sinmag LBC SE Series User manual

© COPYRIGHT 2019 LBC BAKERY EQUIPMENT, INC. 2 REV J 8/2021

Table of Contents

Page 3 Cautions

Page 4 Installation

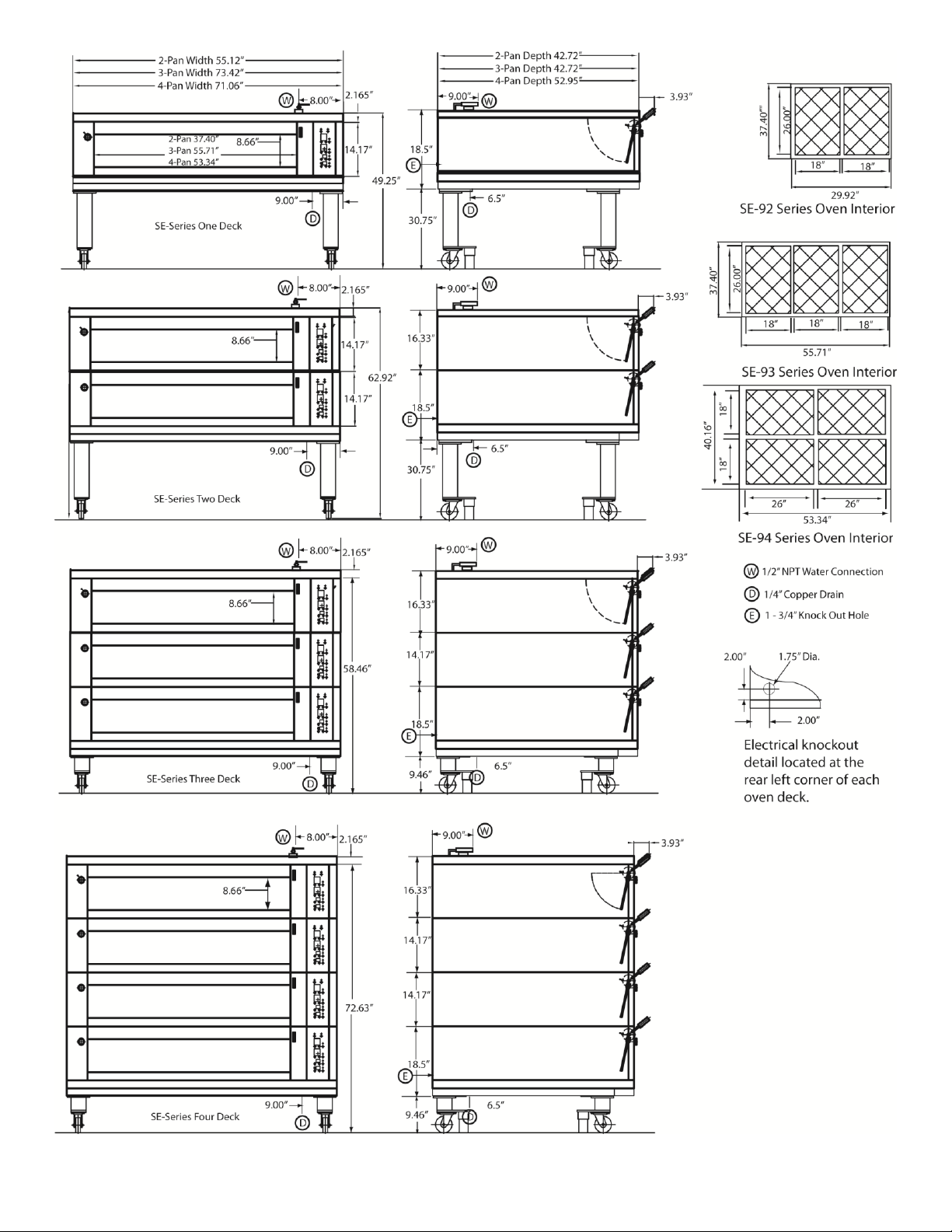

Page 5 Dimensions

Page 6 Connections

Page 9 Start-Up

Page 10 Trouble-shooting

Page 11 Operation

Page 11 Oven Control

Page 12 Loading the oven

Page 12 Starting a Bake

Page 13 Cleaning and Maintenance

Page 15 Parts Illustrations and Lists

Page 20 Notes

Page 22 Limited Warranty Information

© COPYRIGHT 2019 LBC BAKERY EQUIPMENT, INC. 3 REV J 8/2021

DISCONNECT FROM POWER SOURCE WHEN CLEANING AND/OR SERVICING

THIS MACHINE

NEVER ATTEMPT TO CLEAN THIS MACHINE WHILE IT IS HOT OR HEATING AS

RISK OF SERIOUS INJURY COULD RESULT

NEVER OPERATE THIS MACHINE WITH SAFETY COVERS OR INSPECTION

PLATES REMOVED OR WITH SAFETY SWITCHES INOPERATIVE

The SE Deck oven has been packaged to withstand rough handling; however, it

is important that you inspect the shipment for damages, concealed or otherwise

and that you sign the bill of lading to note any such damages. These damages

are the responsibility of the consignee and must be reported to the carrier within

10 days in order to file for a claim.

LBC Bakery Equipment, Inc. will not warrant any equipment that is not installed

by a trained installation contractor or that has not been connected to utilities by

a licensed electrician and plumber. Please consult our warranty at the end of

this document.

CAUTION!

DO NOT OPERATE, CLEAN OR SERVICE THIS MACHINE BEFORE

READING THIS MANUAL AND UNDERSTANDING COMPLETELY THE

SAFETY INSTRUCTIONS FOUND IN THIS MANUAL AND ON THE

MACHINE’S LABELS

IMORTANT!

ALL OPERATORS OF THIS OVEN MUST BE OF LEGAL AGE TO

OPERATE SUCH EQUIPMENT AND MUST BE FAMILIAR WITH AND

UNDERSTAND ALL CAUTION LABELS.

IMORTANT!

THIS OVEN IS DESIGNED FOR DIRECT HEARTH BAKING OF BREAD

PRODUCTS AND PIZZA ONLY. ALL OTHER PRODUCTS MUST BE

BAKED IN A PAN OR ON OTHER MEDIA.

© COPYRIGHT 2019 LBC BAKERY EQUIPMENT, INC. 4 REV J 8/2021

I:

