sinmag LBC LCR5 Guide

© 2017-2020 LBC BAKERY EQUIPMENT, INC. TULALIP, WA PG 1 REV 12/2020

Models LCR5 and LCR7

5-Spit and 7-Spit Rotisserie Ovens

Installation, Service and Parts Manual

LBC Bakery Equipment, Inc.

6026 31st Ave NE

Tulalip, WA 98271, USA

Phone: 888-RACKOVN (888-722-5686)

Fax: 425-642-8310

Email: parts@lbcbakery.com

Website: www.lbcbakery.com

2

READ FIRST T

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE. READ, UNDERSTAND AND FOLLOW

THE INSTRUCTIONS AND WARNINGS CONTAINED IN THIS MANUAL.

W A R N I N G

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

D A N G E R

W A R N I N G

IMPROPER INSTALLATION,

ADJUSTMENT, SERVICE OR

MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR

DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

C A U T I O N

ALWAYS KEEP THE AREA NEAR

THE APPLIANCE FREE FROM

COMBUSTIBLE MATERIALS.

This LBC Rotisserie was manufactured to rigid standards. The appliance has been tested and is listed by Intertek Testing

Services (ETL Semko) and meets applicable safety and sanitation standards.

A) The responsibility of the manufacturer is to supply suitable, comprehensive instructions and recommendations for

proper operation and maintenance.

B) All operations, maintenance and repair of this or any LBC Bakery Equipment appliance must be performed by

properly trained and qualified personnel, and all such operations, maintenance and repair must be performed in a

diligent manner. It is the responsibility of the owner/operator to ensure proper training and diligence of any person

coming into contact with either the subject units or the output (product, fumes or otherwise) of the subject units.

It is the responsibility of the owner/operator to ensure that the subject units are installed and operated in

accordance with OSHA Standard 1910.263.

C) A regular periodic program of cleaning, inspection and maintenance must be established and comprehensive

maintenance records maintained. It is the sole responsibility of the owner/operator to establish, schedule and

enforce the frequency and scope of these programs in keeping with recommended practice and with due

consideration given to actual operating conditions.

D) The appliance must be operated within limits which will not exceed its working limits. It is the responsibility of the

user to operate this appliance in accordance with the rules and limits described in this manual and the published

product specification sheet, and in accordance with the directions and instructions of the owner/operator of the

appliance or employer, and in accordance with applicable federal, state and local laws and ordinances.

3

TABLE of CONTENTS T

Read First . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... . . . . . . . . . . . . . . . . 4

Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Conditions of Installation ....... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Receiving and Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....... . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Controller Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4

SPECIFICATIONS T

Model H* W D1D2D3D4Actual

Weight

Shipping

Weight Freight Class

LCR5 32.5"

31.5" 21.7" 26.3" 27.1" 24.3"

320

lbs

450 lbs 85

LCR7 38.4" 38.9" 26.5" 32.6" 32.6" 31.6"

460

lbs

610 lbs 85

Model Voltage kW Min Circuit Ampacity Max Breaker Size

1 Phase

3 Phase

1 Phase

3 Phase

LCR5

208 VAC

4.0

40

N/A

60

N/A

LCR7

208 VAC

9.0

N/A

40

N/A

60

5

CONFIGURATIONS S

Rotisserie

Stacked Appliances

6.0” Legs or

4.5” Swivel Casters with Brakes

Countertop: 4.0” Legs

Floor: 6.0” Legs or

4.5” Swivel Casters with Brakes

Rotisserie

Countertop or

Floor Mount

Stand Mount

LST5 Stand (for LCR5 Rotisserie) or

LST7 Stand (for LCR7 Rotisserie or

LHC7 Holding Cabinet)

Combinations:

•2 ea LCR5 Rotisseries

•2 ea LCR7 Rotisseries

•1 ea LCR7Rotisserie + 1 ea LHC7 Holding Cabinet

NOTE: When a Rotisserie is stacked with a

Holding Cabinet, It may be installed on the top

or bottom

6

CONDITIONS of INSTALLATION I

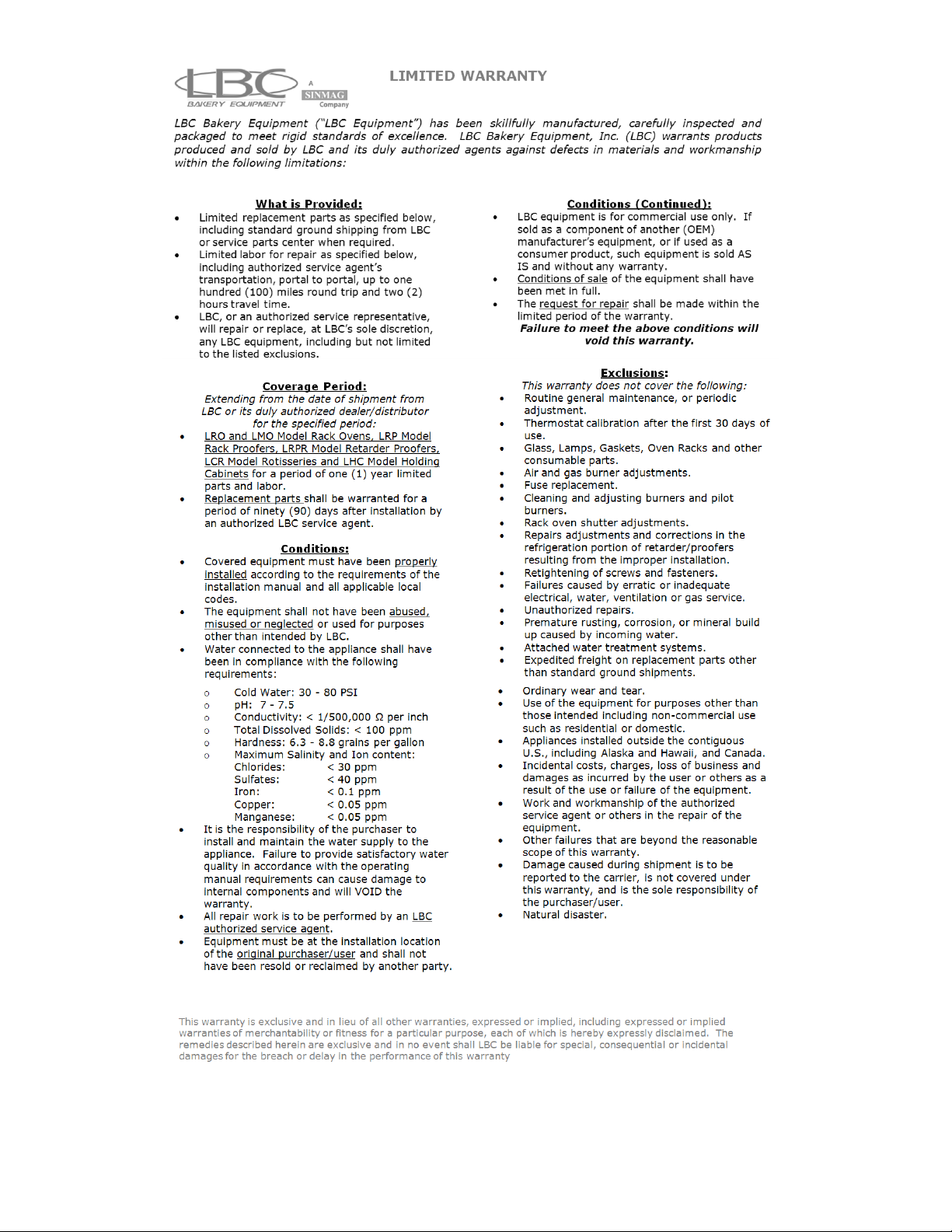

LBC Bakery Equipment Co. shall, for a fee contingent on site location and provided that the conditions of installation

are met, provide a factory-authorized service agency to install the LBC Rotisserie. The job site must be ready for the

installation before LBC Bakery Equipment Co. or its authorized agent arrives. If the installation site is not properly

prepared or if there are construction delays, the customer shall be responsible for all expenses incurred during this

delay. All expenses resulting from job delay or extension, for reasons beyond the control of LBC Bakery Equipment

Co., shall be the responsibility of the customer. Installation shall be conducted during normal business hours. This

installation is for a single trip. Start-up and training are not included.

IN ALL CASES, THE ELECTRICAL, MECHANICAL CONNECTIONS AND VENTILATION MUST MEET ALL FEDERAL, STATE

AND LOCAL CODES OR ORDINANCES.

It is the responsibility of the owner/operator to do the following:

A) Secure all required permits and meet all local code requirements.

B) Ensure the installation site is cleared and ready for installation before the authorized installer arrives on site.

The site shall be smooth and level.

C) Provide electrical utilities within five (5) feet of the installation location per the specifications provided by LBC

Bakery Equipment Co.

D) Provide licensed trades person to make the final electrical connections.

E) Provide adequate ventilation, including vented hoods and associated roof penetrations.

F) Remove all packing materials, crates, etc. resulting from the installation.

G) Provide any sheet metal work required by local codes or otherwise to bridge gaps between appliance and

adjacent walls or other building structures.

7

RECEIVING and UNPACKINGI

C A U T I O N

SHIPPING STRAPS ARE UNDER TENSION AND CAN

SNAP BACK WHEN CUT.

