCING THE EVENT LOG MENU...........................................................................................................................53

9.6 CONTROL SCHEDULING MENU INTRODUCTION...............................................................................................................56

9.6.1 Introduction to the settings menu ..........................................................................................................................57

9.6.2 Operation strategy menu introduction...................................................................................................................58

9.7 LOGIN MENU INTRODUCTION.........................................................................................................................................59

9.8ABOUT THIS MACHINE'S MENU INTRODUCTION..............................................................................................................59

10 TROUBLESHOOTING ...........................................................................................................................................60

10.1 PRELIMINARY INVESTIGATION .....................................................................................................................................60

4

10.2 LED INDICATOR SHOWS TROUBLESHOOTING METHOD.................................................................................................61

10.3 COMMON FAULTS AND SOLUTIONS...............................................................................................................................62

10.4 OTHER FAULTS.............................................................................................................................................................64

11 MAINTAIN...............................................................................................................................................................65

11.1 SAFETY PRECAUTIONS.................................................................................................................................................65

11.2 MAINTENANCE WORK AND CYCLES .............................................................................................................................65

11.3 CHECK AND REPLACE DUST COTTON............................................................................................................................67

11.4 REPLACE ELECTRICALAND ELECTRONIC COMPONENTS ...............................................................................................68

12 APPENDIX...............................................................................................................................................................69

12.1 CUSTOMER DRY CONTACTAND COMMUNICATION PORT DESCRIPTION..........................................................................69

12.2 QUALITYASSURANCE..................................................................................................................................................69

13 CONTACT................................................................................................................................................................70

5

1 Overview

1.1 Applicable models

This document applies to the following device models;

• PDS1-750K-H series

Model Definition

This section introduces product model definition in this user manual, as shown in Fig 1.1:

PDS1- 750K-H-XMY

Cabinet frame power: 750kW

DC/DC single-stage DC converter

DC high voltage version (1500V)

XMY-X modules Y branches

Fig 1.1 Product model definition

For example:

PWS1-750K-H: Indicates 750kW bidirectional DC converter high voltage 1500V model.

Check the equipment nameplate to determine the model.

The illustrations in this document have been reduced to be necessary and may differ from the real product.

The PDS1-750K-H energy storage converter is a series of converters; the rated converter capacity is 750kW,

and the number of modules fully loaded is 8 modules.

Table 1 PDS1-750K-H cabinet backward compatible series list

serial number

model

illustrate

1

PDS1-750K-H-XM1

Single branch model, the number of modules X can choose

8/7/6/5/4/3/2/1

2

PDS1-750K-H-XM2

2 branch models, the number of modules X can choose 8/4

3

PDS1-750K-H-XM4

4 branch models, the number of modules X can choose

8/6/4/2

1.2 Target Group

The tasks described in this document can only be performed by professionals or other qualified persons. Qualified

persons must have the following skills:

•Understand how the product works and how to operate the product

•Understand how the battery works and how to operate the battery

•Training on how to deal with the hazards and risks associated with installing and using electrical equipment

installation

•Installation and commissioning of electrical equipment and installations

•Understand all applicable standards and directives

•Understand and follow this manual and all safety information

6

1.3 Nomenclature Terms and abbreviations

名称

定义

DC

Direct current

BUS

Bus side

BESS

Battery energy storage system

ESS

Energy storage system.

EMS

Energy management system.

BMS

Battery management system.

PCS

Power conversion system.

SLD

Single line diagram

SOH

State of health (of battery), expressed in percentage.

SCR

Silicon controlled rectifier

DOD

Depth of discharge, the rest battery capacity, expressed in percentage.

EOD

End of discharging.

SOC

State of charge (of battery).

UI

User Interface

EPO

Emergency Power Off

SPD

Surge Protecting Device

7

2 Safety Precautions

2.1 Symbols

Symbol

Explanation

Indicates a dangerous situation that, if not avoided, will result in death or serious

injury

Indicates a dangerous situation that, if not avoided, will result in death or serious

injury

Indicates a dangerous situation that, if not avoided, may result in minor or moderate

injury

Indicates that if property damage is not avoided

Draw attention to important information, best practices and tips

NOTE is used to address information that is not related to personal injury,

equipment damage, and environmental degradation.

