sirea MicroARM-A9 User manual

MicroARM-A9

Programmable Logic Controller

User Manual

Date Version Modification

10/09/14 1 Initial version

03/03/15 2 Correction of the digital inputs dra ing

28/01/16 3 Replacing the layout of the card version A by version B

19/02/16 4 Adding section about the choice of system code

15/12/16 5 Correcting a text mistake in section « Selection of the target »

23/08/17 6 The COM0 is in RS232 on the A version of the card and in TTL on the B version of the

board

23/03/18 7 Translated version, sections 5 to 9 added, ne layout follo ing SIREA’s graphic chart

1

MicroARM-A9

Programmable Logic Controller

Table of content

1. Introduction ................................................................................ 3

2. Charateristics .............................................................................. 3

2.1 Board presentation............................................................................................3

2.2 LED meanings.....................................................................................................4

2.3 Mechanical dimension.......................................................................................4

3. Connections ............................................................................... 5

3.1 Digital..................................................................................................................5

3.1.1 Digital input..................................................................................................................5

3.1.2 Digital output...............................................................................................................5

3.2 Analog.................................................................................................................6

3.2.1 Analog input................................................................................................................6

3.2.2 Analog output..............................................................................................................6

3.2.3 Internal board analog input........................................................................................6

3.3 Communication port..........................................................................................7

3.3.1 COM0 RS232................................................................................................................7

3.3.2 COM1 RS232 TTL........................................................................................................7

3.3.3 COM2 RS485................................................................................................................7

3.3.4 COM3 RS485................................................................................................................7

3.4 HMI......................................................................................................................8

3.5 Po er supply......................................................................................................8

4. Standby ...................................................................................... 8

5. Saved variables ........................................................................... 9

6. Choice of target ......................................................................... 9

. Safety and warnings .................................................................... 9

8. Protection device ...................................................................... 10

9. Elimination ............................................................................... 10

10. Cleaning ................................................................................. 10

11. Technical features ................................................................... 10

2

MicroARM-A9

Programmable Logic Controller

1. Introduction

This manual describes the specific features of the MicroARM-A9.

For information common to programming, see the "MicroLADDER manual". To visualize

better the corresponding addresses in MicroLADDER, they appear in color, on the sides of

the diagrams.

2. Charateristics

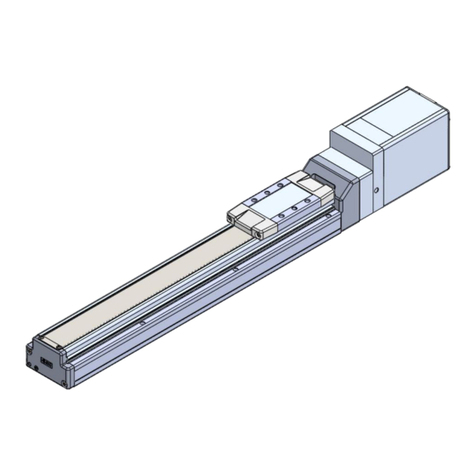

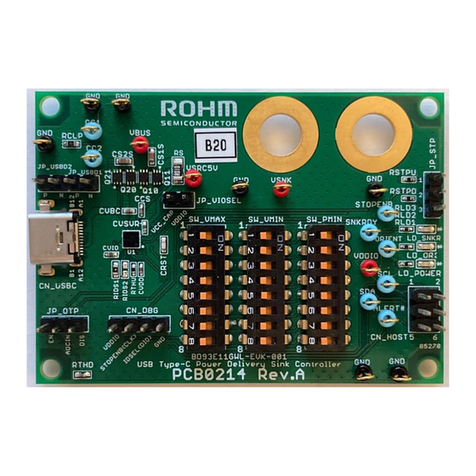

2.1 Board presentation

Afficheur Ethernet Mode PROG Reset

Sonde débug

RS232 #1

+3V3 T R 0V

Reset

Reveil

Entrées ana

0V U/I2 0V U/11

Sortie ana 1

0V

Iout

Sortie ana 2

0V

Iout

Configuration

entrées ana

Config I

Config U

RS485#3

0V B A

Terminaison

RS485#3

RS232#0

+3V3 T R 0V

Terminaison

RS485#2

RS485#2

0V

0V

B

A

+12V

+12V

A

B

0V

0V

Entrées TOR

E1

0V

E2

0V

Entrée réveil

Reveil

0V

Alimentation

Terre N Ph

ou

0V +24V NC

Mini interface

Afficheur

détachée

au montage

Sorties relais

R2 C2 T2 R1 C1 T1

SAV1254B

➔ARM7 LPC1788 Cortex Processor

➔512Ko Flash (to save the monitor and the application)

