sinmag LBC LCR7 User manual

Models LCR5 and LCR7

5-Spit and 7-Spit Rotisserie Ovens

Operator’s Manual

LBC Bakery Equipment, Inc.

5901 –23rd Drive West, Suite 105

Everett, WA 98203

Phone: 888-RACKOVN (888-722-5686)

Fax: 425-642-8310

Email: service@lbcbakery.com

Website: www.lbcbakery.com REV D 8/2013

2

READ FIRST T

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE. READ, UNDERSTAND AND FOLLOW

THE INSTRUCTIONS AND WARNINGS CONTAINED IN THIS MANUAL. IT IS THE RESPONSIBILITY OF

THE OWNER/OPERATORS OF THIS APPLIANCE TO TRAIN, SUPERVISE AND AUTHORIZE ANY PERSON

DESIGNATED AS AN OPERATOR. ALL OPERATORS MUST READ AND UNDERSTAND THIS MANUAL.

W A R N I N G

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

D A N G E R

W A R N I N G

IMPROPER INSTALLATION,

ADJUSTMENT, SERVICE OR

MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR

DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

C A U T I O N ALWAYS KEEP THE AREA NEAR

THE APPLIANCE FREE FROM

COMBUSTIBLE MATERIALS.

Your LBC Rotisserie was manufactured to rigid standards. The appliance has been tested and is listed by Intertek Testing

Services (ETL Semko) and meets applicable safety and sanitation standards.

A) The responsibility of the manufacturer is to supply suitable, comprehensive instructions and recommendations for

proper operation and maintenance.

B) All operations, maintenance and repair of this or any appliance must be performed by properly trained and qualified

personnel, and all such operations, maintenance and repair must be performed in a diligent manner. It is the

responsibility of the owner/operator to ensure proper training and diligence of any person coming into contact with

either the subject units or the output (product, fumes or otherwise) of the subject units. It is the responsibility of

the owner/operator to ensure that the subject units are installed and operated in accordance with OSHA Standard

1910.263.

C) A regular periodic program of cleaning, inspection and maintenance must be established and comprehensive

maintenance records maintained. It is the sole responsibility of the owner/operator to establish, schedule and

enforce the frequency and scope of these programs in keeping with recommended practice and with due

consideration given to actual operating conditions.

D) The appliance must be operated within limits which will not exceed its working limits. It is the responsibility of the

user to operate this appliance in accordance with the rules and limits described in this manual and the published

product specification sheet, and in accordance with the directions and instructions of the owner/operator of the

appliance or employer, and in accordance with applicable federal, state and local laws and ordinances.

3

TABLE OF CONTENTS T

CHAPTER PAGE

Read First . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safe Operating Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Equipment Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Control Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation

How to Program and Save a Recipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

How to Run a Recipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4

SAFE OPERATING RULES (Part 1 of 2) I

YOU MUST READ AND UNDERSTAND THIS SECTION BEFORE YOU OPERATE THIS APPLIANCE.

Hot Surfaces

The appliance may be hot. Do not contact hot surfaces in the appliance interior without proper protection.

Contact with hot surfaces can cause serious burns, loss of skin and hair and the use of limbs.

The appliance door may not stay open and may close on its own.

Avoid contact with hot surfaces when loading or unloading the oven. Use appliance mitts to handle spits,

forks or baskets. Contact with hot product can cause you to react suddenly and result in spilling or dropping

the product, which can cause physical harm.

Hot Water and Steam

This appliance produces steam in the process of cooking. When opening the loading door, hot air and steam

will be released from the oven interior. Steam is very hot and contact can cause serious burns, loss of skin

and hair, loss of the use of limbs and serious injury to eyes and internal organs. Excessive contact with steam

can even result in loss of life. Open the loading door slowly and keep your face and hands clear of the

opening.

Steam produced by the appliance can cause the floor to become wet. If this happens, wipe or mop up the

water and alert other employees of the hazard.

Steam and/or hot water may be expelled through the appliance drain. The drain line should be connected to

a proper air gap drain during installation to allow excess water to be evacuated from the work area. Steam

and water from the drain may be very hot and contact can cause serious burns, loss of skin and hair, loss of

the use of limbs and serious injury to eyes and internal organs.