2.2 Important Safety instructions

This user’s manual is about installation and operation of Sinexcel PDS1 series 750kW Bi-directional DC

converter.

Before installation, please read this user’s manual carefully.

The PDS1 must be commissioned and maintained by the engineers designated by the manufacturer or the

authorized service partner. Otherwise, it might endanger personal safety and result in device fault. Any damage

against the device caused thereby shall not be within the warranty scope.

The PDS1 cannot be used for any circumstance or application related to life support device.

This manual contains important instruction for Models of PDS1 series that shall be followed during installation

and maintenance of the PDS1.

Any contact with copper bar, contactor and terminal inside the device or connected with the loop of utility grid

might result in burning or fatal electric shock.

Don’t touch any terminal and conductor connected with the loop of utility grid.

8

There might be an electric shock risk inside the device!

Any operation related to this device will be conducted by professionals.

Pay attention to the safety precautions listed in safety instruction and installation documents.

Pay attention to the safety precautions listed in operating and installation manual and other documents.

Large leakage current

Before connecting input power supply, please ensure that the grounding is reliable.

The device must be grounded complying with the local electric codes.

When storage battery is connected to PCS, there may be DC voltage at input port. Please pay attention to it

during operation or check the battery system user manual

Don’t touch electric parts within 15 minutes after power outage!

There is dangerous energy in capacitance storage. Don’t touch device terminal, contactor and cooper bar and

other electric parts within 15 minutes after disconnecting all device power supplies.

All maintenance and preservation inside the device require using tools and shall be conducted by trained person.

The components behind the protective cover plate and dam board which are opened by tools cannot be

maintained by users.

Please read this user’s manual before operation.

2.3 Additional Information

Links to additional information can be found at http://sinexcel.us/ or www.sinexcel.com.

9

3 Product Introduction

3.1 System Introduction

Bidirectional DC converter is usually a conversion device between photovoltaic and battery, photovoltaic power

generation can charge the battery. It can also be a conversion device between the battery and the DC bus, the

battery can be discharged to the DC bus, and the DC bus can charge the battery.

Using DCDC single-stage topology, The voltage input range on both sides is wide: 500-1500V, and there is no

distinction between high and low voltage, and the voltage ranges on both sides can overlap.