➔16Mo of video RAM

➔512Ko of saved RAM extensible to 512K

3

Relay output

Analog input

Alarm

Unbug

sensor

Display

Input alarm

Alarm

0V

Mini

interface

Display

detached

when

mounting

Power supply

Ground Ph or

0V +24V C

Digital input

Analog output

Analog input

MicroARM-A9

Programmable Logic Controller

➔1 RS232 (COM0) port ith SubD 9 points connector for the A version of the card

and in TTL for the B version of the card. This port is available for loading or free of

use

➔1 RS232 TTL (COM1) port for loading or free of use

➔1 RS485 (COM2) port for loading or free of use ith double connector and 12Vdc

supply

➔1 RS485 (COM3) port for loading or free of use ith termination resistance jumper

➔1 Jtag port for the debug

➔1 Ethernet connector ith 4 autonomous communication sockets (optionnal)

➔1 USB port

➔1 RTC (Real Time clock) ith backup battery

➔1 EEPROM 16Ko on bus I2C (to backup variables)

➔1 connector for a 4,3 inches touch-screen graphic display (480 x 272 pixels) ith

backlight or or 7 inches touch-screen graphic display (800 x 480 pixels) ith

backlight

➔1 microSD card holder (the card must be formated in FAT32)

➔2 digital inputs

➔2 digital outputs ith RT relay

➔2 analog inputs 0-10V or 0-20mA isolated

➔2 analog outputs 0-20mA

➔2 configuration inputs on jumper (GC2 and GC3) (under the processor)

➔1 pressure and temperature sensor mounted on the card

➔1 reset push-button (Inter1)(located on top of the SubD 9 points) picked up by

jumper (J2)(Located at the top left of the processor)

➔1 jumper to load programs (J1) (located at the top of the processor)

➔1 push-button for the alarm (Inter2)(located on top of COM3) picked up by the

connector

2.2 LED meanings

L1 : Presence of a SD card (next to the microSD card connector)

L2 : Working order of the Programmable Logic Controller (PLC) (on the right of the

processor)

L3 : Presence of 5 V tension supply (on the top left of the battery)

L5 : Presence of 3,3 V tension supply (on the top left of the Ethernet connector)

L8 : Presence input tension supply (next to the po er pack)

L6, L7, L9, L10, L11 : Ethernet next to the Ethernet connector

LD2 : Presence and use of USB port next to the USB connector

See red circles on dra ing section 2.1.

2.3 Mechanical dimension

4

MicroARM-A9

Programmable Logic Controller

3. Connections

The follo ing connection diagrams are in the same direction as the layout diagrams of the

board at the beginning of this document. The line symbolizes the edge of the board.

3.1 Digital

3.1.1 Digital input

The input byte goes up linking the input to the 0 V.

3.1.2 Digital output

This is% Q100 and% Q101. Each output has a relay ith an RT

contact. See iring on the implantation.

5

212 mm

220 mm

96 mm

I0

0V

I1

0V

R1 C1 T1

%Q100%Q101

R2 C2 T2

MicroARM-A9

Programmable Logic Controller

3.2 Analog

3.2.1 Analog input

% IW103 and IW104: analog input voltage (0-10 V =

0-10 000 points) or current (0-20ma = 0-20 000

points) configurable by jumper. See iring and

configuration on the implantation.

1 2 3 4

EA1 GND EA2 GND

%IW103 0V %IW104 0V

3.2.2 Analog output

%QW100 and %QW101 : outputs 0-20mA. 20 000 points = 20mA.

1 GND 0V

2 SA1 %QW100

3 GND 0V

4 SA2 %QW101

3.2.3 Internal board analog input

% IW100: temperature of the sensor implanted on the board in tenth of a degree.

% IW101: atmospheric pressure of the sensor implanted on the card in hectopascal.

% IW102: the po er supply voltage of the card at the output of the AC/DC block or

upstream of the DC/DC block in MV.

6

%IW104 %IW103

Jumpers configured in voltage

Jumpers

1

2

3

4

4 3 2 1

MicroARM-A9

Programmable Logic Controller

3.3 Communication port

3.3.1 COM0 RS232

Standard broaching on DB9 (A version of the board) or see broaching on the

implantation(B version of the board).

1 2 3 4

V3.3 TX0 RX0 0V

3.3.2 COM1 RS232 TTL

See broaching on the implantation.

1 2 3 4

V3.3 TX1 RX1 0V

3.3.3 COM2 RS485

1 GND

2 GND

3 B

4 A

5 12V

See broaching on the implantation. This port has 2 connectors

ith a 12 Vdc po er supply. Its function is to feed 2 sensors

and to communicate ith it.

