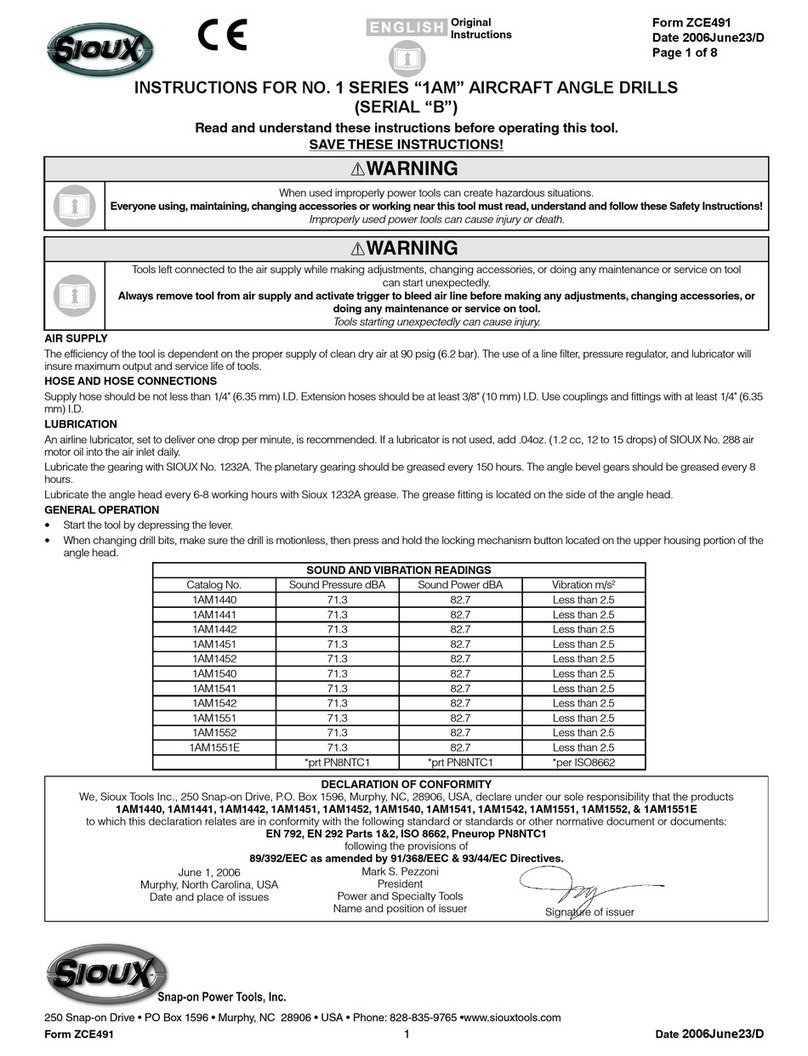

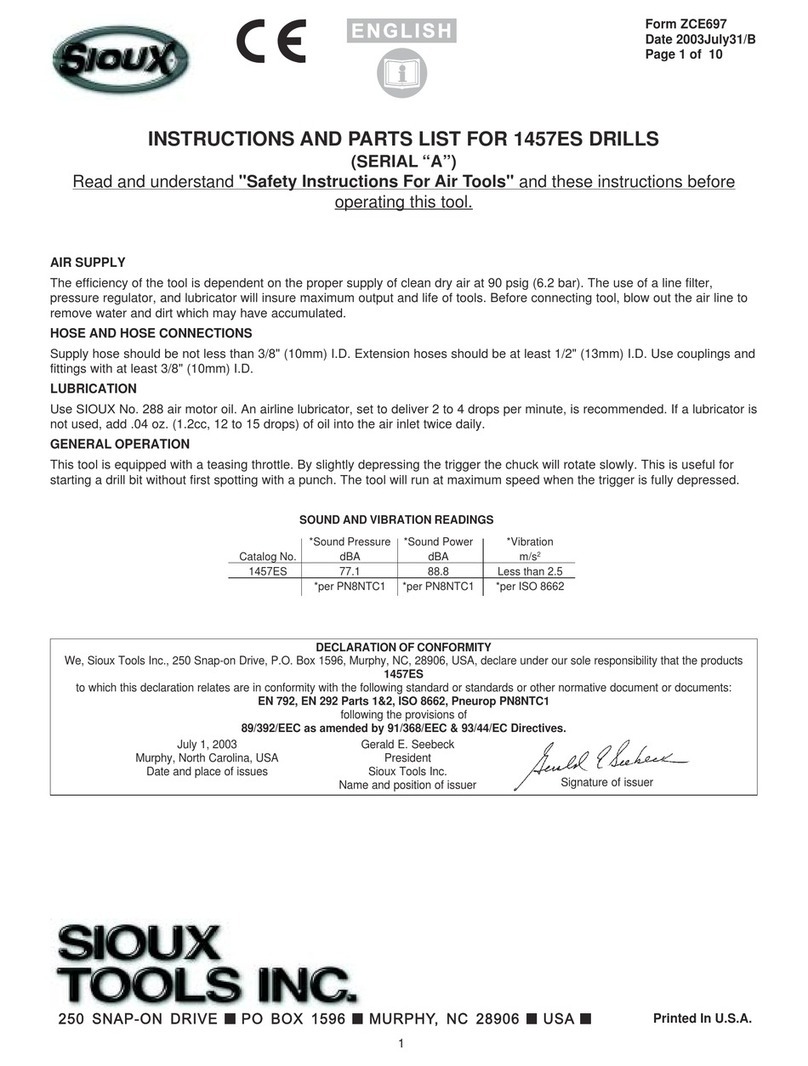

Form

#

2482

Model

5434

&

5434KL

Date

2-98/~

3/8"

CapacityStraight Drill

Mo,del5434TB

-

7/16"Tke

Buffer

IMPORTANT

Read

these

instructionscarefully

before

Installing,

operating,

servicing

or repairing

this

tool.

Keep

these

Instructions

In

a

safe

accessible

place.