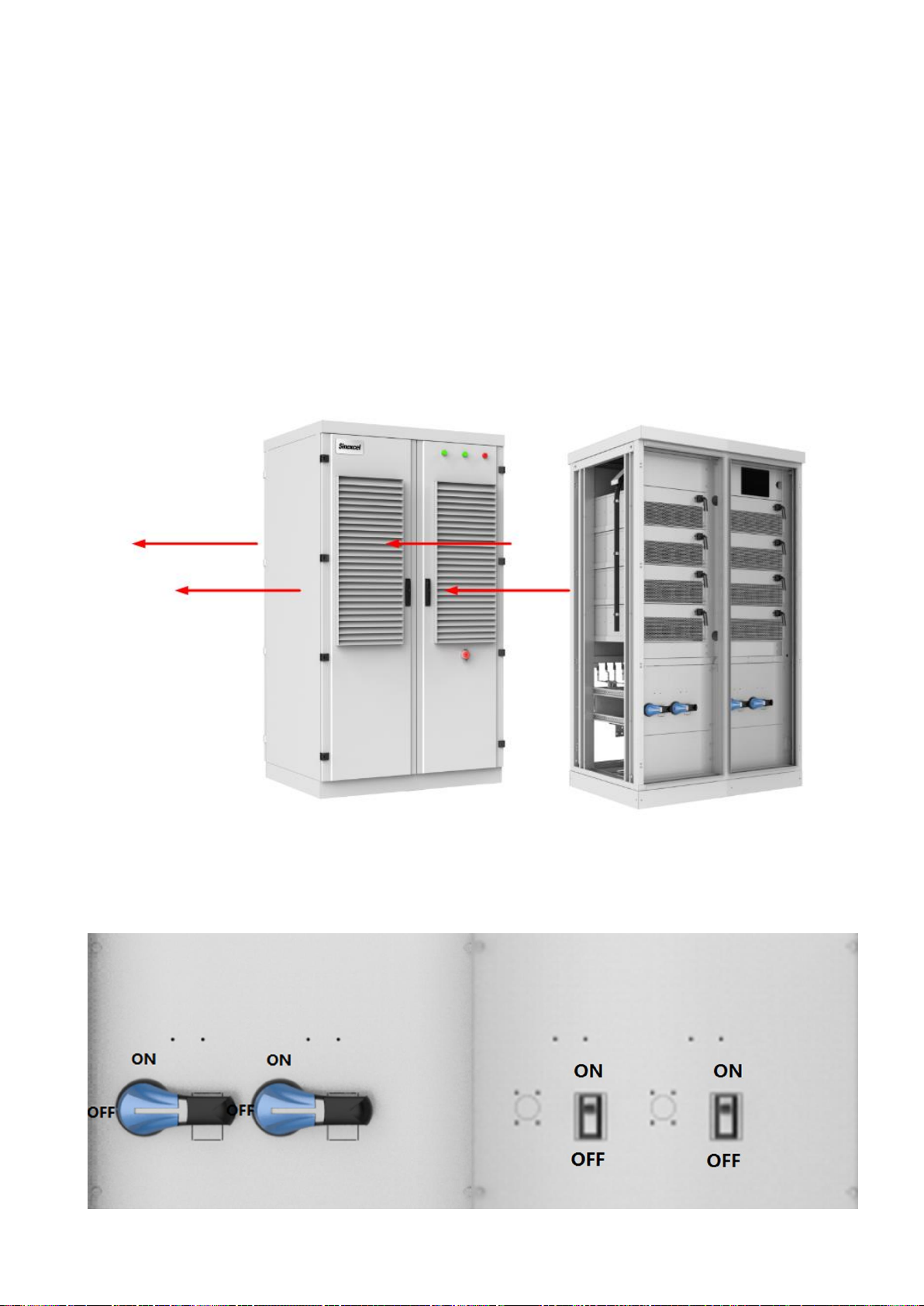

3.2 Bidirectional DC Converter Appearance

Fig 3.1 Appearance of bidirectional DC converter

Location

describe

1

Power (POWER) indicator

2

Running (RUN) indicator

3

FAULT indicator

4

Air intake shutters

5

Door lock

6

Emergency stop knob

10

3.3 System schematic

PDS1-750K-H bidirectional DC converter consists of 8 DC/DC converter modules, These modules identify

master and slave systems through DIP switch dial codes on the panel. One of the modules is used as the master,

and the other modules are used as slaves to synchronize with the master. The equipment is equipped with SPD

protectors, high and low voltage side switches and auxiliary power distribution units. Fig 3.2 is the topology of

the system.

Fig 3.2 Schematic diagram of bidirectional DC converter system

main

contactor

input/output

current

sensor

Fuse

Bridge arm

current

sensor

soft start

Internal bus buck-boost bridge Internal bus

main

contactor

input/output

current

sensor Fuse

soft start Battery

PV Battery

Fig 3.3 Schematic diagram of bidirectional DC converter circuit system

PDS1-750K-H consists of 8 DC modules, the DC side can be used as 1/2/4 branch,

and the BUS side is 1 branch.

11

3.4 Module introduction

Fig 3.4 Front View of DC Module

Position

Description

Description

1

Rear power plug-in terminals

white - high pressure

2

Multi-function indicator port

Communication,

dial code, indicator light

3

hanging ears

Module fixing ears

4

handle

not load bearing

RUN

FAULT

1

2

3

4

CANA

CANB

CANC

OFF ON COM1 COM2

No.

