SINUS PLASMA 35/40 User manual

1

PLASMA LINE

SINUS PLASMA 35/40

USER MANUAL

MANU.115.X.PLA.xx 2009 beta

Valued Customer,

Hoping you will find our product to your satisfaction, we welcome you to our family,

informing you that the ERGUS marked machines have been ISO 9000:2001 certified, thus

guaranteeing greater product reliability and quality.

Tec.La is certified by RINA for quality system.

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

GENERAL SAFETY INFORMATION..........................................................................................4

THE PLASMA CUTTING.............................................................................................................6

DESCRIPTION OF POWER SOURCE........................................................................................6

1. Placing the equipment..............................................................................................................7

2. Receipt of materials.................................................................................................................7

3. Front panel controls.................................................................................................................8

INSTALLATION OF PLASMA CUTTING MACHINES................................................................9

1. Plasma cut defects.................................................................................................................11

2. Cutting capability....................................................................................................................11

TORCH MAINTENANCE...........................................................................................................11

TORCH SAFETY.......................................................................................................................11

TORCH EXPLODED VIEW .......................................................................................................12

TECHNICAL DATA ...................................................................................................................13

BLOCK DIAGRAM....................................................................................................................14

SPARE PARTS LIST.................................................................................................................15

GENERAL SAFETY INFORMATION

GENERAL SAFETY INFORMATIONGENERAL SAFETY INFORMATION

GENERAL SAFETY INFORMATION

Electric shock

ELECTRIC SHOCK CAN KILL.

•Do not touch the parts under high voltage;

•Disconnect the power supply from mains before any intervention;

•Operator must be insulated from the piece to be cut and from the ground, wearing insulated

gloves and clothing;

•Do not work with damaged or poorly connected cables or with slack cable clamps;

•Keep work clothing and your body, dry;

•Do not work in moist or wet areas;

•Do not lean against the pieces to cut;

•Protect the power source with a suitable circuit breaker, placed near the workpiece, if possible;

•Do not use the machine if any of its protection parts have been removed;

•Make sure that the mains in use is earthed.

Explosions

•Do not cut above or near containers under pressure;

•Do not cut containers that have combustible or inflammable contents;

•Do not cut in areas containing explosive dusts, gases or vapours;

•Always use a pressure gauge to connect the machine gas hose to the bottle;

•Do not use damaged or leaking bottles;

•Do not use bottles that do not show what kind of gas they contain;

•Do not expose bottles to sources of excessive heat;

•Never mix the gas inside bottles;

•Have always refilled bottles by specialized companies;

•Avoid accidental contact between bottles and the electrode or other parts under voltage;

•Replace gas hoses that show damage;

•Keep pressure reducer efficient;

•Use only pressure reducers manufactured for the specific gas.

Fire

•Avoid flames being generated by sparks, slag and incandescent materials;

•Make sure that fire extinguishing devices are available near the work area;

•Remove inflammable and combustible materials from the area.

Burns

•Protect the body from burns and ultraviolet radiations by wearing protective flameproof clothing (gloves –

headwear – shoes – helmets, etc.);

•Wear a protective helmet;

•Keep the electrode or torch tip away from your body and other people’s bodies;

•Make sure that there is first aid equipment near the work area;

•Do not wear contact lenses, the intense heat of the arc could glue them to the cornea;

•Replace mask glass if it is damaged or not suited to the specific cutting job;

•Wait for the cut workpieces to cool completely before touching them with your hands.

Fumes

Cutting produces fumes and harmful metallic dusts, therefore:

•Clean the material to be cut if solvents or other materials that can release toxic gases are present;

Do not cut metals covered with or containing lead, cadmium, graphite, zinc, chrome, mercury, if there is not an

adequate exhaust fan;

•WARNING: do not use oxygen for ventilation!!!

Radiation

The cutting arc produces radiations that can harm eyes and cause skin burns. Use suitable protection.

Noise

The cutting arc respects current legislation on noise levels (not exceeding 80db); Protective ear

plugs or muffs must be worn to avoid damage when working overhead or in small areas.