C A U T I O N

THIS APPLIANCE WEIGHS UP TO 610 LBS. FOR SAFE

HANDLING, INSTALLER SHOULD OBTAIN HELP AS

NEEDED OR EMPLOY APPROPRIATE MATERIAL-

HANDLING EQUIPMENT (SUCH AS A FORKLIFT, DOLLY

OR PALLET JACK) TO REMOVE THE UNIT FROM ITS

PACKING MATERIALS AND TO MOVE IT TO THE PLACE

OF INSTALLATION.

Receiving

Upon receiving the appliance, immediately check for damage (both visible and concealed) and loss. Visible damage must

be noted on the freight bill at the time of delivery and signed by the carrier’s agent. Concealed damage or loss means

damage or loss which does not become apparent until the merchandise has been unpacked. If concealed damage or loss

is discovered upon unpacking, make a written request for inspection by the carrier’s agent within 15 days of delivery.

All packing material should be kept for the inspection. DO NOT return damaged merchandise to LBC Bakery Equipment;

you must file your claim with carrier.

Location

Prior to unpacking, move the appliance as near to its intended location as practical. Existing packaging will help protect

the oven from physical damage normally associated with moving it through hallways and doorways.

Unpacking

The appliance will arrive inside a wood frame and affixed to a pallet. Remove the wood frame and strapping bands before

lifting the unit from the pallet and placing in its intended location.

8

INSTALLATION (Part 1 of 3)0

C A U T I O N ANY STAND, COUNTER OR OTHER DEVICE ON WHICH

THIS APPLIANCE WILL BE LOCATED MUST BE

DESIGNED TO SUPPORT ITS WEIGHT

C A U T I O N

THIS APPLIANCE WEIGHS UP TO 610 LBS. FOR SAFE

HANDLING, INSTALLER SHOULD OBTAIN HELP AS

NEEDED OR EMPLOY APPROPRIATE MATERIAL-

HANDLING EQUIPMENT (SUCH AS A FORKLIFT, DOLLY

OR PALLET JACK) TO REMOVE THE UNIT FROM ITS

PACKING MATERIALS AND TO MOVE IT TO THE PLACE

OF INSTALLATION.

C A U T I O N ALL ELECRICAL, MECHANICAL CONNECTIONS AND

VENTILATION MUST MEET ALL FEDERAL, STATE AND

LOCAL CODES OR ORDINANCES.

INSTALLATION OF THIS APPLIANCE MUST BE

DONE BY PERSONNEL QUALIFIED TO WORK

WITH ELECTRICITY. IMPROPER

INSTALLATION CAN CAUSE INJURY TO

PERSONNEL AND/OR DAMAGE TO

EQUIPMENT.

W A R N I N G

N O T I C E

During the first few hours of operation, you

may notice a small amount of smoke coming

from the rotisserie and/or a faint odor. This is

normal in a new oven and will disappear after a

few hours of use.

Clearances

Minimum clearance from combustible construction: 0” from sides, 1” from back (single-door ovens only) or 6” from back

(double-door ovens) and 6” from top. This appliance may be installed on combustible surfaces. The installation location

must allow adequate clearances for servicing and for the proper operation of the loading door(s).

Legs, Casters or Stand

Legs or casters are available for single and stacked appliance combinations. Additionally, a single unit may have a stand.

install the appliance on legs, casters or a stand with the stainless steel hardware provided (16 ea of the following: 10-1.2

x 20mm hex bolts, 10mm split lock washer and 10mm plain washers).

Stacking

If stacking appliances, gently place the top oven on the bottom oven with the doors and sides aligned. When a Rotisserie

is stacked with a Holding Cabinet, it may be installed on the top or bottom. Secure the appliances through the pre-

attached stacking brackets at the underside of each appliance and into the threaded receiving holes at the topside of each

appliance. Use the stainless steel hardware provided (16 ea of the following: 10-1.2x20mm hex bolts, 10mm split lock

washers and 10mm plain washers). Check both appliances to ensure they are level.

Skewers or Baskets

Unpack the optional skewers or baskets (shipped inside the oven) and install on the carousel wheels. Skewers slide into

the existing holes in the wheels. Baskets hang from the pins located at the inner surfaces of the wheels. No mounting

hardware is required to install these parts. Before installing, wash parts in warm, soapy water and rinse with clean water.

9

INSTALLATION (Part 2 of 3))

Drip Plates

Unpack both drip plates (shipped inside the oven) and place at the bottom of the oven cook chamber.