Fig 3.5 Schematic diagram of the multi-function indicating terminals of the DC module

silk screen

describe

directions

RUN

Running lights

green

FAULT

Fault indicator

red

No.

phone number dial

The phone number dialing is binary

dialing

CANA B C

CAN communication matching resistance dial

Improve signal quality

COM1 2

Module communication port

communication

OFF ON

Dial status direction indication

Left dial is OFF, right dial is ON

12

Figure 3.6 Schematic diagram of the control box

serial number

name

directions

1

Multifunctional Communication Panel

Ethernet port, parallel, USB,

EPO button

2

Multifunctional dry contact panel

Including 485, CAN and dry contacts

3

Module communication port

Module communication terminal

4

hanging ears

fixed module

5

handle

not load bearing

3.5 Dimensions and Weight

The dimensions of the PDS1-750K-H DC converter are shown in Figure 3.7. The net weight of the product is about

845kg, and the specific weight is based on the actual standard.

Fig 3.7 Dimensions of PDS1-750K-H

13

3.6 Heat dissipation and fire protection

The PDS1-750K-H DC converter is an IP54 outdoor unit. It adopts the structure design of front air and rear air outlet.

The outdoor air enters through the air intake window at the front of the DC converter, and the hot air is discharged

through the exhaust port on the back of the converter. The fire protection design adopts a device filled with clean fire

extinguishing agent to surround the top of the whole machine. When the surface of the device encounters heat, it

blasts to form a natural nozzle, and the fire extinguishing agent is released to achieve the effect of suppressing the

fire. The ventilation design is shown in the left picture of Fig 3.8, fire protection design As shown in Fig 3.8 on the

right.