Use caution to avoid slipping when operating this appliance or when in the area of the appliance. In the

event that the drain becomes clogged, continued use of the appliance may result in water spilling onto the

floor in the general work area around the appliance. If the drain becomes clogged and water spills on the

floor:

oStop using the appliance to prevent more water spillage.

oMop up and clean up any water on the floor in front of the appliance or in the surrounding work area.

oAlert other personnel, employees, customers or observers of the hazard.

oNotify supervisor, servicer or maintenance persons and have the drain unclogged.

In the normal operation of the appliance, product intended for cooking may spill onto the floor. If this

happens:

oMop up and clean up any product on the floor in front of the appliance or in the surrounding work area.

oAlert other personnel, employees, customers or observers of the hazard.

Sharp Edges and Pinch Hazards

Use caution to avoid contact with sharp edges. Doors, covers, etc. may have edges that can cut or snag skin

and clothes. Use caution when working on, cleaning or servicing the appliance.

Keep hands and fingers out of the path of the loading door when closing to avoid pinching.

Strains, Over-Extension, Over-Exertion and Lifting Hazards

Use caution when loading or unloading heavy product from the appliance. Cooked product may be heavy

and result in sprains, strains or injury to back, arms, hands or legs. Do not lift more than you are safely

capable of lifting.

Other Precautions

Never stand on top of the appliance for any reason.

Do not store anything on top of the appliance.

The oven is not a self-cleaning appliance –do not attempt to burn off surface contamination.

5

SAFE OPERATING RULES (Part 2 of 2) I

YOU MUST READ AND UNDERSTAND THIS SECTION BEFORE YOU OPERATE THIS APPLIANCE.

Smoke or Fire Hazard

If you see flames or smoke in or around the appliance:

oTurn the appliance off and contact your supervisor or an authorized service provider.

oCall 911 or contact fire safety personnel in accordance with your employer’s emergency plan.

oDo not open the loading door as this will allow oxygen to reach any flames and may cause injury to

persons, property damage and may cause loss of life.

Do not operate the appliance or any other appliance if you hear bangs, pops or other abnormal noises. Turn

off the appliance and contact your supervisor or authorized service provider.

Do not allow any flammable materials to be put into the appliance. The following materials are flammable:

oGasoline and petroleum products, including wax and tar.

oWood chips, wood and paper.

oFlour dust and fine corn meal that can become airborne.

oCharred baked products or any other burned material.

oAnimal and vegetable fats that vaporize or become overheated.

Do not operate the appliance if an attached fire suppression system or fire alarm system is dysfunctional or

has been discharged. Contact your supervisor or contact the fire safety system servicer.

If a fire suppression system discharges while you are operating the appliance, turn off the appliance and

follow your employer’s emergency plan, or exit the building or work area.

Electrical Hazard

Do not operate the appliance if electrical covers are removed or there are frayed, burned or exposed wires or

if any live electrical terminals are exposed. Turn off the appliance and any circuit breaker or disconnect

device supplying electrical power to the appliance as described in your employer’s emergency plan.

Do not operate the appliance if any circuit breaker or fuse connected to the appliance becomes tripped and

cannot be reset. Contact your supervisor or authorized servicer or electrician to correct the condition before

operating the appliance. Alert other employees and service personnel to the hazard.

Do not operate the appliance if you feel an electrical shock when in contact with the appliance or other

devices attached to the appliance. Contact your supervisor or authorized servicer or electrician to correct the

condition before operating the appliance. Alert other employees and service personnel to the hazard.

Improper Operation

Do not operate the appliance if covers, doors or other components are removed.

Do not operate the appliance if any other person has applied a lock-out on the electrical supply or has tagged

the appliance in a way to suggest that the appliance not be used. Contact your supervisor for further

instructions or refer to your employer’s safety plan.

Health and Safety in Cooked Products

For the safety and health of those who will consume goods produced through the use of the appliance, use

all caution and diligence to prevent the ingestion of any item or material that is unsafe or unfit for human

consumption.

