Siqura 1210 TRA-TRB User manual

© Siqura 2017

Version 021403-2f

ADS1200 (MW10)

ADS 1200

Audio, data and contact closure multiplexers for fiber-optic links

USER MANUAL

1. General description

ADS 1200 systems offer combined full duplex

transmission of data, audio and contact closure

signals, all independent, over one or two multimode or

single-mode optical fibers (TRA/TRB or TRX

respectively, see figures 1a, 1b). For technical

specifications, consult section 5.

Two 4-wire audio channels and two contact closure

channels are available on the topmost pair of modular

connectors (port 1 and port 2). The data section

comprises two RS-485/RS-422 (Manchester and

biphase compatible) and two RS-232 channels, on the

two lower modular connectors.

Internal dip switches control the configuration (2/4

wiring and type; default is 4-wire RS-485) of the RS-

4xx interfaces. If necessary, the RS-485 interfaces can

be adapted to use biasing; by default, the data

interfaces are transparent. By removing a jumper and

output rewiring, port D1 can be used for digital

current loop. Audio input impedance is jumper

selectable. The contact closure outputs are potential-

free and open on synchronisation failure.

LEDs indicate power and local as well as remote sync

status (see section 2), and also monitor data I/O.

The 7TE modules will slot into the backplanes of

TKH Security’s MC 10 or MC 11 power supply

cabinets. Stand-alone models (/SA option, see

supplementary manual) needs an external 12 Vdc

power supply.

