From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

6

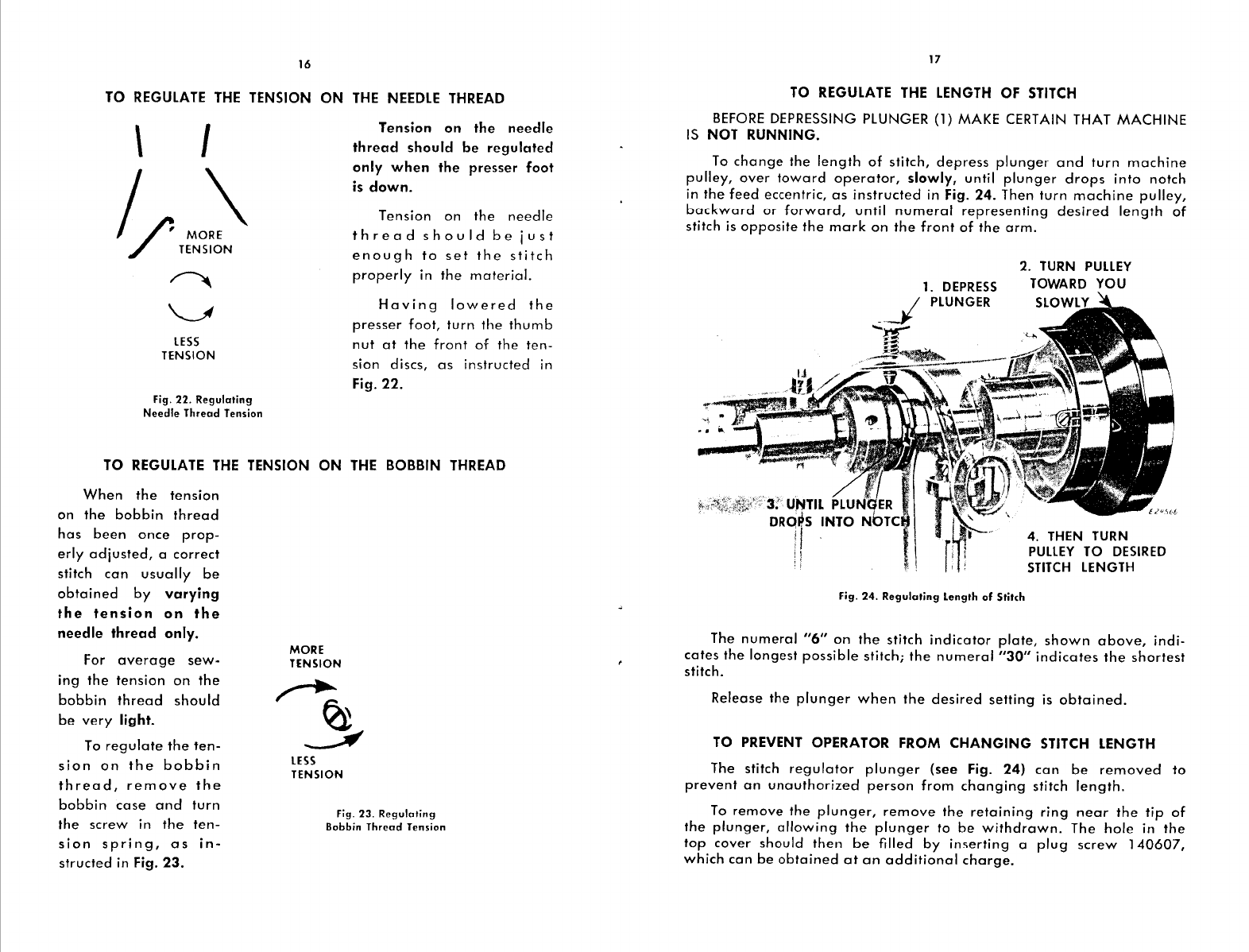

ADJUSTMENT OF ROTATING

HOOK

OIL FLOW REGULATOR

The

sewing

hook

is

automatically

lubricated.

The flow

of

oil

rs

controlled

by

the

oil

flow

regulator

illustrated

below.

1

-----·

143350

"~.,,

I

, . :

"'

:

...

