Sumitomo TYPE-71c User manual

OME1124015

Direct Core Monitoring Optical Fiber Fusion Splicer

TYPE-71C

Guide to operation

This product has been designed and manufactured to assure personal

safety. Improper use can result in fire, electric shock or injury to persons.

Please read and observe all warnings instructions given in this operation

manual.

Use your splicer only for its intended purpose.

The meaning of these symbols

In the product and this operation manual, symbols are used to highlight warnings and cautions for

you to read so that accidents can be prevented. The meanings of these symbols are as follows:

Symbol used in the product

This symbol, where it appears on the unit, indicates that hazardous voltage

is present inside of the splicer.

The meaning of these symbols

This symbol indicates a warning, caution, or danger and alerts you important

instructions have been included on the product or in the manual.

This symbol indicates actions that are prohibited.

This symbol indicates actions that must be taken.

The meaning of Warning and Caution

This symbol indicates explanations about extremely dangerous matters. If

users ignore this symbol and handle the splicer the wrong way, serious injury

such as fire or electric shock, or death could result.

This symbol indicates explanations about dangerous matters. If users ignore

this symbol and handle the splicer the wrong way, bodily injury and damage

to the equipment could result.

Caution

Warning

Be sure to read all the following warnings and cautions before use.

[Warning]

<Setting up and using splicer>

1. This fusion splicer performs an arc discharge. Do not use the splicer in a hazardous

location in which inflammable gas can generate or only electrical apparatus for

explosive gas atmosphere can be used.

2. Never use spray cleaners such as Freon or Flammable gas on the splicer.

Decomposition of arc by heat will cause toxic gas, or abnormal arc may result in

damage or fire.

3. Do not use and store the splicer out of the locations defined in a brochure and this

manual. Doing so can cause splicer malfunction or deterioration, resulting in fire or

electric shock.

4. To reduce the risk of fire, electric shock or malfunction, do not allow the splicer to be

exposed to rain and get liquid such as water or a metallic object inside the splicer.

Doing so can cause fire, electric shock or malfunction by shorting out internal

components.

5. Never use the battery pack, AC adapter and battery charger, and power cables for

the machines other than the specified splicer. Doing so can cause these items to

damage, resulting in fire or heat generation.

6. Do not make mechanical or electrical modifications to the splicer since this may

expose you to dangerous voltage or other hazards.

7. Do not touch the electrodes during and after arc discharge. Doing so can cause

personal injury or electric shock.

8. The heating plate of the heat shrink oven may be hot during heating. Do not touch

the protection sleeve directly after heating. Doing so can cause burn. A protection

sleeve may also be hot after heating. Handle with care.

9. Do not operate the splicer in the rain. Doing so can cause AC adapter or battery pack

to be short-circuited.

10. Do not expose the splicer to extremely high temperature and high humidity or to

direct sunlight for prolonged periods.

11. Do not continuously use the heat shrink oven for long hours, keeping it high

temperature. Doing so can cause heat shrink oven to malfunction.

The following case is the exception for repairing and replacing the product free of

charge:

The Heating duration is set to a long time (e.g. 180 sec.) and the Finish temperature

is set to a high temperature (e.g. 200 °C). The heat shrink oven is used for long hours

by continuing to press the Heat key shortly after the heat cycle is completed.

12. Only use alcohol to clean the splicer. To prevent malfunction and damage, do not use

any other kind of chemicals.

13. Never use spray cleaners such as Freon or flammable gas on the splicer. Heat by arc

can cause chemical reactions to occur to gas component, which will deteriorate a

microscope lens, resulting in a loss of splicing capability.

14. Parts that compose the heat shrink ovens might become high temperatures. When

those parts are damaged, do not use it and contact our service center.

15. Because it is likely to injure by shards of glass when the monitor is damaged, do not

use it and contact our service center.

16. When parts that compose this product and the accessory (battery pack, AC adapter,

and power cord, etc.) are damaged, do not use it and contact our service center.

17. Do not use this product near the electronic equipment that handles a highly accurate

control and the faint signal such as the heart pacer. The influence of the

miss-operation of electronic equipment might be given.

18. Avoid places with too much dust or dirt. Dirt or dust that can accumulate in the fusion

splicer causes short circuit and insufficient cooling, which may lead to splicer

malfunction or deterioration, resulting in fire or electric shock.

19. Only use the battery pack, AC adapter, battery charger and power supply cord for the

splicer as defined in this manual. Failure to do so can cause these items or the fusion

splicer to damage, resulting in fire or electric shock.