Installation Section

A: Installation

The SE deck oven requires some assembly by an authorized LBC trained service

technician.

In the US the SE deck oven must be installed in accordance with:

1. State and local codes

2. National Electrical Code (ANSI/NFPA no. 70, latest edition) available from

the National Fire Protection Association, Batterymarch Park, Quincy MA

02269

In Canada, the SE deck oven must be installed in accordance with:

1. Local codes.

2. Canadian Electrical Code (CSA C22.2 No. 3 latest edition) available from

the Canadian Standards Association, 5060 Spectrum Way, Mississauga,

Ontario L4W 5N6

Check with your local building department to determine if the oven will need to

be placed under a hood. Information on the construction and installation of

ventilating hoods may be obtained from Vapor Removal from Cooking

Equipment, NFPA Standard no. 96 (latest edition)

The installation location should be free and clear of all obstruction.

The floor should be smooth and level and must be capable of supporting the

weight of the appliance.

Allow adequate clearance at the sides of the oven for serviceability. Allow 42” at

the front of the oven so that it can be pulled forward for servicing.

The SE deck oven is equipped with four (4)

leveling feet located under the equipment

stand, two at the front and two at the rear.

Once the oven is installed in its operating

position, lower the feet by turning them

clockwise to level and secure the appliance

from movement.

© COPYRIGHT 2019 LBC BAKERY EQUIPMENT, INC. 5 REV J 8/2021

© COPYRIGHT 2019 LBC BAKERY EQUIPMENT, INC. 6 REV J 8/2021

Deck ovens are shipped individually and will need to be stacked. It is very important to

use the proper material handling equipment.

1. Place the stand in an area that is level and can support the weight of the oven.

2. Lower the feet on the stand so that it will not move during the assembly process.

3. Place the first deck on the stand and secure it in place using the supplied XXX

fasteners.