Do not use the appliance if you see any material floating in the air in the appliance or if you see any foreign

matter in the finished food product.

Do not use the appliance if you smell unfamiliar smells or if you smell any odor that you know to be

unhealthy.

Do not under-cook any product that can carry bacteria such as but not limited to e-coli, salmonella or any

other pathogen.

Do not cook, roast or handle any meat or meat product that contains any known diseases or pathogens.

In all cases, follow all food-safe practices as mandated by law and your employer.

6

EQUIPMENT DESCRIPTION I

Exterior Dimensions

Model LCR5: 32.5” [826mm] Height 31.5” [800mm] Width 26.3” [668mm] Depth

Model LCR7: 38.4” [975mm] Height 38.9” [988mm] Width 32.6” [828mm] Depth

NOTE 1: The depths shown are for LCR5-2D and LCR7-2D two-door (pass through) ovens and exclude handles. For

LCR5-1D, add 0.8” [20mm]. There is no change in depth for the LCR7-1D.

NOTE 2: The heights shown do not include the legs, casters or stand. For countertop legs add 4.0” [102mm]. For

floor legs add 6.0” [152mm]. For casters add 4.5” [114mm]. For the stand add 32.1” [815mm].

Construction

The exterior top, front, rear and sides are constructed of stainless steel, as is the oven cook cavity (including the

carousel parts, drip plates, spits, forks and baskets). The exterior underside is constructed of stainless steel and

corrosion-resistant aluminized steel.

The loading doors include double-pane tempered safety glass with a low-energy coating for increased efficiency.

The inner panes are hinged to make cleaning easier.

The oven cook cavity is insulated with high-temp insulation for reduced heat loss and increased energy

efficiency.

High-output halogen lamps are located at the upper front and rear of the oven to thoroughly illuminate the cook

chamber for easy viewing.

Performance

Fast-acting heater elements are utilized for energy-efficient convective cooking.

Top-mounted fans thoroughly circulate convection air for even browning of the food product.

Capacity

LCR5: 15—20 Chicken Capacity

LCR7: 28—35 Chicken Capacity

Controls

Simple, intuitive and easy-to-understand layout.

Large displays for time, temperature and recipe number.

Sear, roast and warm/hold buttons to facilitate recipe setups.

Up to 3-event recipe capability.

Storage for up to 20 recipes.

6 quick-select buttons for your most-frequently-used recipes.

Carousel and interior fans automatically stop when loading door is opened and automatically resume when door is

closed.

Press-and-hold jog button to rotate carousel while door is open for easier loading and unloading.

Buzzer alarm to indicate end of cook cycle.

Set point ranges from 145-480oF [63-250oC].

Temperature scale can be either oF or oC with a single button press.

On shutdown the last recipe settings used is retained in the control memory and reappears on subsequent startup.

7

CONFIGURATIONS S

Rotisserie

Rotisserie

Countertop or

Floor Mount

Stand Mount

Stacked Appliances

6.0” [152mm] Legs or

4.5” [114mm] Swivel Casters

with Brakes

LST5 Stand (for LCR5 Rotisserie) or

LST7 Stand (for LCR7 Rotisserie or

LHC7 Holding Cabinet)

Combinations:

