6

TO

REPLAC

L

T.HE

BOBBIN

-

AND

-

THREAD

-------

UPPER

-

THR

'

E~DI~G

~----'--~

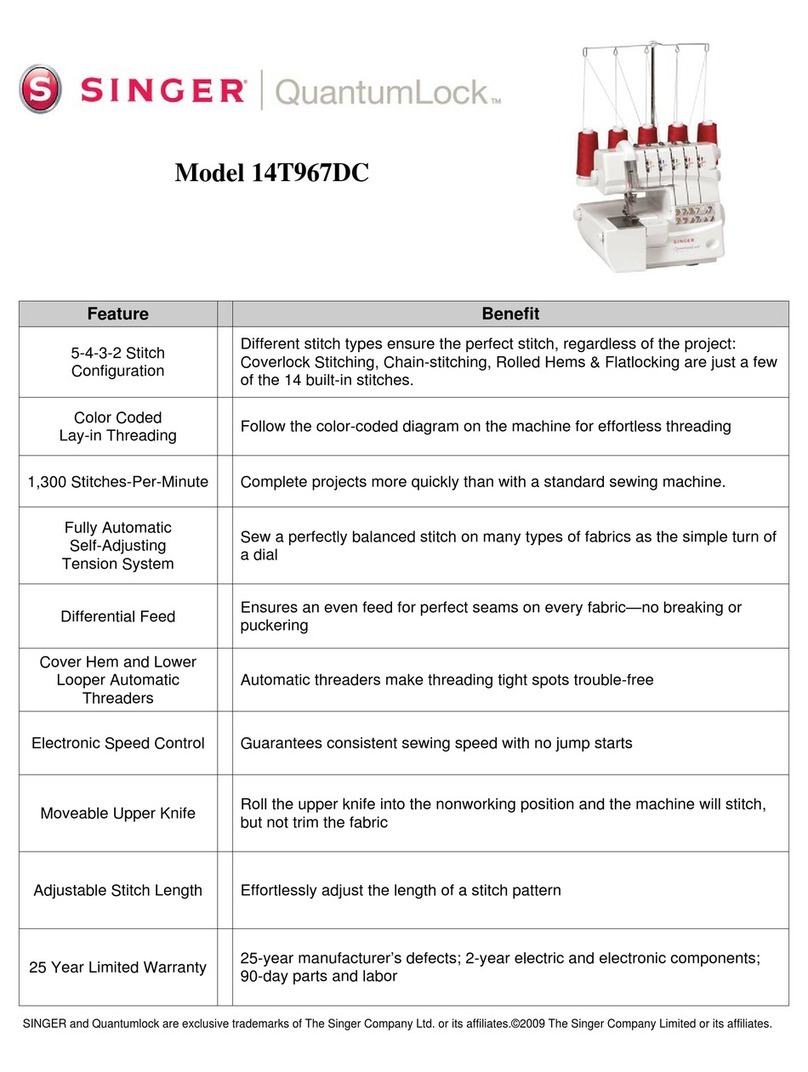

THE BOBBIN

CASES

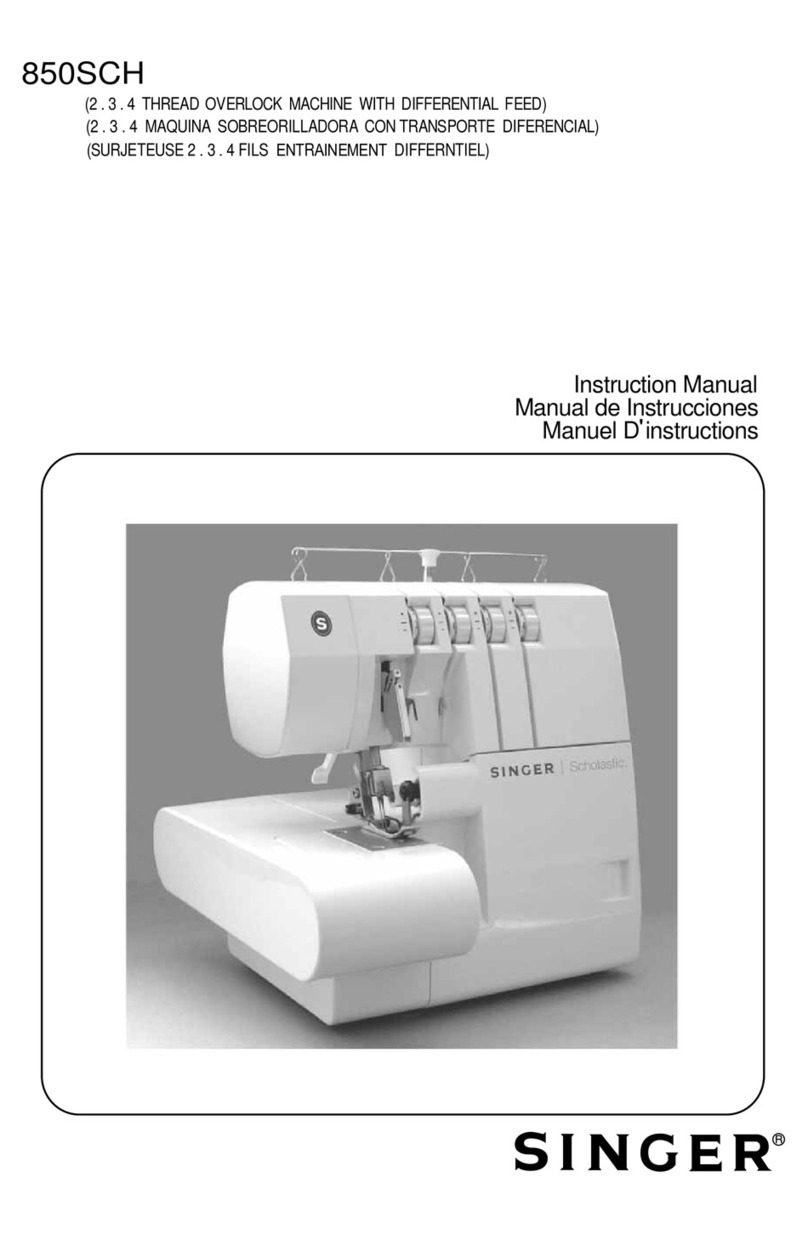

The following instructions

apply

to

both

bobbin

cases:

2 K

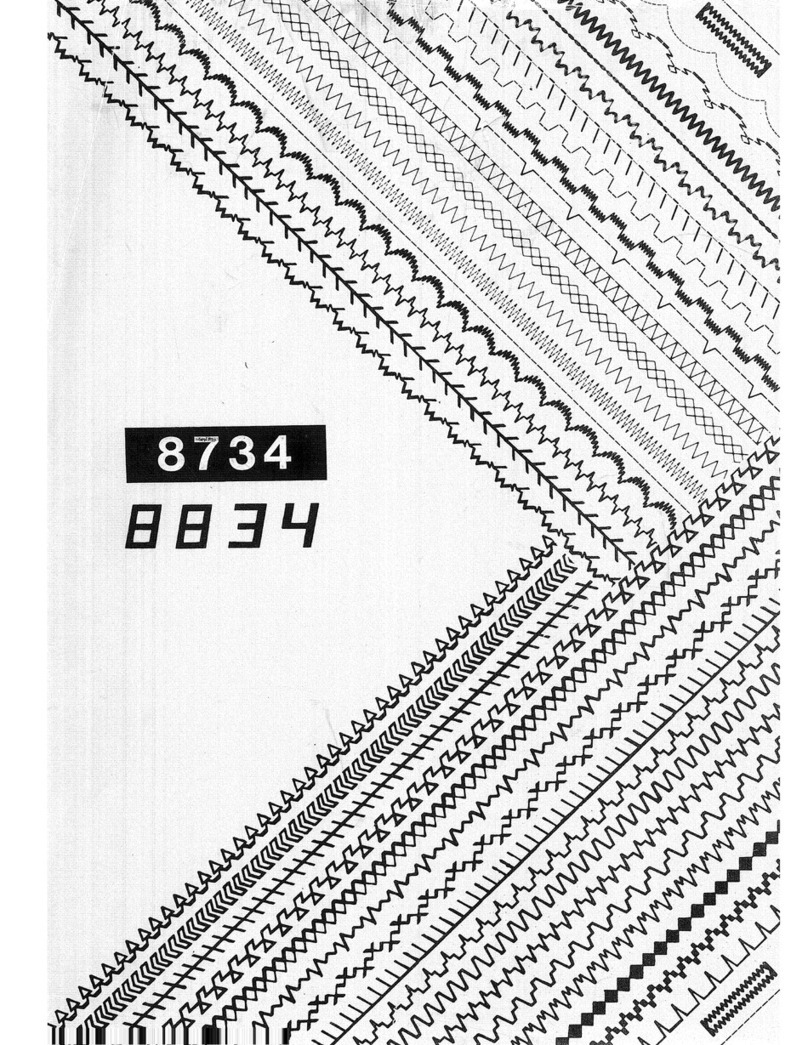

Fig. 8. Threading Bobbin Cases

Hold the

bobbin

between

the

thumb

and

forefinger

of

the

right

hand,

the

thread

on

the

bottom from left

to right,

and

place

ft

on

the

center

stud

of

the

bobbin

case,

then push

down

the

latch

K,

as

shown

in Fig.

B.

Draw

the

thread

into

the

slot 1

in

the

edge

of

the

bobbin

case

and

back

of

the

projection 2,

leaving

a

loose

end

of

thread

about

two

inches long

above

the

slide. When closing

the

slides,

leave

just

enough

space

for

the

threads

to

pass

through.

TO

SET

THE

NEEDLES

Turn

the

machine

pulley

over

toward

you

until

the

needle

bar

moves

up

to its

highest

point. Loosen

the

set

screws

In

the

needle

holder

and

put

the

needles

up

into the

holder

as

far

as

they

will go, with

the

long

grooves

of

the

needles

facing

each

other

and

the

eyes

of

both needles directly

in

line with

the

arm

of

the

machine, then tighten the set screws.

