SIRI ITALY 100 Operating instructions

WET CUTTING SAW

ITALY 100

OPERATING AND MAINTENANCE MANUAL

Italy 100 cutter Use and Maintenance Manual Ver. 1.1

1

Contents

1 INTRODUCTION.................................................................................. 5

1.1 General ...............................................................................................5

1.2 General information on machine use........................................................6

1.3 General precautions regarding machine use..............................................6

1.4 Pictographs relating to operator qualification ............................................7

1.5 Pictographs relating to safety .................................................................8

2 MACHINE PRESENTATION .................................................................. 9

2.1 General ...............................................................................................9

2.2 General notes ....................................................................................10

2.3 Airborne noise emission.......................................................................10

2.4 Technical data....................................................................................10

2.5 Identification plates ............................................................................11

2.6 Type of discs usable ............................................................................ 12

3 SAFETY COMPONENTS AND RESIDUAL RISKS................................... 13

3.1 Mechanical safety devices ....................................................................13

3.1.1 Disc guard .........................................................................................13

3.2 Electrical safety devices....................................................................... 13

3.2.1 Magnetothermal switch........................................................................ 13

3.3 Residual risks.....................................................................................14

3.3.1 Risk of cuts........................................................................................14

3.3.2 Risk to the eyes..................................................................................14

3.3.3 Risk to hearing ...................................................................................14

Italy 100 cutter Use and Maintenance Manual Ver. 1.1

2

4 INSTRUCTIONS FOR USE AND MAINTENANCE .................................. 15

4.1 Introduction....................................................................................... 15

4.2 Permitted use..................................................................................... 15

4.3 Required personal protection devices.....................................................15

4.4 General warnings................................................................................ 15

4.5 Warnings on use................................................................................. 16

4.6 Warnings on machine maintenance .......................................................17

5 MACHINE INSTALLATION AND STARTUP .......................................... 19

5.1 Handling the machine..........................................................................19

5.2 Preparing the working area .................................................................. 19

5.3 Assembling the machine ......................................................................20

5.3.1 Material provided................................................................................ 20

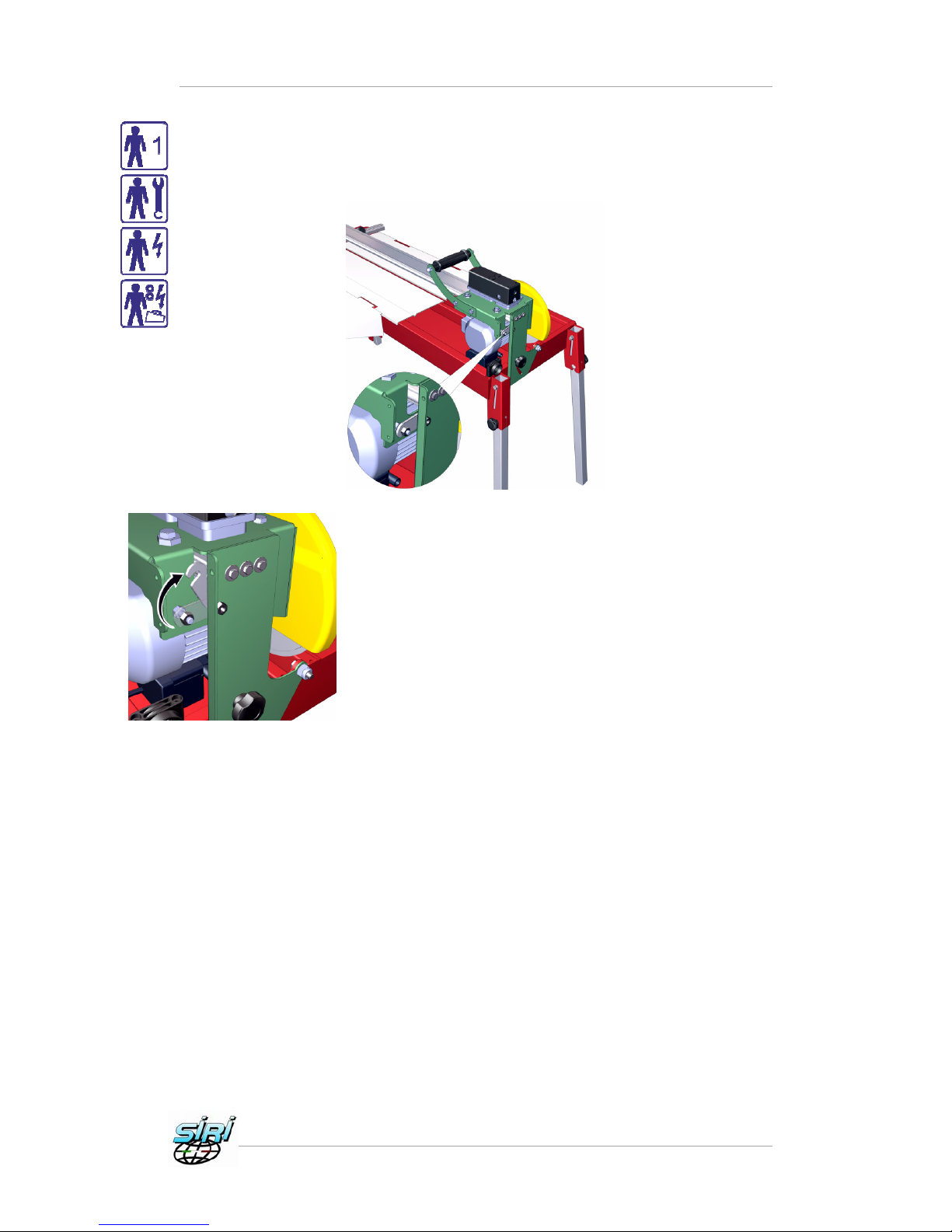

