Sinexcel PDS1-45k User manual

PDS1-45k/ PDS1-60k

DC-DC Converter User Manual

Ver 1.00

User's Manual

Sinexcel PDS1 DC-Boost Converter

Data Version V1.0

Date of filing2023-02-07

Applicable toPDS1-45k, PDS1-60k

Shenzhen Sinexcel Electric Co., LTD provides a full range of technical support for customers, users can

contact the nearest office or customer service center of Shenzhen Sinexcel Electric Co., LTD

Shenzhen Sinexcel Electric Co., LTD.

All rights reserved. Contents are subject to change without notice.

Shenzhen Sinexcel Electric Co., LTD

Company website: www.sinexcel.com

Address:Block 6, Block 2, Nanshan Baiwangxin Hi-Tech Industrial Park, No.1002 Songbai Road, Nanshan

District, Shenzhen, China

Postcode:518055

Customer Service Hotline:0755-8651-1588

Company Fax:0755-8651-3100

E-mail: service@sinexcel.com

Catalog

Chapter 1 Overview .....................................................................................1

Model Definition ..............................................................................................................................................................1

Explanation of Symbols....................................................................................................................................................1

Manual Tip Identifiers .....................................................................................................................................1

Transformer Tip Identifiers..............................................................................................................................2

Safety instructions ............................................................................................................................................................2

Safety instructions in mechanical installation..................................................................................................3

Safety instructions in the electrical connection ...............................................................................................4

Safety instructions during operation of the equipment ....................................................................................4

Safety instructions for repair and replacement ................................................................................................5

Miscellaneous..................................................................................................................................................5

Caution .............................................................................................................................................................................6

Personnel requirements ...................................................................................................................................6

Scope of use of the equipment.........................................................................................................................6

Enclosure marking...........................................................................................................................................6

Instructions ......................................................................................................................................................6

Chapter 2 Introduction of optical storage system ........................................................7

System Application...........................................................................................................................................................7

System structure diagram ................................................................................................................................7

Dimension ........................................................................................................................................................................8

Appearance display diagram.............................................................................................................................................8

Technical Parameters........................................................................................................................................................9

Technical description......................................................................................................................................................11

Principle Description .....................................................................................................................................11

Function Description .....................................................................................................................................12

Derating.........................................................................................................................................................12

Chapter 3 Equipment transportation, storage and installation ...........................................14

Transportation and Storage.............................................................................................................................................14

Installation flow..............................................................................................................................................................15

Unpacking and inspection...............................................................................................................................................15

Converter identification and preparation ........................................................................................................................15

Installation requirements ................................................................................................................................................16

Environmental requirements..........................................................................................................................16

Carrier requirements......................................................................................................................................17

Electrical Connection .....................................................................................................................................................17

Recommended System Configuration ...........................................................................................................17

Terminal Introduction....................................................................................................................................18

System grounding..........................................................................................................................................19

DC output side wiring ...................................................................................................................................20

Photovoltaic input side wiring.......................................................................................................................21

Connecting the communication cable............................................................................................................23

Single module application system connection...............................................................................................26

Multi-module application system connection................................................................................................27

Post-installation inspection.............................................................................................................................................28

Equipment installation check.........................................................................................................................28

Electrical and communication check .............................................................................................................29

Chapter 4 Control and parameter setting process ........................................................30

Web connection ..............................................................................................................................................................30

Multi-module multi-monitoring application settings ......................................................................................................31

Step 1.............................................................................................................................................................31

Step 2.............................................................................................................................................................32

Step 3.............................................................................................................................................................33

Step 4.............................................................................................................................................................33

Step 5.............................................................................................................................................................34

Step 6.............................................................................................................................................................34

Single monitoring application setting .............................................................................................................................35

Step 1.............................................................................................................................................................35

Step 2.............................................................................................................................................................37

Step 3.............................................................................................................................................................38

Step 4.............................................................................................................................................................38

Step 5.............................................................................................................................................................39

Step 6.............................................................................................................................................................39

Step 7.............................................................................................................................................................40

Switching........................................................................................................................................................................40

Check before power on..................................................................................................................................40

Power-on steps ..............................................................................................................................................40

Steps to shut down the device........................................................................................................................41

Chapter 5 Maintenance and repair.......................................................................43

Working environment and operating condition inspection .............................................................................................43

Electrical and fixed partsconnection check.....................................................................................................................43

Cleaning and cleaning ....................................................................................................................................................43

Chapter 6 APPENDIX ...................................................................................45

Appendix I:Quality assurance and after-sales service ................................................................................................................45