4. Stack other decks on top of each other and secure them in place using the

stacking kits clips and fasteners.

5. Use a suitable 1.75” strain reliever to connect the power supply to the oven.

6. Wire the decks together using copper wire suitable for 90 degrees C and suitable

for the amperage of the branch circuit protector supplying the ovens.

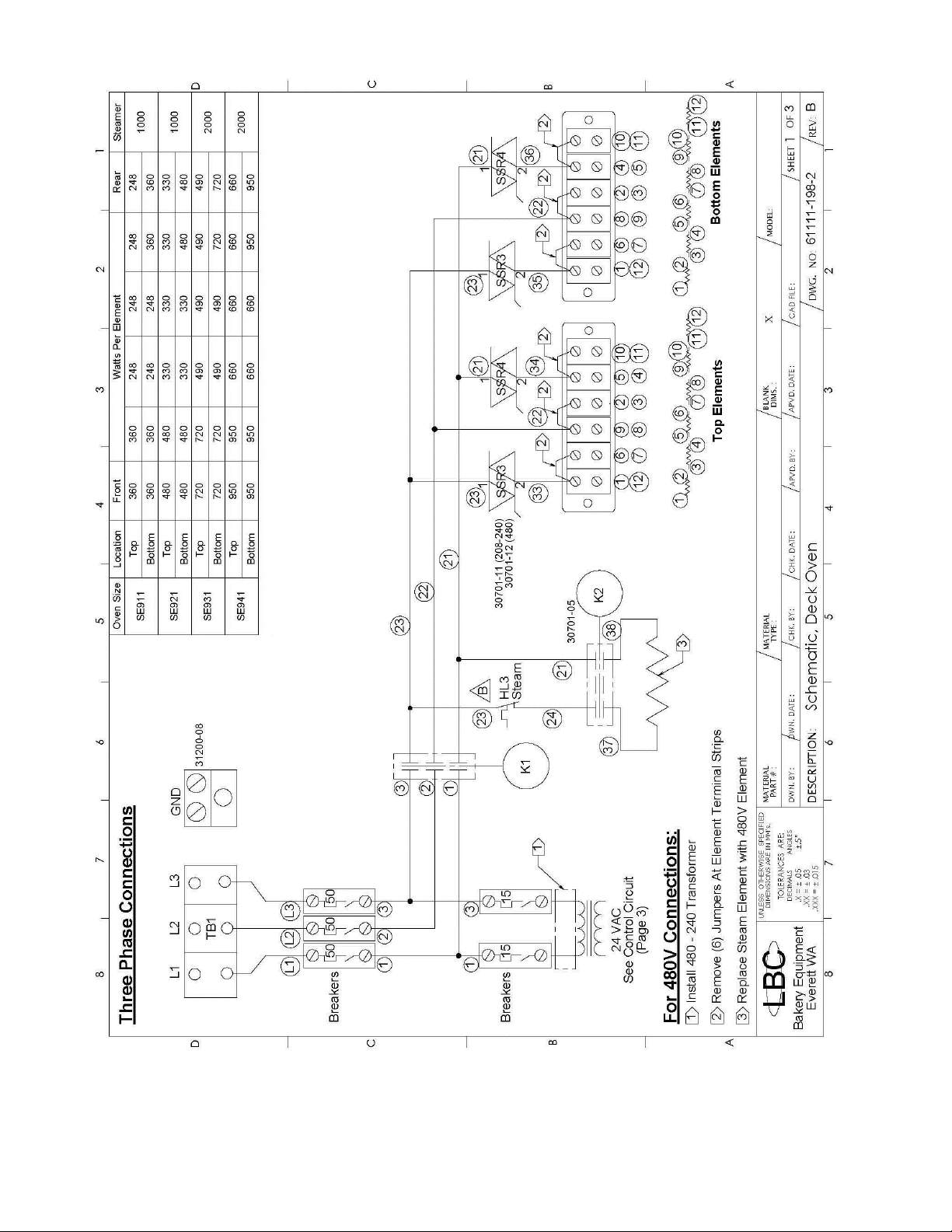