Electrical Power Connection

A mounting plate with a 1.25” hole to connect an electrical conduit connector is installed at the bottom of the control

compartment. The plate may be moved to the top or rear of the appliance to accommodate different connection points

as shown in the Specifications section of this manual. Use flexible conduit or cord if the oven is installed with casters,

providing sufficient length to allow the oven to be moved for cleaning without applying tension to the electrical

connections.

Safety Tether

Units on casters must be secured to a building structure with the safety tether provided. Affix one end of the tether to a

side panel of the unit (the non-control side is recommended) using any existing panel mount screw. An additional hole

must be drilled next to the existing mount screw to affix the 2-hole plate located on either end of the tether. A drill bit and

mounting hardware are provided in the tether kit. Attach the loose end of the tether to a secure structure and affix the

warning label provided (“WARNING – ATTENCION: RISK OF ELECTRIC SHOCK …”) to the control-side panel.

Interim Inspection

Prior to turning oven on, verify the following:

•Loading door(s) open/close freely past 90owithout obstruction

•All packing materials have been removed from inside oven

•Carousel wheel shipping ties (at left hand carousel support hub and/or right hand drive arm) have been removed

•Clear protective plastic covering data plate has been removed

•Fingerprints, tape residue, etc. have been cleaned from oven interior and exterior

•Any loose screws have been tightened; any loose power connections have been tightened

Controller Startup Check (Refer to Controller Operation section)

While oven is connected to live power, press the control panel power button and verify that the following conditions occur

on initial startup:

•Recipe number appears in the recipe LED display

•For recipes 1 through 6, the corresponding “quick select” recipe button status light is illuminated

•Oven pre-heats (elements are energized) to the temperature programmed in the open recipe

•Carousel wheel rotates

•Interior lights are off

•Interior heat-circulation fans are on

•Control compartment axial fan is on

•Values appear in the actual temp, set point and timer LED displays

10

INSTALLATION (Part 3 of 3) )

Loading Door Switch Check

While the oven is preheating, open the loading door and verify the following conditions:

•The word “door” flashes in the timer display (NOTE: For ovens with two doors, each door must be checked

independently)

•Heat is off (elements are de-energized)

•Carousel wheel stops rotation

•Interior lights are off

•Interior heat-circulation fans are off

Jog Feature Check

While the oven is preheating, open the loading door and allow the carousel to stop rotating. With the door open,

press-and-hold the jog button and confirm that the carousel rotates. Also confirm that the carousel stops when the

jog button is released.

Interior Lights Check

While the oven is preheating, press the start/stop button and verify that both interior lights illuminate.

Set Temperature Scale

Simultaneously press-and-hold set point up and down arrows for 3 seconds to change scale from oF to oC and back.

Controller Calibration

Insert a thermocouple inside the appliance cook chamber at the center of any oblong hole in the fan cover. Route

the probe wire out of the loading door opening and adjust the oven set point to 350oF (177oC). Allow the oven to

reach the set point and stabilize for at least 90 minutes. If the thermocouple reading and the controller actual

temperature differ by more than a couple degrees, the control must be calibrated. To begin, make a note of the

temperature difference between the thermocouple and the controller actual temperature, then turn the control

power button off and hold the probe button for 3 seconds until a value appears in the set point display. Use the set

point up or down arrow to add or subtract the difference in temperature. (EXAMPLE: If the thermocouple is 10o

higher than the actual temperature, add 10. If the thermocouple is 10olower than the actual temperature, subtract

10.) Turn the control button on and re-check the thermocouple against the controller actual temperature. Repeat

this procedure until the two temperatures match.

11

CONTROLLER OPERATION )

ACTUAL

TEMP

SET

POINT

TIMER

POWER

SET

PROGRAM SELECT

START

STOP

WARM

ROAST HOLD

SEAR

OPERATE

1 2 3

4 5 6

SAVE

JOG

BACK

+3

Quick-Select Recipe

Buttons

Easy access to

most-frequently-used

recipes

Recipe Save Button

After creating a recipe,

press this button twice

to save it

Change Temperature Scale

Simultaneously press-and-hold

up and down arrows for 3

seconds to change scale from

oF to oC and back

Timer Start/Stop

and Reset But

ton

Press to start/stop timer;

press-and-hold for 3

seconds to reset timer

Jog But

ton

Press-and-hold this

button to rotate carousel

position when loading

door is open

Cook Event Buttons

Use these when creating a

recipe; up to 3 events may

be programmed

(NOTE: To ignore sear

and/or roast events, enter a

time of 00:00 for that event)

Recipe Arrow

Buttons & Display

Use arrow button to

scroll through recipes

(1 through 20); recipe

number will appear in

display

Back +3 Button

Use this button to go

back one event while a

recipe is running

12

PARTS LIST (Part 1 of 5) W

N O T I C E

Service on this or any other LBC appliance must

be performed by qualified personnel. For an

approved service representative in your area,

visit our website at www.lbcbakery.com or call

our factory toll free at 1-888-722-5686.