20. Only use a voltage within the indicated power voltage. Failure to do so can cause fire

or electric shock.

21. Check for condensation before operation. If necessary, dry the splicer with a hair

dryer. If water or other liquid, a metallic object or other foreign substance gets inside

the splicer, immediately turn off the power and disconnect the power plug. Contact

our qualified service personnel.

22. In a high location, take safety measures to prevent fall of operators. Dropping the

splicer could result in personal injury. Fix the splicer to a worktable or a tripod with the

screw on the bottom of the splicer.

23. If an abnormal condition such as unusual noise, smoke or unusual odor occurs,

immediately turn off the power and disconnect the power plug. Next, contact our

qualified service personnel.

24. Be sure to turn off the splicer and unplug the power cord or remove the battery pack

before replacing the electrodes.

25. Only use Sumitomo genuine electrodes (ER-10). And use the splicer with electrodes

installed in it. Failure to do so can cause the splicer to damage, resulting in fire,

electric shock or malfunction.

1. To reduce the risk of electric shock, do not plug/unplug the power cord or remove the

battery pack with wet hands.

2. Disconnect the power cord by grasping the plug, not the cord. Failure to do so can

cause damage to the power cord, resulting in fire, electric shock or malfunction.

3. Before charging the battery pack, make sure that the pins of the battery charge cord

are not bent or broken. Using the battery charge cord with a bent or broken pin can

cause internal short circuit, resulting in fire or electric shock.

<Handling of power cord and plug >

<Handling of battery pack>

1. Do not burn the battery pack or throw it into a fire. Doing so can cause heat

generation, bursting and fire.

2. Do not place the battery pack in microwave ovens and high-pressure containers.

3. Do not let water or sea water wet or soak the battery pack. Safety and protective

devices to prevent danger are built in the battery pack. If these devices are damaged,

excessive current flow can cause abnormal chemical reaction in battery fluid, heat

generation, bursting and fire.

4. Do not throw or impact the battery pack. Safety and protective devices to prevent

danger are built in the battery pack. If these devices are damaged, excessive current

flow can cause abnormal chemical reaction in battery fluid, heat generation, bursting

and fire.

5. Do not pierce the battery pack with nails, strike the battery pack with a hammer, or

step on the battery pack. Doing so can cause internal short circuit, heat generation,

bursting and fire.

6. Do not disassemble or modify the battery pack. Safety and protective devices to

prevent danger are built in the battery pack. If these devices are damaged, excessive

current flow can cause loss of control during charging or discharging of the battery

pack, heat generation, bursting and fire.

7. Make sure the polarities are correctly connected. Do not attempt to connect the

battery pack or other equipment when you cannot do. Reversed connections can

cause abnormal chemical reaction in battery fluid, heat generation, bursting and fire.

8. Do not solder any lead wires directly to the battery pack. Do not directly connect the

positive and negative terminals with a conductive material such as a wire. Do not

carry or store the battery pack together with any personal jewelry, hairpins or other

Metallic objects. Doing so can cause an electrical short circuit. Also excessive current

flow can cause abnormal chemical reaction in battery, heat generation, bursting and

fire.

9. Only use a specified battery charger. Failure to do so can cause the battery to be

overcharged or excessive current flow can cause abnormal chemical reaction in

battery fluid, heat generation, bursting and fire.

10. Use the battery pack only for the application for which it was designed. Failure to do

so will result in a loss of performance and a shortened life expectancy. Also excessive

current flow can cause loss of control during charging or discharging of the battery

pack heat generation, bursting and fire.

[Caution]

<Transportation and storage>

1. This product is a precision instrument. When transporting the splicer, use its specified

carrying case to protect the splicer from excessive shock or impact.

2. Do not use and store the splicer out of the locations defined in a brochure and this

manual. Failure to do so can cause splicer malfunction or deterioration, resulting in

fire or electric shock.

3. Do not store any items other than the product, package contents and optional

accessories in the carrying case. Overloading the case can cause damage to the

body of the carrying case, case handle, strap and latch.

4. Do not throw or fall the carrying case. Doing so can cause damage to the body of the

carrying case, case handle, strap and latch.

5. Do not use a carrying case where there is a visible sign of damage and screw

looseness.

6. Do not store the hand strap in the windshield. It causes damage to the machine.

7. Do not carry the machine grabbing the hood or the monitor.

8. Do not brandish the machine with the hand strap, and brandish neither AC adapter

nor the power cord. There are fear of machine damage and the injury.

