Form

#

Z551

Date4-99IA

C?

0

b

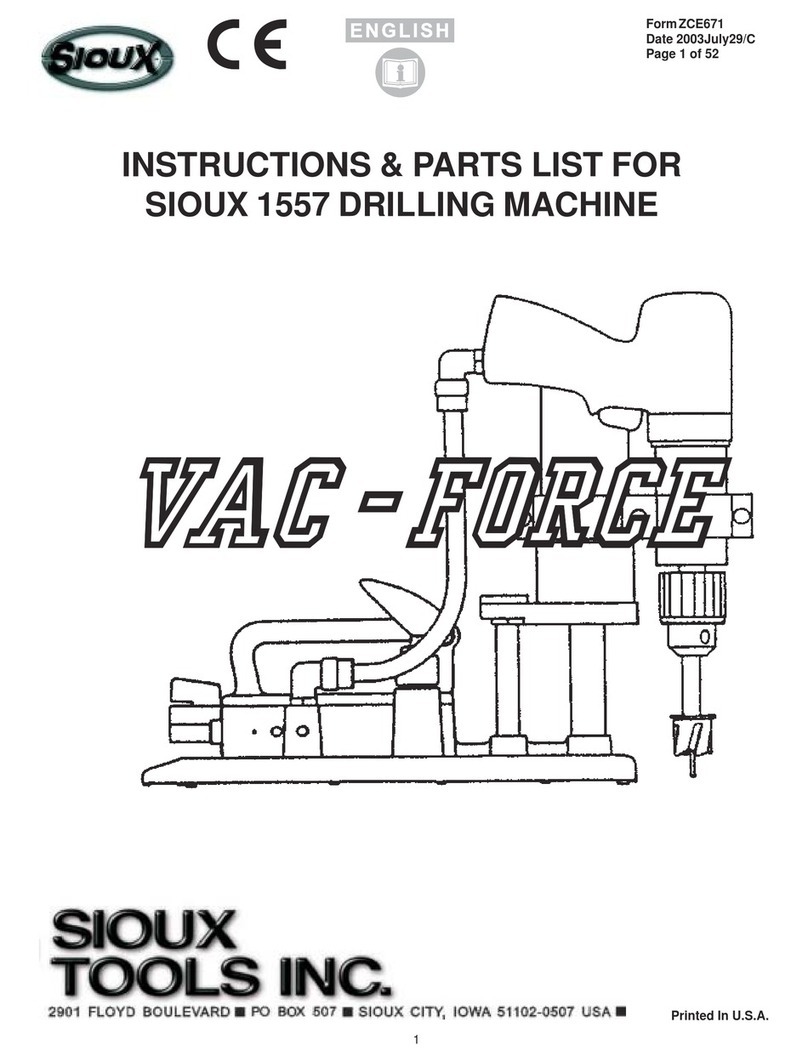

Model

5203

318"

Reversible

Micro

Drill

II

-----

IMPORTANT

I

I

Read

these instructionscarefully beforeinstalling,operating,servicing or repairingthis

tool.

Keep

these instructionsin a safe accessibleplace,

SAFETY

MESSAGES

Personal

Safety

Equipment

Use

-

Safety

Glasses YES

Safety

rules

when using

a

5203

Drill

Use

-

Safety

Gloves

Use

-

Safety

Boots

Use

-

Breathing

Masks

Use

-

Ear

Protectors

YES

-

Use may produce flying objects. Always use safety

A

WARNING

Always ReadInstructionsBefore

@

UsingPowerTools

goggles.

-

Useaccessoriesratedat above

1,550

RPM.

-

Prolongedexposure tovibrationmay cause injury.

-

Read

all

instructionsbeforeusingthistool.Alloperators must

befullytrainedin

its

use andawareof these safety rules.

-

Donotexceedthe maximumworking air pressure.

-

Usepersonalprotectionequipment as recommended.

-

Usecompressedaironly atthe recommended

conditions.

-

If

the

tool aooears

to

malfunction, remove from

use

Operator Instructions

Includes:

Safetv

Rules

@

AlwaysWear Safety Goggles

@

Wear HearingProtection

Avoid ProlongedExposure

dh

T

oVibration

immediatelyandarrangefor serviceandrepair.Ifitisnot

practicaltoremovetoolfromservice,thenshutoff theair

ores seen

Use

Work

Stations

Putting Into Service

Operating

Dismantlingand

Assembly.

supply to the tool and write or have written a warning

noteand attach

it

tothe tool.

-

If

tool isto be usedwith a balanceror other suspension

device, ensure that the tool is firmly attached to the

suspension/supportdevice.

-

When operating the tool, always keep the body and

particularlythehandsaway fromtheworking attachment

fixed to the tool.

-

Thetool isnotelectrically insulated. Neverusethetool if

there is any chance of coming into contact with live

electricity.

-

Always when using the

tool,

adopt a firm footing andlor

position and grip the tool sufficiently only to overcome

any reaction forces that may result from the tool doing

work. Do notovergrip.