1

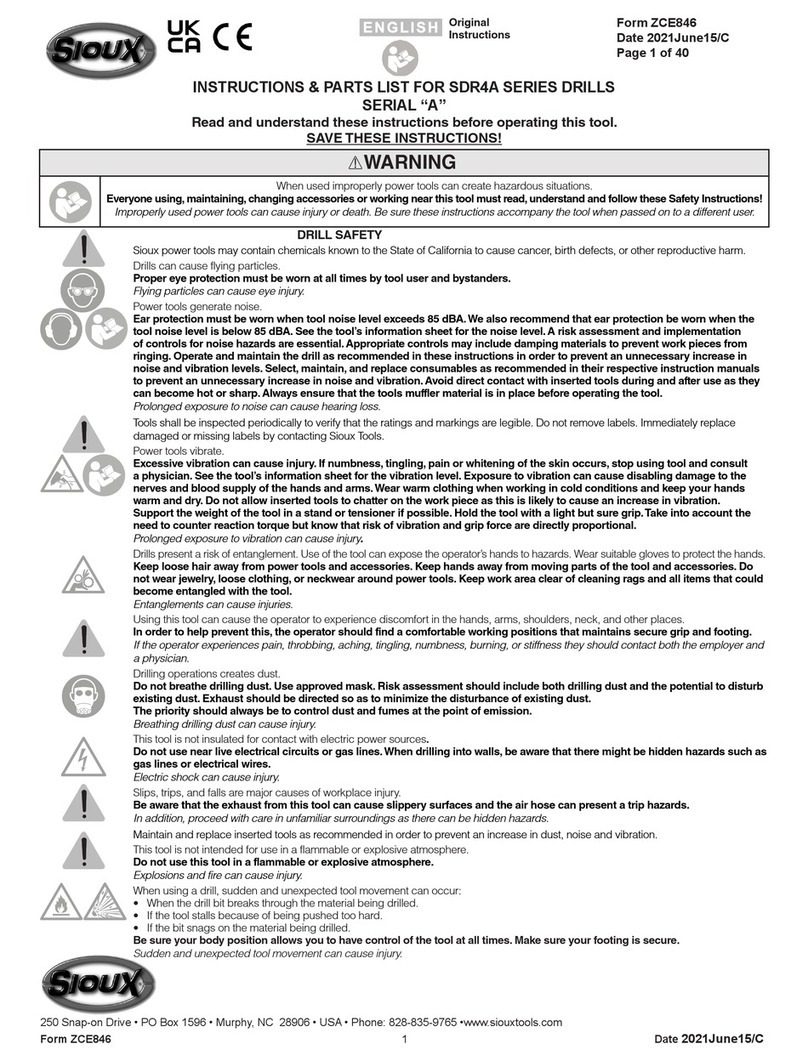

SAFETY

MESSAGES

1

A

WARNING

1

Operator

Instructions

I

Safety

rules

when

using

a

5434

&

5434KL

Drill

or

5434TB

Tire

Buffer

Use

-

Safety Gloves

Use

-

Safety

Boots

Use

-

Breathing

Masks

Use

-

Ear

Protectors

YES

-

Use may produce flying objects. Always use safety

goggles.

-

Use

accessories

ratedatWe

2,500

RPM.

-

Prolongedexposure

to

vibration

may

causeInjury.

-

ReadallInstnxfiCTTCbeforeusingthtetoot.Atopeiatiremust

befuKytainedInitsusaandawareof

thesesafety

nies.

-

Do

not

exceed

the

maximum

working

air

pressure.

-

Use

personal

protection

equipment

as

recommended.

-

Use

compressedair

only

at

the recommended

conditions.

-

If

the

tool

appears to malfunction, remove from use

Immediately

and

arrange for

service

and

repair.lf

h

IS

not

practical

toremove

tool

from

service,

(hen

shut

off

theair

supply

to

the

toot

and

write

or

have written

a

warning

note

and

attach

it

to

the

toot.

-

If

tool

Is

to

be

used

with

a

balancer

or

other

suspension

device, ensure that the tool

is

firmly attached to

the

suspensidsupportdevice.

-

When operating the tool. always keep

the

body

and

particularlythehands

away

from

theworking,attachment

fixed

tothe

tool.

-

The

tool

Is

not

electricallyInsulated.Neverusethetool

If

there

Is

any

-chanceof coming Into

contact

with live

electricity.

-

Always

when

using

the tool,

adopt

a

finn

footing

and/or

position

and

grip

the

tool

sufficiently

only