9. Do not use the machine with the lid of the battery Pack slot opened.

10. Before carrying the case, make sure that there is no visible sign of damage and

screw looseness on the handle and latch. If the case with damage and screw

looseness is carried, it could drop down, causing personal injury or splicer

malfunction.

11. Before picking up the case, ensure that the latch is completely locked. Carrying the

case with the latch unlocked can cause the case to fall open and result in personal

injury or splicer malfunction due to heavy impact.

12. Be careful that your fingers not to be caught in the hinge part and the lid when you

open and shut the case.

13. Confirm the work table of the carrying case is surely fixed to the case when you

carry it.

14. Do not modify the handle, strap or strap attachment points. Only use the carrying

strap supplied by us.

15. Avoid places with too much dust or dirt. Dirt or dust that can accumulate in the

fusion splicer causes short circuit and insufficient cooling, which may lead to splicer

malfunction or deterioration, resulting in fire or electric shock.

16. If you are not going to use the splicer for a prolonged period, remove the battery

pack from the splicer. Failure to do so will shorten a battery life.

17. Unplug the fusion splicer or remove the battery pack before attempting any

maintenance or if not using the splicer for a prolonged period. Failure to do so can

cause fire.

18. The monitor, the hood, and the heater clamping, etc. do the opening and shutting

operation. Be careful of your fingers not to be caught.

<Handling of optical fiber >

1. Never look into optical fibers or the end of an optical cable attached to the optical

output when the device is active. The laser radiation can seriously damage your

eyesight.

2. Wear safety glasses at all times for protection from glass fibers.

< Others >

1. Make sure the polarities are correctly connected. Do not attempt to connect the

battery pack or other equipment when you cannot do. Reversed connections can

cause abnormal chemical reaction in battery fluid, heat generation, bursting and fire.

2. Do not carry or store the battery pack together with any personal jewelry, hairpins or

other Metallic objects. Doing so can cause an electrical short circuit. Also excessive

current flow can cause abnormal chemical reaction in battery fluid, heat generation,

bursting and fire.

3. Do not use a dry cell battery and the batteries differing in capacity, type, and

manufacturer. Doing so can cause heat generation, bursting and fire.

4. The battery's optimum charging temperature range is 0 to 40˚C. Under high

temperature conditions such as in direct sunlight or near a fire, safety and protective

devices to prevent danger which are built in the battery pack will be activated,

resulting in failure of charging. Or if these devices are damaged, excessive current

flow can cause loss of control during charging or discharging of the battery pack, heat

generation, bursting and fire. Avoid charging the battery pack at extremely low

temperature (below 0˚C). Failure to do so may lead to deterioration in performance

and battery leakage.

5. Always turn off the power to the splicer after use. Failure to do so can cause the

battery to be over discharged and deteriorated in performance.

6. In the event the battery pack leaks and the fluid gets into one's eyes, do not rub the

eyes. Immediately wash them thoroughly with clean water enough from the tap and

consult a doctor urgently.

7. Unplug the fusion splicer or remove the battery pack before attempting any

maintenance or if not using the splicer for a prolonged period. Failure to do so can

cause fire.

8. Pay attention not to drop the battery pack when installing and removing it. Dropping

the battery pack can cause personal injury.

1. Do not press the keys on the keypad with a sharp object ( e.g. a ballpoint pen,

screwdriver, or nail ) Doing so will damage the keypad.

2. Do not press strongly the touch screen with a sharp object.

3. Do not use or store the battery pack at high temperature, such as in strong direct

sunlight, and in cars during hot weather. This can cause deterioration of the battery.

4. Even if you are not going to use the battery pack for a prolonged period, charge it

once a year.

5. Do not press the liquid crystal display with force or the display may fail.

6. Take care to keep spliced fiber straight. Do not flex it back and forth. Doing so can

cause the spliced fiber to be broken, resulting in loss of the long term reliability of the

fiber.

7. Do not use a canned air for cleaning. Chemical reaction may deteriorate the lens,

resulting in a loss of splicing capability.

<Battery handling and charging>

8. Check the voltage of AC power before use. The AC adapter should be grounded to

earth. If voltage or frequency beyond the range stated flows in the AC adapter, a

safety and protective device to prevent danger is activated and the AC adapter will

stop. In that case, a new AC adapter should be purchased. Please contact our

qualified service personnel.

9. Charge the battery pack within the following temperature range. Failure to do so may

lead to deterioration in performance.

*Battery pack’s required temperature range: 0°C ~ +40°C

10. Before using the battery pack for the first time, charge it.

11. The battery pack is consumables. Repeated charging and discharging decreases

battery life.