~1~

Chapter 1 Overview

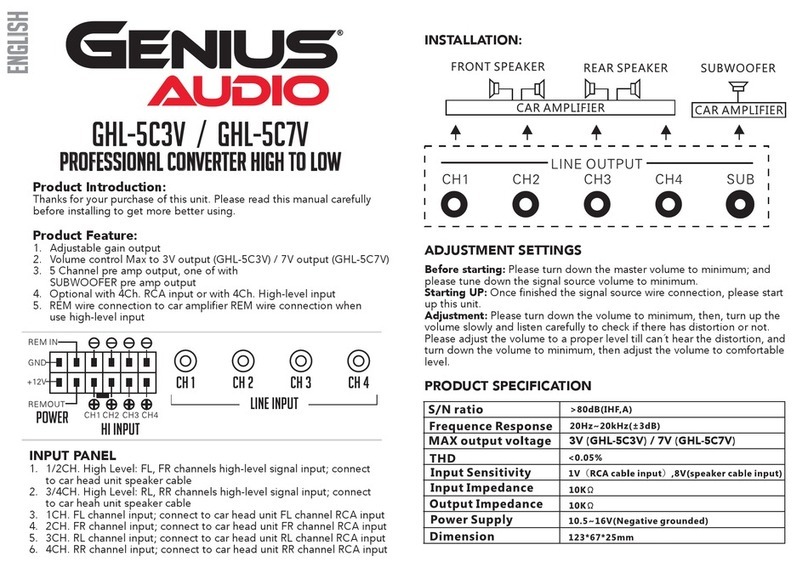

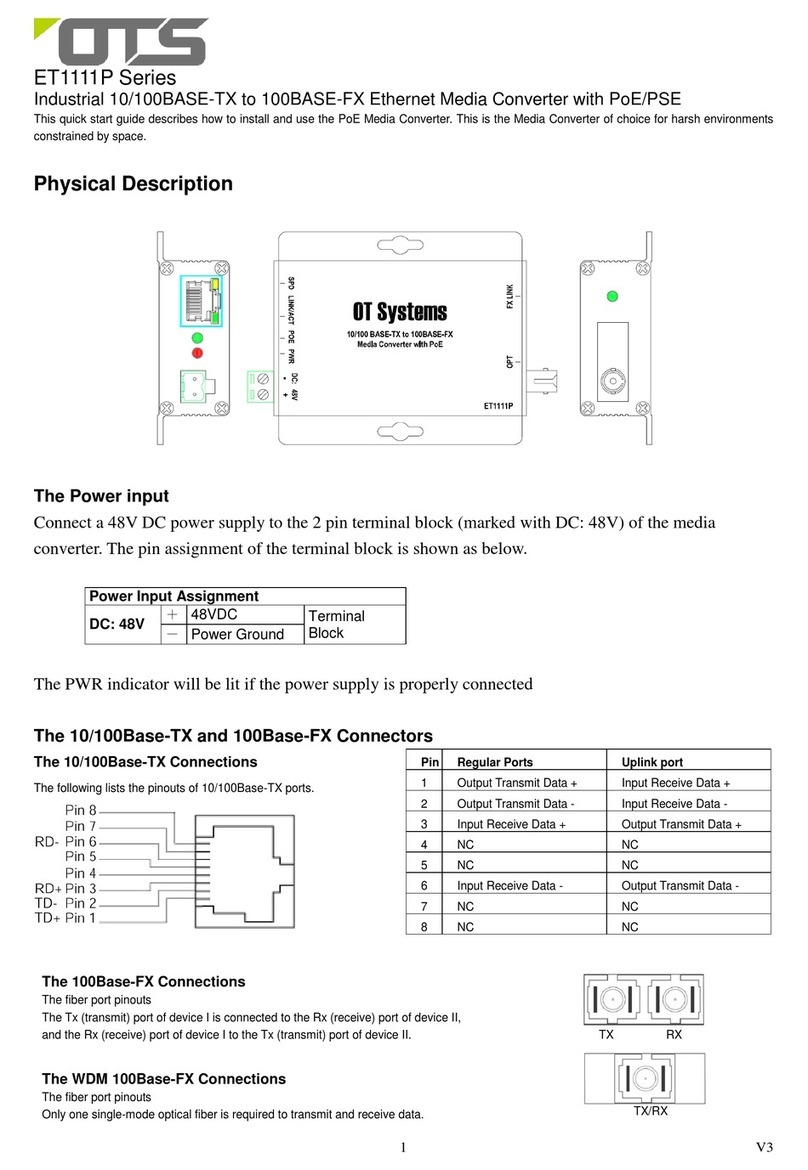

Model Definition

Model Definition.

PDS 1 -

DC converter with wideinput voltage range

SingleConversion

Power:45k --- 45kW

60k --- 60kW

SN Definition

SH0 YYMMDD

Module part number

YY:Year

MM:Month

DD:Date

Sinexcel code

Serial number

Figure 1-1 Model Number an SN Number Definition

Explanation of Symbols

This manual covers the installation and use of the Sinexcel Electric PDS1-45k/PDS1-60k DC-DC Boost

Converter.

To ensure the user's personal and property safety or efficient use of this product, please read this manual

carefully before installation and use.

Manual Tip Identifiers

The following is a list of identifiers used in this manual. Please read carefully and understand the

meaning of each identifier.

~2~

DANGER

This symbol indicates that there is a danger during operation and that failure to comply with

such warnings may directly result in serious injury or death.

WARNING

This symbol indicates that there are potential hazards during operation and failure to comply

with such warnings may result in personal injury or death.

CAUTION

This symbol indicates that there is a potential hazard during operation and that failure to

comply with such warnings may result in damage to the equipment.

"Instructions" are additional information in the manual that emphasize and supplement the

content, and may also provide tips or tricks to optimize the use of the product and help you solve

some of the problems in your application efficiently.

Transformer Tip Identifiers

The following is a list of identifiers used on DC-DC boost converters. Please read carefully and

understand what each identifier represents.

5min

This symbol indicates that after the converter is disconnected from the PV panel and the

energy storage converter, it is necessary to wait for 5 minutes before touching the internal

conductive devices.

This symbol indicates that the surface of the machine is hot during operation, so do not

touch the surface of the machine!

Please read the product manual carefully before performing any operation on the

converter.

Danger of electricity! Only professional and qualified personnel should install and

electrically operate this equipment.

Safety instructions

The PDS1-45K/PDS1-60K DC-DC boost converter is designed and tested in strict accordance with the

relevant international safety standards. The installation, commissioning, operation and maintenance

processes must comply with the safety practices for electrical and electronic equipment. Improper use or

~3~

misuse may endanger the personal safety of the operator or third parties, as well as damage the converter

or other property. To avoid this, the following safety precautions must be strictly observed during operation

and maintenance, which are described in detail in the respective sections.

WARNING

All installation, commissioning and maintenance operations must be performed by qualified

personnel. Professional technicians must meet the following conditions.

An engineer appointed by the manufacturer or its agent.

Have received professional training.

A complete reading of this manual and familiarity with safety matters in the operation

of electrical and electronic equipment.

Familiar with the relevant safety codes for electrical systems.

Professional technicians meeting the above requirements may perform the following tasks.

(1) Installation of the converter.

(2) Construction of PV-storage systems according to customer requirements.

(3) Commissioning of the PV-energy storage system.

(4) Operation, commissioning and maintenance of the PV-energy system.

CAUTION

Risk of injury if the equipment is operated incorrectly!

The instructions in the manual must always be followed when moving and placing the

converter.

Improper handling of the equipment may lead to electric shocks, burns, contusions,

etc.

Damage to the equipment caused by any private modification and dismantling of the

system (or equipment) operation without permission is not covered by the warranty.

Safety instructions in mechanical installation

DANGER

Always ensure that the converter is free of any electrical connections before installing the

converter.

CAUTION

Poor ventilation of the installation environment will affect the system performance!

Good ventilation needs to be ensured during the operation of the equipment. It is important

to keep the unit upright and the air ducts smooth, with no strong drafts blocking the air flow near

the air outlets, to ensure adequate cooling inside the unit.

~4~

Safety instructions in the electrical connection

DANGER

Do not touch the metal terminals of the PV panels without adequate protection.

CAUTION

The cables used in the photovoltaic-storage system must be firmly connected, well

insulated, and of proper gauge.

CAUTION

All electrical installations must meet national/regional electrical standards.

Permission must be obtained from the electricity authority of the country/region in which it is

located in order to operate on the grid.

Before connecting to the input power source, be sure to ground the system reliably and

comply with local electrical standards.

Safety instructions during operation of the equipment

DANGER

Any touching of the copper strip, contacts, terminals, etc. inside the equipment connected

to the photovoltaic panels and the energy storage converter circuit may cause a fatal burn or

electric shock!

Do not touch the terminals and conductors connected to the photovoltaic panels and

energy storage converter circuits.

Pay attention to any instructions and safety documentation regarding the connection

to the PV panel and the energy storage converter.

WARNING

There is a risk of electric shock inside the device! Do not open the converter housing while

the converter is in operation or under power.

A complete and closed cabinet enclosure protects the operator's personal property.

Any operation of this equipment needs to be performed or directed by qualified

personnel.

Please pay attention to the safety precautions listed in the user manual and other

documents.

Do not disconnect the input side when the output side of the converter is under load. If

disconnection is necessary, perform a shutdown operation first. Disconnect the input only after

disconnecting the output side disconnect switch of the converter and confirming that no voltage

is present.

~5~

CAUTION

It is strictly forbidden to block the air duct with foreign objects while the converter is in

operation.

Safety instructions for repair and replacement

DANGER

Improper maintenance operations on the equipment may lead to injury or equipment

damage. Before performing any operation, the user must strictly follow the following steps.

Disconnect all external connection switches and confirm with a multimeter that there

is no voltage at the converter ports.

Wait for at least 5 minutes until the internal energy storage components are

discharged, during which time it is strictly forbidden to touch the charged parts of the

equipment terminals, contacts, copper row, etc. with human body or any conductor.

Please carry out maintenance operations with an escort after complete power supply

to prevent any unexpected situation.

CAUTION

Do not allow unrelated personnel to enter the maintenance site!

Temporary warning signs must be posted or barriers erected to prevent unrelated persons

from entering the electrical connection or maintenance area when performing electrical

connection and maintenance work.