2 ea LCR5 Rotisseries

2 ea LCR7 Rotisseries

1 ea LHC7 Holding Cabinet + 1 ea LCR7 Rotisserie

NOTE: When a Rotisserie is stacked with a

Holding Cabinet, It may be installed on the top

or bottom

Countertop: 4.0” [102mm] Legs

Floor: 6.0” [152mm] Legs or

4.5” [114mm] Swivel Casters

with Brakes

8

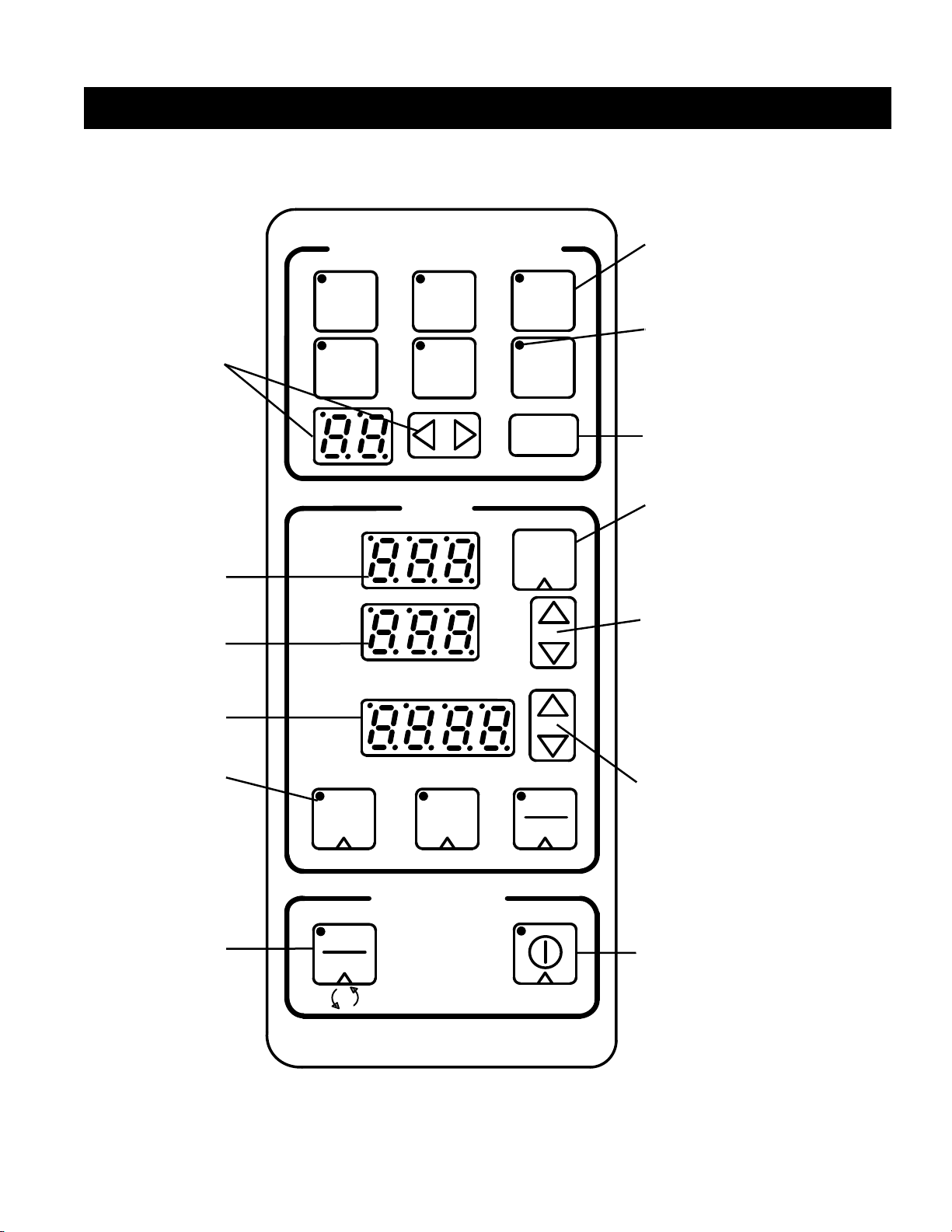

CONTROL OVERVIEW (Part 1 of 3) L

See pages 9 and 10 for more thorough descriptions of the features shown below

ACTUAL

TEMP

SET

POINT

TIMER

POWER

SET

PROGRAM SELECT

START

STOP

WARM

ROAST HOLD

SEAR

OPERATE

1 2 3

4 5 6

SAVE

JOG

BACK

+3

E1. Quick-Select Buttons

Easy access to most-frequently-

used recipes

E3d. Recipe Save Button

Save up to 20 recipes

E1. Recipe Arrow

Buttons & Display

Use arrow button to

scroll through recipes;

recipe number will

appear in display

C. Set Point Arrow Buttons

Use to adjust temp set point

B. Change Temperature Scale

Simultaneously press-and-hold

up and down arrows for 3

seconds to change scale from

oF to oC and back

D. Timer Start/Stop

and Reset Button

Press to start/stop timer;