12. Store the battery pack within the following temperature range. Failure to do so may

lead to deterioration in performance.

*Battery pack storage temperature range: -20°C ~ +50°C (if stored for less than 1

months) -20°C ~ +40°C (if stored for less than 3 months) -20°C ~ +20°C (if stored for

less than 1 year)

13. Charge the battery pack fully before storing it for a prolonged period.

14. Even if you are not going to use the battery pack for a prolonged period, charge it

once a year.

15. If you are getting fewer than splice cycles per fully charged battery, consider

replacing the battery pack by a new one.

16. When disposing of the battery pack, contact our qualified service personnel or follow

the local regulations.

17. Although bright spots or dark spots may appear on the screen, this is a unique

characteristic of liquid crystal displays, and such do not constitute or imply a machine

defect.

18. We recommend your splicer to be annually over-hauled to keep it in good condition.

19. Glass fiber fragments are extremely sharp. Handle with care.

20. Turn off the splicer before maintenance work. Failure to do so can cause electric

shock.

21. Be sure to remove moisture, alcohol or dust on the heater element with a dry cotton

swab.

22. Only use Sumitomo genuine electrodes (ER-10). Failure to do so can cause the

splicer to malfunction.

23. Do not clean the electrode. Doing so can cause unstable arcing performance.

24. Storing and transporting the splicer with the battery pack installed can cause the

battery pack to be damaged or deteriorated, resulting in fire. Remove the battery

pack from the splicer before storage.

25. Transporting the splicer with fiber holders loaded can cause the V-grooves or clamps

to be damaged, resulting in the failure of splice. Remove the fiber holders from the

splicer before storage.

26. Ensure that the strap should be completely secured.

27. Whenever you use the strap rings, be sure to hold the splicer with your hand. Failure

to do so can cause the splicer to turn over and accessories such as fiber holder will

drop.

The European Union has enacted a Directive 2002/96/EC on Waste

Electrical and Electronic Equipment (WEEE Directive). This directive is

applicable in the European Union member states. The crossed out

wheelie bin symbol found on our products indicates that it should not be

disposed of together with household waste.

To prevent possible harm to human health and the environment, waste

electrical equipment must be disposed of in an approved and

environmentally safe recycling process.

For further information on how to dispose of the product correctly, please

contact the product supplier, or the local authority responsible for waste

disposal in your area.

WEEE Directive (Waste Electrical and Electronic Equipment; 2002/96/EC)

RoHS Directive (2011/65/EU)

The TYPE-71C optical fusion splicer is RoHS-compliant.

IMPORTANT: REGION LIMITATION

WARNING:

This product is sold for the use in a limited sales area and the sale, resale, transfer,

lease or otherwise of this product to the other regions is prohibited, except written

consent of Sumitomo Electric Industries, LTD.

YOU NEED TO AGREE ABOUT A SOFTWARE LICENCE AND REGION LIMITATION

BEFORE USE.

Reference of Sales Area and Sumitomo Sales & Service Representatives:

Sales Area Sumitomo Sales and Service Representatives

North & South America SEL . Sumitomo Electric Lightwave Corp.

Europe, Middle east, Africa

(EMEA)

UK

SEEL SEEL : Sumitomo Electric Europe Ltd.

China SEA Sumitomo Electric Asia, Ltd.

SEAC Sumiden Asia(Shenzhen) Co., Ltd.

Thai, Vietnam SET Sumitomo Electric(Thailand) Limited

Indonesia, Singapore SEPS Sumitomo Electric Interconnect

Products (Singapore) Pte Ltd.

India, South Asia SETI SEI Trading India Pvt. Ltd.

Philippines SEPI SEI (philipines) Incorporated

Japan SEI Sumitomo Electric Indutries,Ltd.

Other sales area and authorized sales and service agencies may be provided

according to the country, area and trading conditions. Refer to the information

which appears on the splicer screen.