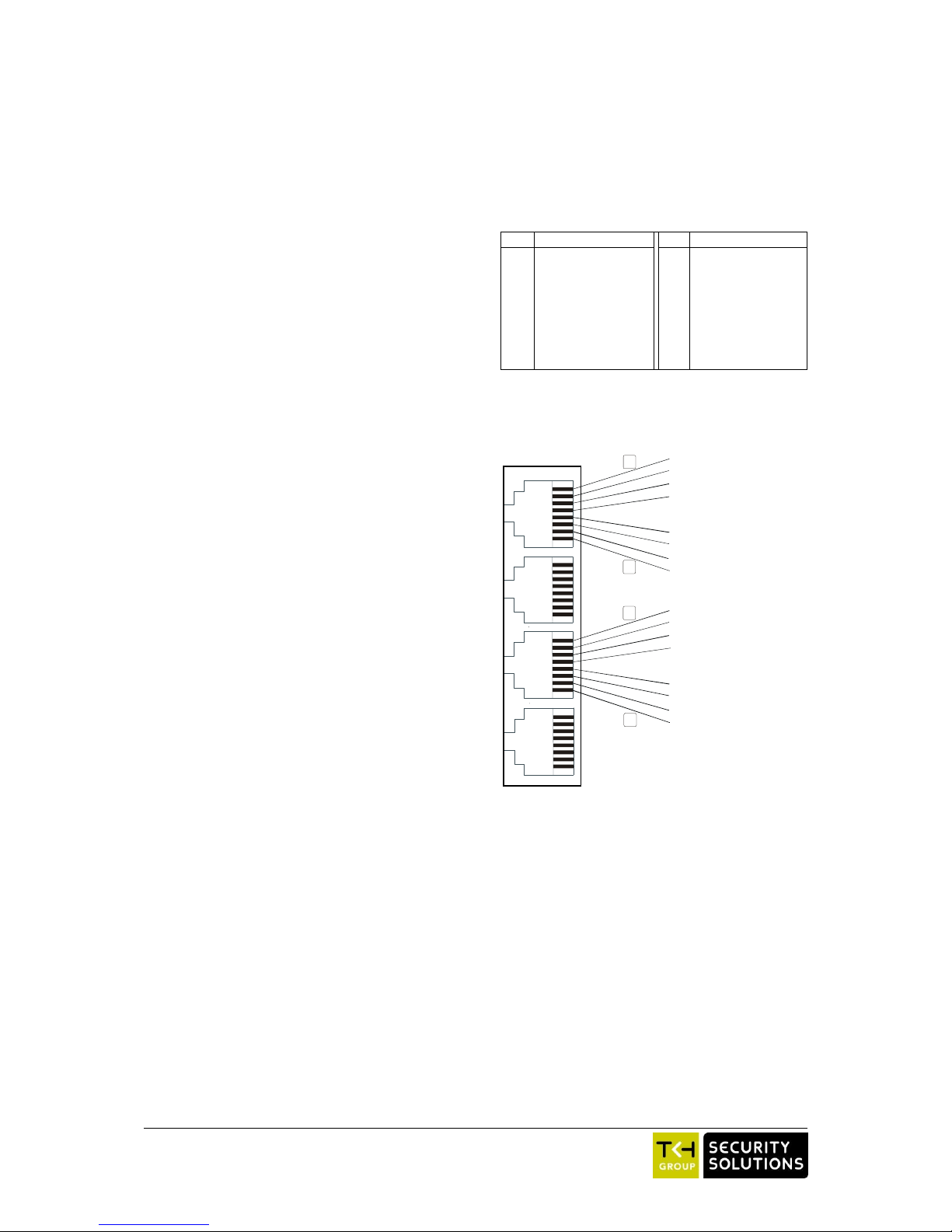

2. Connectors and indicators

Indication

Meaning

o

(ST or FC connector)

Optical input (two-fiber units)

o

(ST or FC connector)

Optical output (two-fiber units)

o

(ST or FC connector)

Optical input/output

(single-fiber units)

Modular sockets:

A1/CC1

audio1, contact closure 1

A2/CC2

audio2, contact closure 2

D1/D2 (D1: see text)

RS-485 (422), RS-232

D3/D4

RS-485 (422), RS-232

System status LEDs:

*SYNC

(red)

No sync from optical in,

or no internal sync

(orange)

No sync @ remote optical in

(green)

All sync OK

*DC

(green)

DC power good

Data status LEDs:

*D1, *D3

red/green

RS-485 input to D1,3 = 1/0

off

high-Z

*D2, *D4

green/off

RS-232 input to D2,4 =1/0

Table 1. Connectors and indications on the ADS 1200 front

panel (the modular sockets take RJ-45 plugs)

3. Configuration and installation

3a) Configuration

Interface selection and configuration are performed

using switches and jumpers on the circuit boards of

the ADS 1200 units. To access these elements, each

unit must be opened by taking out the two front

panel Phillips head screws indicated in figure 1 and

partially sliding out the circuit board (shown in

figure 2).

An ADS 1200 data board has two 8-fold (S1, S2)

and one 4-fold (S3) dip switch blocks. The first

switch of each block and the ON positions are also

indicated in figure 2.

The jumper-pin groups A and B control audio input

impedance of A1 and A2, respectively; jumper C

regulates the current loop impedance of one of the

RS-485 data outputs (see below).

Data interface selection: the 4 dip switches in bank

S3 determine the RS-4xx interface type available

on ports D1 and D3 as per table 2.

Figure 1. ADS front panels: TRA (left, similar to

TRB, one-fiber), and TRX (right, two-fibers)

2

Interface

type

port D1

port D3

S3-1

S3-2

S3-3

S3-4

RS-485 2-w.

0

0

0

0

RS-485 4-w.

0

1

0

1

RS-422

1

0

1

0

Table 2. Choosing RS-485 interface types

using dip switch bank S3

Two-wire RS-485 mode uses the input terminals for

I/O. In older ADS/VAD units, for two-wire mode the

+ in and + out needed to be combined, as well as - in

and - out; old and new units can be used together with

the old-style cable layout.

Current loop output: The RS-485 output impedance

of port D1 can be made suitable for digital 20 mA

current loop ('TTY') applications by pulling a 2-pin

jumper (C2-3) from the board, thus inserting a resistor

into the non-inverting data line. The jumper may be

put on pins C1-2 to save it. Current loop I/O should

use only non-inverting lines and signal ground (see

figure 3); the interface type should be set to RS-485

(4-w). Input signal voltage on A-GND (IN+-GND)

should be at least 4V.

RS-485 line biasing: In most cases, the RS-485 data

interface works with the default settings. If, however,

data line biasing is called for by other equipment

connected to the ADS 1200, biasing impedances may

need to be applied and dwell times set. With the other

dip switches configured for RS-485 mode, the

eightfold switch banks S1 (for interface D1) and S2

(for interface D3) on the ADS 1200 circuit boards

(figure 2) control attachment of two bias impedance

resistors to both input and inverting input (table 3

below).

