From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

DESCRIPTION

INSTALLATION

LUBRICATION

CONTENTS

OPERATOR

INFORMATION

ADJUSTMENTS

Arm

Shaft

Connection

Belt Replacement

Bobbin

Case

Opener, AdJusting 17

15

INDEX

Installation

1

3

3-5

6-7

. 8 -

17

3

Bobbin

Case

Opener,

Timing.

Lubrication

.

3-

4

15

Needles.

Bobbin

Case,

Removal

From

Sewing

Hook

Bobbin

Removal .

Bobbin

Replacement

Bobbin

Thread Tension

Bobbin

Winding

Description

of

Machines.

Feed Dog

Adjustment

Feed

Eccentric

Adjustment

Feed Reversing Mechanism .

14

7

7

8

7

1-2

16

16

9

5

Needle Bar Height

11

Needle Bar Position Relative

to

Presser Bar

11

Needle Bar Rock Frame Removal

17

Needle Setting

5

Need

le

Thread Tension

8

Pressure

on

Material

9

Speed

5

Stitch

Length Regulation 9

Feed Reversing Mechanism

Adjustment

Hook

Height .

11

Take-up Lever Removal

.

17

Thread

Controller

.

Hook

Lubrication

.

Hook

Position Relative

to

Needle

Hook

Removal

Hook

Timing

.

12

4-5

13

14

13

Thread Tensions

Threading

Bobbin

Case

Threading

(Lower)

Threading

(Upper)