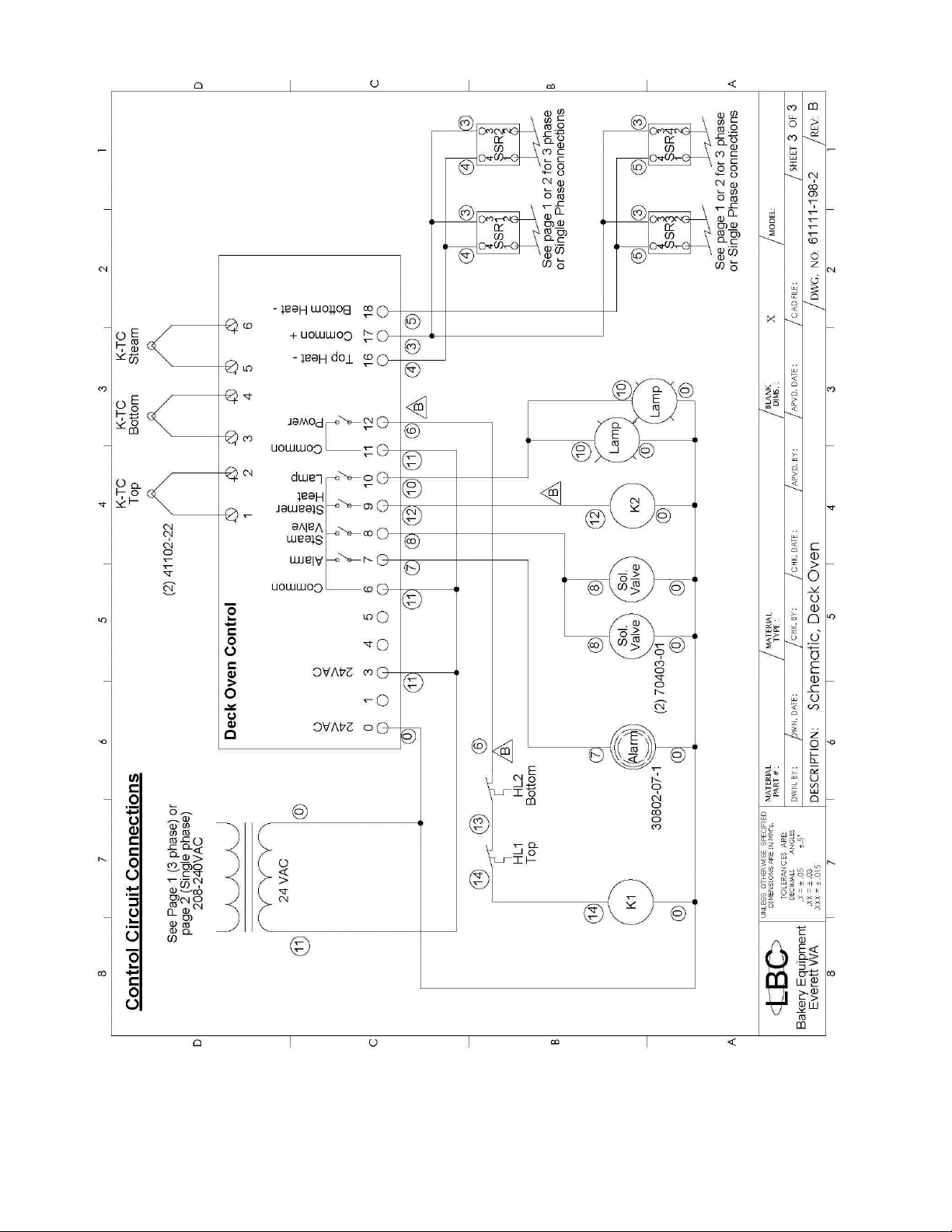

B: Electrical Connections

Electrical connection must comply with all applicable State and local codes and in

accordance with the NEC and NFPA.

Electrical connections MUST be made by a licensed electrician.

A separate service disconnect should be installed so that main power can be

disconnected during service.