Press-and-hold for 3

seconds to reset timer

G. Jog Button

Press-and-hold this

button to adjust carousel

position when loading

door is open

D. Timer Arrow Buttons

Use to change cook time

C. Set Point Display

E2. Cook Event Buttons

Press to access existing

settings or to program

new settings for sear,

roast and warm/hold

steps

D. Timer Display

C. Actual Temp Display

E1. Recipe Indicator Light

Illuminates to indicate when a

quick-select recipe has been

opened

A. Power Button

F. Back +3 Button

Use this button to back a

running recipe up one event

to change time and/or temp

9

CONTROL OVERVIEW (Part 2 of 3)(Con tinu )

N O T I C E

During the first few hours of operation, you may

notice a small amount of smoke coming from the

rotisserie and/or a faint odor. This is normal in a

new oven and will disappear after a few hours of

use.

A Power Button. Press this button to turn the oven on or off. The Power indicator light will remain on whenever

the appliance is connected to an electrical supply.

B Change Temperature Scale. The oven can display temperatures in either oF or oC. To change from one scale to

the other, simultaneously press-and-hold both Set Point arrows for 3 seconds. Unless selected otherwise, this

scale will remain active for all future startups. Saved recipes will automatically change to the selected scale.

C Set Point and Actual Temperature. Use the set point arrows to enter the desired temperature, which will appear

in the adjacent set point display. The oven will heat or cool to match the set point and the oven temperature will

appear in the actual temp display

DCook Timer. The timer start/stop and reset button can be used in the following ways:

1Start the Timer. Press the start/stop button once to start the timer. When the timer is counting, the timer

colon will flash. If the loading door is opened while the timer is counting, the countdown will automatically

pause. The countdown will resume when the door is closed. A buzzer will sound when the timer has

counted to zero. Press any button on the control to silence the buzzer.

2Stop the Timer. If the timer is counting, press the start/stop button again to stop the countdown. When

the timer is stopped, the entire timer display will also flash.

3Reset the Timer. Press-and-hold the button to reset the timer.

4Jog Feature. If the loading door is open, the cook timer button will function as a jog button. See the Jog

Button description in this section.

E Recipe Features

1 Storage and Quick-Select Buttons. Up to 20 recipes may be stored. Six large, numbered Quick-Select

buttons allow easy access to your most-frequently-used recipes with a single button push. All recipes can

be accessed with the Program Select arrows. The recipe numbers will appear in the adjacent display as you

advance through the recipes.

2 Cook Event Buttons. The sear, roast and warm/hold buttons allow you to create up to 3 cooking events.

(NOTE: The set point and timer values for all 20 recipes have been factory-programmed for your

convenience. These values may be used as is or changed as needed.)

10

CONTROL OVERVIEW (Part 3 of 3) )