5.3.2 Fitting the legs ................................................................................... 20

5.3.3 Releasing the carriage .........................................................................21

5.4 Connecting to the mains ......................................................................22

5.5 Filling the cooling water tank ................................................................ 22

5.6 Turning on the machine....................................................................... 23

5.6.1 On/off switch .....................................................................................23

5.6.2 Adjusting the water flow ...................................................................... 23

6 MACHINE USE................................................................................... 25

6.1 Basics for machine use ........................................................................ 25

6.2 Operation .......................................................................................... 25

6.2.1 Linear cut ..........................................................................................25

6.2.2 Diagonal cut ...................................................................................... 27

6.2.3 Angle cut........................................................................................... 28

Italy 100 cutter Use and Maintenance Manual Ver. 1.1

3

7 MACHINE MAINTENANCE AND SPARE PARTS.................................... 31

7.1 Warnings on machine maintenance .......................................................31

7.2 Periodic maintenance schedule ............................................................. 31

7.2.1 Daily maintenance ..............................................................................31

7.2.2 Weekly maintenance ...........................................................................32

7.2.3 Monthly maintenance ..........................................................................32

7.2.4 Half-yearly maintenance ......................................................................33

7.3 Scheduled maintenance summary table .................................................34

7.4 Troubleshooting..................................................................................34

7.4.1 Insufficient cooling water flow .............................................................. 34

7.4.2 Difficult carriage sliding .......................................................................34

7.4.3 Poor cutting performance..................................................................... 35

7.5 Placing the cutter out of service ............................................................35

7.6 Exploded drawings and list of spare parts...............................................36

DECLARATION OF CONFORMITY .................................................................. 39

Italy 100 cutter Use and Maintenance Manual Ver. 1.1

4

1 Introduction

IMPORTANT

BEFORE CARRYING OUT ANY OPERATIONS ON THE MACHINES, THE TRAINED

OPERATORS AND TECHNICIANS MUST CAREFULLY READ THE INSTRUCTIONS

CONTAINED IN THIS MANUAL (AND IN THE ATTACHED DOCUMENTS) AND

FOLLOW THEM WHILE CARRYING OUT THE VARIOUS OPERATIONS.

IF YOU HAVE ANY DOUBTS CONCERNING THE INTERPRETATION OF THESE

INSTRUCTIONS, CALL OUR TECHNICAL SERVICE FOR HELP.

1.1 GENERAL

This instruction manual refers to:

MACHINE TYPE: ITALY 100

SERIES AND TYPE: ........

YEAR OF MANUFACTURE: 20....

This manual contains the main information on storage, transport, installation, use,

supervision and maintenance of the machine. This manual forms an integral part of the

machine and must be kept throughout its lifetime for future consultation.