IMPORTANT: PATENT NOTICE

This product and/or the use of this product are/is covered by one or more of the

following Patents of Sumitomo Electric Industries, LTD.:

Australia Patent No(s).: 2002222577; 2006235914

Design No(s).: 314929; 329420

Canada Patent No(s).: 2183840; 2431138

Design No(s).: 120205; 133128

China P. Rep. Patent No(s).: 1820115.6; 98109577.1; 200780001246.9

Design No(s).: 200730144402.X; 200930286514.8

Europe Design No(s).: 000712583-0001; 001183206-0001

France Patent No(s).: 1355177; 1892547

Germany Patent No(s).:

0880039; 1355177; 1892547

Italy Patent No(s).: 1355177; 1892547

Sweden Patent No(s).:

0880039; 1355177; 1892547

United Kingdom Patent No(s).: 0880039; 1355177; 1892547; 2420633

Hong Kong S.A.R. Patent No(s).: 1106961

India Patent No(s).: 232249

Design No(s).: 209372; 225957

Japan Patent No(s).: 3065271; 3111649; 3119822; 3952822;

4032960; 4161984; 4196972; 4305468;

4367597; 4457873; 4613796

Design No(s).: 1311936; 1382022

Malaysia Design No(s).: MY07-00454-0101; MY09-01316-0101

Singapore Design No(s).: D2007/402/A; D2009/1085/Z

South Korea Patent No(s).: 646124; 859070; 878095

Design No(s).: 30-0472617; 30-0594853

Taiwan Patent No(s).: 1233507

Design No(s).: D122221; D140150

United States Patent No(s).: 5,777,867; 6,206,583; 6,966,708; 7,140,786;

7,412,146; 7,546,020

Design No(s).: D578,072; D628,462S

IMPORTANT : TYPE-71C SOFTWARE USER LICENSE

ATTENTION : The software installed in the TYPE-71C SPLICER (“this software”) is the property of

SUMITOMO ELECTRIC INDUSTRIES, LTD. The usage of this software is granted by a license.

CAREFULLY READ AND THIS LICENSE BEFORE USING THIS PRODUCT.

The copyright and all other rights to this software, its documentation and the writings concerning this

software (“the writings”), which contain CD-ROM, operation manual, guiding document, data tables,

command lists, writing information (photos, images, drawing, text) on appended other printed

materials, shall remain with SUMITOMO ELECTRIC INDUSTRIES, LTD. By commencing the use of

this software, you acknowledge that you have read the following license and indicate that you agree to

its terms. In case of disagreement, contact SUMITOMO ELECTRIC INDUSTRIES, LTD. or our product

supplier.

LICENSE AGREEMENT

Copyright © 2011 SUMITOMO ELECTRIC INDUSTRIES, LTD. All rights reserved.

This license is the entire agreement between SUMITOMO ELECTRIC INDUSTRIES, LTD. and you.

1. LICENSE

The following restricted rights are granted. YOU MAY :

a) use on a splicer in which this software is installed.

b) create or distribute a construction manual based on the writings on condition that you clarify

their source.

c) create an execution report of construction based on displayed information, and the writings.

d) create a document (manual or execution report) concerning the maintenance of the splicer in

which this software is installed or control its splice-quality upon displayed information and the

writings.

e) make one copy of the writings for archival or backup purpose.

2. RESTRICTIONS

The following act is forbidden on this license, except our prior written consent. YOU MAY NOT :

1) sell, distribute, rent, lease, transfer, or disclose the whole or part of the writings to the public or

unidentified parties and transfer, disclose or display the electrical format of the writings through

online media.

2) make copy of the writings except as permitted in this license.

3) reverse engineer, decompile, disassemble this software and analyze, modify or merge the

program.

3. CONTRACTING PARTIES

If you rent, lease, transfer, or resell the splicer, in which this software is installed, to a corporation or

other entity, then this agreement is formed by and between SUMITOMO ELECTRIC INDUSTRIES,

LTD. and such entity. You shall be liable for such entity to agree to the same all conditions of this

license.

4. TERM AND TERMINATION

This agreement shall continue in effect until terminated. You may terminate the agreement at

anytime by stopping the use of the splicer in which this software is installed. If you fail to comply

with any of the provision of this license, your license will be automatically terminated. Upon

termination, you shall transfer the writings to the owner of splicer (In the case that you transfer the

splicer to other corporation or entity) or return them to us, otherwise erase or destroy them by

appropriate means. You shall forever hold in confidence all trade secrets brought by this license.

Further you agree not to disclose to any third party.

5. LIMITATION OF LIABILITY

SUMITOMO ELECTRIC INDUSTRIES, LTD. and our supplier shall not be liable for consequential,

incidental or accidental damages in connection with this software or this agreement and whether

this software shall meet your special requirements, special efforts or special method beyond the

range described in the operation manual concerning this software.

6. GENERAL

If any provision of this agreement is declared by the court of competent jurisdiction to be invalid,

illegal, or unenforceable, such provision shall be severed from the agreement and the other

provisions shall remain in full force and effect.

