Use SINGER* needles, Catalogue

1361

(88x9)

made

in a

variety

of

sizes.

These needles have a nickel finish but may be

supplied

with

chromium

finish

when

so

ordered.

Chrome

plating

of

sizes

9

and

smaller

is

not

recommended.

ORDERS FOR NEEDLES should specify

Quantity required,

Size

number and Catalogue

number.

Examples

...

"100

Size 16, Catalogue

1361

(88x9) Needles"

Sizeof the needle to be used

should

be determined

by

type

of

material

being

sewn

and

by

size

of

thread

which

must

pass

freely

through

the

eye

of

needle.

HOLD THIS END

ROLL

OVER

TOWARD

YOU

Fig,

t1.

How to Detormine Thread Twist

TO

SET THE NEEDLE

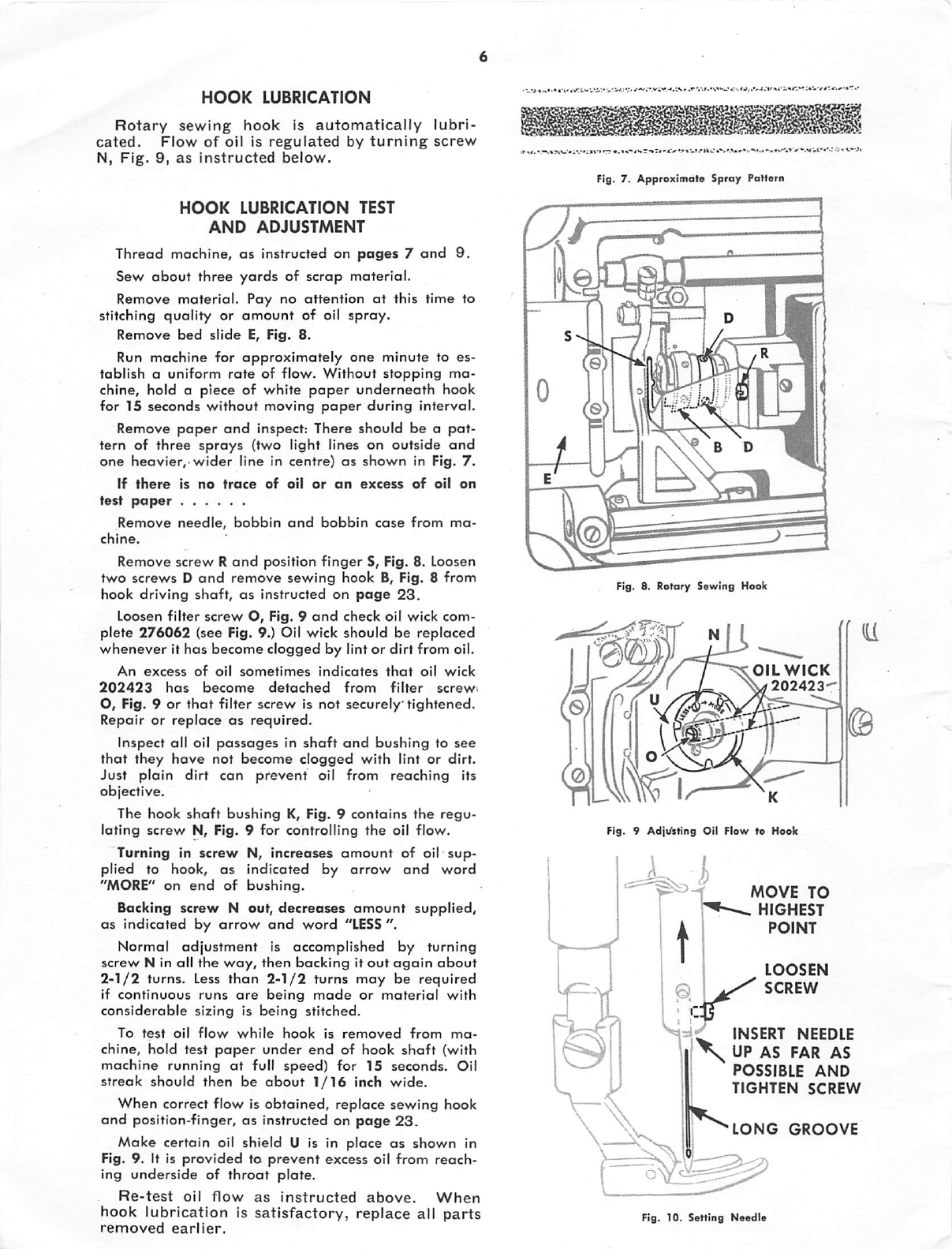

Turn machine pulley over away from you until

needle

bar

is

at

its

highest

point,

as

shown

in

Fig.

10,

page

6.

Loosen

needle

clamping

screw. Remove old

needle

and insert new needle up into needle

bar

as far as

it will

go.