If your copy of the manual becomes unreadable, ask the manufacturer for a new copy:

SIRI SRL

Via R. Dalla Costa 44/46

41122 MODENA (ITALY)

Tel. 059/313191 - Fax 059/311362

MEMBER OF THE EXPO CONSORTIUM - MODENA

specifying the machine type and the serial or order number printed on the machine

identification plate.

THE OFFICIAL LANGUAGE CHOSEN BY THE MANUFACTURER IS ITALIAN.

The manufacturer shall not be held liable for translations into other languages which do

not match the source language and meaning.

This manual reflects the machine status at the time it is supplied and cannot be

considered inadequate if updated following new experience. SIRI reserves the right to

update the manuals without any obligation to update earlier versions or to informusers

of machines supplied previously. All proposed updates to the manual and/or the

machines shall be considered provided for information purposes only.

Should you need any information on machine updates, SIRI Customer Service will

gladly help you.

SIRI is relieved of all responsibility for improper use of the machine, for example:

a) Use by untrained staff

b) Use not in compliance with the regulations in force

c) Incorrect installation

d) Power supply defects

e) Poor maintenance

Italy 100 cutter Use and Maintenance Manual Ver. 1.1

5

f) Unauthorised modifications or operations

g) Use of non-genuine spare parts or not specifically for the model

h) Total or partial inobservance of the instructions

i) Exceptional events.

1.2 GENERAL INFORMATION ON MACHINE USE

The aim of this manual is to provide the user with general knowledge of the machine as

well as maintenance instructions to ensure its good functioning.

Before starting any installation, maintenance and repair operations, carefully read this

manual. It contains all the necessary information for proper use of the machine and to

prevent injury. ·

The frequency of the checking and maintenance operations described in this manual is

the minimum necessary to ensure efficiency, safety and a long life of the machine in

normal operating conditions. Nonetheless, you should constantly monitor the machine

and promptly take action in the event of faults. ·

All routine maintenance operations, checks and lubrication must be carried out with the

machine off and disconnected from the energy supplies (electrical and other).

WARNING

Any unauthorised modification or tampering with the machine and its safety

systems relieves the manufacturer of all responsibility in terms of warranty

and safety.

1.3 GENERAL PRECAUTIONS REGARDING MACHINE USE

This machine has been designed and constructed to be used according to the standard

rules of conduct when working with machines; the manufacturer therefore takes for

granted that the machine operators are knowledgeable with these rules.

The user is responsible for informing and training the operators and ensuring

that everyone that will be operating on the machine read these instructions.

•Where a safety key selector or safety key lock is provided, the maintenance

technician or the operator must remove the key and personally pocket it or put

it in safe place where unauthorised staff cannot access it.

•Do not allow unauthorised staff to operate on the machine.

•DO NOT START THE MACHINE IF IT MALFUNCTIONS IN ANY WAY

•Before using the machine, make sure that any dangerous condition has

appropriately been eliminated.

•Make sure that all the guards and other protections are in place and that all the

safety devices are present and in working order.

•Make sure that there are no foreign objects in the operating area.

•When there is a risk of being hit by projecting or falling solid parts or similar,

wear goggles with side shields, a hard hat and gloves if necessary.

•Personal protection devices must be used where prescribed.

Italy 100 cutter Use and Maintenance Manual Ver. 1.1

6

PRECAUTIONS REGARDING ELECTRICAL EQUIPMENT

Connection, startup, maintenance, measurements and adjustments of the electrical

equipment or its components may only be carried out by qualified electricians. When

working on live electrical components, strictly observe the regulations in force.

1.4 PICTOGRAPHS RELATING TO OPERATOR QUALIFICATION

The meaning of the symbols used in this manual is given below. These symbols are

shown at the beginning of a paragraph to indicate the staff the paragraph addresses, it

being understood that the contents of this MANUAL MUST BE FULLY READ and therefore

MUST BE KNOWN TO all the machine users and everyone that will be performing any

type of operation on it.

Generic worker: operator with no specific skills capable of carrying out only

simple tasks on instructions of qualified technicians.

Hoisting and handling means driver: operator qualified for use of material

and machine lifting and transport means (strictly following the instructions of

the manufacturer), in compliance with the laws in force in the country of use.