Switch

bank S1 for D1

bank S2 for D3

Function (RS-485 mode set)

1-3

dwell time select, see table 4

4 ON

inverting input tied to +5V over 390

5 ON

inverting input tied to +5V over 10 k

6 ON

line termination 120 (default = off)

7 ON

input tied to GND over 10 k

8 ON

input tied to GND over 390

Table 3. Choosing bias resistances, dwell times and line

termination for interfaces D1 and D3

Note that the 'soft zero' biasing adaptation method

used ties the inverting ('negative') input to the

higher voltage, while the biasing resistor of the

normal input is tied to signal ground. This provides

a well-defined bus state when no driver is active.

The first three dip switches of the banks S1 and S2

on the circuit boards (figure 3) are used to

configure the tristate-sensing/dwell timing of

interface D1 and D3, respectively, if biasing of

RS-485 lines is used, to help indicate the

conclusion of transmission (table 3). Dwell time is

approximately 10*bit length or slightly longer.

Setting

no.

Switch

bank S1 for D1

bank S2 for D3

Dwell

time

(±7%)

Data

rate

(bit/s)

1

2

3

0

OFF

OFF

OFF

*

0-max

1

OFF

OFF

ON

**

0-max

2

OFF

ON

OFF

0.17 ms

64000

3

OFF

ON

ON

0.34 ms

38400

4

ON

OFF

OFF

0.67 ms

19200

5

ON

OFF

ON

1.35 ms

9600

6

ON

ON

OFF

2.68 ms

4800

7

ON

ON

ON

5.38 ms

2400

*) default, hardware tri-state detect (1V differential sense,

not to be used together with line-biasing)

**) logic high in the data directly drives the output enable

(i.e. no delay). This setting is especially suitable for

very low data rates.

Table 4. Dip switch settings for unbiased and biased

RS-485 interfacing. Settings 1-7 all need bias resistors

to define zero.

Depending on the actual data rate, switches 1-3 of

block S1 and S2 should then be set as per table 4

(read the notes below). Default is all three switches

off, i.e. hardware tristate sensing.

Notes on dwell times:

- When in doubt about which of two dwell times to

select, use the longer of the two.

- Settings 1-7 only work if the lines are biased to a

‘soft zero’.

- The serial receiver dwell timing circuitry (re)starts

a timer on the rising edges of input data from the

copper side, at the same time sending an output

Figure 3. Current loop connections

U603

11

ON

S1 S2 S3

1

2

3

1

2

3

1

2

3

A

B

C

ADS TRX 650 2033 3

WWJJ

1

Figure 2. ADS TRA/B printed circuit board; details left out

for clarity. Take care not to damage the optical fiber

floating above the board.

GND

B (IN-)

A (IN+)

GND

B (OUT-)

A (OUT+)

220 ohm,

internal

jumper removed

3

enable signal to the serial data transmitter on the other

side of the optical link. When the timer is allowed to

run out (no more rising edges, meaning no more data),

this output will get no enable signals anymore and will

go into tristate, freeing up its line.

- Different dwell times may be used within the system.

Mixing hardware-tristate-detect onone side and dwell-

time on the other side is also feasible.

- The setting of tristate/dwell time in a unit does affect

the data fed into that unit, i.e. the way data is output at

the remote unit.

RS-485 line termination: Line termination impedance

of interfaces D1 and D3 may be set to low (120 )

using dip switch 6 of bank S1 and S2, respectively

(table 3). Default is high impedance.

Audio port impedance: Audio input impedance in the

ADS 1200 can be set by moving jumpers A (for audio

interface A1) and/or B (for interface A2) on the upper

circuit board (fig. 2). A jumper on pins 1-2 selects

high impedance for that port (default); shorting pins 2

and 3 lowers the audio input impedance to 600 Ohms.

3b) Installation

Provide the units with power and connect appropriate

cabling (twisted pair for long electrical links).

Through-connecting the signal ground lines is

recommended. If SYNC problems occur after

powering up, check the optical link first.