Fig 3.8 PDS1-750K-H DC converter ventilation and fire protection design

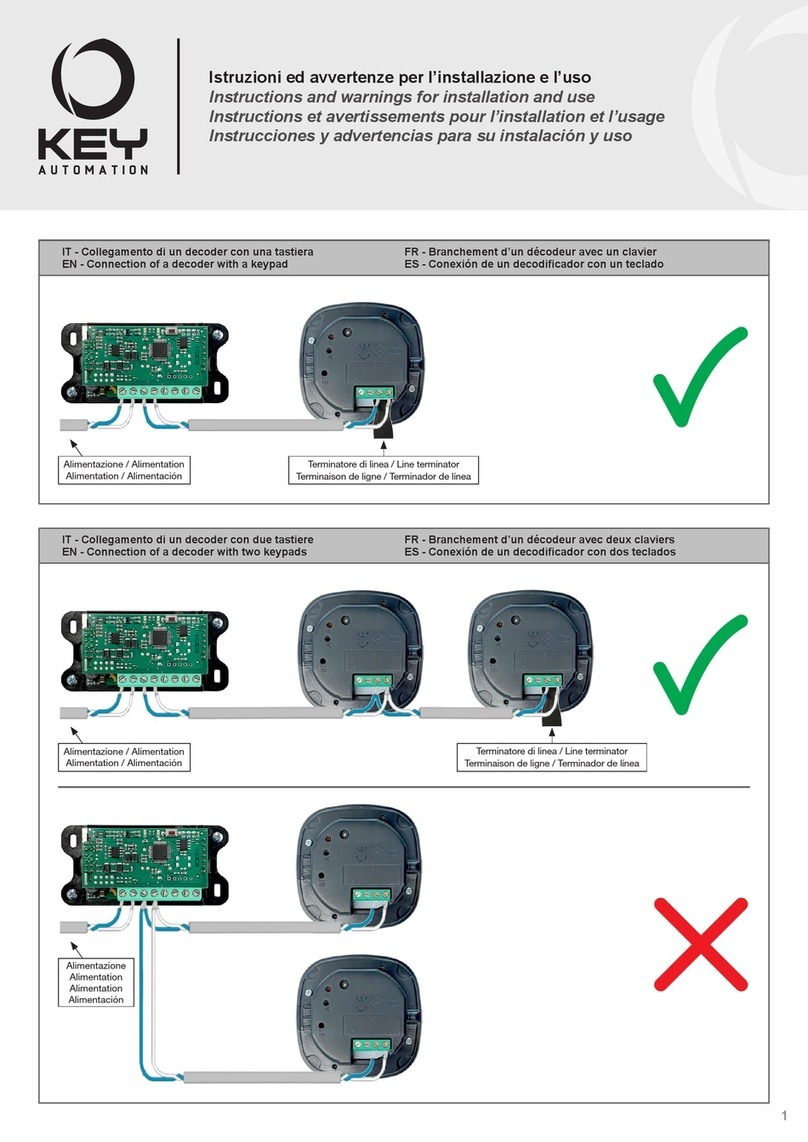

3.7 Switch status

14

Left - disconnector version Right picture - circuit breaker version

Location

name

illustrate

ON

ON

position

Isolation switch (rotate clockwise) - handle longitudinally Breaker (toggle up)

- handle up

OFF

OFF

position

Isolation switch (turn counterclockwise) - handle horizontally Circuit breaker

(toggle down) - handle down

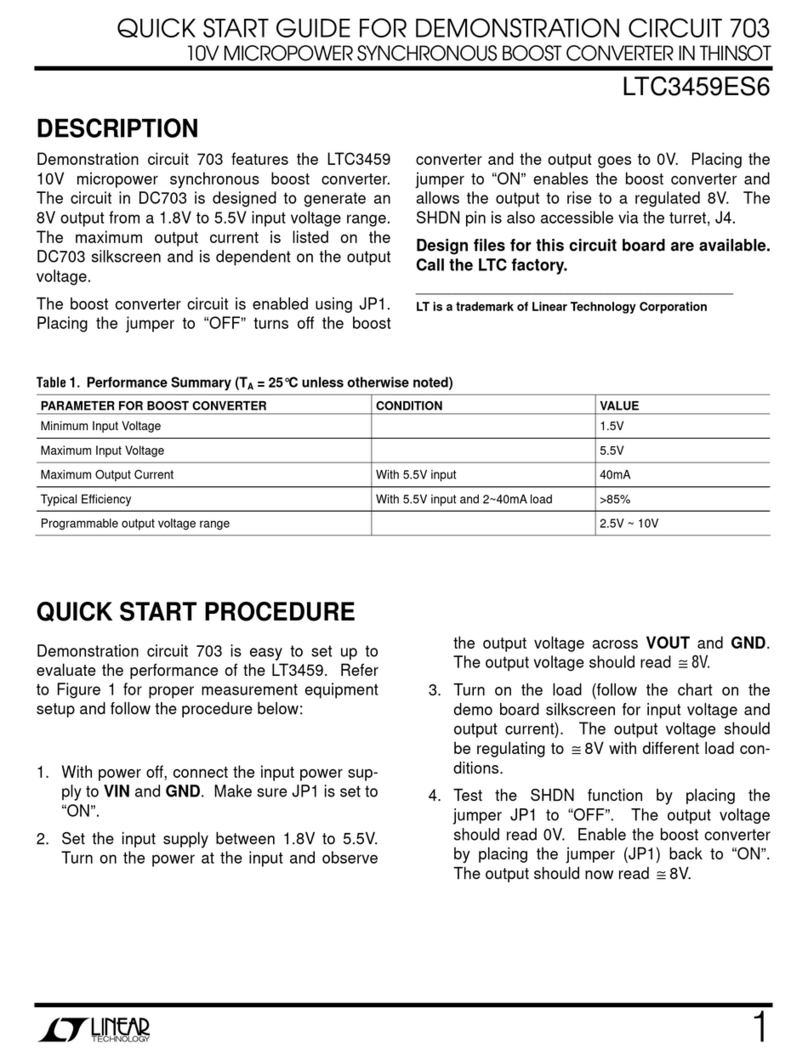

4 Specifications

Technical Data Sheet

model

PDS1-750K-H

DC

rated power

750kW

Max power

825kW

DC side voltage range

500~1500V

Number of DC side

1/2/4

DC side max current

825/413/207A

BUS side voltage range

500~1500V

Number of BUS side

1

BUS side max current

825A

number of modules

8

System

Max conversion efficiency

98.6%

Dimensions (W×H×D)