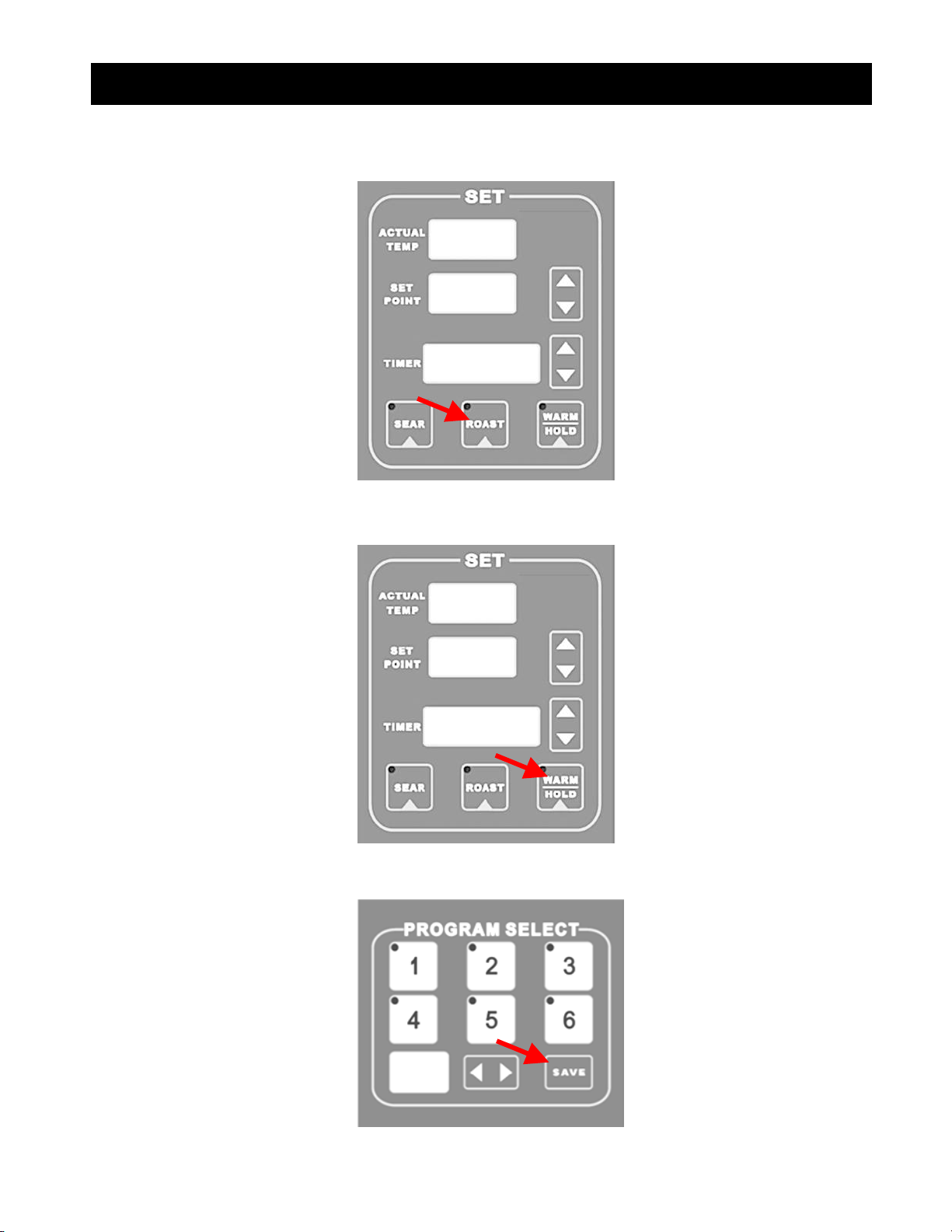

3 Creating and Saving Recipes. To create and save a recipe, do the following:

aSear. Press the sear event button. The sear button light will flash, indicating the sear event is

in programming mode. The temperature and timer values will appear in the adjacent

displays. Use the set point and timer arrows to enter the desired temp and time. (NOTE: If

you wish to skip the sear event for your recipe, change the timer value to “00:00”.)

bRoast. Press the roast event button. The roast button light will flash, indicating the roast

event is in programming mode. The temperature and timer values will appear in the adjacent

displays. Use the set point and timer arrows to enter the desired temp and time. (NOTE: If

you wish to skip this event for your recipe, change the timer value to “00:00”.)

cWarm/Hold. Press the warm/hold event button. The warm/hold button light will illuminate,

indicating the warm/hold event is in programming mode. The temperature will appear in the

adjacent display. (NOTE: The timer display will be blank while in warm/hold mode.)

dSave the Recipe. Press the save button twice to save the recipe.

F Back +3 Button. This button allows you to back up one event to change temperature and/or time in a

running recipe. A single press backs the program up one event and adds 3 minutes to that event.

G Jog Button. Press-and-hold this button to rotate the carousel while the loading door is open. You can also

rotate the carousel by closing the door.

11

OPERATION (Part 1 of 4) )

How to Program and Save a Recipe

Press the power button to turn the oven on.

Select a recipe number. Up to 20 recipes may be saved. Buttons 1 through 6 are Quick-Select buttons

intended for your most-used recipes. Recipes 7 through 20 can be accessed with the program select arrows.