The followings are a registered trademark or trademark of Corning Incorporated.

Corning®, LEAF®, MetroCor® ,ClearCurve™

TrueWave® is a registerd trademark of Furukawa Electric North America, Inc.

BendBright® and TeraLight™ are a registered trademark or trademark of Draka holding.

CasaLight™ is a trademark of Prysmian Cables and Systems.

The followings are a registered trademark or trademark of Sumitomo Electric Industries, Ltd.

MicroCore™, Sumitomo Z™, PureGuide®, PureMetor®, PureAccess®, UltraAccess®

SD and SDHC logos are trademarks of the SD-3C LLC.

FlashFX® Pro™ is a trademark of Datalight, Inc.

IMPORTANT SAFETY PRECAUTIONS

IMPORTANT: REGION LIMITATION

IMPORTANT: PATENT NOTICE

IMPORTANT: TYPE-71C SOFTWARE USER LICENSE

Table of contents

1. General •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 1-1

Product overview ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 1-1

Optical fiber requirement ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 1-1

Features overview •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 1-1

Standard package ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 1-2

Optional accessories ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 1-3

Consumables •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 1-3

Structure •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 1-5

Fusion splicer •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 1-5

Keypad •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 1-6

V-grooves, electrodes, other components •••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 1-7

Heat shrink oven •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 1-8

Input/output panel ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 1-8

Caution label ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 1-9

2. Splice / protection ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-1

Preparing power supply •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-2

AC operation ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-2

Battery operation •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-3

Battery level check •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-4

Battery charging ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-5

DC operation (car battery) ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-6

Precautions for battery pack •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-6

Operating procedures ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-7

Turning on the TYPE-71C •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-7

Initial screen •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-8

Stripping the fiber coating / Cleaning the bare fiber ••••••••••••••••••••••••••••••••••••••••••••••• 2-9

Cleaving the fiber •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-10

Inserting fibers into the splicer •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-12

Arc test ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-13

Arc test procedure ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-13

Fiber preparation •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-15

Starting the automatic splice •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-16

Splice protection ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-20

Drop cable splicing •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-22

Applicable cable ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-22

Required items ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-22

Preparation ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-22

Removing cable sheath •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-23

Fiber preparation procedures 1 (AP-FC6SA is available) •••••••••••••••••••••••••••••••••••••••• 2-24

Fiber preparation procedures 2 (AP-FC6SA is not available) •••••••••••••••••••••••••••••••••••• 2-26

Inserting the fiber into the splicer ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-27

Splice protection•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2-28

Sumitomo Electric Industries, Ltd. reserves the right to change the specification or design

without notice and may therefore not coincide with the contents of this manual. E&OE

3. Daily cleaning and checking up••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 3-1

Cleaning ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 3-1

Names of components ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 3-1

Cleaning V-grooves ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 3-2

Cleaning V-grooves ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 3-2

Cleaning LEDs ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 3-2

Cleaning bare fiber pads ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 3-3

Cleaning lens protection glass •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 3-3

Cleaning heat shrink oven ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 3-4

Replacing electrodes •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 3-5

Electrode replacement procedures •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 3-6

Packing and storage instructions •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 3-8

4. Functions •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4-1

Splice and heater conditions settings •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4-1

Function settings •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4-9

Maintenance settings ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4-12

Splice data storage function•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4-13

USB connection function ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4-14

Software download via internet ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4-14

Login function••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4-14

Help function•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4-15

5. Other convenient functions•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5-1

Back monitor type ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5-1

Universal clamp•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5-2

Dual heat shrink oven •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5-2

Fiber holder operation •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5-3

Detachable/attachable bare fiber pads••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5-4

Heater clamp operation••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5-5

Auto start •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5-6

Tripod fixing screws ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5-6

Splice data storage function ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5-6

Hand strap •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5-7

6. Troubleshooting •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6-1

Arc problems ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6-1

Fiber breaking •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6-1

Splicer does not power up ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6-1

Warranty and repair service ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6-2

Error message list •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6-3

TYPE-71C Specifications ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 6-4

1-1

1. General

Thank you very much for purchasing the TYPE-71C MicroCore™ Fusion Splicer

(hereinafter called “the TYPE-71C”).

The TYPE-71C automatically pre-inspects and aligns a pair of optical single fibers with

equipped microscopes, and then fuses them together with heat from an electric arc to

form a low-loss splice. A protection sleeve is applied over the bare glass and cured in

the built-in heat shrink oven.

Before using the TYPE-71C, read all instructions completely.