to

6wrcorne

any

reaction

forces

that

may result

from

the

too)

doing

work.

Do

not overgrip.

-

Use

only

con-act

spare

parts

for

maintenanceancfrepadr.

Do

not Improvise or make temporary repairs. Major

servicing

and

repairs

should

only

be

carriedoutbvnereonstminedtodoso.

7

-

DO

not

taps,

wire,

etc.

the

WOW

valve

In

'Ona position.

The

throttle

trigger/ fever,

etc.

must

always

be

free

to return to

the

'Off'

position when

released.

-

Ahvfwsshutoffthealrsupptytothetool

and

press

the

"On/Off

valve

to

exhaust

the

air from

the

lead hose before

fitting, removing

or

adjusting

the

Wng

attachment

fitted

to

the

tool.

-

Beforeusbgthetoolmakesurethata

shut

off

device

has

been

fitted

to

the

supply

One

and

the

position

Is

known

@

AlwaysWear SafetyGoggles

<fi)

wear

HearingProtection

Avoid

ProlongedExposure

A

o

Vibration

and

easilyaccessible

so

that

thealrsupplytothe

tool

can

be

shut

off

In

an

emergency.

-

Check

hose

and

fittings regularly

(or

wear.

-

Take

care

against

entanglement

of

the moving

parts

of

the

tool

with

clothing, hair,

ties,

cleaning

rags,

rings,

jewelry, watches,bracelets,

etc.This

could

cause

the

body

or

parts

of

the

body

to

be

drawn

towards

and

incontact

with

the

moving

parts

of the

tool

and

could

be

very

dangerous.

-

It

Is

expected

that

users

will

adopt

safe

woridng

practices

and

observa

all

local,

regional

or

country

legal

requirements

whenInstalling,

using

or

maintaining

(he

tool.