The recipe number selected will appear in the adjacent display.

Setup or deactivate the sear step. To setup, press the sear button and enter a set point and time. If you

prefer to deactivate the sear step, enter a sear time of “00:00.”

12

OPERATION (Part 2 of 4) )

Setup or deactivate the roast step. To setup, press the roast button and enter a set point and time. If you

prefer to deactivate the roast step, enter a roast time of “00:00.”

Setup the warm/hold step. To setup, press the warm/hold button and enter a set point. (NOTE: The warm/hold

step has no time parameter and the timer display will be blank.)

Press save button twice to save your recipe. The oven will automatically adjust to the set temp of the first step

with an active timer value.

13

OPERATION (Part 3 of 4) )

How to Run a Recipe

Press the power button to turn the oven on. (NOTE: The oven will automatically heat to the set temp of the first

recipe step with an active timer value.

Select your recipe. Buttons 1 through 6 are Quick-Select buttons intended for your most-popular recipes.

Recipes 7 through 20 may be accessed with the program select arrows. The recipe number selected will appear in

the adjacent display. The oven will automatically heat to the temperature shown in the set point display.

After the oven has reached temperature, load your product for cooking. (NOTE: When the loading door is open,

the timer start/stop button converts to a carousel jog button. Press the jog button to rotate the carousel wheel

and release the button to stop the wheel.)

14

OPERATION (Part 4 of 4) )

Close the loading door and press the timer start button. The timer light and the timer colon will change to from

steady on to flashing to indicate the timer is active and counting down. (NOTE 1: To stop the timer, press the

timer start button a second time. Press the timer start button a third time to resume the countdown. NOTE 2:

To reset the timer, press and hold the timer start button for 3 seconds. NOTE 3: The timer countdown will pause

whenever the loading door is opened and resume when the loading door is closed again.)

A brief buzzer alert will sound when one step finishes and another begins. Press any button to silence the alert.

If needed, both the temperature and/or time can be modified for the step showing in the control displays. (NOTE

1: Only the currently-displayed step can be changed. NOTE 2: To save the modifications, press the save button

twice. Otherwise, the modifications will not be saved into memory.)

When the buzzer alert sounds to indicate the cook cycle has elapsed, open the door and check the internal

temperature of the cooked product with a temperature probe.

Either remove the cooked product or leave it in the oven during the warm/hold step.

15

MAINTENANCE and CLEANING W

C A U T I O N

MOST CLEANERS ARE HARMFUL TO THE SKIN,

EYES, MUCOUS MEMBRANES AND CLOTHING.

PRECAUTIONS SHOULD BE TAKEN WHEN USING

THEM. WEAR RUBBER GLOVES, GOGGLES OR

FACE SHIELD AND PROTECTIVE CLOTHING.

CAREFULLY READ THE WARNING AND FOLLOW

THE DIRECTIONS ON THE LABEL OF THE

CLEANER TO BE USED.

DISABLE ELECTRICAL POWER AT SERVICE

BREAKER BEFORE CLEANING OVEN.

W A R N I N G

KEEP WATER AND SOLUTIONS OUT OF

CONTROLS. NEVER SPRAY OR HOSE

CONTROL CONSOLE.

W A R N I N G

C A U T I O N ALWAYS KEEP THE AREA NEAR THE APPLIANCE

FREE FROM COMBUSTIBLE MATERIALS.

C A U T I O N

KEEP THE FLOOR IN FRONT OF THE APPLIANCE

CLEAN AND DRY. IF SPILLS OCCUR, CLEAN

THEM IMMEDIATELY TO AVOILD THE DANGER

OF SLIPS OR FALLS.

N O T I C E Never use chlorine-based cleansers on this

appliance. Chlorine corrodes stainless steel.

N O T I C E

To maintain optimum safety and performance,

it is recommended that a program of regular

maintenance be implemented. It is the sole

responsibility of the user to establish, schedule

and enforce such a program. Although the actual

service schedule will vary depending on the

environment in which the equipment is

operating, it is recommended that the above be

done by an LBC-authorized service

representative every six months.

After Each Use

Remove all skewers or baskets from the carousel. Wash them with warm water and soap and rinse with water.