Read this manual carefully in its entirety to fully understand

machine capabilities. Save this manual in a location in which you

can easily get to see.

Product overview

The TYPE-71C can splice the following optical fiber types.

Material Silica glass

Profile type SMF (ITU-T G.652), MMF (ITU-T G.651),

DSF (ITU-T G.653), CSF (ITU-T G.654),

NZDSF (ITU-T G.655, G.656), BIF (ITU-T G.657), EDF

Fiber diameter 80 - 150μm *1

Fiber coating diameter 100 - 1,000μm

Fiber count Single fiber

Cleave length *2 5 - 16mm (Over 250μm coating diameter with the

length less than 8mm requires fiber holder operation.)

*1 Fiber diameter except 125μm are only applied in the factory temperature and 0m altitude.

*2 The applicable fiber protection sleeves vary depending on the cleave length.

The TYPE-71C key features are:

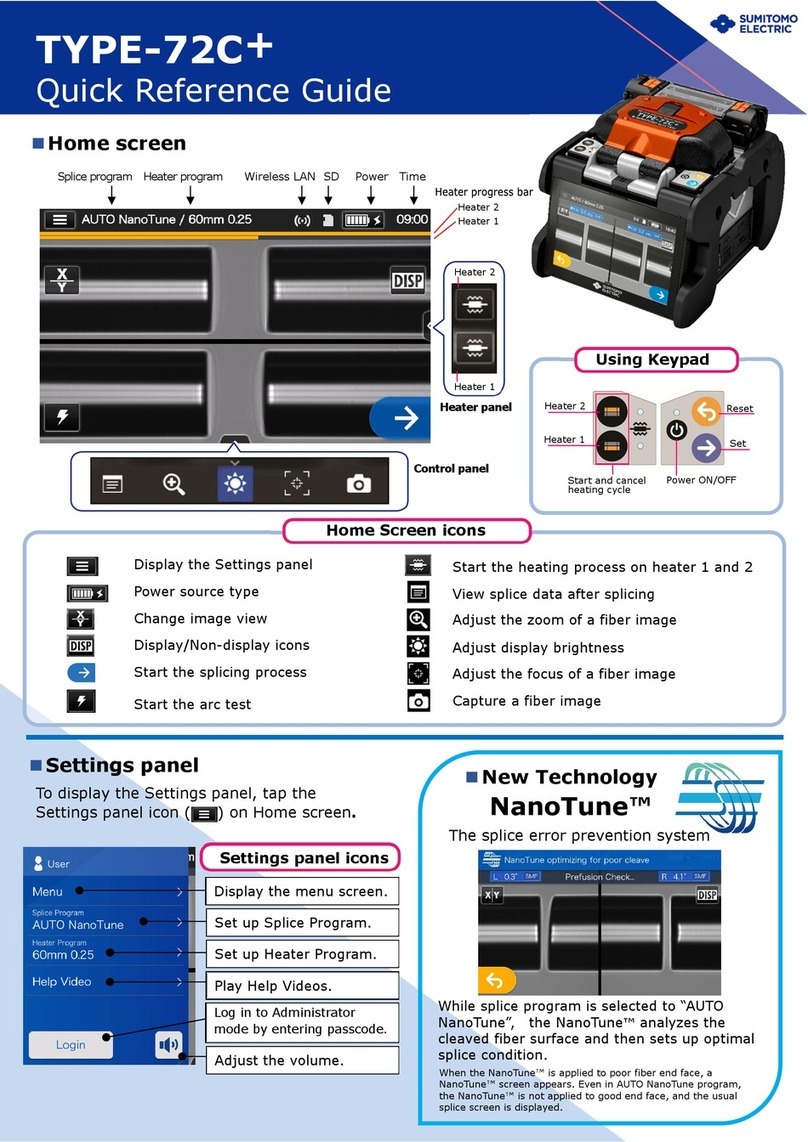

・Touch screen monitor (For more information, refer to page 2-8.)

4.1 inch LCD monitor with touch screen operation enables to confirm fiber images

easily. The splicer can be operated by touching the icons on the screen. The

working efficiency has improved dramatically.

• Dual heat shrink oven (For more information, refer to page 2-20, 5-2.)

Following the conventional model TYPE-39, 2 heat shrink ovens are equipped with

the fusion splicer. The ovens run individually and splicing operation can be

improved more effectively.

Optical fiber requirement

Features overview

Caution

1-2

• Auto start (For more information, refer to page 5-6.)