CAUTION

Restart the converter only after removing faults that affect the safety performance of the

converter.

the converter may only be re-powered after a complete power down of 1 minute.

The converter does not contain service parts inside, so if you need any repair service, please

contact our after-sales service.

CAUTION

Do not replace the internal components of the converter without permission. We will not be

responsible for any warranty or joint and several liability for any damage caused by this.

CAUTION

Contact or improper handling of printed circuit boards or other electrostatic sensitive

components can cause damage to the device.

Avoid unnecessary contact with the circuit board.

Observe electrostatic protection codes and wear anti-static bracelets.

Miscellaneous

WARNING

All safety markings, warning labels, and nameplates on the transducer.

must be clearly visible.

~6~

They must not be removed or covered.

Caution

Personnel requirements

The transducer must be commissioned and maintained by an engineer appointed by the manufacturer

or its agent. Failure to do so may endanger personal safety and cause equipment failure, and any resulting

damage to the equipment is not covered by the warranty.

Scope of use of the equipment

Converters are for commercial/industrial use only and may not be used as any energy saving equipment

associated with life support equipment.

Enclosure marking

The chassis marking contains important information for safe operation of the converter and must not be

torn or damaged.

Make sure the chassis marking is legible and replace it immediately if it becomes damaged or obscured.

Instructions

To make it easier for the user to read this manual, a large number of pictures are included. The pictures

are only for illustration purpose, please refer to the actual product for detailed display.

~7~

Chapter 2 Introduction of optical storage system

System Application

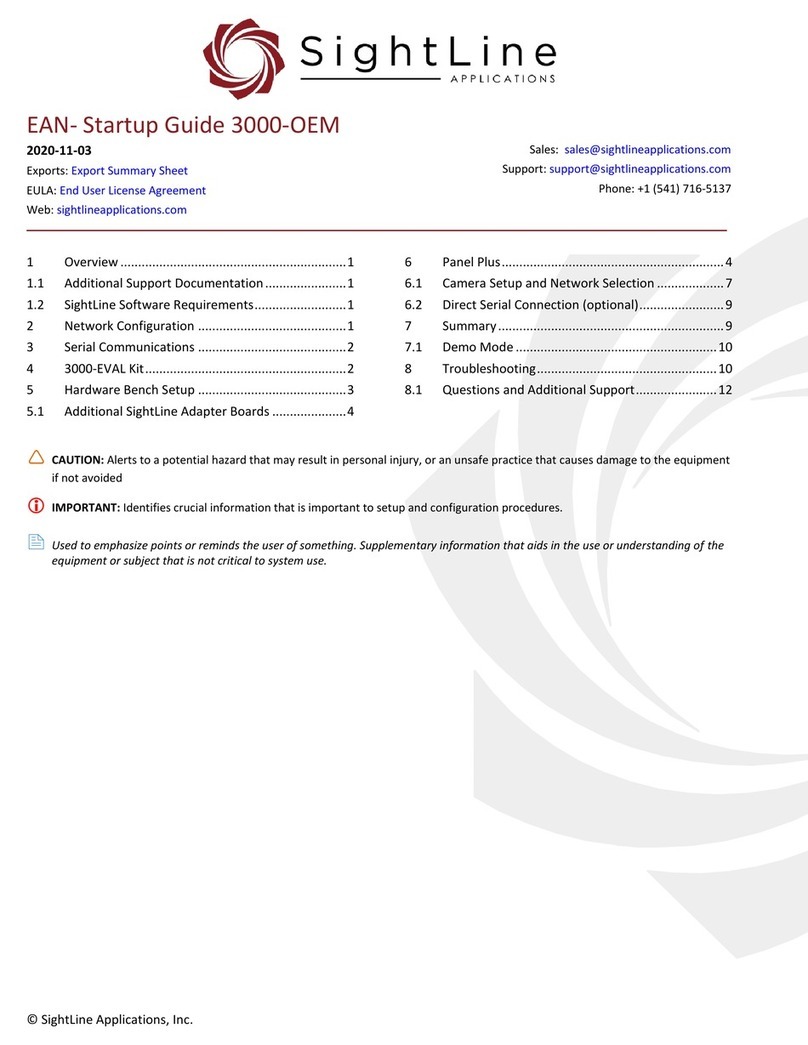

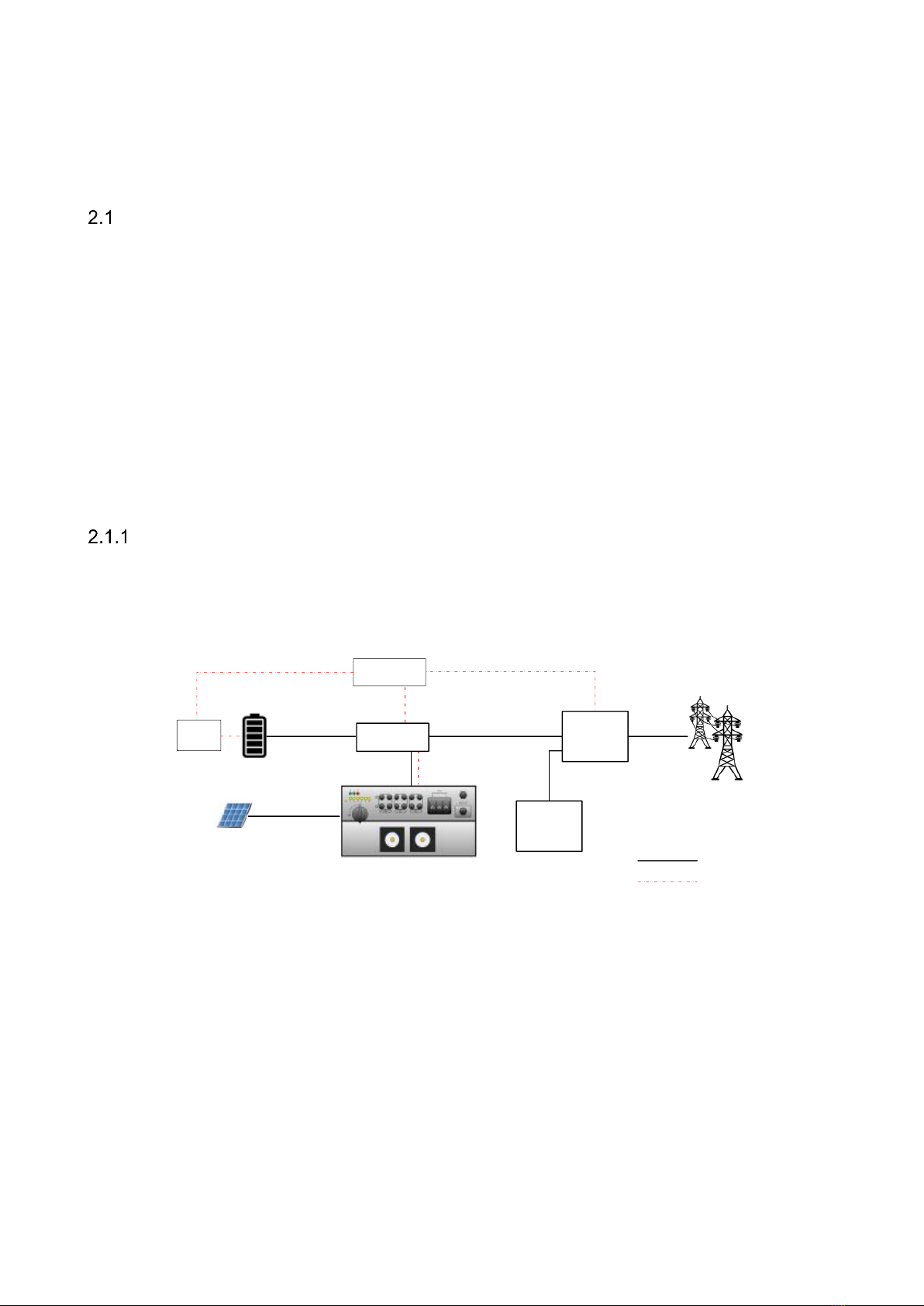

As shown in Figure 2-1, the photovoltaic storage system built by DC-DC booster converter includes

battery (group), energy storage converter, intelligent power distribution unit, EMS and BMS, and PV module.