Make certain

that

single continuous groove

of

needle faces

away

from hook

(toward

the

left end

of machine, as shown in Fig. 10, page 6) with eye

of

needle

directly

in

line

with

arm

of

machine.

Securely tighten clamping screw.

CHECK

NEEDLE

OFTEN

TO

MAKE

SURE

THESE

DEFECTS

ARE

NOT

PRESENT . . .

•

Wrong

needle

for

thread

and

material

in use—

a

cause

of

threod

breakage.

•

Bent

needle, clogged needle eye or dirty needle

groove—causes

of

skipped

stitches.

•

Hook

or burr on

needle

point—cause

of

picking

or

fraying

of

material.

•Incorrect

setting

of needle—a

cause

of

needle

breakage.

THREAD

Left

twist

thread

should

be

used

in

needle.

Either

right

or

left

twist

thread

can

be

used

in

bobbin.

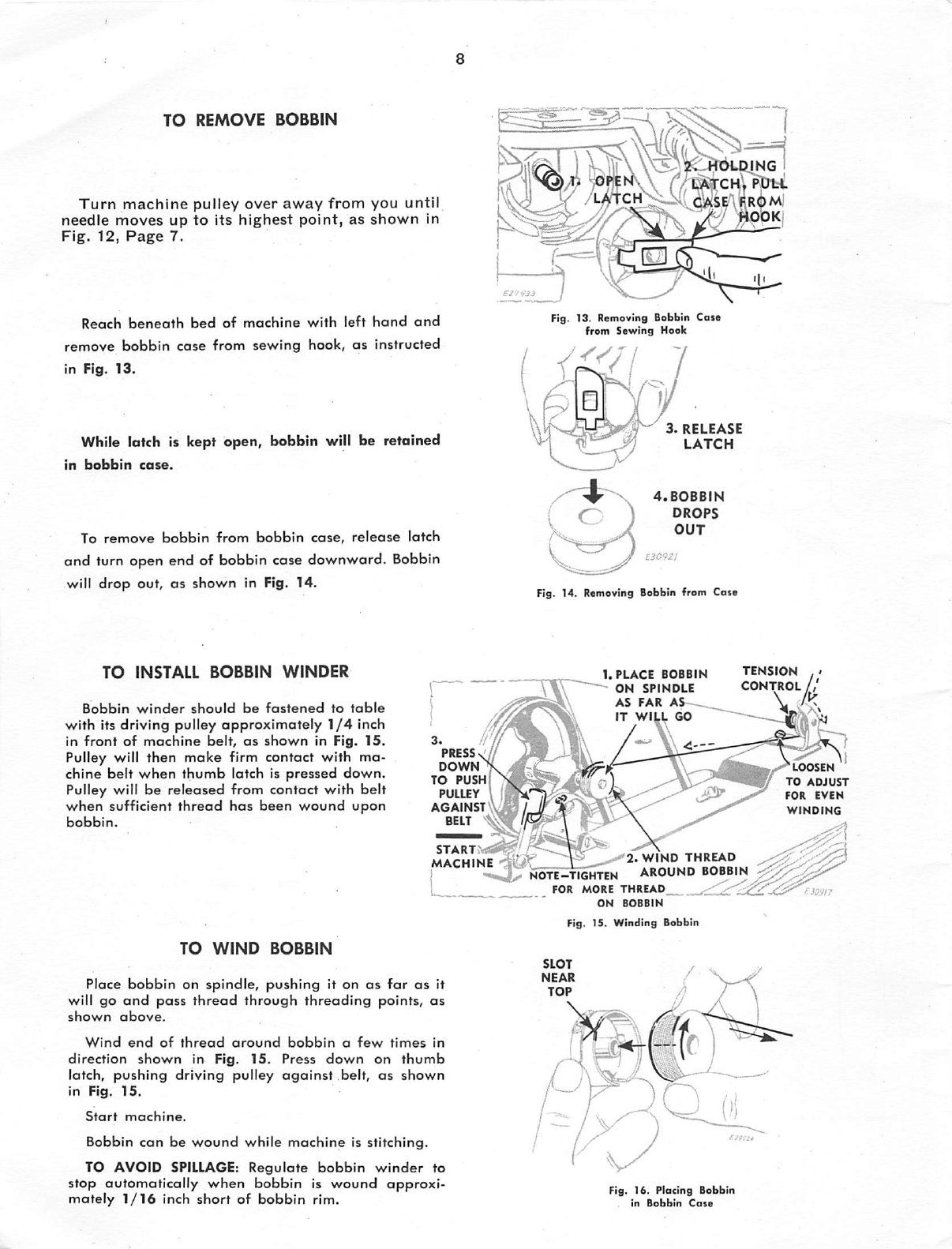

Hold

thread

as

shown in Fig. 11. Twirl

thread

over

toward you between thumb and forefinger of right

hand; if left

twist,

strands

will

wind tighter; if right

twist, strands will unwind or separate.