Daily

Remove the drip plates and skewers or baskets. Sink-wash these parts with warm water and soap.

Clean the oven interior and exterior with warm water, soap and a soft cloth. Clean the rotor wheel and shaft, walls and ceiling

parts. Clean the control with a damp cloth only. Do not allow water to run down the face of the control.

With the loading door open, hinge the inner glass frame outward for cleaning. Do not use abrasive cleaners or

wash pads as abrasives will damage the low-energy coating.

NOTE: Oven models LCR5 and LCR7 are not designed to be self-cleaning. Do not attempt to burn off surface

contamination.

16

PARTS LIST W

N O T I C E

Service on this or any other LBC appliance must

be performed by qualified personnel. For an

approved service representative in your area,

visit our website at www.lbcbakery.com or call

our factory toll free at 1-888-722-5686.

C A U T I O N

USE OF ANY REPLACEMENT PARTS OTHER THAN

THOSE SUPPLIED BY LBC OR THEIR AUTHORIZED

DISTRIBUTORS CAN CAUSE BODILY INJURY TO

THE OPERATOR AND/OR DAMAGE TO THE

APPLIANCE AND WILL VOID ALL WARRANTIES.

BOTH HIGH AND LOW VOLTAGES ARE

PRESENT INSIDE OF THIS APPLIANCE WHEN

THE UNIT IS PLUGGED/WIRED INTO A LIVE

RECEPTACLE. BEFORE REPLACING ANY PARTS,

DISCONNECT THE UNIT FROM THE ELECTRIC

POWER SUPPLY.

W A R N I N G

To order any of the parts or accessories listed below, visit our website at www.lbcbakery.com. You may also call our

factory toll free at 1-888-722-5686, or fax us at 1-425-642-8310, or email us at service@lbcbakery.com.

Item No.

Part Description

Quantity

Per Oven

Part No.

Usage

1

1000W Interior Light

2

31602-08

5-Spit Only

500W Interior Light

2

31603-87

7-Spit Only

2

Stand with Casters

1

LST7

7-Spit Only

3

4" Adjustable Leg

4

180-733-4

Countertops Only

4

6" Adjustable Leg

4

180-733

Floor Installations

5

Carousel Assembly, Stainless Steel

1

180-768-1

5-Spit Only

Carousel Assembly, Stainless Steel

1

180-768-2

7-Spit Only

Carousel Assembly, Non-Stick Coating

1

180-768-1C

5-Spit Only

Carousel Assembly, Non-Stick Coating

1

180-768-2C

7-Spit Only

6

Angle Spit, Stainless Steel

5

LCR5-SV

5-Spit Only

Angle Spit, Stainless Steel

7

LCR7-SV

7-Spit Only

Angle Spit, Non-Stick Coating

5

LCR5-SV-C

5-Spit Only

Angle Spit, Non-Stick Coating

7

LCR7-SV-C

7-Spit Only

7

Fork Spit, Stainless Steel

5

LCR5-SF

5-Spit Only

Fork Spit, Stainless Steel

7

LCR7-SF

7-Spit Only

Fork Spit, Non-Stick Coating

5

LCR5-SF-C

5-Spit Only

Fork Spit, Non-Stick Coating

7

LCR7-SF-C

7-Spit Only

8

Basket, Stainless Steel

5

LCR5-SB

5-Spit Only

Basket, Stainless Steel

7

LCR7-SB

7-Spit Only

Basket, Non-Stick Coating

5

LCR5-SB-C

5-Spit Only

Basket, Non-Stick Coating

7

LCR5-SB-C

7-Spit Only

9

Loading Door Handle Assembly

1 or 2

180-781-1

5-Spit Only

Loading Door Handle Assembly

1 or 2

180-781-2

7-Spit Only

10

Hand Held Probe Kit

1

Kit, Rotisserie 5

All

31603-87

180-733

180-768-1

180-768-1C

LCR5-SF

LCR7-SF

LCR5-SB

LCR7-SB

17

NOTES T

18

This manual suits for next models

1

Table of contents

Other sinmag Oven manuals