Heat, jets of melted metal and sparks

During cutting, the heat, jets of melted metal and sparks can cause fires:

•Do not cut near inflammable materials.

•Avoid carrying any type of combustible material such as lighters or matches.

•

The cutting arc can cause burns. Keep the torch away from your body and other people’s bodies;

Electromagnetic disturbance

The power source respects legislation regarding electromagnetic disturbances and is suitable for work in industrial

surroundings.

However, it is necessary to remember and take necessary provisions if there are disturbances to:

•Data transmission systems;

•Communication devices;

•Switch board controls;

•Safety equipment;

•Calibration and measurement instruments.

Pacemaker wearers

The magnetic fields coming from high voltage or frequency can interfere with pacemakers.

Pacemaker wearers must consult their doctor before using this type of equipment or working in the area where it is

present.

Moving parts

Keep all protective doors and coverings in place;

Keep hands, hair and clothing away from moving parts (fan, rotator, wire feeder for MIG machines).

DANGER SIGNS

ACCIDENT PREVENTION SIGNS

GENERIC DANGER

EXPLOSIVE MATERIAL

INFLAMMABLE MATERIAL

DANGEROUS ELECTRICAL

TENSION

POISONOUS SUBSTANCES

BLINDING

SAFETY FOOTWEAR

REQUIRED

BODY PROTECTION

REQUIRED

PROTECTIVE GLOVES

REQUIRED

EYE PROTECTION

REQUIRED

HEARING PROTECTION

REQUIRED

EXTINGUISHER

FIRST AID

THE PLASMA CUTTING

THE PLASMA CUTTINGTHE PLASMA CUTTING

THE PLASMA CUTTING

This procedure cuts all conductor materials such as: Fe • Stainless steel • aluminium • brass • copper, etc... The

plasma cut is used for rapidly cutting all conductor materials, without creating burrs and without deforming even the

thinnest sheet metal. All this is due to the very high temperatures (about 20,000°C – 36.000 F°) of th e plasma arc,

which is created using the nitrogen present in the air (about 78%) and the current generated by the power source.

These two elements are conducted into the calibrated hole of the plasma torch nozzle, forming the concentrated,

consistent arc for metal cutting.The pilot arc start-up creates the cutting arc, starting at a distance from the piece or

in contact with it, since it perforates the insulation created by paints, oxides, plastic coating, etc.; this avoids all

problems created by contact starting without the pilot arc.

DE

DEDE

DESCRIPTION OF POWER SOURCE

SCRIPTION OF POWER SOURCESCRIPTION OF POWER SOURCE

SCRIPTION OF POWER SOURCE

Portable SINUS PLASMA 35/40 ADV single phase inverter generator is a systems for cutting carbon steel,

stainless steel, aluminium and other metals with the compressed air plasma technique starting with a pilot arc.

Their basic parts are:

1. Control electronics

2. Power electronics

Reduced size and weight make these cutters ideal for operators having frequent moving jobs.

The inverter frequency eliminates the characteristic noise of old generation electronic power sources. The cut is

more effectively controlled due to the progress of electronic research.

The quality of materials used for manufacturing the ERGUS machines guarantees high performance, long life and

low maintenance.

BEFORE PLUGING AND USE, READ THIS INSTRUCTION MANUAL CAREFULLY.

By following the instructions you can avoid incorrect machine installation.

Damage due to incorrect use invalidates the guarantee.

FOR SPECIAL MAINTENANCE, CONTACT THE DEALER. REPAIRS MADE BY UNAUTHORISED SERVICE

CENTRES INVALIDATE THE GUARANTEE.

Plasma cutting power sources are designed for professional use and must be used exclusively by qualified

personnel.

This equipment can work under particularly heavy duty and with temperatures between –10°C (14°F) and +40°C

(104°F).

Compressed air

Insulator

Cutting arc

Base material

Nozzle

Electrode

1. Placing th q

1. Placing th q1. Placing th q

1. Placing th quipm nt

uipm ntuipm nt

uipm nt

Avoid placing the equipment in areas that limit the air flow from the fan and from the ventilation grids (do not cover

the power source).