Use only Copper Wire Rated at 90 Degrees Centigrade

The oven must be installed with the provided lanyard securely attached to the

stand and to the wall. Verify that all connections are long enough so that the

oven can be pulled forward to the extent of the lanyard without straining any

connection.

Electrical and grounding connections must comply with the applicable portions of

the National Electrical Code and or other local codes.

© COPYRIGHT 2019 LBC BAKERY EQUIPMENT, INC. 7 REV J 8/2021

Disconnect the electrical power to the unit and follow lockout / tag out

procedures.

C: Water Requirements

As with all steam related products, water filtration and regular filter

replacements, coupled with routine deliming are required.

Proper water quality can improve the taste of the food prepared in the oven,

reduce liming and extend equipment life. Local water conditions vary from one

location to the other. The recommended water hardness is 2.0 to 6.0 grains of

hardness per gallon with pH from 7.0 to 8.0. Chlorides must not exceed 30 parts

per million. Water hardness above 6.0 grains per gallon should be treated by a

water conditioner (water softener or in-line water treatment). Water hardness

below 4.0 grains per gallon may also require a water treatment system to reduce

potential corrosion.

© COPYRIGHT 2019 LBC BAKERY EQUIPMENT, INC. 8 REV J 8/2021

D: Plumbing Connections

:

Water and waste piping and connections shall comply with the international

Plumbing Code 2003, International Code Council (ICC), or to the Uniform

Plumbing Code 2003, International Plumbing and Mechanical Officials (IAPMO)

Plumbing connections must comply with applicable sanitary, safety and plumbing

codes and provide adequate backflow protection to comply with applicable

federal, state and local codes. A 100 mesh strainer must be installed

immediately upstream of a check valve-type back-flow preventer.

Each oven deck is equipped with a “Steam Pod” located behind the access panel

rear of the oven(s); drains are required for these steam pods. Note: this

appliance has atmospheric steam generation and does not create any positive

pressure in the oven chamber or in the steam generator pods.

Water to this appliance should be treated to prevent build-up of minerals and

rust in the steam pods and water system.

The bottom deck oven is supplied from the factory with a ½”

NPT ball valve and “Y” strainer. The water supply connection is

made at the ½” ball valve. The supply connection should be

made with a suitable flexible line to allow the oven to be

moved in and out of position.

Subsequent decks will need to have the

water lines linked together using the

supplied braided hoses, 10mm copper

tubing, and compression fittings.

Inspect final connections for leaks.

Water Supply

Drain

© COPYRIGHT 2019 LBC BAKERY EQUIPMENT, INC. 9 REV J 8/2021

E: Start-Up

Before using the oven for the first time, when new stone deck is installed, or if

the stone deck has been cleaned with water, the baking stone need to be slowly

“baked in” prior to start-up. Use the following chart as a guide for the first

start-up to properly season the baking stone.

Parameter

Step 1

Step 2

Step 3

Step 4

Step 5

Top Heat

150 F

250 F

350 F

450 F

550 F

Bottom Heat

150 F

250 F

350 F

450 F

550 F

Bake Time

30 Min.

30 Min.

30 Min.

30 Min.

30 Min.

Steam

None

None

None

None

None

Steam Vent

Open

Open

Open

Open

Open

© COPYRIGHT 2019 LBC BAKERY EQUIPMENT, INC. 10 REV J

8/2021

F: Trouble Shooting

Oven does not heat Check main power is on

Check internal circuit breakers

Check that over-temp limit has not tripped (This is

a thermal device, allow to cool and re test)

Check voltage at elements

Check that contactors have not tripped; reset if

necessary.

Oven Slow to Heat Check supply voltage matches rating on data plate

Electrical phase is out

Check that all elements are operational

Check internal circuit breakers

Temp display reading backwards Thermocouple wire backwards

Oven looses temp. Excessive steam time

Circuit breaker tripped out

Element out

Contactor tripped

Uneven baking Oven not loaded correctly (see page 10)

Element out

Circuit breaker tripped

Contactor tripped

No Steam Water supply is not on

Ball valve closed

Blockage in “Y” Trap

Solenoid defective

For the installation company:

I/we certify that the SE-9 model

electric deck oven serial number(s)

has been installed and tested and is in excellent operating

condition.

