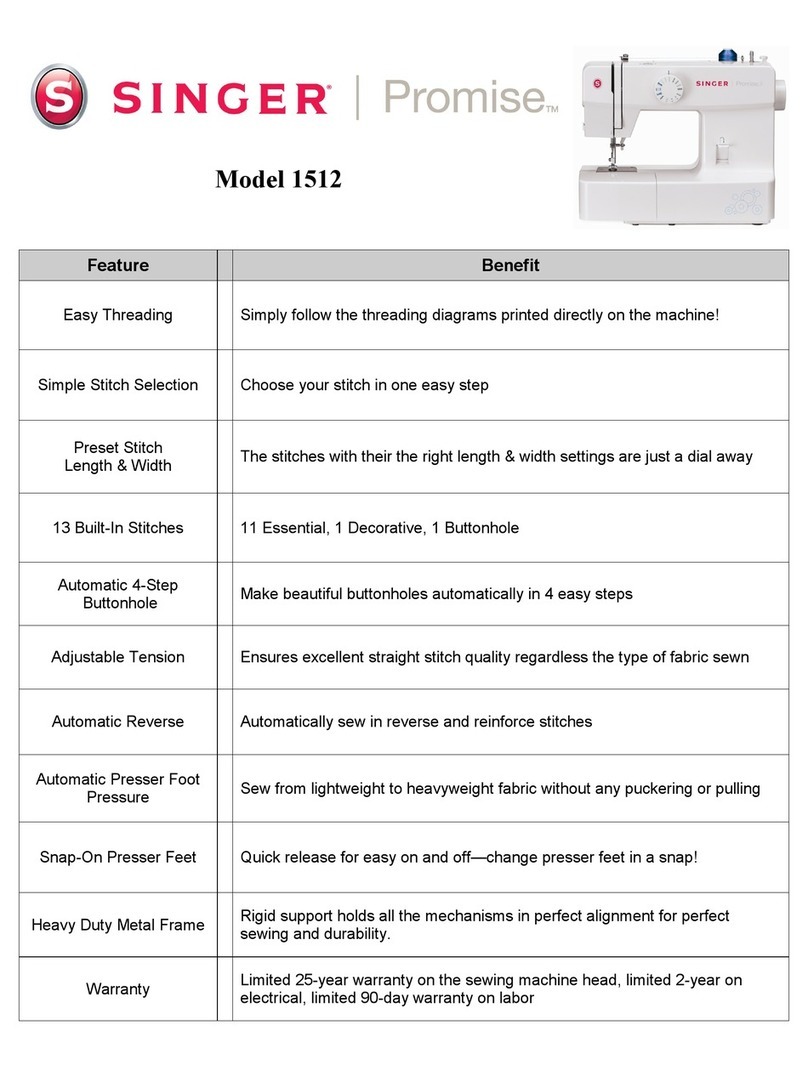

TABLE

OF CONTENTS

DESCRIPTION

OF

MACHINES ••••••••••••••••••••.••• 3

OPERATION•••••••••••••••••••••••••••••••.•••••••••••.••• 3-6

ADJUSTMENT••••••••...••.•.••••.••.••••••••••••••••••• 6-10

Accessories

•.••••••••••.•••.••••••••••••••••••••••••••••58-79

Adjusting Device••...••••••••••••••••••••••••••••••••••••• 36

Arch Clamp•••••..••••••••.••.•••••.•••••• 12, 40-44, 52,

56

Arm

Shaft,••••••••.•.••..••••.•••••••••••••••••••••••••••••.•

14

End

Play

Removal••••••••••••••••••••••••••••••••••• 8

Barring,•••.••••••••••••••••••••••••••••••••••••••••••••••••••• 3

Buttonholes•••••..••••••••••••••••••••••••••••••• 42,

52

Pockets

••••••••••••••••••••••••••••••••••••••••••• 46,

50

Bell Crank••••••••••••••••••••••••••••••••••••••••• 8, 22,

52

Belt Guard••••••••••••••••••••••••••••••••••••••••••••••18,

58

Belt Loop

Tacking...................................

3,

56

Belt Tension••••••••••••••••••••••••••••••••••••••••••••••••• 9

Bobbin,

•.....................................................

24

Removal

•••.•.•••.•••.•.•••••••••••••••••••••••••••••••. 4

Winding

.••.••••••.••••••••••••••.•.••••••••••••••••••••• 5

Bobbin

Case,

••••••••••••••••••••••••••••••••••••••••••.•••• 24

Remova1...

••

••••••

••

••••••••

•••

•••••••

••••

••

••

•••••••

••

4

Replacement

••••••••••••••••••••••••••••••••••••••••••

5

Threading•••••••••••••••••••••••••••••••••••••••••••••• 5

Bobbin Thread

Tension..................................

6

Bobbin

Winder,

•.••••.•.• •••••••••••••••••••••••••••••••••

32

A.....

.1ents

••••••••••••••••••••••••••••••••••••••••

5, 6

Bow Fas.dning

.........................................

3,

42

Brake Installation•••••••••••••••••••••••••••••••••••••••••

10

Brake Lining Care•••••••••••••••••••••••••••••••••••••••• 10

Button

Clamp

•.............••.•••.•......••.•••••.••..•.....

34

Button Sewers•••••••••••••••••••••••••••••••••••••• 3, 36-38

Cam,

..............................................

3, 38-52,56

Timing

•..••••••.••.••..•••••.•..••••.•••.••......•••••.•

8

Clamp Lifting Mechanism••••••••••••••••••••••••••••

3,

22

Cleaning

.•................•..........•.......•.•...•..........

4

Clearance under Clamp

....•..•..........•..............•••

3

Covers

.•..•..•......