The PV modules are connected to the DC-DC boost converter to realize the PV boost, and the MPPT control

is performed in real time according to the PV string energy state. After the boost, the DC bus of the storage

converter is connected through the bus side, and the discharge power of the storage converter is dispatched

through RS485 communication with EMS to realize the effective power transmission; the DC side of the

storage converter is connected to the battery pack, and the AC side is connected to the industrial load or

grid connection through the intelligent power distribution unit, and the energy management between the

three is performed through EMS to realize the energy dispatch of the photovoltaic storage system.

System structure diagram

The structure diagram of the optical storage system is as follows. The energy storage converter pushes

the data to the EMS, DC-DC boost converter or other upper computer system in real time.

RS485

【2】【6】【7】

【8】

Ethernet/RS485

EMS Ethernet/RS485

BMS

Intelligent

distribution

cabinet

Load

RS485

【1】

【3】

【5】

【4】

PCS

Legend

Power cable

Communication line

【9】

Figure 2-1 Energy storage system structure diagram

(1) PV module

(2) BMS battery

management system

(3)DC-DC booster

converter

(4) Battery pack

(5) EMS energy

management system

(9) Household and

industrial loads

(6) Energy storage

converters

(7) Intelligent power

distribution unit

(8) Grid

~8~

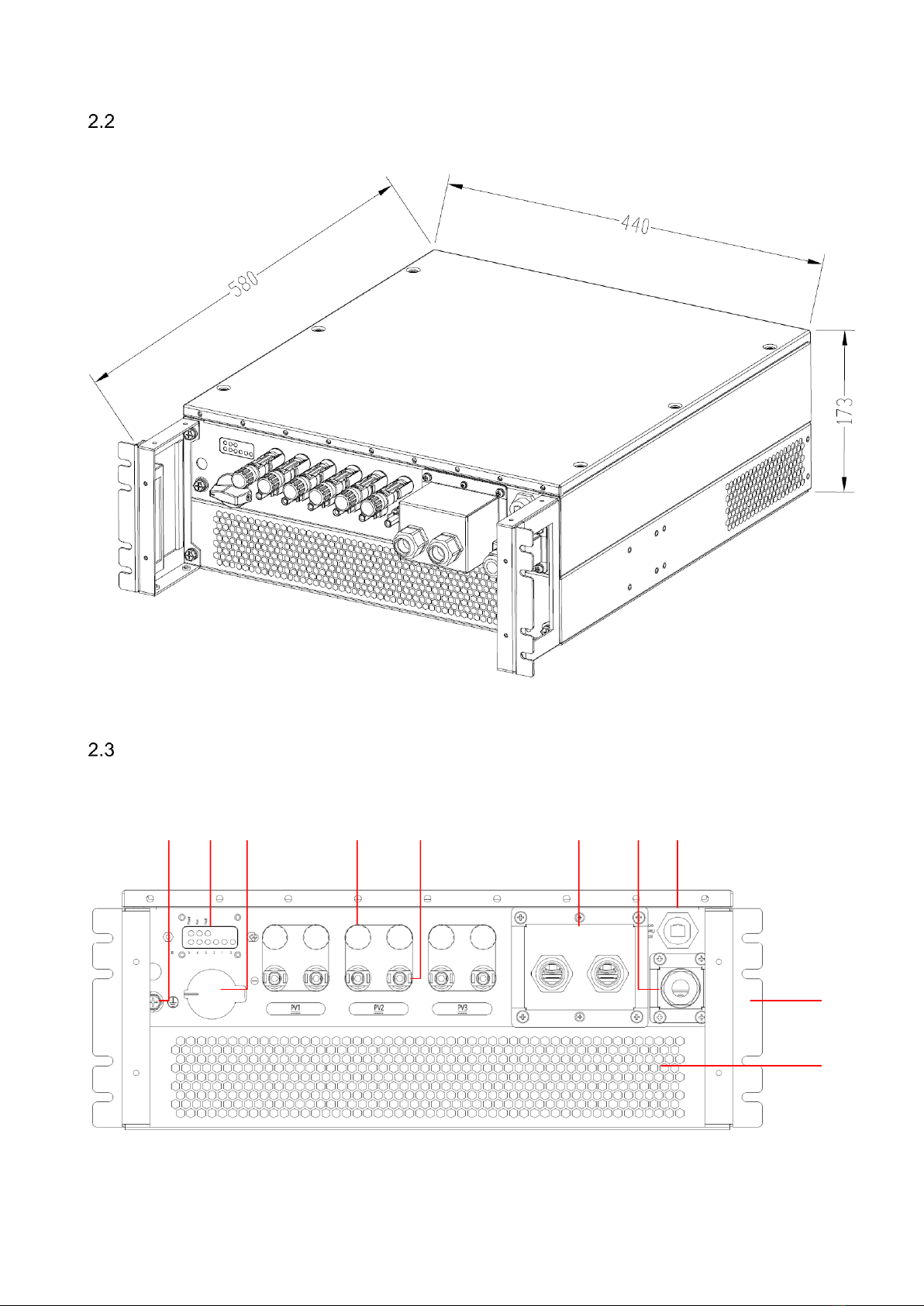

Dimension

Theoutline dimensions of PDS1-45K/PDS1-60K module models are shown in Figure 2-2.

Figure2-2PDS1-45K/PDS1-60K module external dimension diagram (unit: mm)