C A U T I O N

USE OF ANY REPLACEMENT PARTS OTHER THAN

THOSE SUPPLIED BY LBC OR THEIR AUTHORIZED

DISTRIBUTORS CAN CAUSE BODILY INJURY TO

THE OPERATOR AND/OR DAMAGE TO THE

APPLIANCE AND WILL VOID ALL WARRANTIES.

BOTH HIGH AND LOW VOLTAGES ARE

PRESENT INSIDE OF THIS APPLIANCE WHEN

THE UNIT IS PLUGGED/WIRED INTO A LIVE

RECEPTACLE. BEFORE REPLACING ANY PARTS,

DISCONNECT THE UNIT FROM THE ELECTRIC

POWER SUPPLY.

W A R N I N G

13

PARTS LIST (Part 2 of 5) W

14

PARTS LIST (Part 3 of 5) W

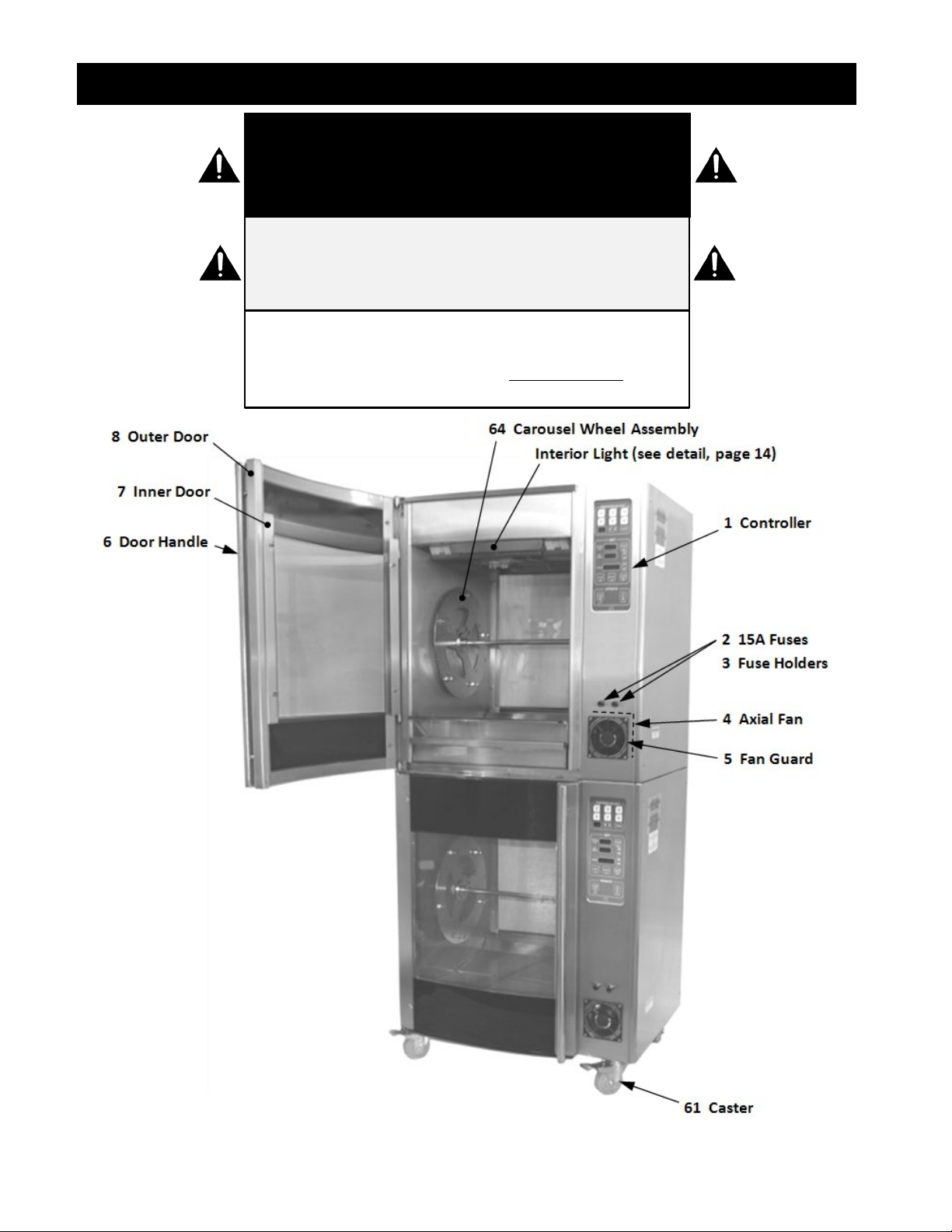

Item No.

