SingleTact SingleTact Standard User manual

USER MANUAL

EXPERIENCE

INCREDIBLE

PERFORMANCE

V2.3

pg. 2

Copyright © 2017- www.SingleTact.com

CONTENTS

1INTRODUCTION............................................................................................................................................... 3

2INTERFACE DESIGN ......................................................................................................................................... 4

2.1 Connectivity.............................................................................................................................................. 5

2.2 Analog Interface....................................................................................................................................... 6

2.3 I2C Interface.............................................................................................................................................. 7

2.4 I2C Operations ........................................................................................................................................ 10

2.4.1 I2C Write Operation ........................................................................................................................ 10

2.4.2 I2C Read Request Operation ........................................................................................................... 11

2.4.3 I2C Read Operation.......................................................................................................................... 11

2.5 Conversion Detail ................................................................................................................................... 13

2.6 Product Categories................................................................................................................................. 14

3TROUBLESHOOTING SingleTact .................................................................................................................... 15

3.1 Arduino UNO not detected by PC. ......................................................................................................... 16

3.2 Invalid setting error on PC (Popup reports” Failed to set”)................................................................... 16

3.3 No Analog output (remains at 0V). ........................................................................................................ 16

3.4 Analog output stays at 0.5V. .................................................................................................................. 16

4EXAMPLE USE CASE....................................................................................................................................... 17

4.1 PC and Arduino Example........................................................................................................................ 18

4.2 Programming the Arduino UNO with SingleTact Example..................................................................... 20

4.3 Arduino Demo Outline ........................................................................................................................... 22

4.4 Example .NET API ................................................................................................................................... 26

5Resources...................................................................................................................................................... 27

6Glossary......................................................................................................................................................... 28

7Revision History ............................................................................................................................................ 29