······•••••••••••••••••••••••

.•....•

18,

36

Description

of

Machines••••••••••••••••••••••••••••••••• 3

Driving

Arm,

..............................

.

...

.

.............

20

Adiustment.............................

.

..............

7

End

Play

Removal

(Arm

Shaft)••••••••••••••••••••••••• 8

Engaging

Arm,

......................................

.......

28

Adiu

stment....................

.

.....................

..

9

~

~=~e~~J:

rs~~Sc~;.;r•

•••

•••••••••••

•••

••••

o o

••••

o

••••

31

42

Feed

Plate

Carrier Bar •••••••••••••••••• 12, 36, 40,

56

Feed

Plate

Positioning

••••••.••

••

..•••••••••••.•••••.••.• 7

Flat

Bed

Work

Plate

•••••••••••••••••••••••••••••

3,

54, 79

Gauge 239369

..........................

.

..

...

..

......

..•. 6, 1

Interlocking Arm................................

.......

26

Knife

Bar

.........••.......

•••••••••••••••••••••••••••••••••• 16

Knife Holder•••••••••.••••.••••••.••••••.•.••.••.•••..•••••• 42

Knife

Thread

Holder

...........................

.

...

.

.....

.

38

Knives,

...•........•..............

....

...........

.

.......

18, 42

Adiustment•••.•.•••.•.••••••••••••.••.••••. •••••••••••• 8

Lateral

Rock Shaft•••••••••••

••

•••••

••••••••••••••••• 20,

36

Length of Tack Adjustment•••••••••••••••••••

••

.

••

•

••••

• 1

Lifting

Arm

....

····•••••••••••••

••

•

••

•

•••

•

••••••

•

••••

•

•••••

•• 6

INSTRUCTIONS FOR ORDERING••••••••••••.••••.•••

11

PARTS LIST••••••••••••••••••••.••••••••.••.••••••.•.•• 12-79

NUMERICAL LIST•••.•••••••••••••••••••••••••••••••• 80-84

INDEX

Line

Tack•••••••••••••••••••••••••••••••••••••••••••••••••••• 3

Link

Arm

Adjustment••••••••••••••••••••••••••••••••••••• 7

Longitudinal Rock Shaft.•••••••••••••••••••••••••• 20, 36

Lubrication and Cleaning•••••••••••••••••••••••••••••••• 4

Machine

Pulley,

•••••••••••••••••••••••••••••••.••••••••

3,

14

Driving

Accessories

••••••••••••••••••••••••. 7

4,

76

Machine

Pulley

(loose), Packing••••••••••••••.••••••• 4

Needle,••••••••••••••••••••••••••••••••••••••••••

3,

4, 36, 40,

48,

6G'

Setting..................................................

4

Sizes

....................................................

4

Needle Bar,•••••••••••••••••••••••••••••••••••••••••••••••• 22

Height

Setting.......................................

6

Stroke..................................................

3

Needle Bar Crank••••••••••••••••••••••••••••••••••••••••• 14

Needle Thread Tension•••••••••••••••••••••••••••••.•••• 6

Oiling

..•...•...•.•...................•........................

4

Oscillating

Shafts••••••••••••••••••••••••••••••••••••••••• 6

Recoil Absorbing Mechanism••••••••••••••••••••••• 9,

26

Sewing

Strops

...........................................

3,

44

Shoe Tacking•••••••••••••••••••••••••••••••••••••••

3,

40, 48

Size

of

Needles

............•.......•.................•....••

4-

~---,...._

,

..,.

Shuttle,••••••••••••••••••••••••••••••••••••••••••••••••• 24, 36

Timing

••••..•.•••••.•..••.....•..•.•..............••..•.

7

Shuttle Driver Adjustment•••••••••••••••••••••••••••••••• 7

Space

behind Needle••••••••••••••••••••••••••••••••••••••• 3

Speed

........

••••••••••••••••••••••••·····················..

...

3

Split

Feet

....•............••....••..................•........

44

Starting Lever,

......•....•......................•..........

26

Adiustments

••..••••.•...•...••..••.........•••.•.••.•.

9

Stop

Motion,

Brake

.......................................

26

Installation••••.•••.••••••.••••.•••.••.•.•••••••••••••

10

Stop

Motion Timing••.••••••.••••••••••.•..•..••.•••••••••.

lO

Tacking Adiustments

....................................•

1

Tacking Belt Loops

......•..•••.•........•.••.•.•...•

3,

56

Tension,

••••••••••••••••••••••.••••••.••..••••.•.•••..•••••••

28

Regulation

...••....•....•••..•...................••..•••

6

Tension Position Guide,••••••••••••••••••••••••••• 22, 23

Adiustment

.............................................

6

Thread Cutter on

Face

Plate

••••••••••••••••••••••••

3,

18

Thread Guide

.....................•........•......•.....

5,

28

Thread

in

9••••••••••••••••••••••••••••••••••••••••••••••••••••

5

Thread Retainers•••••••••••••••••••••••••••• 5, 28, 36, 42

Thread

Wiper...........................

22, 36, 44,52,

56

Throat

Plate

••••••••••••••••••••.••••••.••••• 18, 36, 40, 42

Tripping Mechanism Adjustment•••••••••••••••••••••••• 8

Tripping

Points,

.•.....•.....•.••..................

3,

38-50

Timing

...•.•.....••..•..•••..•..•....•....••••••.•...••.

.

lO

Twist

of

Thread......................................

.

.....

4

Uneven Winding, Correction for•••••••••••••••••

••

••••

5

"V"

Belt

Tension Adjustment••••••••••••••••••••

••

•

•••

9

Vertical Drive

Shaft

..........•.....•.....................

30

Width

of

Tack Adjustment••••••••••••••••••••••••••

••••

• 1

From the library of: Superior Sewing Machine & Supply LLC