Part Description

Quantity

Part No.

Usage

1

Controller

1

40102-76

2

15A Fuse

2

30900-01

3

Fuse Holder

2

30901-02

4

Axial Fan

1

71500-33

5

Fan Guard

1

50201-11

6

Handle, Loading Door

1

180-781-1

5-Spit only

Handle, Loading Door

1

180-781-2

7-Spit only

7

Loading Door, Inner

1

71300-32

5-Spit only

Loading Door, Inner

1

71300-30

7-Spit only

8

Loading Door, Outer - Front

1

71300-33F

5-Spit, front door only

Loading Door, Outer - Rear

1

71300-33R

5-Spit, rear door only

Loading Door, Outer - Front

1

71300-31F

7-Spit, front door only

Loading Door, Outer - Rear

1

71300-31R

7-Spit, rear door only

20

Element, 2kW, 208 VAC

2

11090-37

5-Spit only

Element, 3kW, 208 VAC

2

11090-38

7-Spit, Washdown

Element, 3kW, 208 VAC

0 or 1

11090-39

7-Spit only

Element, 2kW, 208 VAC

2 or 3

11090-40

7-Spit 1 phase only

21

Capacitor, Fan (2.2μF)

2

40704-11

22

Thermocouple Temperature Sensor

1

41100-31

23

Relay

3

30701-05

24

Alarm

1

30802-07-1

25

Contactor

1

30700-17

26

Transformer

1

31400-26

27

Power Distribution Block

1

30500-07

28

High Limit Cutout

1

30401-33

29

Gearbox (90 Degrees, 1:90 Ratio)

1

30200-50

30

Gearbox (1:10 Ratio)

1

30200-49

31

Motor

1

30200-51

15

PARTS LIST (Part 4 of 5) W

Item No. Part Description Quantity Part No. Usage

32

Capacitor, Motor (4.0µF)

1

40704-10

40

Thermal Snap Disc (Relay Protection)

2

30301-05

41

Fan, Ceiling

2

71500-32

42

Fan Blade, Ceiling

2

180-205-1

50 Door Switch Assembly 1 or 2 180-767-2

51 Thermal Snap Disc (Lights) 2 30301-06 7-Spit only

52

Lamp Holder

4

31602-09

5-Spit only

53

Lamp, 1kW

2

31602-08

5-Spit only

54

Lamp Holder

4

31602-21

7-Spit only

55

Lamp, 500W

2

31603-87

7-Spit only

Optional Parts and Accessories

Item No. Part Description Quantity Part No. Usage

60

Stand with Casters

1

LST7

7-Spit only

61

Caster (Swivel with Brake)

4

72901-33

62

4” Adjustable Leg

4

72901-35

63

6” Adjustable Leg

4

72901-34

64

Carousel Assembly, Non-Stick Coating 1 180-768-1C 5-Spit only

Carousel Assembly, Stainless Steel

1

180-768-1

5-Spit only

Carousel Assembly, Non-Stick Coating

1

180-768-2C

7-Spit only

Carousel Assembly, Stainless Steel

1

180-768-2

7-Spit only

65

Angle Spit, Stainless Steel

5

LCR5-SV

5-Spit Only

Angle Spit, Non-Stick Coating

5

LCR5-SV-C

5-Spit Only

Angle Spit, Stainless Steel

7

LCR7-SV

7-Spit Only

Angle Spit, Non-Stick Coating

7

LCR7-SV-C

7-Spit Only

66

Fork Spit, Stainless Steel

5

LCR5-SF

5-Spit Only

Fork Spit, Non-Stick Coating

5

LCR7-SF-C

5-Spit Only

Fork Spit, Stainless Steel

7

LCR5-SF

7-Spit Only

Fork Spit, Non-Stick Coating

7

LCR7-SF-C

7-Spit Only

67

Basket, Stainless Steel

5

LCR5-SB

5-Spit Only

Basket, Non-Stick Coating

5

LCR5-SB-C

5-Spit Only

Basket, Stainless Steel

7

LCR7-SB

7-Spit Only

Basket, Non-Stick Coating

7

LCR7-SB-C

7-Spit Only

68

Restraint Kit (Safety Tether)

