Singer 591UTT User manual

Other Singer Sewing Machine manuals

Singer

Singer 302U406EV User manual

Singer

Singer 1409 User manual

Singer

Singer 211W151 User manual

Singer

Singer 221K Installation and operation manual

Singer

Singer 14U286B User manual

Singer

Singer Ultralock 14U 34B/234B Manual

Singer

Singer 157-3 Quick start guide

Singer

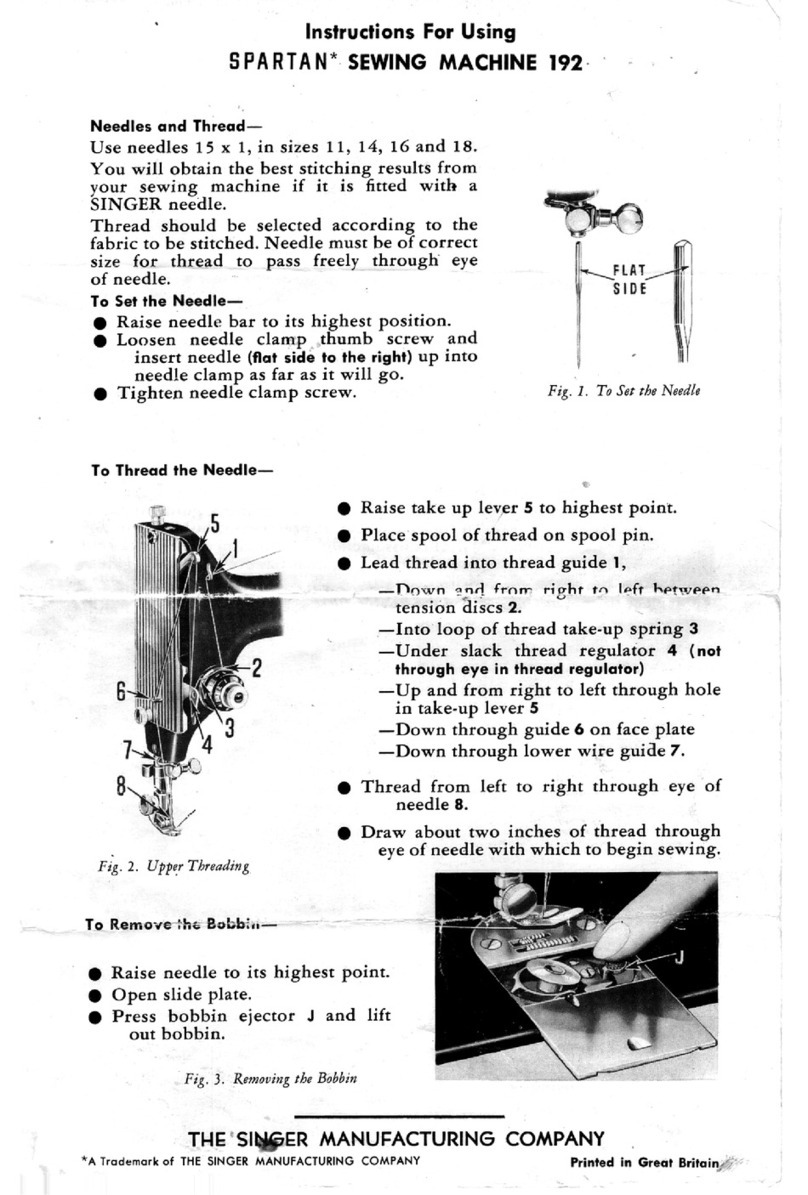

Singer SPARTAN 192 User manual

Singer

Singer 400W21 User manual

Singer

Singer SUPERA User manual

Singer

Singer 177C User manual

Singer

Singer 112W131 Setup guide

Singer

Singer 114W110 Installation and operation manual

Singer

Singer 2810 User manual

Singer

Singer 92-20 Quick start guide

Singer

Singer 147-80 Setup guide

Singer

Singer 400W11 Quick start guide

Singer

Singer 22W165 to W170 User manual

Singer

Singer 7902 Specifications

Singer

Singer 457U135 Setup guide