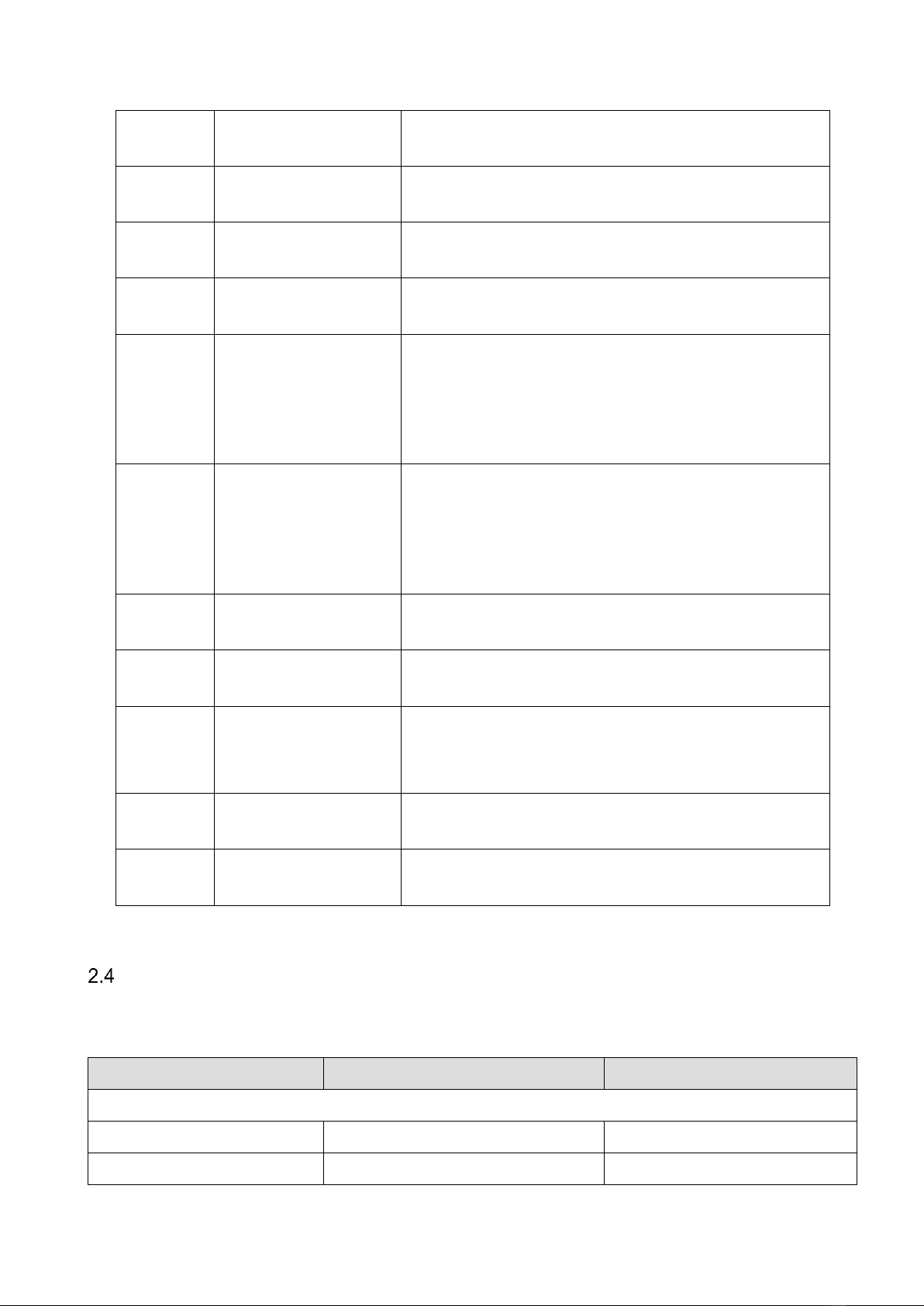

Appearance display diagram

The appearance of the PDS1-45K/PDS1-60K module panel is shown in Figure 2-3.

12 3 456 7 8

9

10

Figure2-3PDS1-45K/PDS1-60K module model panel appearance diagram

~9~

SN

Name

Description

1

Ground terminal

Grounding protection wire fixed point

2

Indicator light

To indicate the working status and ID of the module

3

PV input switch

To turn on/off the photovoltaic input

4

PV positive input port

MC4 terminal*6

To connect positive power cables to the photovoltaic

module

5

PV negative input port

MC4 terminal*6

To connect negative power cables to the photovoltaic

module

6

DC output port

To connect power cables to the PCS system

7

Signal interface

External communication interface

8

Reserve signal

interface

Not supported at present

9

Handle

Extraction and install module, not for load-bearing

10

Vent

Fan cover and air duct vents

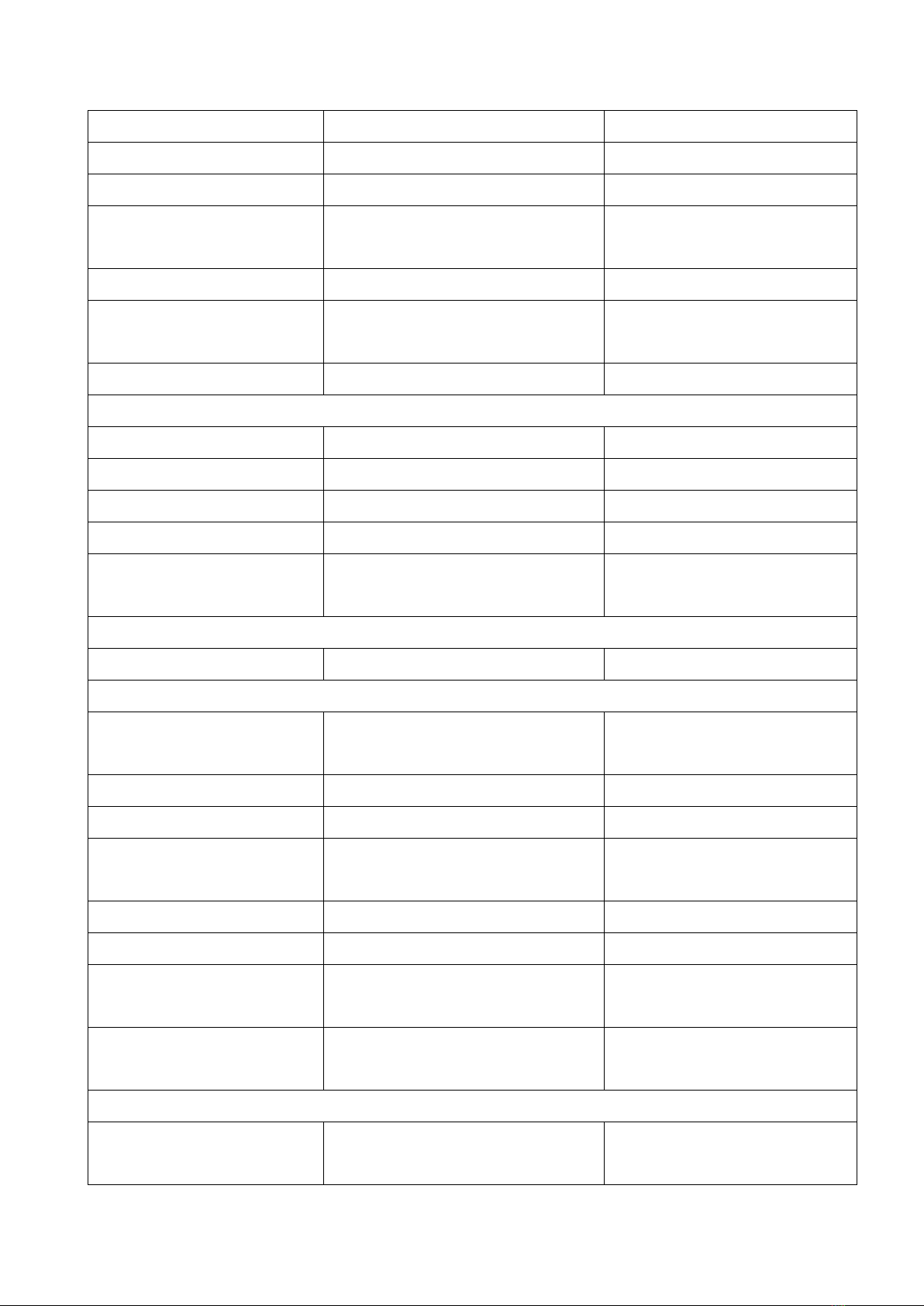

Technical Parameters

The technical parameters of DC-DC boost converter are shown in the following table.