-~,;

_-1=-

-b~:::::~

- -

~~'\---=

E2;!4//

~

140551

Fig. 5. Oil Flow

Regulator

in Hook

Shaft

Bushing

The oil

flow

regulator

is

set

at

the

factory

for

automatic

lubrica-

tion

of

the

hook

under

average

sewing

conditions.

If

more

or

less oil

is

desired,

turn

the

adjusting

thumb

screw

140551,

Fig. 5, clockwise to

increase

the

flow

of

oil

to

the

hook,

as

indicated

by

the

(+)

sign

under

its

arrow

on

the

head

of

the

thumb

screw,

or

turn

it

counter-

clockwise to decrease

the

flow,

as

indicated

by

the

(-)

sign

under

its

arrow

on

the

head

of

the

thumb

screw

140551.

To

determine

whether

the

oil

is

properly

flowing

to

the

hook,

withdraw

the

bed

slide

and

hold

a

piece

of

thin

paper

under

the

hook

while

the

machine

runs

for

ten

seconds.

There

should

be

a

slight

trace

of

oil

on

the

paper.

If

there

is

not,

adjust

the

oil

flow

regulator,

as

instructed

above,

or

replace

the

oil filter

143350,

Fig. 5,

in

the

head

of

the

hook

shaft,

as

instructed

on

page

32.

HINTS FOR

PERFECT

OPERATION

When

in

operation,

the

top

of

the

machine

pulley

must

always

turn

over

toward

the

operator.

Do

not

run

the

machine

with

the

presser

foot

resting

on

the

feed

without

cloth

under

the

presser

foot.

Do

not

run

the

machine

when

both

bobbin

case

and

needle

are

threaded

unless

there

is

material

under

the

presser

foot.

Do

not

try

to

aid

the

machine

by

pulling

the

fabric

lest

you

bend

the

needle.

The

machine

feeds

the

work

without

assistance.

The

slide

over

the

bobbin

case

should

be

kept

closed

when

the

machine

is

in

operation.

If

the

sewing

hook

should

become

excessively

warm,

it

may

be

due

to

an

insufficient

supply

of

oil

lo

the

hook

(see

instructions,

above,

for

adjusting

oil

flow

regulator).

NEVER

TOUCH

THE

STITCH REGULATOR PLUNGER WHILE

THE

MA-

CHINE

IS

RUNNING.

7

NEEDLES

Needles

for

Machines

of

Class

251

are

as

follows:

PRESSER

TYPE

NEEDLES

--

- - . -

----

MACHINE

BAR

OF CLASS

AND

LIFT

MATERIAL VARIETY SIZES

251-1 9

/32

inch

Light

88

X 9 8, 9, 10, 11, 12, 13,

14, 16, 17, 18, 19,

20,

21,

and 22

-

--

- - -

--

-------

-

--

------

251-2

5/16

inch

Medium-Heavy

8, 9, l 0, 11, 12, 13,

to

Light

16

X

257

14, 16, 17, 18, 19,

~-----·-

----

-

-----

-

--------------

- - -

--

20,

21,

22,

23,

and

251-3

3/8

inch

Heavy

to

Light

Regular

24

---

251-3

7/16

inch

Extra-Heavy

]6

X

261

16, 18, 19,

21,

22,

to

Light and 23

The

above

needles

are

regularly

nickel

finish

but

are

available

with

chromium

finish if

so

ordered.

The

size

of

the

needle

to

be

used

should

be

determined

by

the

size

of

the

thread

which

must

pass

freely

through

the

eye

of

the

needle.

Rough

or

uneven

thread,

or

thread

which

passes

with

difficulty

through

the

eye

of

the

needle,

will

interfere

with

the

successful

use

of

the

machine.

Orders

for

needles

must

specify

the

Quantity

required,

the

Size

number,

also

the

Class

and

Variety

numbers,

separated

by

an

x.

The

following

is

an

example

of

an

intelligible

order:

"l

00

No.

16,

88

x 9

Needles."

The

best

stitching

results

will

be

obtained

by

using

needles

sold

by

Singer

Sewing

Machine

Company.

THREAD

Left

twist

thread

should

be

used

in

the

needle.

Either

right

or

left

twist

thread

can

be

used

in

the

bobbin.