6 12V

7 A

8 B

9 GND

10 GND

3.3.4 COM3 RS485

See broaching on the implantation.

1 2 3

GND 0V B A

7

1 2 3 4

1 2 3 4

1

2

3

4

5

6

7

8

9

10

1 2 3

MicroARM-A9

Programmable Logic Controller

3.4 HMI

3.4.1 Inputs

% IW0: Horizontal position of the clicked point on the screen.

% IW1: Vertical position of the clicked point on the screen.

3.4.2 Outputs

% Q0: On/off screen backlight.

% QW0: Po er of the display backlight.

On the EDT screens, the backlight is not adjustable. It orks properly on URT screens.

3.5 Po er supply

The board can be po ered either

alternating or continuous depending on the

po er supply that is elded to the board.

Note : the yello arning sticker is only

present on the board hen the alternating

(« alternatif ») current is chosen.

4. Standby

The standby is caused by the instruction:

AlimOff();

The alarm is caused by:

- Press the Wake up PB

- RTC (Time and date of the alarm must be programmed)

- By communication on the COM3 (be a are that a simple polarization of the line causes

the alarm, the 0v must be connected)

Code for programming and activating the date and time of the alarm:

Date d;

long t

t = … ;

d = timeToDate (t);

stRtcAlarm.cSeconde = d.sec;

stRtcAlarm.cMinute = d.min;

8

+9 to 36V

Ground

eutral

Phase

MicroARM-A9

Programmable Logic Controller

stRtcAlarm.cHeure = d.hour;

stRtcAlarm.c our = d.mday;

stRtcAlarm.cMois = d.mon;

RtcWriteAlarm (KB_TRUE);

Code to turn off the date and time of the alarm:

RtcWriteAlarm (KB_FALSE);

5. Saved variables

There's a saved RAM. This allo s to manage histories.

6. Choice of target

In MicroLADDER, once the system code is imported, the target must be chosen. There are

4 target types for the MicroARM-A9: µArm A9 A (7"), µArm A9 A (4"3), µArm A9 B (7"),

µArm A9 B (4"3).

The choice bet een version A and B is based on the memory that is mounted on the

board. In version A, there are 16 MB of video RAM (IC10 in the top right has the reference

48LC8M16A2) and 512 KB of saved RAM (only U2 in the upper right is present). In version B

there are 32 MB of video RAM (IC10 in the top right has the reference 48LC16M16A2) and

1024 KB of saved RAM (U1 and U2 in the top right are present).

The choice bet een 7 " and 4 "3 is based on the size of the screen.

. Safety and warnings

If the device is not used as per these instructions, the safety of people and

equipment can be compromised. We disclaim any liability for any material

damage or due to improper handling or failure to comply ith the safety

instructions.

The interventions on the devices must be made by staff ho are competent to ork on

electric installations.

Before all interventions, all po er supplies must be s itched off. The cutting devices on

the installation must be dimensioned and placed according to the standard UTE C

15-100.

For all interventions on a device installed on an electric installation, the Personal Protective

Equipment (PPE) as defined by the safety regulations on the electric installations must be

carried by the orker.

In the event of a failure or malfunction, the device must not be opened and must be

returned to the factory.

9

MicroARM-A9

Programmable Logic Controller

Observe the follo ing pictograms:

Attention.

On the product label this symbol means that the notice must be consulted.

In this manual, this symbol indicates important information.

Direct current.

Alternating current.

This device is CE approved and complies ith the national and European

guidelines.

8. Protection device

Quick fuse protections must be positioned on the 24 volt continuous start feeding the

PLC. These fuses ill be sized according to the number of devices set in series behind the

start.

9. Elimination

Old electronic devices are recyclables goods that should not be thro n into the

trash can. If the device reaches the end of its life, it should be eliminated in

accordance ith the legal regulations in force to the recovery centres in your

municipality. Elimination in the household trashes is prohibited.

10. Cleaning

For cleaning, use a clean, dry, antistatic, lint-free cloth ithout corrosive products.

11. Technical features

Po er supply 9 to 36 V or 110 to 230 V

Maximum operating Altitude 2000 m

Maximum operating Temperature 45 °celsius

Maximum Operating Humidity 70 %

10

Table of contents

Other sirea Controllers manuals

Popular Controllers manuals by other brands

DTronics

DTronics DT-RDX Firmware update manual

Aquavibe

Aquavibe MRC-2U Operation and installation manual

LEGRAND

LEGRAND 0 663 35 quick guide

Coster

Coster RTE 982 quick start guide

National Instruments

National Instruments RMC-8354 installation guide

Mitsubishi Electric

Mitsubishi Electric A1SJ71PB96F user manual