Table 2-1 Technical parameters table

Technical specifications

PDS1-45k

PDS1-60k

Photovoltaic side

Rated allowable power

45kW

60kW

Maximum inputvoltage1

1100V

1100V

~10~

Rated input voltage

600V

600V

Starting Voltage

250V

250V

MPPT voltagerange2

200~830V

200~1000V

Full Load MPPT Voltage

Range

430V~750V

575~900V

Number of MPPTs

3

3

Number of MPPT input

strings per circuit

2

2

Maximum input current

35A/35A/35A

35A/35A/35A

DC bus side

Rated allowable power

45kW

60kW

Operating voltage range

700V~830V

600~1000V

Rated Voltage

700V

700V

Rated Current

65A

86A

Maximum working

current

65A

86A

Efficiency

Peak efficiency

>99%

>99%

Basic parameters

Module size (width,

height and depth)

440*175*580mm

440*175*580mm

Net weight

22kg

22kg

Heat dissipation method

Air-cooled

Air-cooled

Working temperature /

humidity

-25-60

-25-60

Protection grade

IP66

IP66

Noise

≤70dB

≤70dB

Altitude

4000m (>3000m derating)

4000m(greater than

3000m reduction)

Working environment

pollution level

II

II

Protection

Photovoltaic reverse

connection protection

Yes

Yes

~11~

Insulation impedance

detection

Yes

Yes

Photovoltaic side switch

Yes

Yes

Temperature protection

Yes

Yes

Nighttime PIDrepair3

Yes3

Yes3

Photovoltaic input surge

protection

DC level 2 lightning protection

DC Class 2 lightning

protection

Fan/contactor failure

Yes

Yes

Leakage current

protection

Yes

Yes

Terminal Type

DC Busbar Terminal

Type

OT Terminals

OT Terminals

Photovoltaic terminal

type

MC4 terminal

MC4 terminal

Display/Communication

Display

LED

Communication

RS485/CAN(reserve)/RS232(reserve)

Certification

Safety certification

IEC62109,UL1741

EMC

EN61000 series

Notes.

1、The maximum input voltage is the maximum voltage that the PV input side of the converter

can withstand. Input voltage exceeding this voltage may damage the converter.

2、If the input voltage is not in the working voltage range, the inverter will not work properly.

3、This function is related to the power distribution system, the default is not enabled; customers

can set the enable or disable, and the compensation direction according to their needs.

Technical description

Principle Description

The DC-DC boost converter will decide whether to connect to the energy storage system according to

the strength of the PV module, when the PV module energy is weak, the DC-DC boost converter will

disconnect from the energy storage system due to the PV input undervoltage, and other components of the

energy storage system will realize energy deployment; when the PV module energy is strong, it will reach

~12~

the starting voltage of the DC-DC boost converter, and the PV open circuit voltage is within the MPPT

operation range. At this time, the DC-DC booster converter is normally connected to the energy storage

system, and the DC-DC booster converter can start working to raise the DC bus voltage to the normal

operating range of the energy storage converter, and MPPT control is performed according to the energy

strength of the PV module at this time. It can realize the conversion from wide input range to low output

range.

Function Description

Thefunctions of the PDS1-45K/PDS1-60K can be basically summarized as follows.

PV power boost control: The DC-DCboost converter can beconnected to the bus side of the DC of the

energy storage converter to realize PV access through MPPT boost, which can transmit PV power to the

battery for charging and also send PV power to the grid.

Data storage: DC-DC boost converter stores operation information, operation records, fault records and

other information.

Communication function.

⚫The standard RS485 interface can be connected to the energy storage converter for remote

control, remote upgrade and other functions.

⚫Standard RS485, CAN interface, etc. can be used to connect with other devices (reserved,

function not yet open).

Protection functions.

⚫Overcurrent protection

⚫Overload protection

⚫PV short-circuit protection

⚫PV reverse connection protection

⚫Bus bar reverse connection protection

⚫Environmental over-temperature protection

⚫Power module over-temperature protection

⚫Earth leakage current monitoring

⚫Insulation impedance detection and protection

⚫Photovoltaic voltage monitoring

⚫Busbar voltage monitoring

⚫Fan fault protection

⚫Communication timeout protection

⚫Bus bar electric switch fault protection

Derating

Derating of the converter is done to avoid overloading of the converter or to suppress potential faults.

~13~

The converter may be derated under the following operating conditions.

⚫Excessive internal temperature (both ambient and module temperature)

⚫Low photovoltaic voltage

⚫Remote power scheduling

Over-temperature derating

High ambient temperature and poor air duct will cause the converter to derate. Over-temperature

derating regulation is as follows.

⚫When the power device temperature reaches the upper limit, the converter will actively reduce the

input and output power until the power device temperature returns to the normal range, and then

the converter will gradually increase to the set value.

⚫When the ambient temperature inside the machine exceeds the upper limit, the converter will

automatically stop and power off to protect the safety of the machine itself.

The lower limit of over-temperature derating is about 70% of the rated power. If the derating reaches

the lower limit and still does not improve the temperature, the converter will automatically shut down.

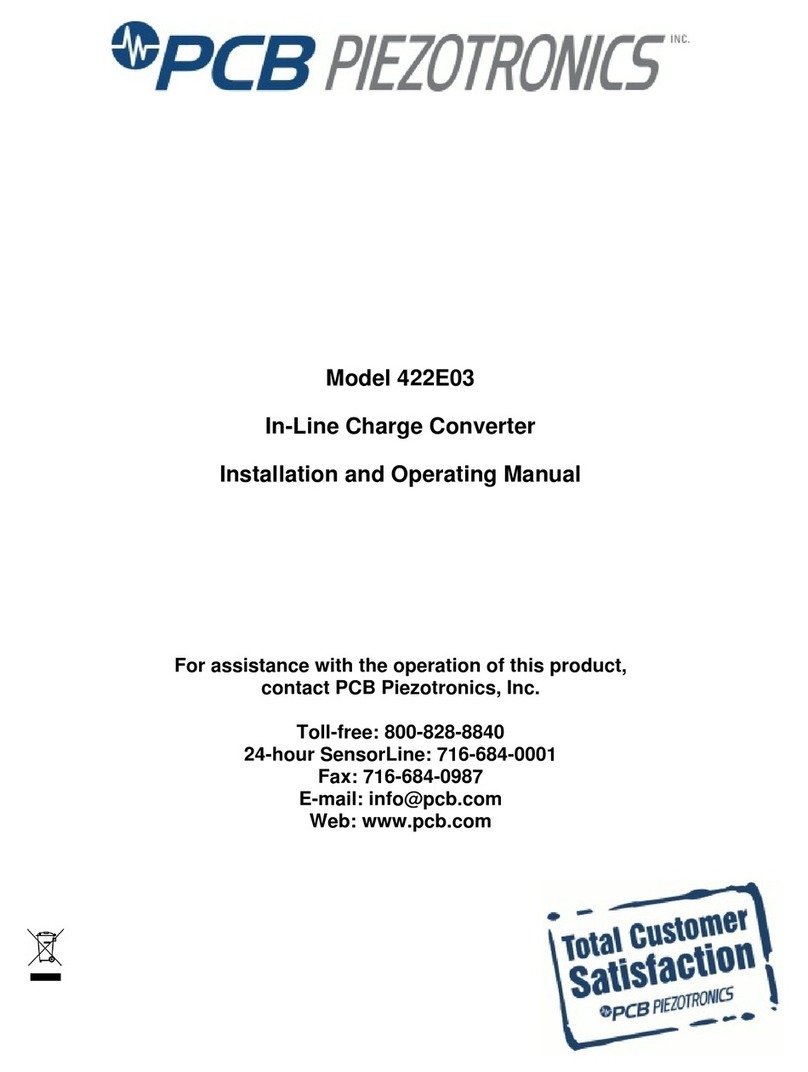

PV under-voltage derating

If the PV voltage does not reach the lower limit point of the full-load MPPT operation range, the DC-

DC boost converter cannot output the rated power at this time, and the PV output current is limited to

the specified range by derating.

