Singer 1200-1 User manual

Other Singer Sewing Machine manuals

Singer

Singer Scholstic 5523 Owner's manual

Singer

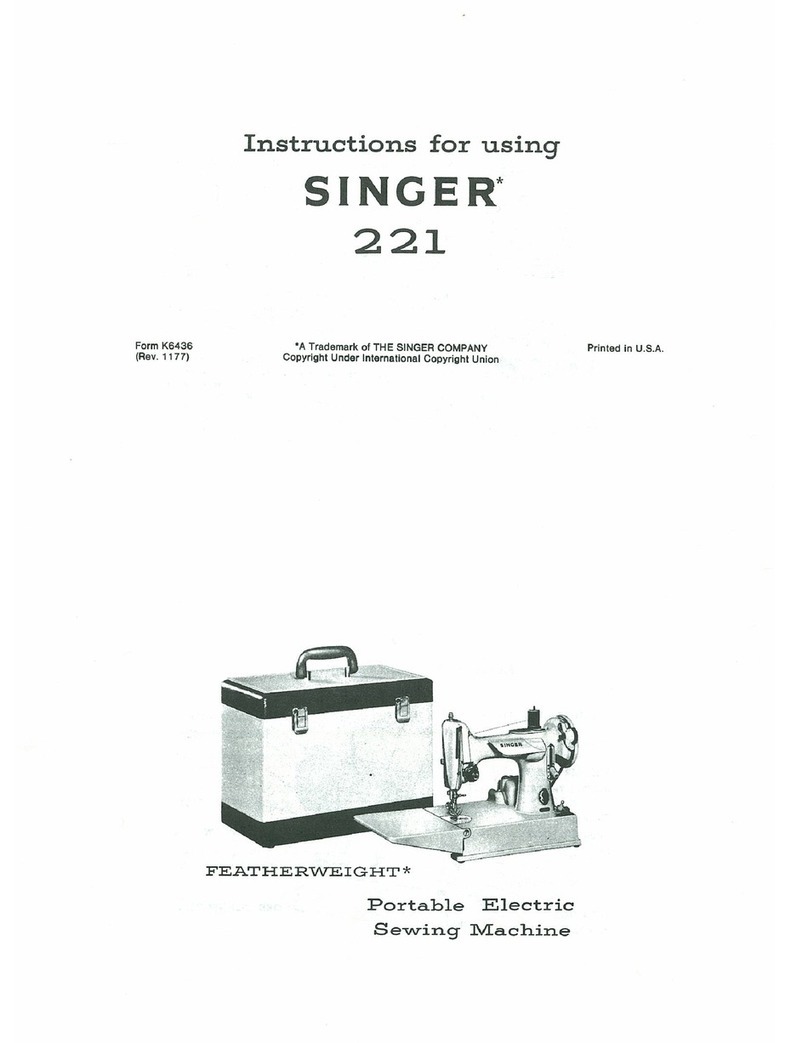

Singer 221 Installation and operation manual

Singer

Singer CG-590 User manual

Singer

Singer 521C User manual

Singer

Singer 147-24 User manual

Singer

Singer 88-1 User manual

Singer

Singer Feather Weight II User manual

Singer

Singer 92-1 User manual

Singer

Singer 246K13 User manual

Singer

Singer 212Wl45 User manual

Singer

Singer 1200A User manual

Singer

Singer QUANTUM 9940 Operation instructions

Singer

Singer 211U566A Setup guide

Singer

Singer 133W101 User manual

Singer

Singer 17 User manual

Singer

Singer S14-88 User manual

Singer

Singer 40751 User manual

Singer

Singer Heavy Duty 14HD854 User manual

Singer

Singer 14SH644 User manual

Singer

Singer 150W4 Quick start guide