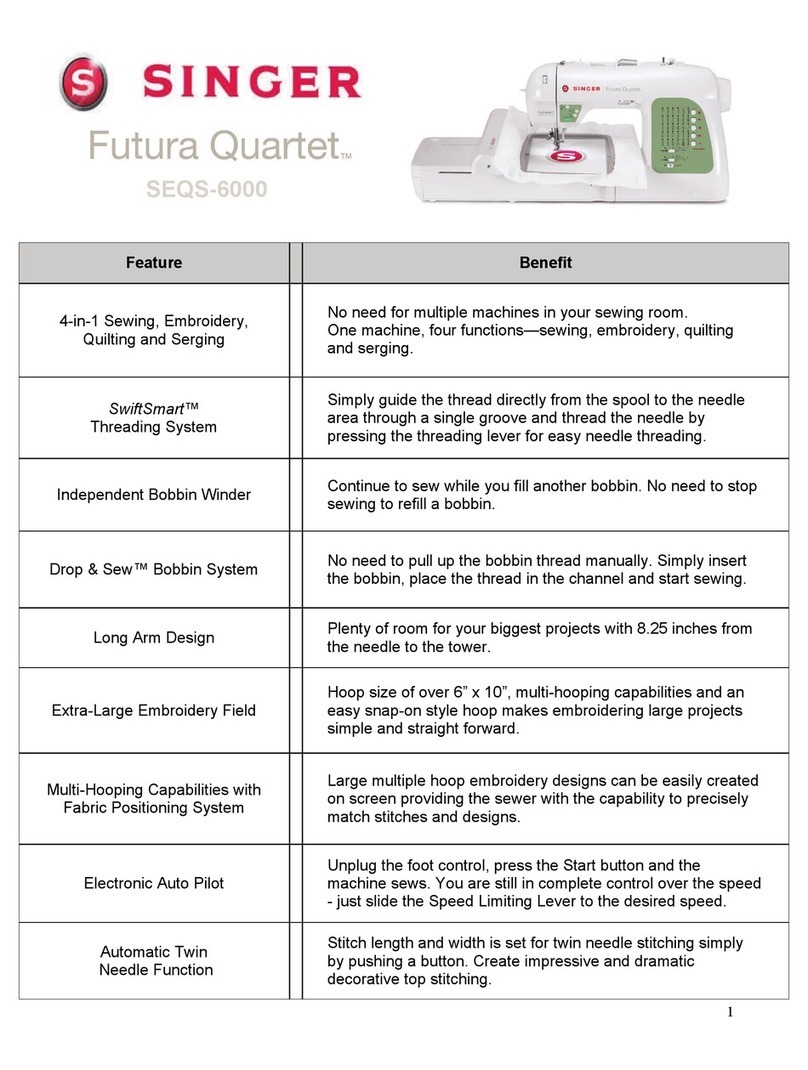

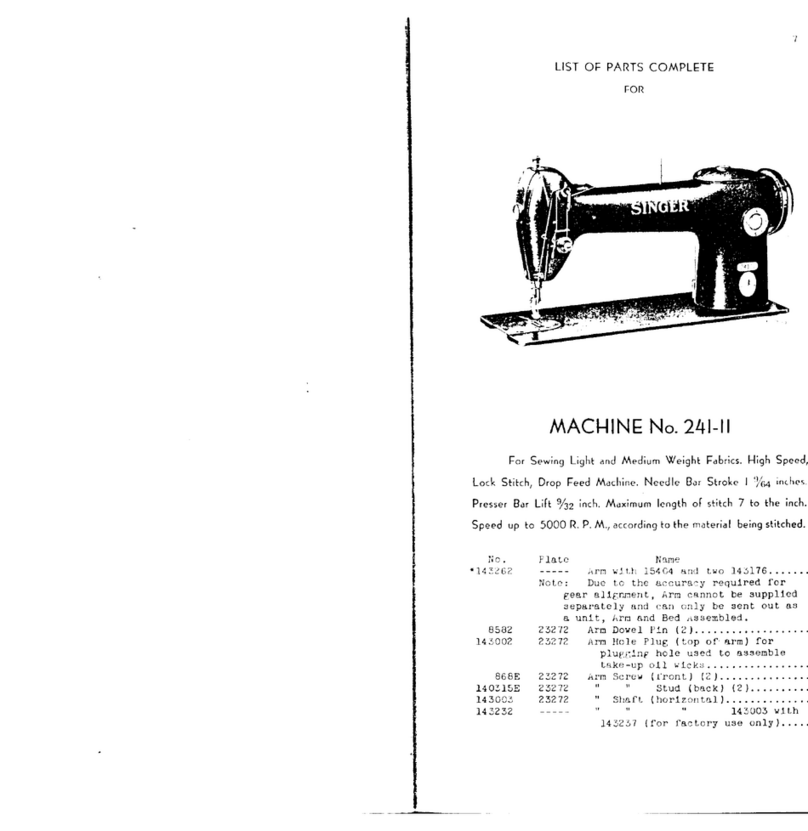

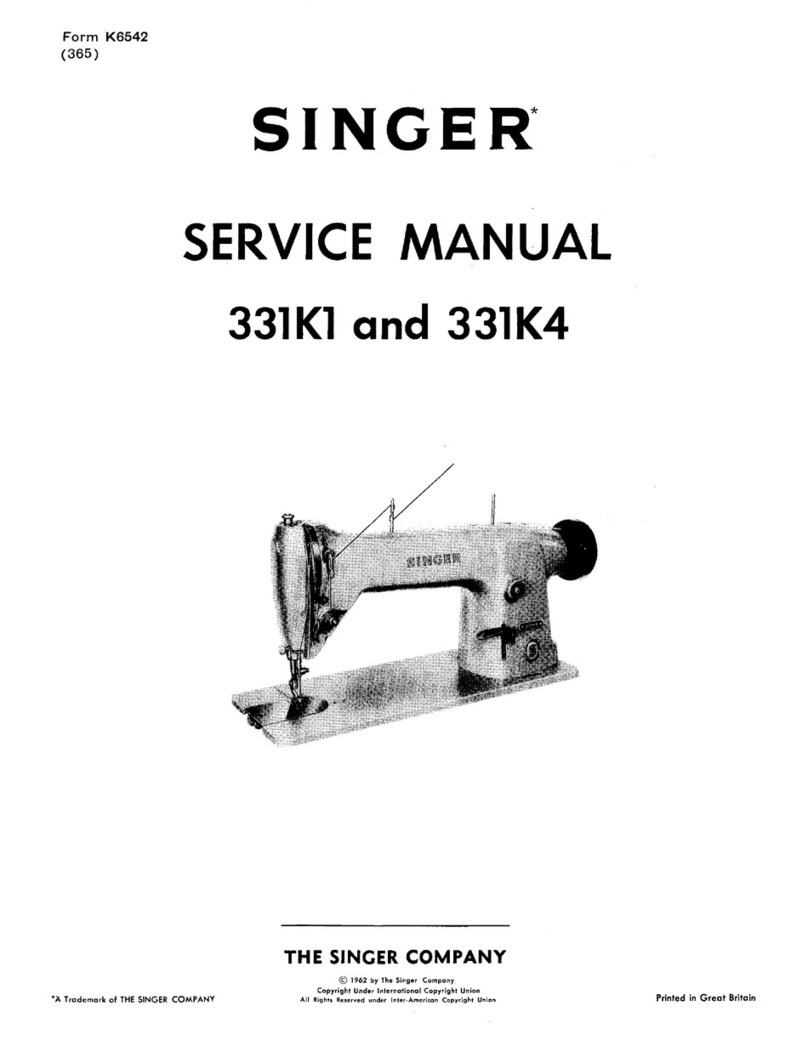

DESCRIPTION OF

MACHINES

High speed

two

needles, long

arm,

lock

stitch,

compound

feed, vertical axis

hook,

flat

becJ

machine,

for

corsets, overalls and

clothing

generally.

GENERAL

FEATURES

The

compound

feeding mechanism

which

consists

of

a

needle feed and

drop

feed, prevents

slipping

of

the

upper

and

lower

plies

of

material

when

being

stitched,

and assists

in

two

or

more plies being fed evenly

to

the

end

of

seam.

Vertical

axis

hook

with

metered

lubrication.

Hooks

can

be removed

without

disturbing

the

hook

shafts.

Adjustable

feed

driving

eccentric

located on

hook

driv-

ing shaft, produces a

uniform

stitch

length at all speeds.

Feed reversing mechanism,

controlled

by

hand

or

foot.

Arm

shaft,

hook

shaft, and

belt

driven

bed shaft are

mounted

in ball bearings at rear and in

automatically

lubri-

cated

plain

bearings at

front.

Plunger

for

changing length

of

stitch

is

on

top

surface

of

bed.

Sleeve

type

take-up.

Belt

drive.

Knee

lifter.

Federal

stitch

type

301.

8

8

7

7

6