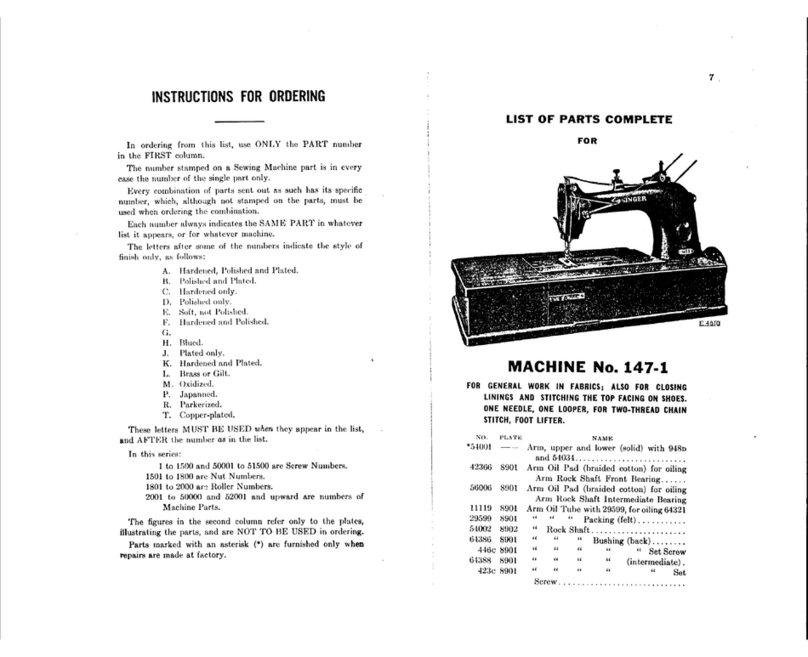

thread guide Fig. 12, which

Is

mounted on the arm

cover.

From

there, pass the thread through the three

(3)

holes of the thread tensioner guide "Q". Starting

with

the top hole,thread

from

rightto

left,

from

leftto

right through the middle hole, and

from

right to left

through the bottom hole. Pass the thread over

and

bet

ween the tension discs "R", from right to left, and wind

it under and around thread controller "S" from right

to left. It is placed under the controller spring "T" and

over the controller projection so that the controller

spring holds the thread down.

Pull

the thread through

the

thread

guide

"U"

and

then

from

right

to

left

through

the eye of the thread take-up "V". Pass it bock again

through the thread guide "U", lead it behind the oil

felt pad "W" and then draw the thread through the

thread guide "X", and from left to right through the

eye of the needle.

PREPARATION

FOR

SEWING

Hold

the

end

of

the

needle

thread

loose

in

the

left

hand.

Turn

the machine pulley towards you

until

the

needle has made one full

stitch

and is bock to its highest

point. By pulling the needle thread, the bobbin thread

will

come through the hole in the feed dog.

Lay

both

threads underneath the presser feet and close the bed

slide completely. Now the machine is ready for having

the material placed under the presser feet.

ADJUSTMENT

OF

THREAD

LUBRICATION

(Figure 13)

The

oil

reservoir

for

thread

lubrication

can

be

filled

through hole "Y", Fig. 13, in the face plate. The amount

of oil going to the oil felt

pad

can be adjusted by nut

"Z";

for more oil, turn counter-clockwise; for less oil.

AA

Figure 13

turn

clockwise.

The

oil

flow

can

be

turned

on

and

off

with the plunger release lever "AA", The oil

flows

when

the lever is in the horizontal position; there is no flow

when it is in the vertical position.

For thread lubrication always use Singer Thread

Lubricant, Type "E".

TENSION

CONTROL

(Figures 11, 13, 14, 15 and 16)

The tension of the needle thread

Is

regulated by

thumb nut "AB",

Fig.

13, and should only be changed

when the presser feet are down and the tension is not

released. Turning the nut clockwise increases

and

turn

ing it counter-clockwise

decreases

the tension.

The tension of the bobbin thread is regulated on the

bobbin case tension spring by means of the adjusting

screw "AC", Fig. 11. Turning it clockwise increases

and

turning it counter-clockwise

decreases

the tension.

Figure 14

With correctly adjusted tensions, the

needle

and

bobbin

threads

should

be

locked

in

the

center

of

the

material as shown in Figure 14.

Figure 15

If the tension on the needle thread is too tight, or if

that

on the bobbin

thread

is

too

loose, the

needle

thread

will

lie straight along the upper surface of the

material as shown in Figure 15.

<J~~

-o-

<y~

Figure 16

If the tension on the bobbin thread is too tight, or if

that

on the

needle

thread

is

too

loose, the bobbin

thread will lie straight along the underside of the mate

rial as shown In Figure 16.

ADJUSTMENT OF

STITCH

LENGTH

(Figure 13)

The stitch length can be adjusted only when the

machine

is

stopped.

Stitch

length,

in

number

of

stitches

per inch, can be read on the stitch length indicator of

the

machine

pulley.

To

changethe

stitch

length,depress

the button "AD", Fig. 13,

and

turn the machine pulley

until the button

engages

(clicks)

with the adjustable

feed drive eccentric. Continue turning until the desired

number

of

stitches

per

inch

appears

opposite

the

mark

on

the

machine arm. Then

release

the

button.