-

Useonly correctsparepartsfor maintenanceand repair,

Do not improvise or make temporary repairs. Major

servicing and repairs should only be

carriedoutbv oersonstrainedto do

so.

7

andeasilyaccessiblesothattheairsupply

to

thetool

can

beshut off in an emergency.

-

Check hoseandfittings regularlyfor wear.

-

Take care against entanglementof the moving parts of

the tool with clothing, hair, ties, cleaning rags, rings,

jewelry, watches, bracelets,etc.Thiscouldcausethebody

or partsof the bodyto be drawn towards andincontact

with the moving parts of the tool and could be very

dangerous.

-

Itisexpectedthat users will adopt safe working practices

and

observealllocal, regionalorcountrylegal

requirements

when installing, usingor maintainingthetool.

-

Take carethatthe exhaustair doesnotpointtowardsany

other person or material or substance that could be

contaminatedby oildroplets.When first lubricatinga tool

or ifthe tool exhausthas a highoil content, do not allow

the exhaustairtocome nearvery hotsurfacesor flames.

-

Neverlaythe tooldownuntiltheworkingattachmenthas

stoppedmoving.

-

When the tool is not in use, shut off the air supply and

press throttletriggerlleverto drain the supply line.

If

the

tool isnottobe usedfor a periodof

time,

first lubricate,

disconnectfrom airsupplyandstoreinadryaverage room

temperature environment.

-

If the tool is passedfrom one user to a new or inexperi-

enceduser, makesuretheseinstructionsareavailableto

bepassedwiththetool.

-

Do not remove any manufacturer fitted safety devices

where fitted, i.e., wheel guards, safety trigger, speed

governors, etc.