Signed by: Date

Please sign and return this to LBC Bakery Equipment, Inc5901 23rd Drive West, Suite 105, Everett

WA 98203

© COPYRIGHT 2019 LBC BAKERY EQUIPMENT, INC. 11 REV J

8/2021

II: Operation Section

Please take a few minute to have all operators read and understand these instructions

CAUTION: Always wear protective gloves or use a wooden oven peel when loading or

unloading the deck oven as there is risk of serious injury from hot surfaces.

© COPYRIGHT 2019 LBC BAKERY EQUIPMENT, INC. 12 REV J

8/2021

A: Controls Operations

1. Press the main On/Off key

2. Using the temperature adjustment keys set the desired top and bottom

temperatures.

a.

Very Important

: The temperature difference between the top and

bottom heat should NEVER be more than 50 degrees.

3. Allow the oven to heat to the desire temperature; at initial start-up allow

30

minutes

for the oven stones to saturate.

a. The steam system will begin heating as soon as the oven is turned on.

4. Set the desired bake time by using the up or down timer keys

5. Set the desired steam time by using the up or down steam timer arrows

a.

Very Important

: It is not recommended that you exceed more than 6

Seconds of steam as this will cause a severe drop in temperature and

poor baking results.

b.

EXTREMELY IMPORTANT

:NEVER STEAM THE OVEN WITH THE

LOADING DOORS OPEN AS RISK OF SERIOUS BURNS WILL RESULT!

c. It will take about 10 minutes between steaming for the system to

recover.

B: Loading the Oven

Depending on your particular model the deck oven will hold either two, three or four

18”x26’ sheet pans wide. If partial loads are going to be used please follow these very

important instructions to ensure you achieve even baking results.

Regardless of the type of pan used it is important to keep them spaced evenly and as

close to centered as possible to avoid uneven baking results.

Product may be placed directly on the oven stones. Use the same centering techniques

as shown above.

CAUTION:

Products such as pizza, artisan bread or other bread products may be

baked directly on the hearth stone. All other products must be cooked in a pan

or on other medium to prevent contact with the deck stone. If food products

spill onto the deck stone, clean by scraping or brushing off the excess material.

DO NOT WASH WITH WATER. See Section

D: Cleaning and Maintenance

for

instructions.

C: Starting a Bake

With the oven loaded and the doors closed press the start stop key.

If steam is desired press the Steam Start Stop key.

To vent the steam pull the vent knob located at the front left of the oven deck.

At the end of the bake, open the oven door slightly to allow and steam to escape the

open the door fully and use a peel to remove the finished product.

© COPYRIGHT 2019 LBC BAKERY EQUIPMENT, INC. 13 REV J

8/2021

D: Cleaning and Maintenance

When the oven is cool:

Inspect the oven interiors and clean any loose debris from the oven stones. A

long handled hearth broom is best.

Remove any baked on product with a brass brush or scraper.

NEVER WASH THE HEARTH STONES WITH WATER OR CHEMICALS AS THEY

MAY BREAK OR SHATTER WHEN HEATED!