pg. 3

Copyright © 2017- www.SingleTact.com

1INTRODUCTION

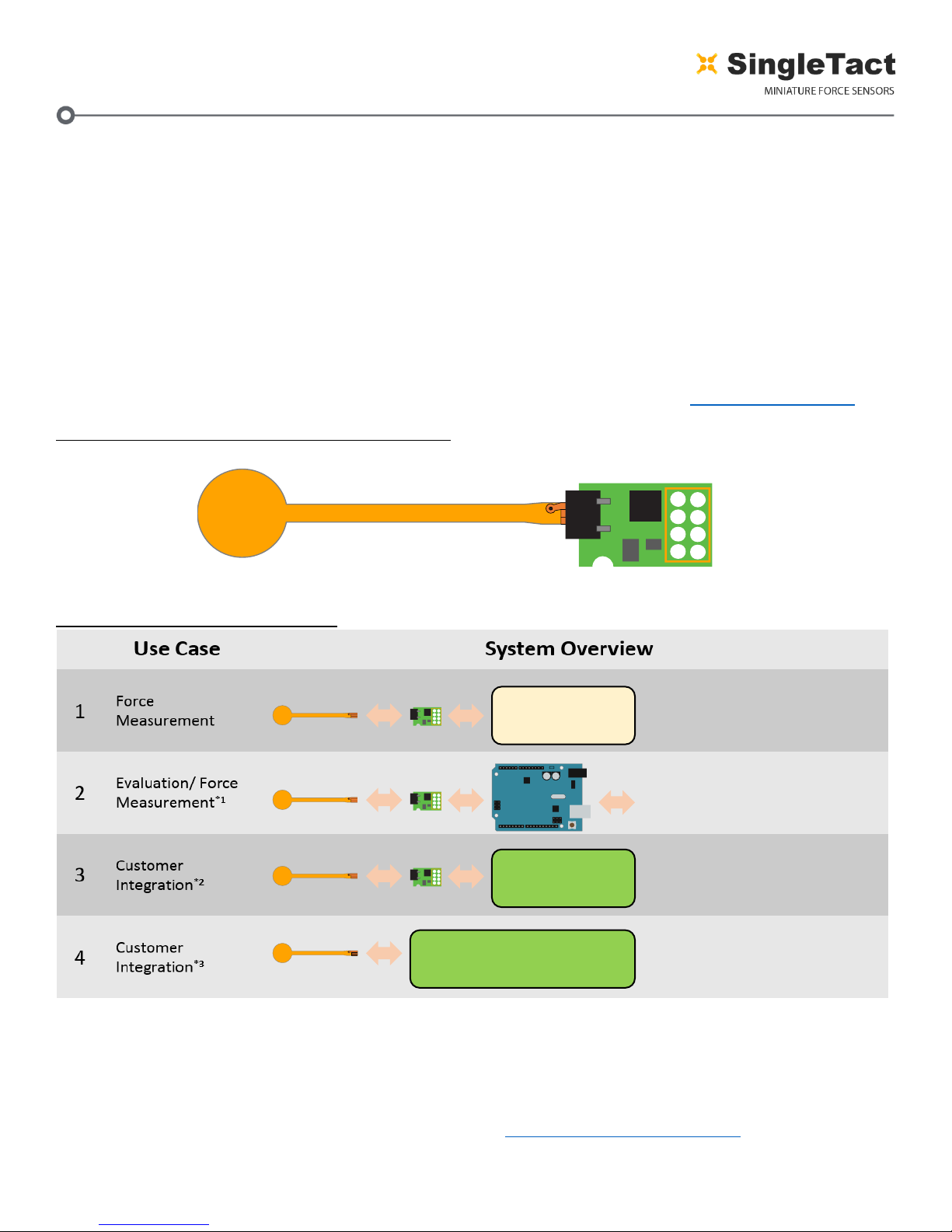

SingleTact is a single element tactile pressure sensor that accurately and reliably quantifies applied

force combined with a simple interface board offering a 0 to 2V analog output for immediate Data

Acquisition (DAQ) integration and an I2C based interface for integration into embedded systems.

Standard and Calibrated sensors (with matched pre-calibrated interface board) are available.

This document provides all the information necessary to interface with the SingleTact including a

sample Arduino digital interface and simple C# PC DAQ software (see EXAMPLE USE CASE)

All demo and API source code is open source and can be downloaded from: www.singletact.com.

Figure 1 SingleTact Sensor and Interface Board

Figure 2 Use Case Configurations

*1 –In addition to the data acquisition example, a .NET library is available to download for simple integration into a user’s

own software suite. See Example .NET API.

*2 –Supports over 100 SingleTact interface boards on a single I2C bus. The interface board firmware can be modified to

fit user’s specific use cases – if required please contact PPS to discuss this option.

*3 –PPS maybe able to assist with this –use the contact links at http://www.singletact.com/contact/.