Make sure that the environment temperature does not exceed of 40°C (104°F), that there is no wet air c ontaining

dusts, acids, salts, concentrations of ferrous or metallic dust.

Check that the mains voltage is the same as the power source voltage.

Make sure that the power available from the mains is adequate for the power required by the generator (see

technical data).

Make sure that the working conditions conform with the IP protection degree.

Casings ensure protection of the electrical components against external agents and against direct contact. They

have various degrees of protection against solids and water, depending on the conditions they are used in.

The degree of protection is shown by the letters IP followed by two digits: the first digit shows the degree of

protection against solid objects and the second the degree of protection against water.

I

Digit

Description II

Digit

Description Additional

field Description

2 Protected against solid objects larger

than 12 mm (for example: a finger). 1 Protected against drops

of water falling vertically. S Equipment not in

operation.

2 Protected against solid objects larger

than 12 mm (for example: a finger). 3 Protected against rain

fall with 60°slope. S Equipment not in

operation.

2. R c ipt of mat rials

2. R c ipt of mat rials2. R c ipt of mat rials

2. R c ipt of mat rials

The package contains:

•1 power source;

•1 user manual;

•1 belt

•1 torch;

•1 earth cable;

•1 kit of consumables.

Make sure that all the materials listed above are in the package. If anything is missing, contact your dealer.

Make sure that the generator has not been damaged during transport. If damage is found, promptly contact your

dealer.

3. Front pan l controls

3. Front pan l controls3. Front pan l controls

3. Front pan l controls

SUNUS PLASMA 35/40

1 ON-OFF LED

2 OUTPUT CUTTING CURRENT REGULATION

3 OVERHEATING LED

4 EARTH CABLE CONNECTOR

5 TORCH CONNECTOR

6 ON-OF SWITCH (on the back panel)

7

PRESSURE GAUGE

INSTALLATION OF PLASMA CUTTING

INSTALLATION OF PLASMA CUTTING INSTALLATION OF PLASMA CUTTING

INSTALLATION OF PLASMA CUTTING

MACHINES

MACHINES MACHINES

MACHINES

SINUS PLASMA 35/40 ADV

All cutting parameter controls are placed on the cutting machine front panel.

•Ref. 4 Connect the earth cable to the piece to cut, making sure that there is good electrical contact, in

particular with sheet metal that is painted, oxidised or has insulation covering. Do not connect the earth

terminal to the piece of material to be removed;

•Ref. 5 Torch connector;

•Ref. 2 Output cutting current regulation;

•Ref. 1 Machine ignition LED;

•Ref. 3 LED showing inverter blocked due to heat overload;

•Ref. 7 Air pressure gauge, regulator and filter (PLACED ON THE BACK PANEL).

Inverter

Cables

Base material

Torch

Compressor

•Press the torch trigger to ignite the pilot arc; when the push button is released air will continue to exit the torch

for a few seconds in order to cool it;

•If within a few seconds the pilot arc does not become a cutting arc, it turns off. To turn it on again, release the

torch trigger and press it again;

•Cutting is made by placing the nozzle at 2 – 3 mm from the work piece. Incline the torch so that when the

cutting arc sparks, the melted metal is not projected onto the nozzle. By pressing the torch trigger, the pilot arc

ignites and by touching the workpiece it becomes a cutting arc. Slowly straighten the torch position and once

the piece is perforated, move the torch forward to proceed with the cut (fig. 1);

fig. 1

•To start cutting thicknesses greater than 2 or 3 mm perforate the material with other equipment, or start from

the outside perimeter of the piece. For lesser thicknesses, work can be started in the middle with the inclinated

torch technique (fig. 2);

fig. 2

•Never touch the front part of the torch (nozzle, electrode, external protection);

•Keep medium speed during cutting; the figure below (fig. 3) shows the results of incorrect cutting speed.