-

Take

care

that

theexhaustairdoes

not

point

towards

any

other

person

or

material

or substance that could

be

-3ontaminatedby

dl

droplets.

When

firo$

lubricating

a

tool

or

If

the

toot

exhaust

has

high

ofl

content,

do

not

allow

theexhaustair

to

comenear

very

hot

surfaces

orflames.

-

Neverlaythe tooldownuntilthe workingattachment

has

stopped

moving.

-

When the

tool

is

not

inuse.

shut

off the air supply

and

press

throttle triggerAever to

drain

the

supplyline.

If

the

tool

Is

not

to

In

used

(or

a

periodof

time,

first

lubricate,

disconnect

from

air

supply

and

storeIn

adry

average

room

temperature

environment

-

If

the

tool

Is

passed

from

one userto

a

neworInexperi-

encedusor,

make

sure

these

Instructionsareavailable

to

be

passed

with

the

tool.

-

Do

not

remove

any

manufacturer fitted safety devices

where

fitted,

I.8..

wheel guards, safety trigger, speed

governors,

etc.

ores seen

Use

Work Stations

Putting

Into

Service

Operating

Dismantling

and

Assembly.

\

\\--w

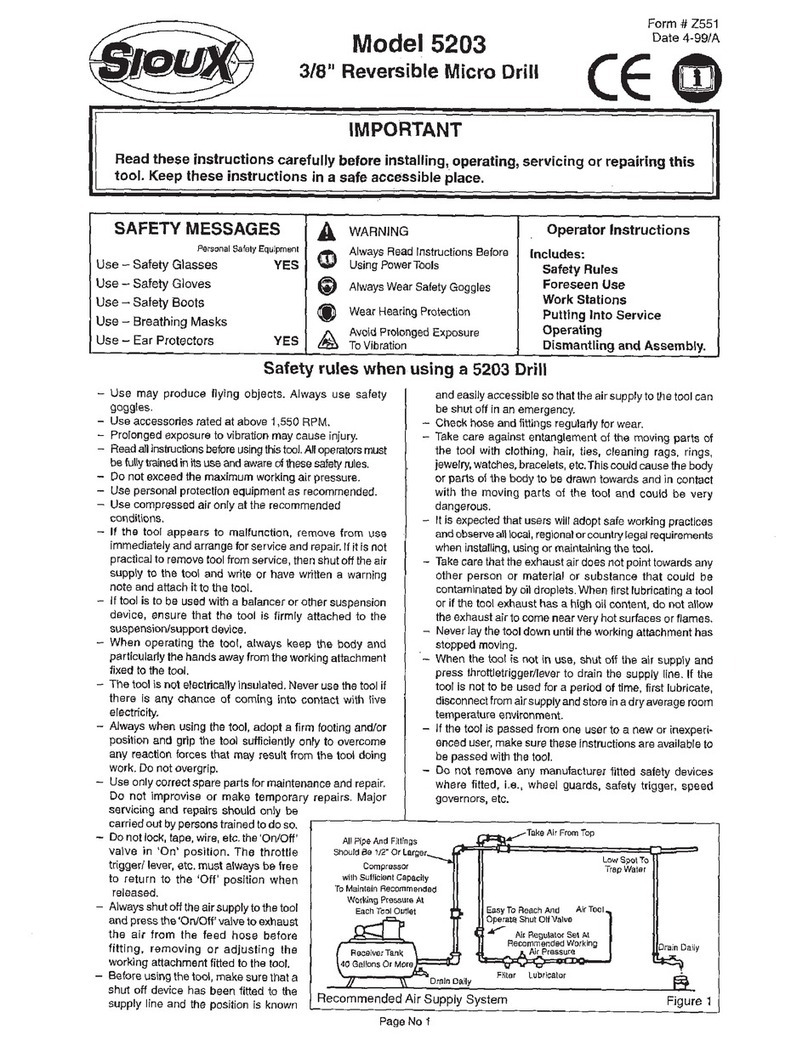

Recommended

Air

Supply

System

Fiqure

1

Page

No

1