-

DO

notlock,tape, wire, etc. the4~n/~ff1

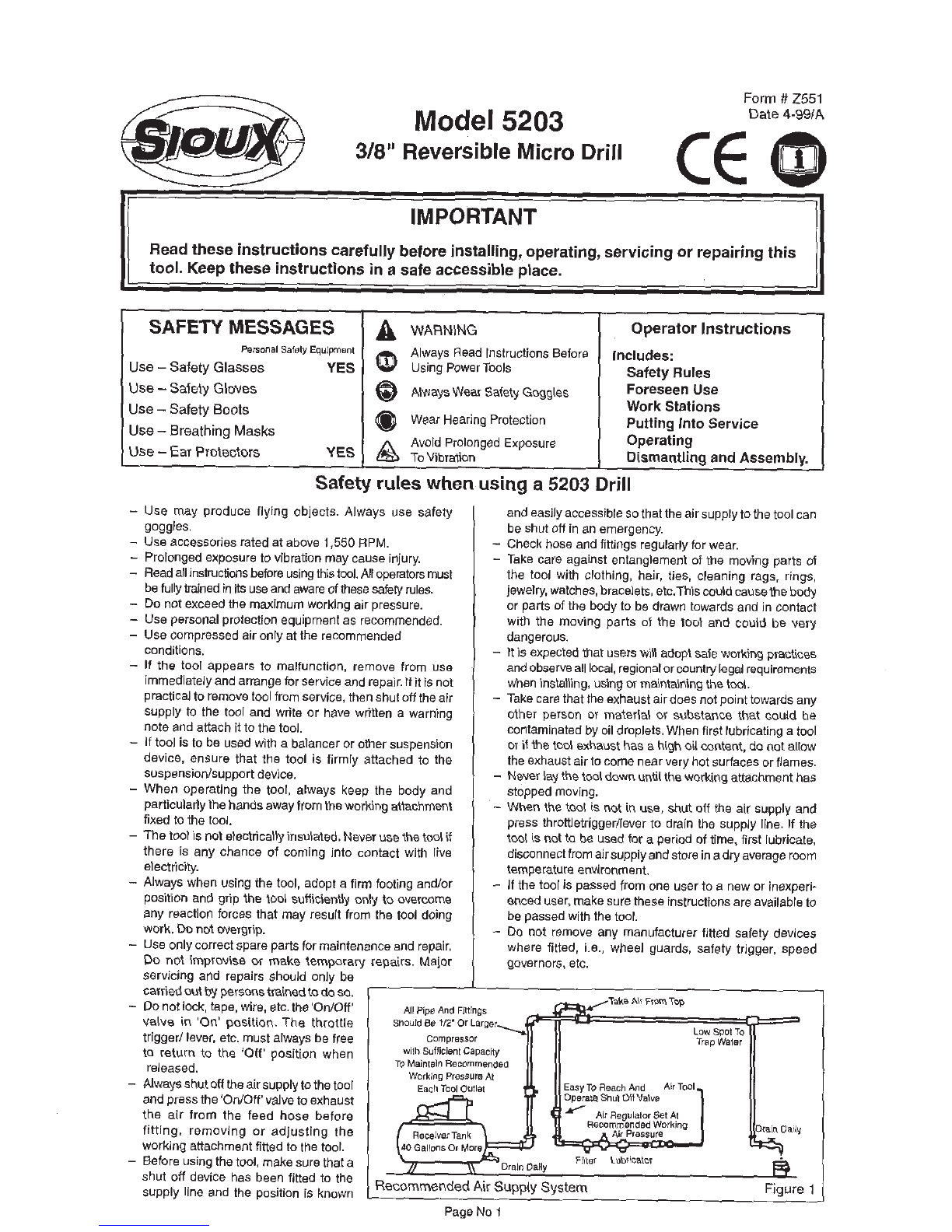

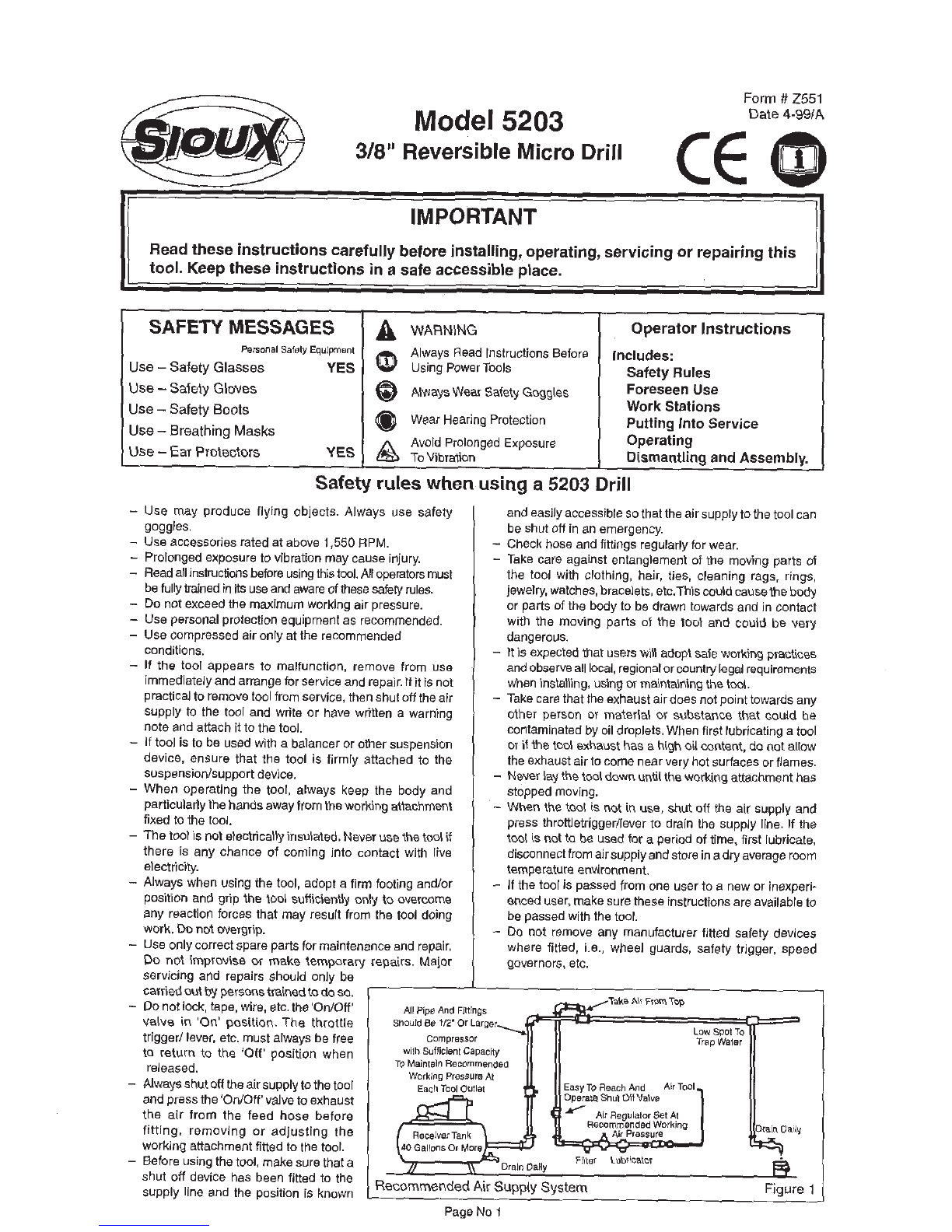

AII

Pipe

And

Fillings

valve in 'On' position. The throttle

ShouldBe

112"

Or Larger

trigger1lever, etc. mustalways be free

to return to the 'Off' position when

released.

-

Always shutoff theairsupplytothetool

andpressthe

'On/Off'

valveto exhaust

the air from the feed hose before

fitting, removing or adjusting the

working attachmentfittedto the tool.

-

Beforeusingthetool, makesure thata

huto device has beefitted to the

Recommended

Air

Supply

System

supply line and the positionis known Figure

1

PageNo

1