Mechanical maintenance technician: qualified technician capable of

running the machine in normal conditions, operating it using the hold-down

buttons with the guards deactivated, and operating on mechanical devices to

carry out adjustments, maintenance or repairs. A mechanical maintenance

technician is normally not qualified to operate on live electric systems.

Electrical maintenance technician: qualified technician capable of running

the machine in normal conditions, operating it using the hold-down buttons

with the guards deactivated, and operating on electrical devices to carry out

adjustments, maintenance or repairs. The electrical maintenance technician

is qualified to operate on live electric systems in electric cabinets and junction

boxes .

Manufacturer's technician: qualified technician made available by the

manufacturer and authorised to carry out complex operations in particular

conditions or in any case as agreed with the user. The manufacturer’s

technicians have mechanical and/or electrical skills.

1.5 PICTOGRAPHS RELATING TO SAFETY

Below are the safety pictograms used on the machine and/or in this manual.

Risk of cuts: Warns the operators that if the operation described is not

carried out according to the safety rules, there is a risk of cutting the hands.

Risk of electrocution: Warns the operators that if the operation described

is not carried out according to the safety rules, there is a risk of electric

shock.

Italy 100 cutter Use and Maintenance Manual Ver. 1.1

7

Risk of projecting fragments: Warns the operators that if the operation

described is not carried out according to the safety rules, there is a risk of

being hit by projecting fragments.

Wear a protective headset: Warns the operators that a headset must be

worn as there is an implicit risk of damage to hearing.

Wear protective clothing: Warns the operators to wear protective

goggles and gloves to prevent injury.

Italy 100 cutter Use and Maintenance Manual Ver. 1.1

8

2 MACHINE PRESENTATION

2.1 GENERAL

The Italy 100 cutter has been designed and constructed to make linear, diagonal and

45° angle cuts in ceramic, marble, granite, porcelain stoneware, Klinker and terracotta

tiles. The diamond disc supplied with the machine is only suitable for cutting ceramic

tiles; for all other materials, use specific discs.

Referring to the figure above, the cutter is made up of the following units:

1) Sliding motor unit (tiltable for 45° angle cuts)

2) Motor

3) Universal diamond disc Italy 100 = 200mm Ø

4) Sliding unit supports

5) Tank

6) Power cable

7) Removable legs

8) Support table

Italy 100 cutter Use and Maintenance Manual Ver. 1.1

9

2.2 GENERAL NOTES

•The machine is intended for industrial use in normal environmental conditions as

defined in point 4.4 of EN 60204-1. These conditions refer to machine use.

•The machine may only be used by specifically trained staff and who have read the

contents of this manual.

•The machine is manually operated.

2.3 AIRBORNE NOISE EMISSION

The sound pressure level was measured in the normal operator working position, i.e.

20cm from the short side of the machine where the tile positioning squares are located.

The value indicated in the table below refers to the machine operating with a continuous

crown disc.