1200×2100×970 mm

weight

845kg

noise

<85dB

Protection class

IP54

allowable ambient temperature

-40~55℃(Derating over 45℃)

cooling method

Forced air cooling

allowable relative humidity

0~95% (no condensation)

allowable altitude

3000m (Derating over 3000m)

Communication

Communication Interface

RS 485,Ethernet,CAN

Communication protocol

ModbusTCP/RTU

BMS access

support

15

5 Storing、lifting and transporting

5.1 Transport and storage

In order to ensure that the energy storage converter is in a better protective state during transportation, please

choose to transport with packaging as much as possible, and transport according to the indications of various signs on

the packaging. The illustrations of the packaging signs are shown in Table 5-1:

Table 5-1 Description of packaging label

Icon

Describe

Center of gravity mark, indicating the center of gravity of the energy storage

converter.

Lifting mark, indicating the position of the chain or rope when lifting the energy storage

converter.

The upward mark indicates the placement method when carrying and placing the energy

storage converter. It is strictly forbidden to put it upside down, horizontally or tilted.

Handle the logo with care, and avoid violent friction or collision during transportation and

placement.

During transportation and storage, the energy storage converter should be protected from

rain or moisture.

Since the center of gravity is not the mechanical center of the energy storage converter, please pay attention to the

center of gravity mark on the packaging box during transportation.

Regardless of whether the converter is packaged or not, it is strictly forbidden to tilt an angle greater than 5°during the

movement. Due to its large size and weight, an excessively large inclination angle may cause the equipment to fall

upside down, causing casualties or equipment damage.

Please avoid physical shocks to the equipment during the movement, such as suddenly lowering or lifting.

Please avoid transporting the energy storage converter under rain or bad weather conditions. If it is unavoidable, please

take necessary protective measures.

16

If the on-site installation is not carried out immediately after the completion of the delivery and acceptance work, the

energy storage converter with outer packaging should be stored in a ventilated, dry, and clean indoor environment. At the

same time, you should also pay attention to the following aspects:

⚫Restore the package to the state at the time of receipt, and the desiccant in the package must be retained.

⚫The storage floor is flat and sufficient to carry the weight of the energy storage converter with the outer packaging.

⚫When storing the equipment, you need to pay attention to ventilation and moisture prevention, and it is strictly

forbidden to store water in the storage environment.

⚫The storage environment temperature is required to be -40℃~+55℃, and the relative humidity of the storage

environment is required to be 0~95%, without condensation.

⚫Take care to deal with the harsh surrounding environment, such as sudden cold, sudden heat, collision, etc., to

avoid damage to the equipment.

⚫Regular inspections, at least once a week. Check if the packaging is intact to avoid insect bites. If the outer

packaging is damaged, it should be replaced immediately.

⚫If the storage time is more than half a year, the package should be opened for inspection, and the desiccant should

be replaced and repackaged.

The energy storage converter is a whole device, and it must not be disassembled during transportation or storage.

Equipment failures caused by modifications not authorized by Sinexcel are not covered by the warranty.

When the equipment is transported and stored, it is strictly forbidden to stack, and no other items are allowed to be

stacked on the top of the equipment.

When the equipment is transported and stored, it should be ensured that the environment in which it is located is free of

corrosive gas, no high-temperature heat source, not excessively dusty, and meets the fire protection requirements.

Storage without packaging is strictly prohibited.

5.2 Transfer

It is recommended to use a forklift to move the entire box body in a short distance without removing the shipping box.

When moving, pay attention to the center of gravity mark and lifting mark position on the box, and ensure that the

transportation tool has sufficient carrying capacity. Lifting is strictly prohibited.

Moving the energy storage converter without a packaging box is usually used near the installation location of the

equipment. It is recommended to use a forklift for operation. When using a forklift, the bottom baffle of the energy storage

converter needs to be removed first.

1) Forklift movement (preferred)

Using a forklift to transport the energy storage converter is a standard way of movement. The center of gravity of the

converter should fall between the two forks of the forklift and be pre-inserted to ensure that it will not tilt after being lifted. As

shown in Figure 1-1, the length of forklift forks shall not be less than 1.2m.