1

72609-51

69

Stacking Kit

1

Kit, Rotisserie 4

70

Hand Held Probe Kit

1

Kit, Rotisserie 5

16

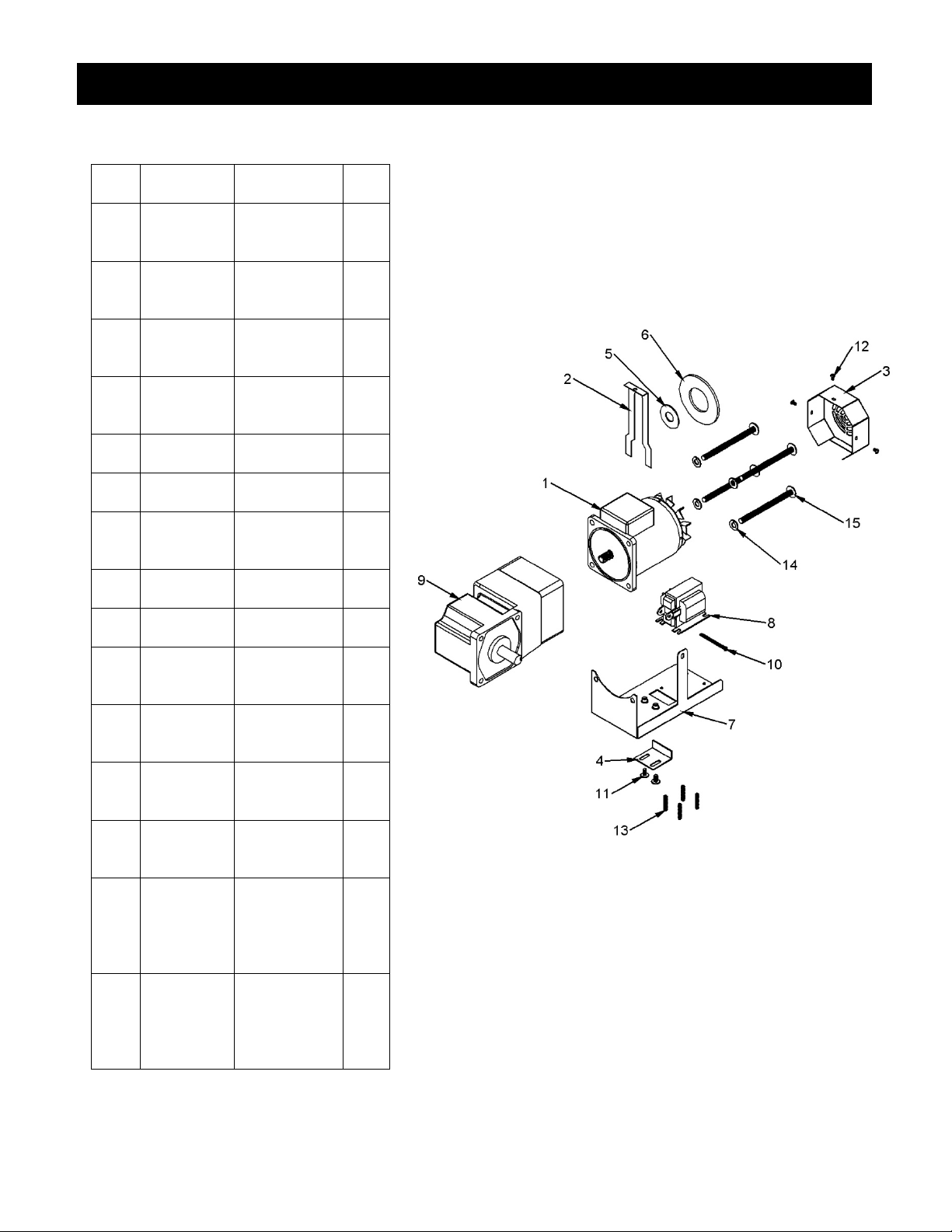

PARTS LIST (Part 5 of 5)W

Motor-Brake Assembly

ITEM

NO.

PART

NUMBER

DESCRIPTION QTY.

1 30200-51

(Capless)

Motor

(208VAC, 1ph,

1600rpm)

1

2 180-481

Lever, Motor

Brake

Solenoid

1

3 180-483

Fan Guard,

Motor Brake

Solenoid

1

4 180-484

Stop, Motor

Brake

Solenoid

1

5 180-485

Ring, Inner -

Teflon

1

6 70200-14

Washer,

Friction

1

7 180-480

Bracket,

Motor Brake

Solenoid

1

8

70403-04-

1-240

Solenoid,

Laminated

1

9 Gearbox

Gearbox -

Rotisserie

1

10

SCREW-PH-

SS-M3.5 x

0.6 x 50mm

PH SS SCREW

(M3.5 x 0.6

x 50mm)

1

11 Stock Part

Screw-Truss-

SS-M5 x

10mm

2

12 Screw -

M3.5

Screw - M3.5

(Drive

Motor Cap)

3

13 Stock Part

Screw-PH-SS-

DrillTip-Phil-

8-18, 1/2"