SingleTact.com

1

2

3

45

6

7

8

MCU

Single Tact.com

1

2

3

45

6

7

8

MCU

Arduino and PC data acquisition

evaluation software

Analogue Out. Connect to multitier,

oscilloscope or data acquisition card

User reads capacitance

using their own circuitry

Single Tact.com

1

2

3

45

6

7

8

MCU

UNO

Single Tact.com

I2C Digital Output. Interface to user

electronics

Single Tact.com

1

2

3

45

6

7

8

MCU

User

Hardware

Analog

Measurement

I2C

I2C

User

Hardware

pg. 4

Copyright © 2017- www.SingleTact.com

2INTERFACE DESIGN

pg. 5

Copyright © 2017- www.SingleTact.com

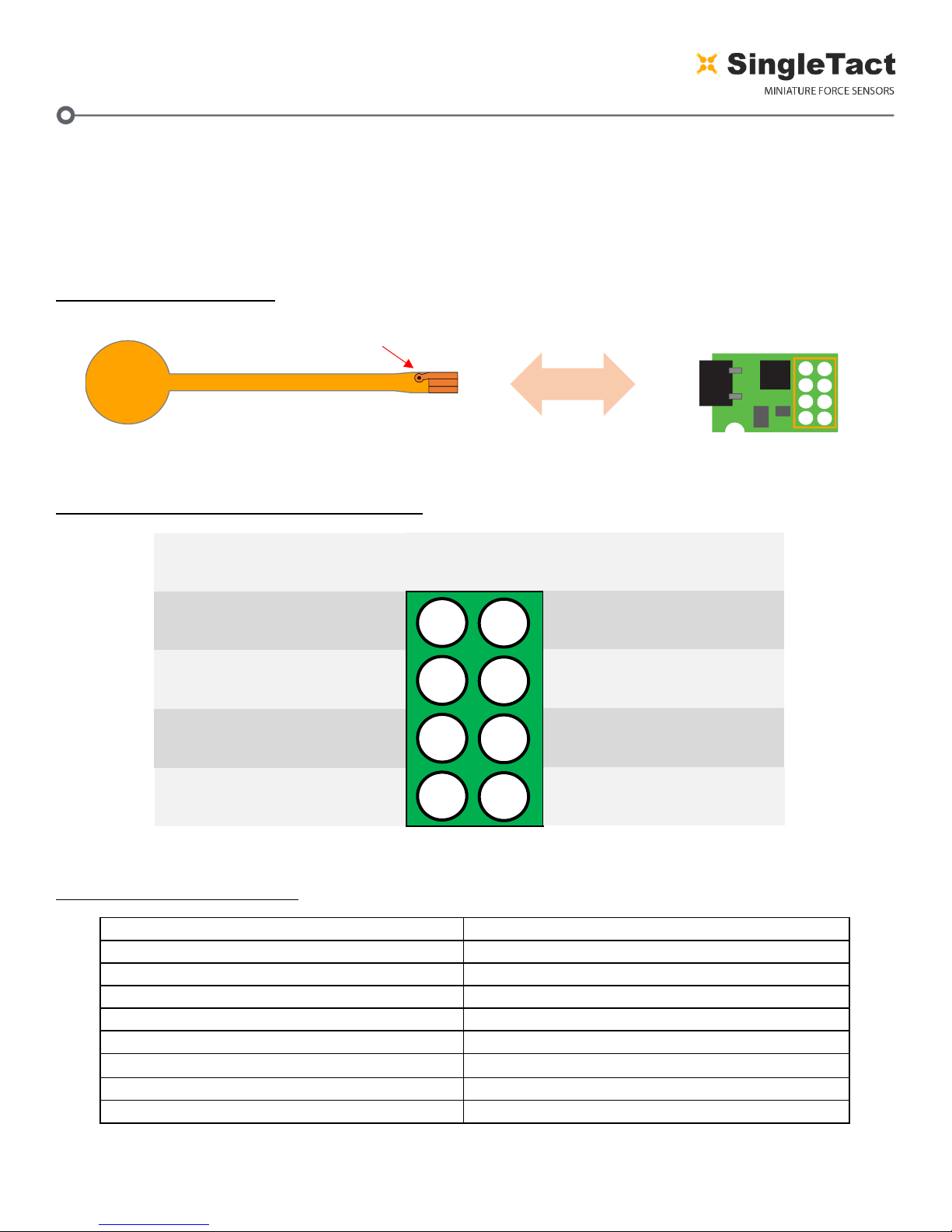

2.1 Connectivity

The sensor is plugged into the FFC connector on the green interface board (with the sensor

connector pads facing upward). The connections are outlined in Figure 4.

Electrical parameters are outlined in Table 1.

Figure 3 Sensor Assembly

Figure 4 Interface board header connections

Table 1 Electrical parameters

Parameter

Value

Supply Voltage, Vcc

3.7 –12V

I2C clock frequency

100KHz or 400KHz

I2C bus level

3 –5V

I2C output range (sensor data)

10-bit (Operational FSR output 9-bit)

Analog output range

0 –2V (Operational FSR output 0.5 –1.5V)

Permitted analog output load

>5K

Frame Sync level

3.3V CMOS output

Sensor update rate (I2C or analog)

>140Hz (dependent on settings)

SingleTact.com

1

2

3

45

6

7

8

MCU

Note via orientation

CONNECTION

Reserved

I2C Interface (SDA)

Frame Sync

Ground

1

4

3

2

8

5

6

7

CONNECTION

Reserved

I2C Interface (SCL)

Analog Out

Vcc

PIN

NUMBER

This manual suits for next models

1

Table of contents