9 A_

~

-

8

ANDH

10

AND K

11

AND

L.

7

ANDG

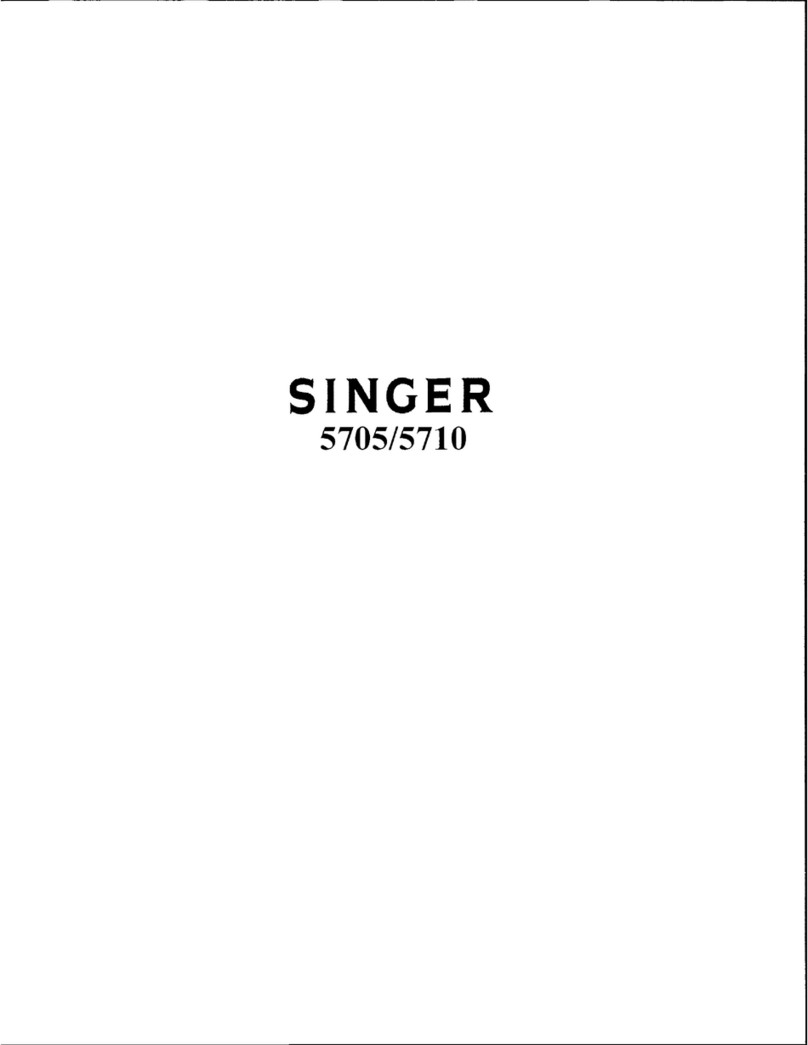

Fig

. 9. Upper Threading

To

thread

the

left

needle

or

the

one

farthest

from

the

upright

part

of

the

arm,

pass

thread

from left spool

on

spool

stand

through

left

guide

at

top

of spool

stand,

down

through

hole

1,

then

through

hole 2

in

thread

guide

on

top

of

arm,

down

through

holes 3

and

4

in

thread

guide

at

front

of

machine,

over

from

right

to

left

between

tension discs 5,

down

under

from

right

to

left

around

thread

controller 6,

up

into fork 7

of

thread

controller

against

the

pressure

of

wire

controller

spring,

up

through

threqd

guide

8,

up

and

from

right

to left

through

upper

hole 9

in

end

of

thread

take-up

lever,

down

through

thread

guide

8

again

and

through

two

thread

guides

10

and

11,

down

through

left hole

12

in

needle

holder

and

from

right

to left

through

eye

of

left

or

outside

needle

13.

To

thread

the

right

needle

or

the

one

nearest

the

up-

right

part

of

the

arm,

pass

thread

from

right

spool

on

spool

stand

through

right

guide

at

top

of

spool

stand,

down

through

hole A,then

through

hole B

in

thread

guide

on

top

of

arm,

down

through

holes C

and

D

in

thread

guide

in

front

of

machine,

under

from

right

to

left

between

right

tension discs

E,

down

under

from

right to left

around

thread

controller

F,

up

into fork G

of

thread

controller

against

the

pressure

of

wire

con-

troller spring,

up

through

thread

guide

H,

up

and

from

right to left

through

lower

hole J

in

end

of

thread

take-up

lever,

down

through

thread

guide

H

again

and

through

two

thread

guides

K

and

L,

down

through

right hole M

in

needle

holder

and

from left to right

through

eye

of

right

or

inside

needle

N.

Draw

about

three

inches

of

thread

through

the

eye

of

each

needle

with which to

begin

sewing.

From the library of: Superior Sewing Machine & Supply LLC