Singer 1422 User manual

Other Singer Sewing Machine manuals

Singer

Singer 321C 133M-04 / TF User manual

Singer

Singer Stylist 533 User manual

Singer

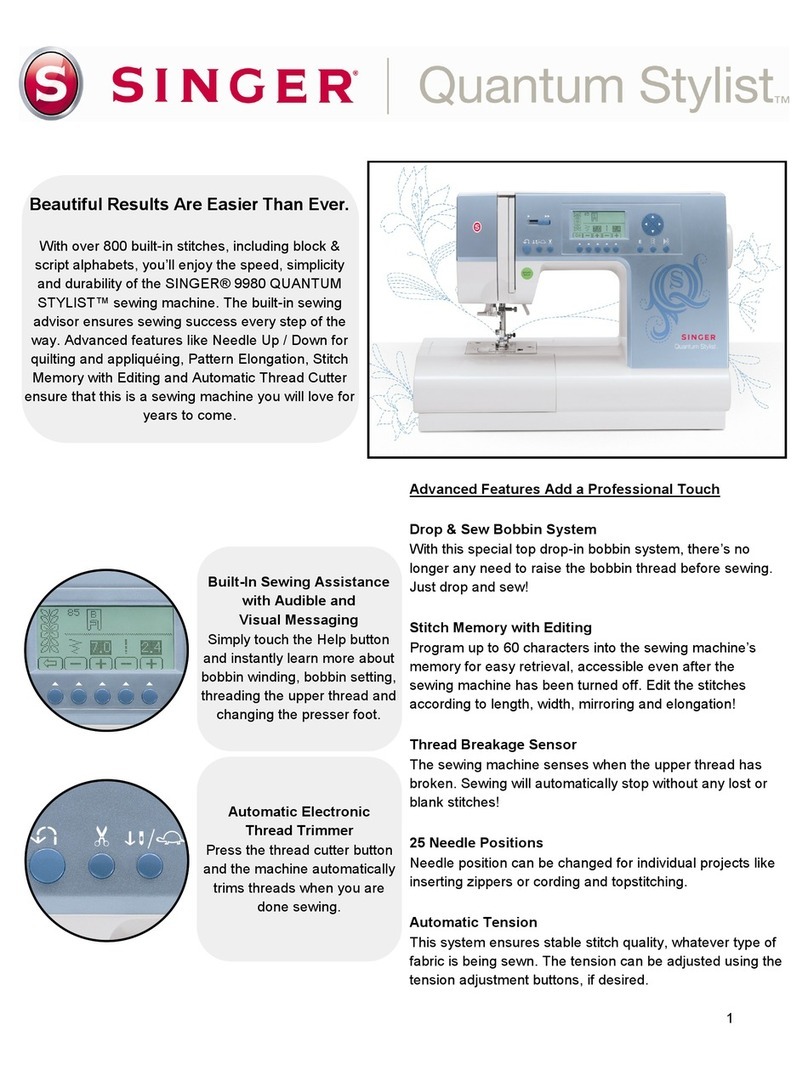

Singer 9980 Quantum Stylist Installation guide

Singer

Singer 231-7 User manual

Singer

Singer 11-30 User manual

Singer

Singer 246K46 User manual

Singer

Singer 241 User manual

Singer

Singer 14U286B User manual

Singer

Singer 14T967DC QuantumLock Operation instructions

Singer

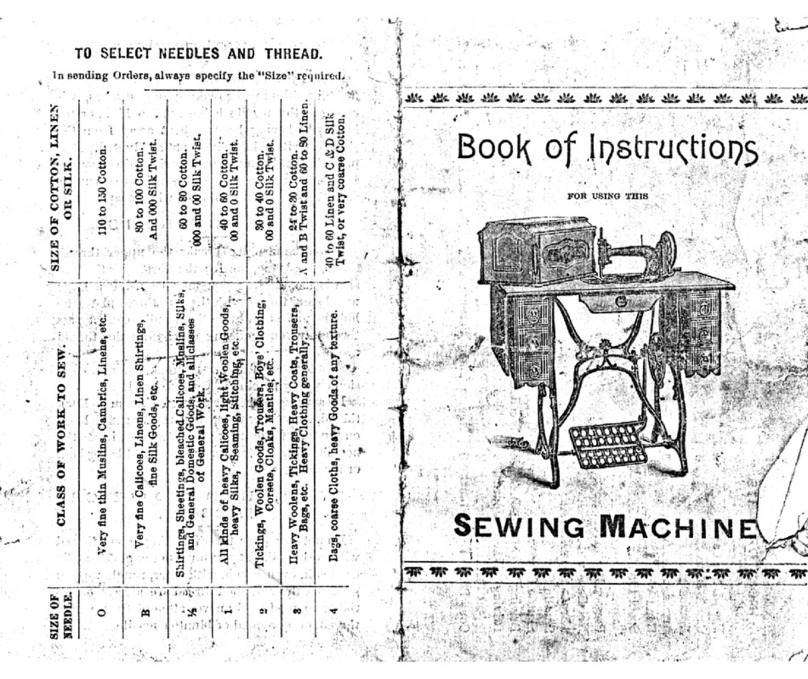

Singer Sewing Machine User manual

Singer

Singer CLASS 7 ONE NEEDLE LOCK STITCH User manual

Singer

Singer 176-21 User manual

Singer

Singer Quantum XL-100 User manual

Singer

Singer 300W class User manual

Singer

Singer 20-2 User manual

Singer

Singer 46W Quick start guide

Singer

Singer 177C User manual

Singer

Singer 5532 User manual

Singer

Singer 2259 User manual

Singer

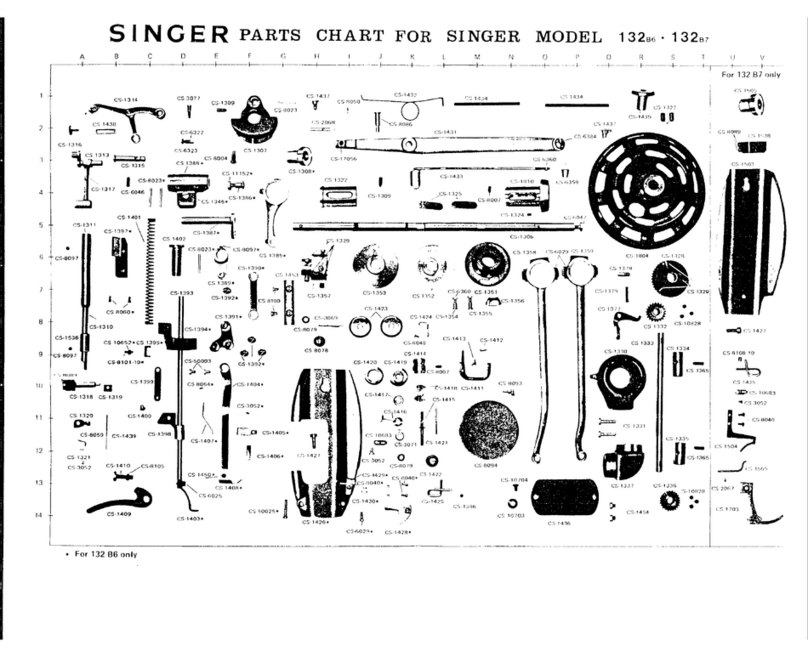

Singer 132B6 User manual