fig. 3

fast

slow

correct

1. Plasma cut d f cts

1. Plasma cut d f cts1. Plasma cut d f cts

1. Plasma cut d f cts

DEFECT POSSIBLE CAUSES

1. Insufficient penetration.

A. Cutting speed too high.

B. Damaged cutting nozzle.

C. Inadequate air pressure.

D. Piece too thick.

E. Cutting current too low.

2. The arc turns off. A. Speed too low.

B. Pressure too high.

C. Feed tension too low.

3. Formation of slag. A. Cutting speed too high.

B. Damaged cutting nozzle.

C. Inadequate air pressure.

4. Unstable arc. A. Damaged nozzle or worn electrode.

5. Short life of consumables. A. Inadequate pressure.

B. Dirty compressed air.

C. Pilot arc extended uselessly.

6. Sparking is difficult.

A. Damaged consumables.

B. Incorrect connection of the earth cable.

C. Inadequate pressure.

D. Damaged torch.

2. Cutting capability

2. Cutting capability2. Cutting capability

2. Cutting capability

Material Carbon Steel Stainless Steel Aluminium Air flow Pressure

Quality Cut

Severance

Quality Cut

Severance

Quality Cut

Severance

Model (mm) (mm) (mm) (mm) (mm) (mm) (lt/min.) (bar)

SINUS

PLASMA 35/40

ADV 10 12 10 12 7 10 100 3,5-4,0

TORCH MAINTENANCE

TORCH MAINTENANCETORCH MAINTENANCE

TORCH MAINTENANCE

Excessive wear of spare parts is caused by wet compressed air, incorrect start-ups from the workpiece middle,

excessive cutting speed.

•The electrode should be replaced when a 1 – 1.5 mm crack forms in its centre.

•The nozzle should be replaced when the centre hole is worn, widened or oval-shaped.

•The swirl baffle should be replaced when one of its ends starts to carbonise.

•The nozzle holder should be replaced when the insulating part deteriorates.

Make sure that the electrode, the swirl baffle and the nozzle are correctly mounted and that the nozzle

holder is turned and tightened.

Lack of attention to these details compromise machine functioning and in particular operator safety (fig. 4)

4) TORCH SAFETY

4) TORCH SAFETY4) TORCH SAFETY

4) TORCH SAFETY

The torch has a safety device that comes in place when the external protection is removed, and prevents the user

from coming into contact with parts under high voltage. Electrical power supply must be turned off each time

maintenance is done or when worn plasma torch parts are replaced.

TORCH EXPLODED VIEW

TORCH EXPLODED VIEWTORCH EXPLODED VIEW

TORCH EXPLODED VIEW

SINUS PLASMA 35/40

ITEM CODE DESCRIPTION

1 CO.52531 PT-40 electrode

2 CO.60028 PT-40 swirl baffle

3 CO.51316 PT-40 nozzle 0,8mm

PT-40 Plasma Torch

4 CO.60389 PT-40 heat shield

TECHNICAL DATA

TECHNICAL DATA TECHNICAL DATA

TECHNICAL DATA

SINUS PLASMA 35/40

DUTY

PLASMA duty cycle

35 A – 40%

PLASMA output at 100% duty cycle

22 A

INVERTER

Mains voltage

230V ±10%

Frequency

50/60Hz

OCV

270 V

PLASMA Nominal Power (100%)

2,3 KW

PLASMA arc voltage

86 – 94 V

Max. current

18 A

Protective Fuses

16 A time-lag

Power factor

0,99

Degree of protection

IP 21 S

Insulation Class

F

Working temperature

-10°C+40°C

Size (mm)

475x150x220

Weight

8 Kg

FEATURES

PLASMA output range

5 – 35 A

Type of arc ignition PLASMA

Pilot arc without H.F.

CUTTING PERFORMANCE

Severance (mm)

12

Quality cut (mm)

10

Air flow (lt/min.)

100

Presure (bar)

3,5 - 4,0

N.B: The manufacturer reserves the right to make changes to product specifications at any time and without notice.

The manufacturer is relieved of all liability for improper or incorrect use of its products that could harm persons or

things.