In addition to the function that automatically starts the splicing process when the

hood is closed, the function that automatically starts the heating cycle when fiber is

placed into the heat shrink oven is provided.

• Fully automatic splice mode (Auto mode)

(1) Auto fiber profiling check and Detection System (For more information, refer to

page 4-3.)

Using Auto fiber Profiling check and Detection System (APDS), the TYPE-71C

recognizes fiber core profile and automatically chooses a correct splice program, and

proceeds to splicing.

(2) Automatic arc calibration (For more information, refer to page 2-13.)

TYPE-71C analyzes the arc and has the function to calibrate the arc condition

automatically at each splice. Therefore, arc test is not needed usually in the Auto

mode.

No. Description Part number Quantity

1 Fusion splicer TYPE-71C TYPE-71C 1 pc

2 AC adapter ADC-1430 1 pc

3 Power cord PC-AC<X> 1 pc

4 Battery pack BU-11 1 pc

5 Cooling tray - 1 pc

6 Spare electrodes ER-10 1 pair (2 pcs)

7 Operation manual (CD-ROM) OME1124015* 1 pc

8 Quick reference guide OME1124030* 1 pc

9 Carrying case (with strap) CC-71 1 pc

*The latest version is provided.

Here is an example of TYPE-71C standard package.

Package contents (example)

The above package is an example. The package contents vary depending on the customers’ requests.

Standard package

Cooling tray

Spare electrodes

Strap for

carrying case

Battery pack

Carrying case

Jacket remover

(Optional*)

*Sold separately

Fiber cleaver

(Optional*)

Power cord

AC adapter TYPE-71C

Operation manual

Quick reference guide

1-3

Optional accessories

Options

Description Part No. Remarks

Battery pack BU-11 Special Li-ion battery for TYPE-71C.

Car battery cable PCV-11 Plugged into a car’s cigarette lighter jack to supply

electric power to splicer

Battery charger BC-11 Use only for the battery pack BU-11.

Fiber holders FHD-1 For drop cable

Tools (Jacket remover, Fiber cleaver, and etc)

Consumables

Fiber protection sleeves

FPS-1

FPS-40*

FPS-S-40*

60mm (50 pcs per package) ••••• Cleave length 8-16mm

40mm (50 pcs per package) ••••• Cleave length 8-10mm

40mm (50 pcs per package) thin sleeve ••••• Cleave length

8-10mm

*The 40mm protection sleeves can be used only if the cleave

length is less than 10mm. Do not use the 40mm protection

sleeves for non-250μm coated fibers.

Description Part No. Remarks

Precision fiber cleaver FC-7R-S

FC-7S

FC-6S(-C)

FC-6S-5C

Applicable coating diameter: 250 - 900μm

Applicable fiber diameter: 125μm

Replacement blade for FC-7R: FCP-20BL(7R)

Replacement blade for FC-7 and FC-6: FCP-20BL

Jacket remover JR-M03 Applicable coating diameter: 250μm, 900μm

Applicable fiber diameter: 125μm

Dispenser HR-3 Dispenser for alcohol

The following optional accessories are provided for the TYPE-71C. For further details,

please contact our sales personnel.

[ JR-M03 ]

[ FC-6S-C ][ FC-7R-S ]

1-4

• Regarding standard equipment, consumables, or optional accessories, please order

the new item you need with the item description and part number to our sales

personnel.

• For repair, please read “Warranty and repair service” at page 6-2 and contact our

maintenance service center.

Protection sleeves

for cable sheath

FPS-D60

60mm (25 pcs per package) ••••• For drop cable and

small-sized indoor cable. Cleave length ≤10mm.

Battery pack (BU-11)

Electrodes (ER-10)

Battery pack and electrodes are considered

consumables that degrade with time and usage and are

replaceable by a customer. Therefore they will not be

covered under warranty.

1-5

Structure

Fusion splicer

2

3

4

6

7

Heat shrink oven

Used to heat and shrink fiber

protection sleeves. 2 heat shrink

ovens (front and rear) are equipped.

Battery pack slot

Battery is installed in this slot with

protection lid.

Input/output panel

DC output terminal for hot jacket

remover and USB port

6

5

7

3

4

2

1

Main body

TYPE-71C fusion splicer

Keypad

Keys are used to turn on/off the power,

perform a splice and heat shrink

protection, and setup functions.

Touch screen monitor

Displays fiber image, splice data and

menu. Touch screen operation enables

to start splicing, heating and feature

setting.

Hood

Provides protection from the

environment.

1 5

Table of contents

Other Sumitomo Welding System manuals