17

In the process of using a forklift to fork, lower and move the energy storage converter, it is necessary to ensure that it is

slow and stable, and the energy storage converter must be placed on a firm and level ground.

In the entire process of using a forklift to operate, it is necessary to strictly abide by the forklift safety operation specifications.

Due to the large volume of the energy storage converter, it may obstruct the driver's sight, so assistance should be provided

for cooperation.

≥1.2m

Fig 5-1 Schematic diagram of forklift

1) Pallet truck movement

The use of a pallet truck to move the energy storage converter is only suitable for conditions where the transportation

route is relatively stable. During transportation, the center of gravity of the converter should fall between the two forks of the

forklift and be pre-inserted to ensure that it will not tilt after being lifted. As shown in Figure 3-2, the length of the forklift forks

shall not be less than 1.2m, the inner distance between the two fork arms of the pallet truck shall not be less than 0.2m, the

outer distance shall not be greater than 0.8m, and the load-bearing capacity of the pallet truck must be ≥1500kg.

In the process of using a forklift to fork, lower and move the energy storage converter, it is necessary to ensure that it is

slow and stable, and the energy storage converter must be placed on a firm and level ground.

In the entire process of using a forklift to operate, the relevant safety operation regulations must be strictly observed. Due

to the large size of the energy storage converter, it may obstruct the operator's view, so assistance should be provided for

cooperation.

≥1.2m

≥0.2m

≤0.8m

Fig 5-2 Schematic diagram of pallet truck

Before moving with a forklift or pallet truck, the bottom baffle of the energy storage converter must be removed,

otherwise the bottom baffle will be damaged.

18

No matter which way you choose to move the energy storage inverter, you must ensure:

⚫Must always pay attention to the position of the center of gravity.

⚫Must be considered the volume and weight at all times.

⚫Must be ensured the safety of operators at all times.

Take necessary auxiliary measures to ensure that the equipment is transported to the installation site in good condition.

5.3 Out of the box inspection

5.3.1 Unpacking

After the DC converter is transported to the vicinity of the installation site, the transport box needs to be

removed. The removal steps are as follows:

①Remove the top panel of the box.

②Remove the wooden side panel of the packing box.

③Remove the shielding material from the packing box.

④Remove the anchor parts that fix the DC converter on the transport wooden bracket.

After removing the anchor parts between the DC converter and the transport wooden bracket, it is strictly

forbidden to transport the DC converter through the wooden bracket.

5.3.2 Test

Before leaving the factory, the DC converter has been checked by the staff of Shenghong Electric and packed

firmly. Nonetheless, the following items need to be checked after the DC converter shipping packaging has been

removed:

Check whether the quantity of each item on the packing list is consistent with the actual item;

Check whether the nameplate data of the product is consistent with the order contract, such as product model,

rated capacity, voltage level, etc.;

Check whether the factory documents and accessories are complete;

Check whether the appearance of the DC converter is consistent with the description in this manual;

19

Check the DC converter for deformation, peeling paint and loose parts.

The packing list of the PDS1-750K-H DC converter is shown in Table 5-2.

Table 5-2 Packing list

serial number

name

quantity

1

PDS1-750K-H-DC converter

(including cabinet door key and related accessories)

1 set

2

PDS1-750K-H User Manual

1 serving

3

Equipment wiring diagram

1 serving

4

Product certification

1 serving

5

Inspection Report

1 serving

6

Warranty Card

1 serving

Installation and debugging can only be carried out on the DC converter that has been inspected correctly and is

complete without damage. During the inspection process, if any problem is found, please contact the transporter

or Shenghong Electric in time.

Table of contents

Other Sinexcel Media Converter manuals

Popular Media Converter manuals by other brands

Roland

Roland VC-1-HS Brochure & specs

iConnectivity

iConnectivity iConnectMIDI quick start guide

Black Box

Black Box IC152A Specifications

Keyautomation

Keyautomation 900EGKD2 Instructions and warnings for installation and use

FibroLAN

FibroLAN S.CON1M User and installation guide

GRASS VALLEY

GRASS VALLEY 2020ADC instruction manual