4

14 Stock Part

Washer -

M7.5 (Drive

Motor-to-

Gearbox

Attachment)

4

15 Screw -

M7.5

Screw - M7.5

(Drive

Motor-to-

Gearbox

Attachment)

4

17

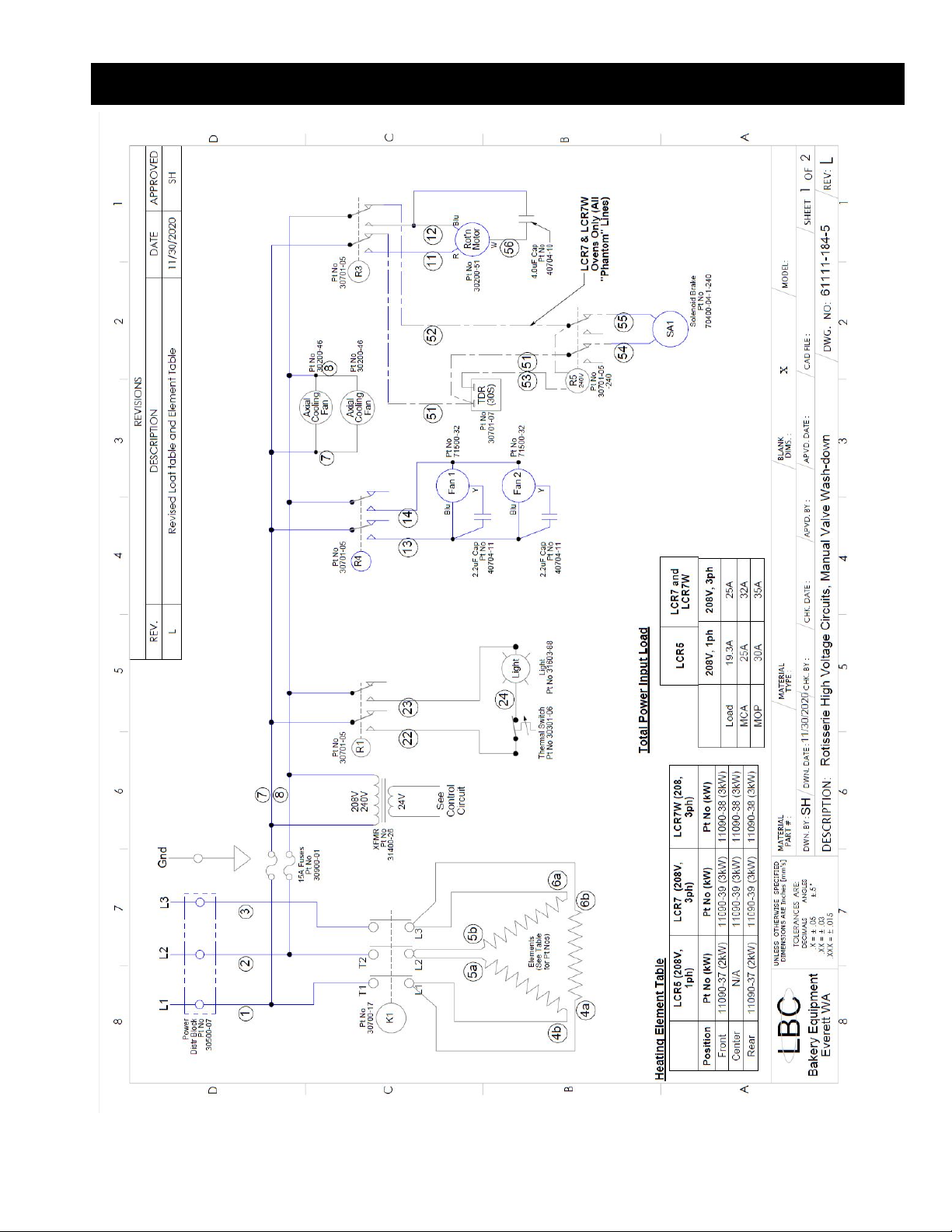

WIRING DIAGRAM (Part 1 of 2))

18

WIRING DIAGRAM (Part 2 of 2))n

19

This manual suits for next models

1

Table of contents

Other sinmag Oven manuals

Popular Oven manuals by other brands

Kampa

Kampa Freedom operating manual

Siemens

Siemens HB778G3 1B Series User manual and installation instructions

KKT KOLBE

KKT KOLBE EU Series Service manual

Lino

Lino FL4 F8PTDS XS installation manual

cecotec

cecotec BOLERO HEXA SM406000 EDGE+ A+ instruction manual

Hotpoint

Hotpoint KSO89CX S operating instructions