200V 750V

45kW

21kW Work zone

430V

200V 900V

60kW

21kW Work zone

571V

Figure 2-4 PDS1-45K/PDS1-60K PV undervoltage derating diagram

~14~

Chapter 3 Equipment transportation, storage and installation

Transportation and Storage

When transporting and storing the converter cabinet, please pay attention to the marking on the packing

box. The following requirements should be met during transportation and storage.

⚫Do not remove the outer packaging of the DC-DC boost converter.

⚫No corrosive gases in the surrounding area.

⚫Storage temperature maintained at -40 ℃~65 ℃ and relative humidity maintained at

0%RH~95%RH.

⚫Non-dusty environment.

⚫Up to 5layersof stacking.

⚫Regular inspection is required during storage. If insects and rodents are found, the packaging

material should be replaced in time.

⚫Comply with fire protection requirements.

⚫After long-term storage, the converter needs to be inspected and tested by professionals before it

can be put into use.

~15~

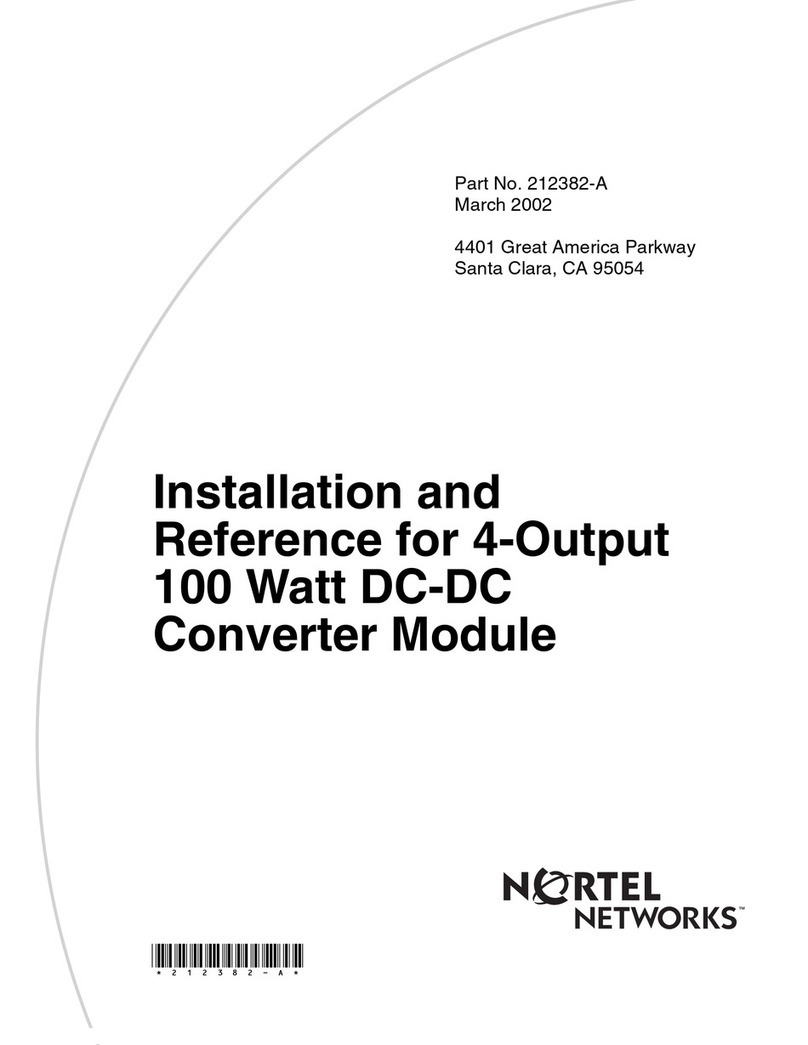

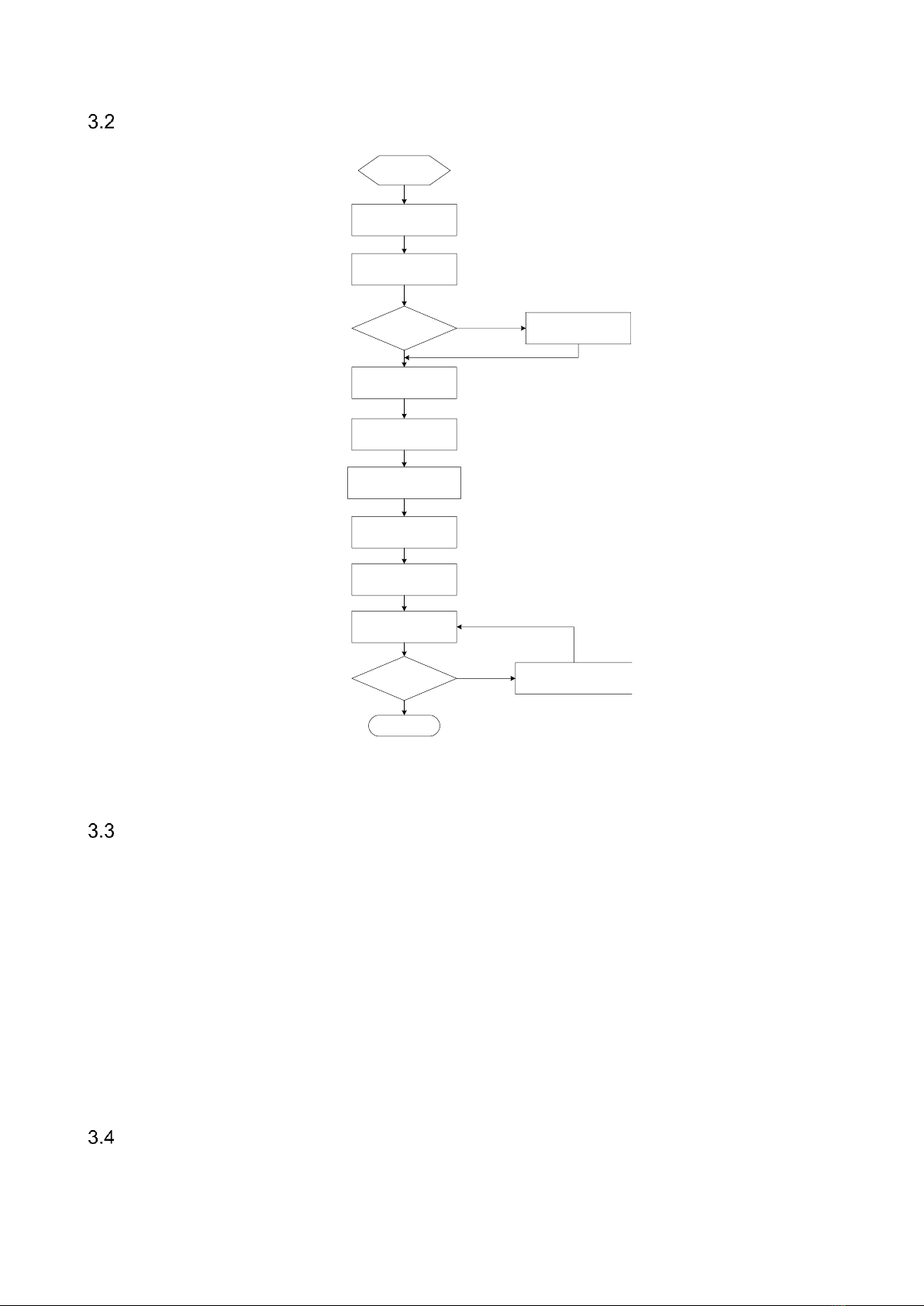

Installation flow

Start

Unpacking

inspection

Read manual

Install? Store

Choose Place

Move

converter

Regular

Electrical

connection

Pre-operation

inspection

Pilot run

TroubleshootingRun?