HIS END

l.21974

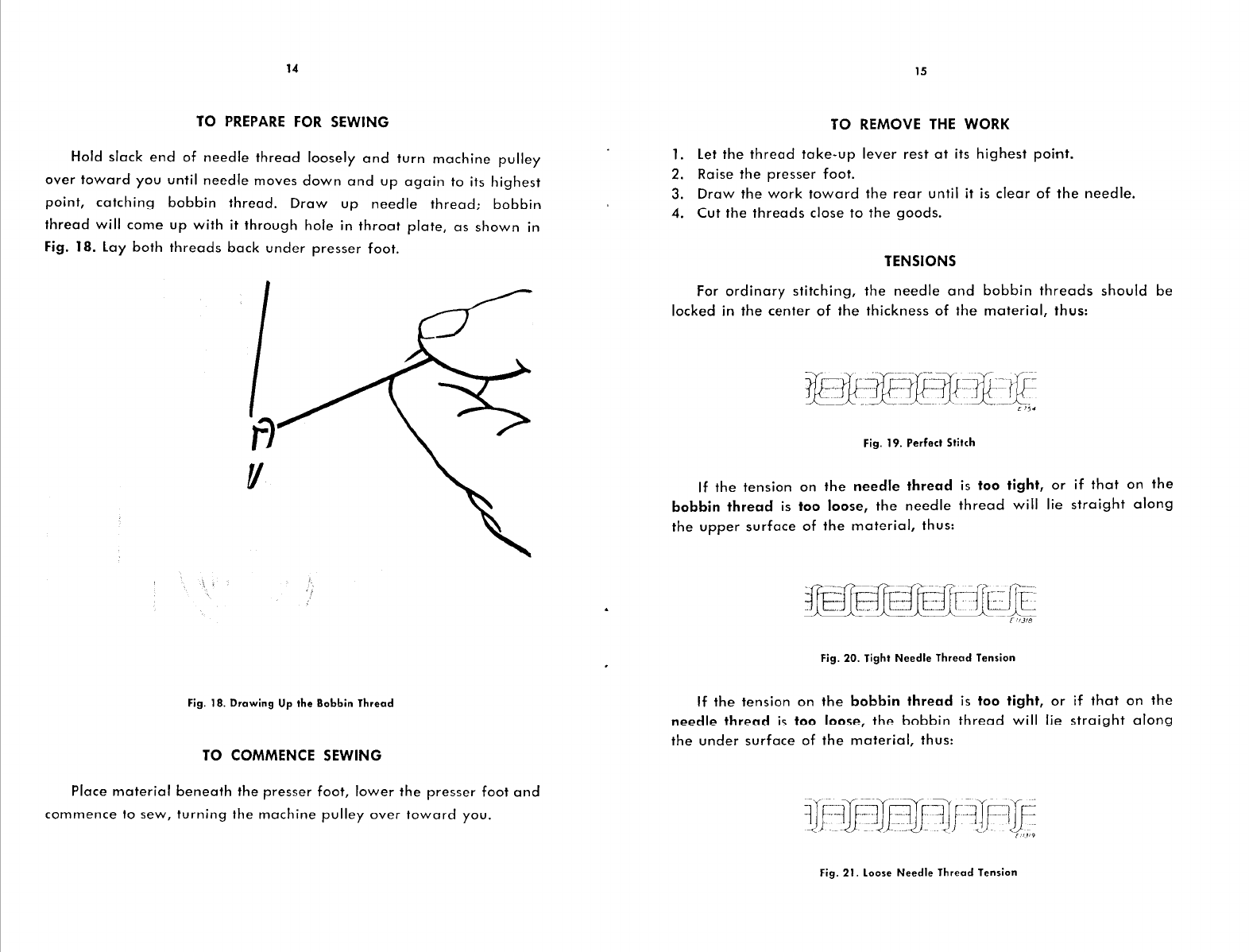

Fig. 6.

How

to

Determine

the Twist

To

determine

the

twist,

hold

the

thread

as

shown

above.

Roll

the

thread

over

toward

you

between

the

thumb

and

forefinger

of

the

right

hand;

if

left

twist,

the

strands

will

wind

tighter;

if

right

twist,

the

strands

will

unwind.