Table of contents

Popular Welding System manuals by other brands

Lincoln Electric

Lincoln Electric POWER WAVE IM924 Operator's manual

ESAB

ESAB ES 300i instruction manual

WORMS

WORMS Robin Subaru MIxte 4500/3.2 Instructions for use

Thermadyne

Thermadyne THERMAL ARC 130 GTS & S CC/TIG operating manual

Lincoln Electric

Lincoln Electric RANGER 305 D CE Operator's manual

Chicago Electric

Chicago Electric MIG 170 Owner's manual & safety instructions

MasterCraft

MasterCraft Power Cut 40i instruction manual

ESAB

ESAB LHI 825 Instruction manual and spare parts list

Hot Max

Hot Max 100WFG Operator's manual

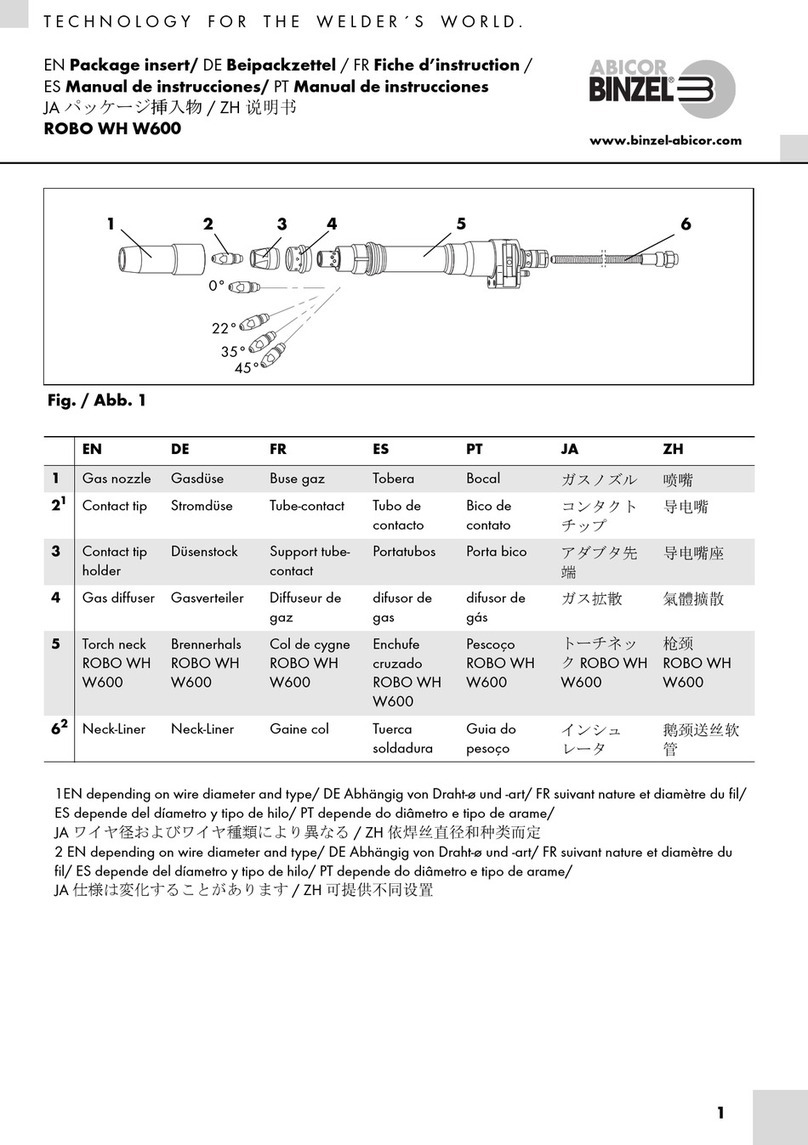

Abicor Binzel

Abicor Binzel ROBO WH W600 Complete Manual and Package Insert

Everlast

Everlast PowerArc 200STi Operator's manual

Northern Industrial

Northern Industrial MIG 130 Operator's manual