Rough

or uneven thread, or thread which passes

with difficulty through the eye of the needle, will

interfere

with

successful

use

of

machine.

m

WRAP

THREAD

l'/2

TURNS

AROUND

DISC

UPPER

THREADING

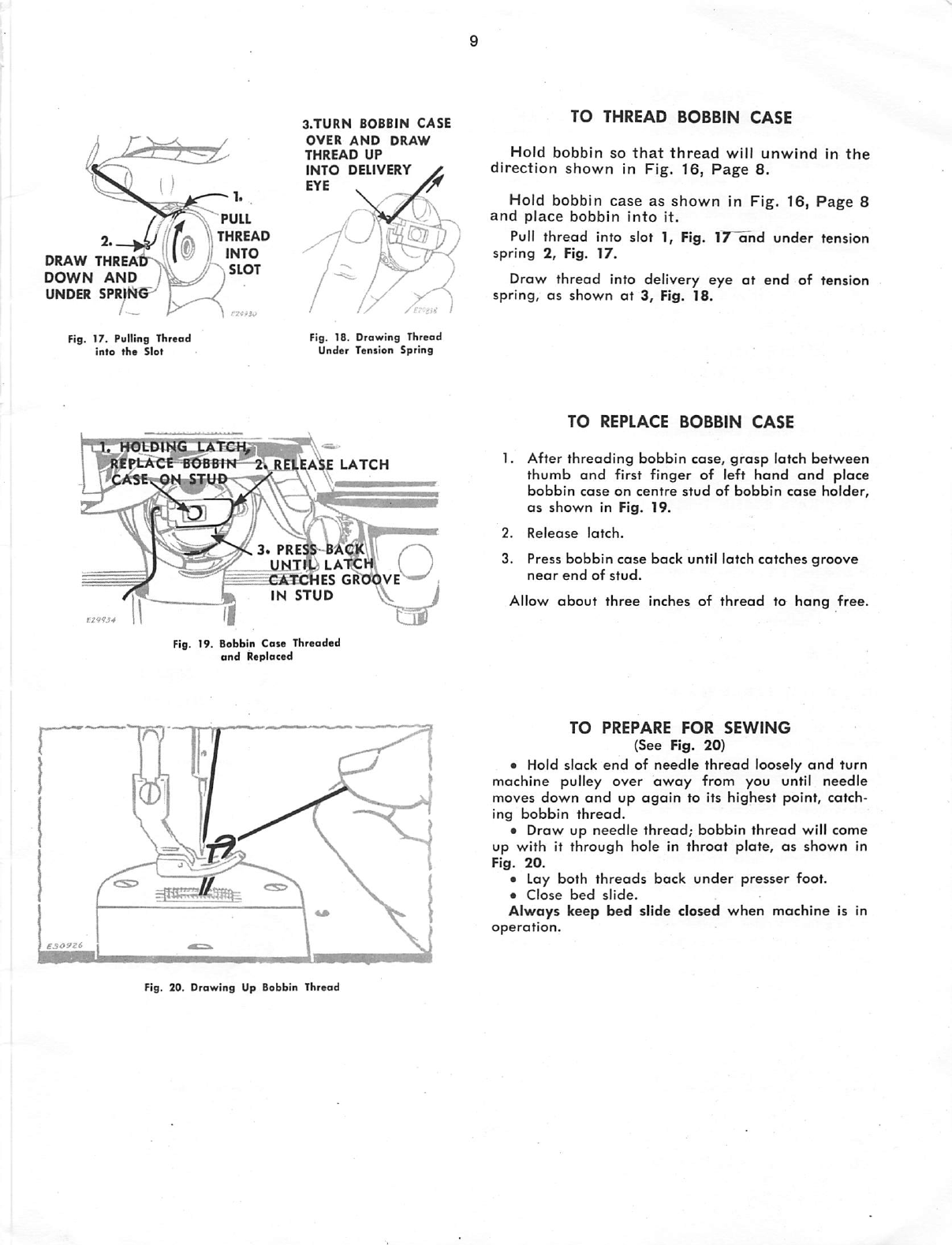

Turn machine pulley

away

from

you until

needle

is

at

its highest

position.

Pass

thread

from

unwinder,

through

threading

points

#1

through

#12

in

order

shown

in

Fig.

12.

When

you

have

become

accus

tomed

to

threading

this

machine,

thread

can

be

passed

from

thread

ing

point

#4

to

needle

with

a

single

continuous

motion.

MOVE

TO

HIGHEST

POINT

Threading

the

Needle

7 5

to

/

\\

to

(Yi

Fig. 12. Upper Threading Completed

Thread

needle

from

left to

right.

Leave

about

three

inches

of

thread

behind

the

presser

foot,

as

shown

in

Fig.

12

with

which

to

start

sewing.

From the library of: Superior Sewing Machine & Supply LLC