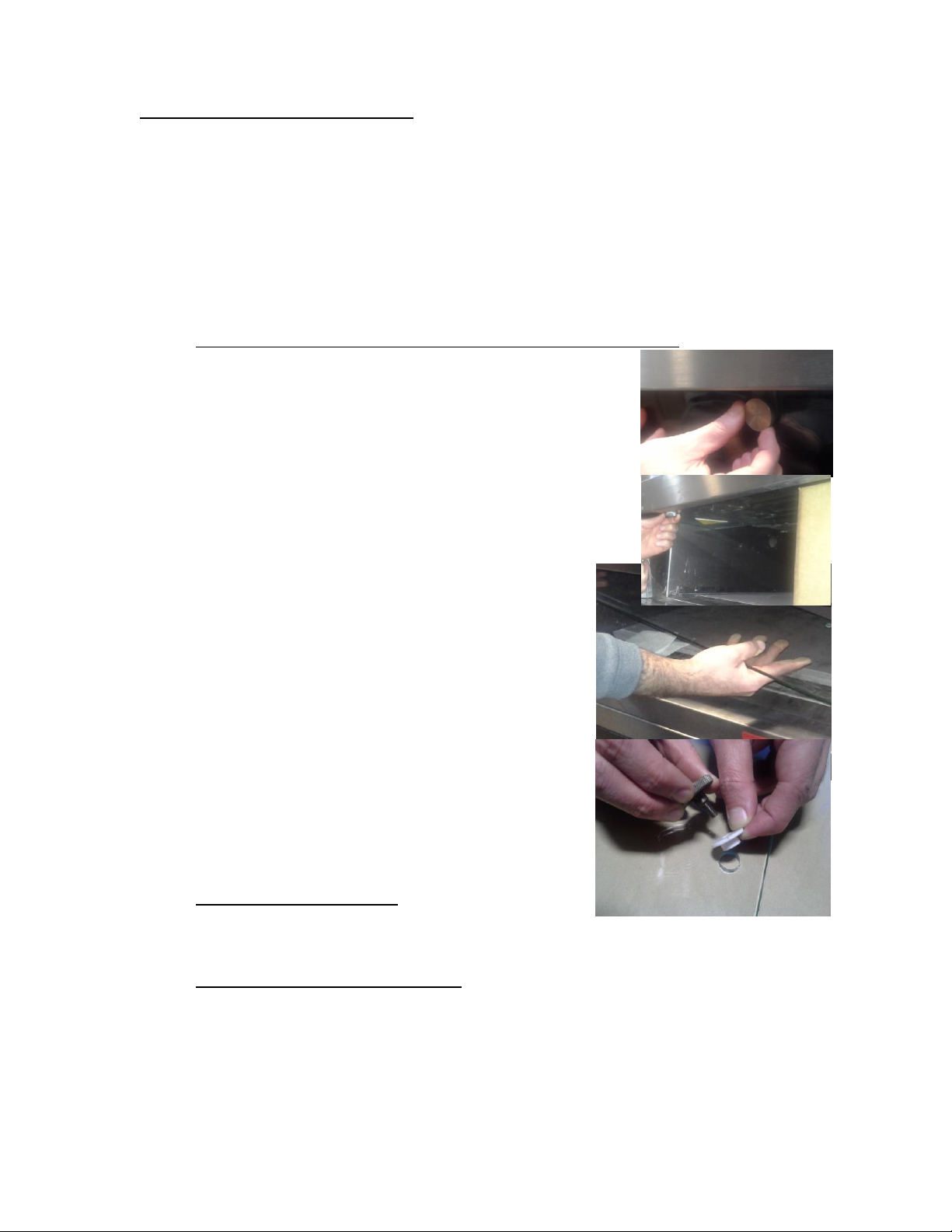

To clean above the door and the back side of the window glass:

1. Allow the oven interior to cool to

room temperature. Remove the

center knurled head screw from the

door glass.

2. Open the door. With assistance,

remove the remaining screws from

the door as shown. If you do not

have assistance, place an 8” box

under the door in the center.

3. Remove the glass from the oven by

tilting one end up as shown. Place

on a clean flat surface. Clean the

glass with paper or cloth and a mild

glass cleaner solution.

4. Use a brush or damp cloth to clean

the space above the door and above

the heating elements. DO NOT

SPRAY WATER INTO THE OVEN.

5. Replace the door in the oven. Use

paper towel to support the glass at

the bottom. Reinstall the knurled

headed screws through the glass

into the hinge. Be sure the Teflon®

washer and hole liners are in place.

Tighten the screws by hand only.

Clean the exterior surfaces with a damp

cloth and polish with a commercial grade

stainless steel polish.

Check and replace any water filters that may have been installed at the incoming

water line.

© COPYRIGHT 2019 LBC BAKERY EQUIPMENT, INC. 14 REV J

8/2021

If needed, you may lift the oven stone(s) to thoroughly clean under them. Use

extreme caution when lifting the stones.

1. Open the loading door. Allow the oven

to cool to room temperature.

2. Remove the door stops on the left and

right side of the door.

3. Remove the angles on the sides of the

deck that hold the deck down.