4. Connector pin assignments

The electrical port pin assignments (table 5) are

such that similar ports of different units may be

connected back to back with reversed cable

(RS-232 interfaces excepted). See figure 5 for the

pin numbering convention used.

Pin

Port 1 (2)

Pin

Port 3 (4)

1

Audio in +

1

RS-485/422 in + **

2

Audio in -

2

RS-485/422 in -**

3

GND

3

RS-232 in

4

CC1out b

4

RS-232 out

5

CC1in (ref. to GND)

5

GND

6

CC1out a

6

GND

7

Audio out -

7

RS-485/422 out -

8

Audio out +

8

RS-485/422 out +

Table 5. Electrical port pin assignments

** see note Figure 5

1

AUDIO1 IN +

AUDIO1 IN -

GND

CC1 OUT B

CC1 IN

(ref. GND)

CC1 OUT A

AUDIO1 OUT -

AUDIO1 OUT +

8

RS-485/422-1 IN + **

RS-485/422-1 IN - **

RS-232-1 IN

RS-232-1 OUT

GND

GND

RS-485/422-1 OUT -

RS-485/422-1 OUT +

1

8

Figure 5.

Socket pin assignments. The second port (A2/CC2) is

similar in layout to port A1/CC1/ while the downmost

port (D3/D4) is similar to the third (D1/D2).

Input connector pins marked ** also work as outputs in

2-wire mode (see text).

4

5. Technical specifications

ADS type >

1200 TRX/

1210 TRA-TRB

1240 TRX/

1250 TRA-TRB

Optical

Wavelength(s)

850/850-1310

1310/1310-1550

nm

Fiber

MM (2x/1x)

SM (2x/1x)

Link budget

201) / 201) at

850 nm

22 / 25 at 1310

nm

dB

Link length

6 / 6

55 / 55

km

Output power

>-151) / >-151)

>-7 / >-7

dBm

Input sensitivity

-35 / -35

-32 / -32

dBm

Audio

Channels

1 at port 1, 1 at port 2 (both full duplex)

Bandwidth

40 to 15k

Hz

Sampling rate

16-bit

I/O level

0 (+6 max)

dBV

SNR

>62

dBA

THD

<1 (at nom. level)

%

Input imped.

<50 kor600 balanced

Output imped.

<50 balanced

Contact closure

Channels

1 at port 1, 1 at port 2 (both full duplex)

Activation at

<0.75 (<1.5 kto ground)

V

Input

+5 V pull-up, 10 k

Output

NO, fail-safe, potential-free

Output switch

1 A @ 30 Vdc

Data (port 3; port 4)

Channels per

port

RS-232; RS-485 2) (2W, 4W),

RS-422 or 20 mA digital CL)

Data format

Asynchronous, serial

Interf. support

C. loop, TTY, TTL, Manch., Bi-ph.

Data rate4)

DC to 64

kbit/s

Sample rate4)

512 ksamples/s

Management

Front panel

LEDS

see text

SNM

management

variables

Voltage, module temp., alarm

status, configuration et al

Environmental and Safety

Operating temp.

-40 to +74

oC

Humidity (max.)

<95 (no condensation)

%

Electrical safety

AL / IEC / EN 60950-1

UL recognition file

E242498

Laser safety

IEC 60825-1, IEC 60825-2

EMC immunity

EN 55024, EN 50130-4,

EN 61000-6-2

EMC emission

EN 55022 (Class B)

FCC 47 CFR 15 (Class B)

Powering

Power cons.

4

W

Power voltages

11-15 (/SA)

Vdc

Mechanical

Opt. connectors

ST (MM) 3), FC (SM) 3)

Data, audio,

CC connectors

for RJ-45 plug (4x)

Dimensions

190x128x35 (7TE)

mm

Weight (appr.)

450

g

1) For 50/125 m fiber, subtract 4 dB

2) Manchester/biphase compatible

3) On one-fiber models, other connectors may be fitted on request

4) Per channel

Table 6. ADS 1200 series, technical specifications

6. Safety, EMC, ESD

General

The safety information contained in this section, and on

other pages of this manual, must be observed whenever this

unit is operated, serviced, or repaired. Failure to comply with

any precaution, warning, or instruction noted in the manual

is in violation of the standards of design, manufacture, and

intended use of the unit.