Over

No

Yes

No

Yes

Figure 3-1 Equipment installation logic flow chart

Unpacking and inspection

Each cabinet needs to undergo strict factory inspection and testing before shipment, and in order to

prevent damage during transportation, it is necessary to carry out unpacking inspection before the energy

storage device is ready for installation.

⚫Check whether the quantity of each item in the packing list is consistent with the physical object.

⚫Check whether the product nameplate data and the ordering contract are consistent, such as the

product model, rated capacity, voltage level, etc..

⚫Checking whether the factory documents and accessories are complete.

⚫Whether the DC converter is deformed and paint is lost.

Converter identification and preparation

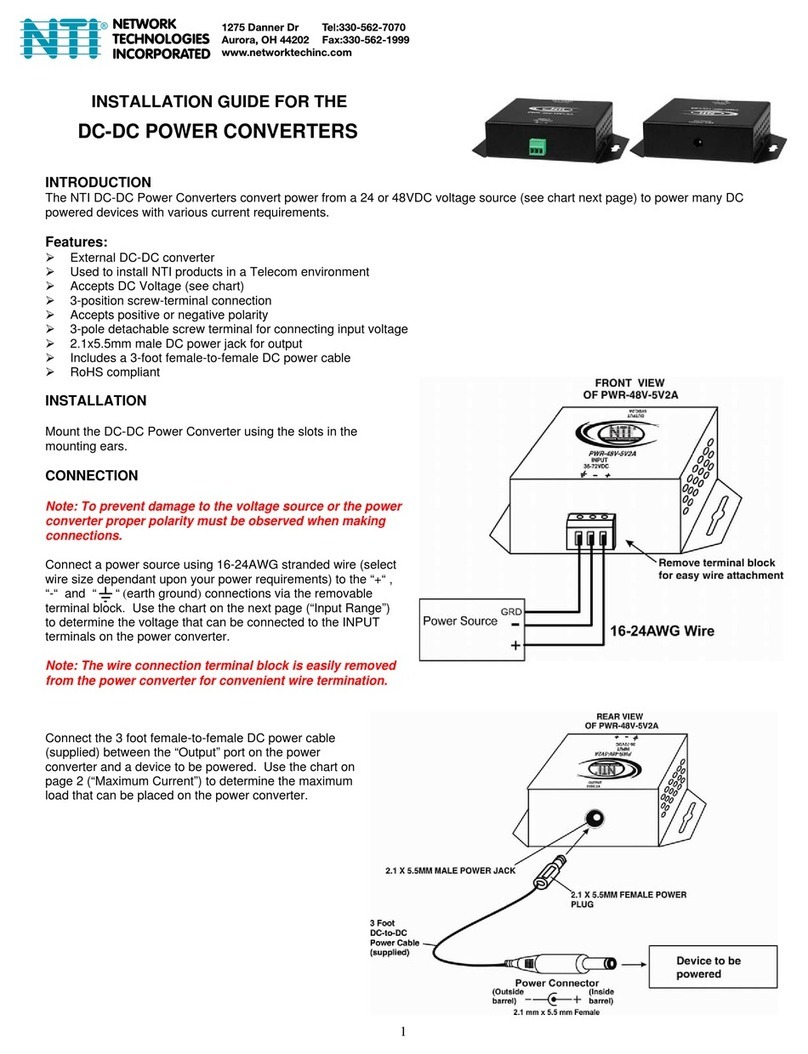

Before installing the converter, please identify the converter type and the corresponding parameters.

This manual suits for next models

1

Table of contents

Other Sinexcel Media Converter manuals

Popular Media Converter manuals by other brands

J-Tech Digital

J-Tech Digital JTECH-4KSP4 user manual

Monacor

Monacor DADC-144DT instruction manual

Network Technologies Incorporated

Network Technologies Incorporated PWR-48V-5V1A installation guide

Sima

Sima SCW-2 user manual

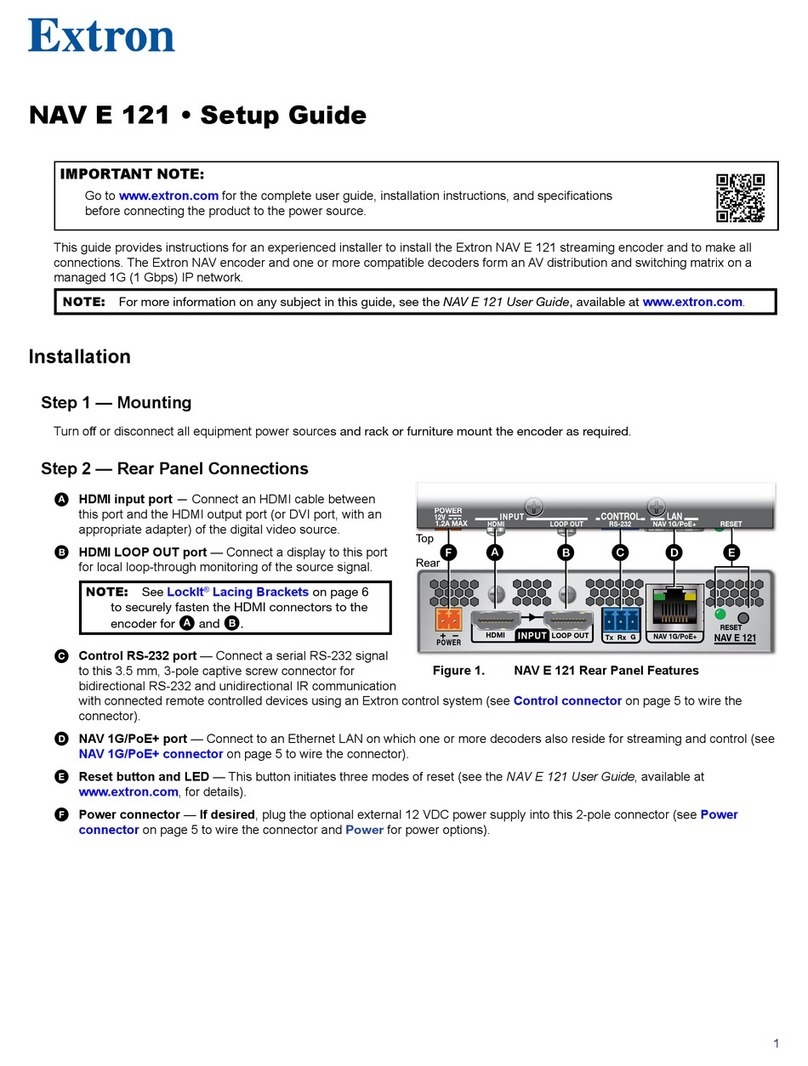

Extron electronics

Extron electronics NAV E 121 Setup guide

Kramer

Kramer VP-435 user manual