4. Place a screw driver or other tool into

the hole in the front of the forward deck

clamp. Lift the deck and slide a board

under the deck.

5. Use a vacuum cleaner to remove any

debris under the deck.

6. Replace the deck and clamp parts when

completed.

7. Replace the door stops on the left and

right sides.

© COPYRIGHT 2019 LBC BAKERY EQUIPMENT, INC. 15 REV J

8/2021

E: Parts Illustrations and Listing

Item No.

Part No.

Description

1

11090-43

Element SE-92X Deck Oven, 208V 330 Watts

1

11090-44

Element SE-92X Deck Oven, 208V 480 Watts

1

11090-45

Element SE-92X Deck Oven, 208V 330 Watts

1

11090-46

Element SE-92X Deck Oven, 208V 480 Watts

1

11090-47

Element SE-93X Deck Oven, 208V 490 Watts

1

11090-48

Element SE-93X Deck Oven, 208V 720 Watts

1

11090-49

Element SE-93X Deck Oven, 208V 490 Watts

1

11090-50

Element SE-93X Deck Oven, 208V 720 Watts

1

11090-51

Element SE-94X Deck Oven, 208V 660 Watts

1

11090-52

Element SE-94X Deck Oven, 208V 950 Watts

1

11090-53

Element SE-94X Deck Oven, 208V 660 Watts

1

11090-54

Element SE-94X Deck Oven, 208V 950 Watts

2

11090-55

Element SE-92X Steam Pod, 208V 1000 Watts

2

11090-56

Element SE-93X and SE-94X Steam Pod, 208V 2000 Watts

2

11090-57

Element SE-93X and SE-94X Steam Pod, 240V 2000 Watts

3

41100-42

Thermocouple, K type

4

30401-33

High Limit Thermostat

5

30401-33-2

High Limit Thermostat; Steam Pod

6

40102-82

Circuit Board, SE Deck Oven

7

30701-12

Solid State Relays

8

30700-17

Contactor, 3-Pole 50 Amp

9

31400-32

Transformer, LRP, 208-240 Primary 24-12 Secondary 40VA CL2

10

70403-01

Solenoid Valve

11

31800-13-1

Circuit Breakers, 15 Amp

12

31602-23

Lamp, Halogen(Behind Panel)

© COPYRIGHT 2019 LBC BAKERY EQUIPMENT, INC. 16 REV J

8/2021

E: Parts Illustrations and Listing

Item

No.

Part No.

Description

6

40102-82

Circuit Board, SE Deck Oven

13

50800-104

Handle, Deck Oven Door

14

71401-34

Oven Stone, SE-92 Two Pan

14

71401-35

Oven Stone, SE-93 Two Pan

14

71401-36

Oven Stone, SE-94 Two Pan

15

71300-34

Oven Door, Glass, SE-92 Two Pan Oven

15

71300-35

Oven Door, Glass, SE-93 Three Pan Oven

15

71300-36

Oven Door, Glass, SE-94 Four Pan Oven

16

50800-105

Knob, Vent

17

72901-39

Caster, Deck Oven Stand

18

72901-40

Leveler Foot Deck Oven

© COPYRIGHT 2019 LBC BAKERY EQUIPMENT, INC. 17 REV J

8/2021

© COPYRIGHT 2019 LBC BAKERY EQUIPMENT, INC. 18 REV J

8/2021

© COPYRIGHT 2019 LBC BAKERY EQUIPMENT, INC. 19 REV J

8/2021

© COPYRIGHT 2019 LBC BAKERY EQUIPMENT, INC. 20 REV J

8/2021

Notes:

This manual suits for next models

4

Other sinmag Oven manuals

Popular Oven manuals by other brands

AEG

AEG BSK792380B user manual

Siemens

Siemens iQ700 CM656GBS1/B8 User manual and installation instructions

Frigidaire

Frigidaire FRIGIDAIRE FEB24S2A Specifications

Siemens

Siemens CB675GB 1 Series instruction manual

NEFF

NEFF B57VS24.0B User manual and installation instructions

Hisense

Hisense BI5221PX Detailed instructions