Installation, adjustment, maintenance and repair of this

equipment are to be performed by trained personnel aware of

the hazards involved. For correct and safe use of the

equipment and in order to keep the equipment in a safe

condition, it is essential that both operating and servicing

personnel follow standard safety procedures in addition to the

safety precautions and warnings specified in this manual, and

that this unit be installed in locations accessible to trained

service personnel only.

Siqura assumes no liability for the customer’s failure to

comply with any of these safety requirements.

UL/IEC/EN 60950-1: General safety requirements

The equipment described in this manual has been

designed and tested according to the UL/IEC/EN 60950-1

safety requirements.

If there is any doubt regarding the safety of the equipment, do

not put it into operation. This might be the case when the

equipment shows physical damage or is stressed beyond

tolerable limits (e.g. during storage and transportation).

Before opening the equipment, disconnect it from all power

sources. The equipment must be powered by a SELV*) power

supply.

When this unit is operated in extremely elevated temperature

conditions, it is possible for internal and external metal

surfaces to become extremely hot.

Optical safety

This optical equipment contains Class 1M lasers or LEDs

and has been designed and tested to meet IEC 60825-

1:1993+A1+A2 and IEC 60825-2:2004 safety class 1M

requirements.

Optical equipment presents potential hazards to testing and

servicing personnel owing to high levels of optical radiation.

When using magnifying optical instruments, avoid looking

directly into the output of an operating transmitter or into the

end of a fiber connected to an operating transmitter, or there

will be a risk of permanent eye damage.Precautions should

be taken to prevent exposure to optical radiation when the

unit is removed from its enclosure or when the fiber is

disconnected from the unit. The optical radiation is invisible

to the eye.

Use of controls or adjustments or procedures other than

those specified herein may result in hazardous radiation

exposure.

The installer is responsible for ensuring that the label

depicted below (background: yellow; border and text: black)

is present in the restricted locations where this equipment is

installed.

The locations of all optical connections are listed in the

Indications and Connectors section of this manual.

Optical outputs and wavelengths are listed in the Technical

Specifications section of this manual.

Hazard Level 1M

5

EMC

Warning: Operation of this equipment in a residential

environment could cause radio interference.

This device has been tested and found to meet the CE

regulations relating to EMC and complies with the limits for

a Class A device, pursuant to Part 15 of the FCC rules.

Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) This device

must accept any interference received, including interference that

may cause undesired operation. These limits are designed to

provide reasonable protection against interference to radio

communications in any installation. The equipment generates,

uses, and can radiate radio frequency energy; improper use or

special circumstances may cause interference to other equipment

or a performance decrease due to interference radiated by other

equipment. In such cases, the user will have to take appropriate

measures to reduce such interactions between this and other

equipment.

Note that the warning above does not apply to TKH Security

products which comply with the limits for a Class B device. For

product-specific details, refer to the EU Declaration of

Conformity.

Any interruption of the shielding inside or outside the equipment

could make the equipment more prone to fail EMC requirements.

To ensure EMC compliance of the equipment, use shielded

cables for all signal cables including Ethernet, such as CAT5E

SF/UTP or better, as defined in ISO IEC 11801. For power

cables, unshielded three wire cable (2p + PE) is acceptable

Ensure that all electrically connected components are carefully

earthed and protected against surges (high voltage transients

caused by switching or lightning).

ESD

Electrostatic discharge (ESD) can damage or destroy

electronic components. Proper precautions should be

taken against ESD when opening the equipment.

*) SELV: conforming to IEC 60950-1, <60 Vdc output, output

voltage galvanically isolated from mains. All power supplies or

power supply cabinets available from TKH Security comply with

these SELV requirements.

7. Product disposal

Recycling The unit contains valuable materials which

qualify for recycling. In the interest of

protecting the natural environment, properly

recycling the unit at the end of its service life is

imperative.

8. EU Declaration of Conformity

The EU Declaration of Conformity for this product is

available at http://www.tkhsecurity.com/support-files.

This manual suits for next models

3

Table of contents