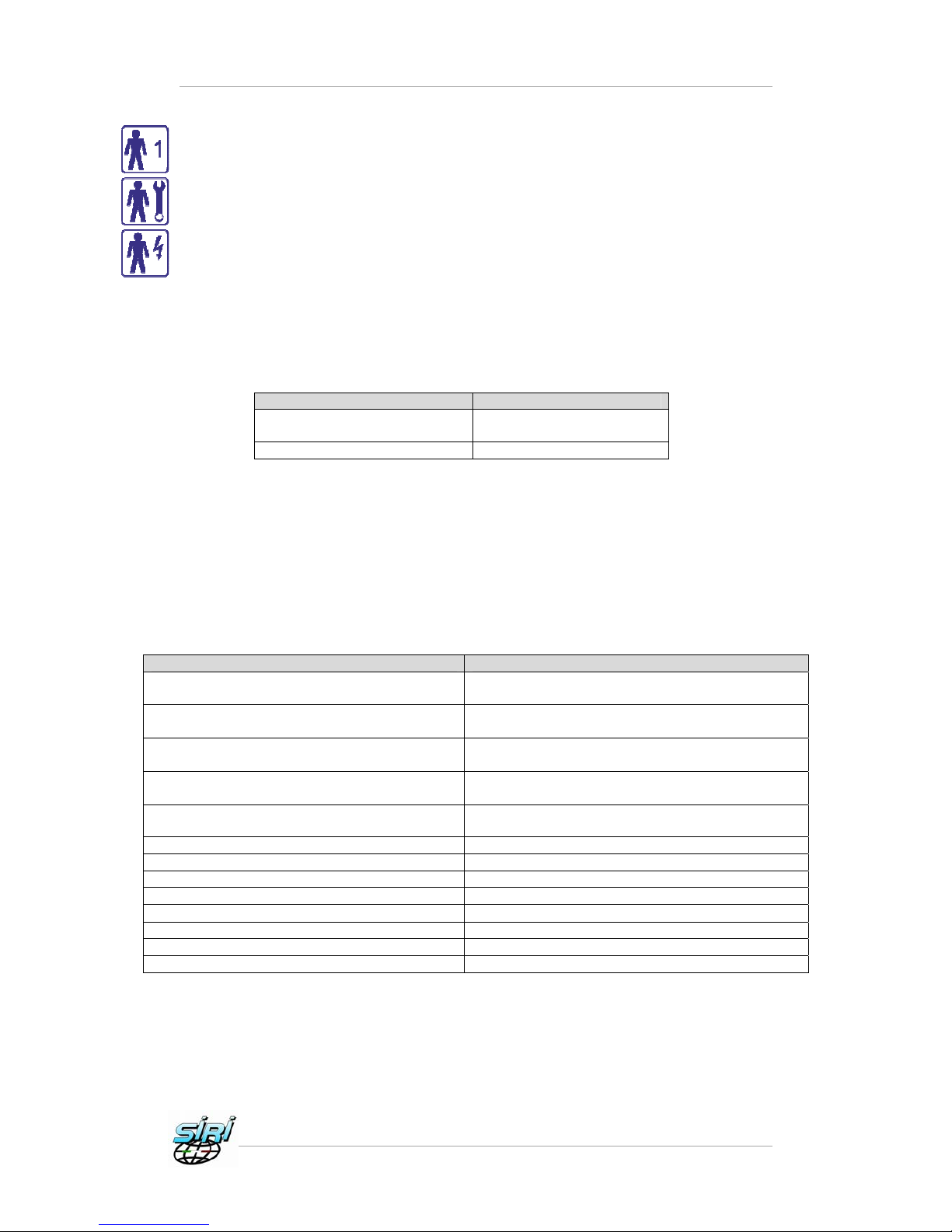

Measurement Sound pressure (dB)

Sound pressure level 90.5 dB (referring to

20µµPa)

Sound power level 97 dB (referring to 1pW)

The measurements were made in accordance with ISO 11201 and ISO 3744.

The sound pressure level generated by the machine is such that anti-noise

protection must be used (headset or ear plugs).

2.4 TECHNICAL DATA

The table below lists the technical data of the machine.

Parameter Value

Electrical power supply SEE THE MOTOR IDENTIFICATION PLATE

Absorption SEE THE MOTOR IDENTIFICATION PLATE

Motor rpm SEE THE MOTOR IDENTIFICATION PLATE

Motor condenser capacity SEE THE MOTOR IDENTIFICATION PLATE

Degree of protection SEE THE MOTOR IDENTIFICATION PLATE

Insulation class F

Maximum cutting length 100 cm

Maximum length for 45° angle cut 100 cm

Maximum tile sides for 45° cut 70cm x 70cm

Maximum cutting height 42 mm

Diamond disc type 200mm Ø continuous crown

Weight 55 kg

Dimensions 154 x 57 x 106 cm (LxDxH)

The operating temperature must be between 0 and 45°C

Italy 100 cutter Use and Maintenance Manual Ver. 1.1

10

2.5 IDENTIFICATION PLATES

The machine has been constructed in compliance with the requirements of Machine

Directive 2006/42/EC and Electromagnetic Compatibility Directive 2004/108/EC. The

declaration of conformity is attached to this manual.

When contacting Customer Service, exactly quote the model, serial number and year

of manufacture of the machine to facilitate fast and precise replies. This data is found

on the identification plate installed on your machine.

The machine and motor unit identification plates are positioned on the outside of the

right-hand side upright as shown in the figure.

It is prohibited to alter and remove these identification plates.

The identification plates bear the following data:

- Manufacturer’s name and address

- Machine type

- Serial number

-CE marking and year of manufacture of the machine.

- Power voltage in volts and frequency in Hz

- Maximum absorption in amperes

Italy 100 cutter Use and Maintenance Manual Ver. 1.1

11

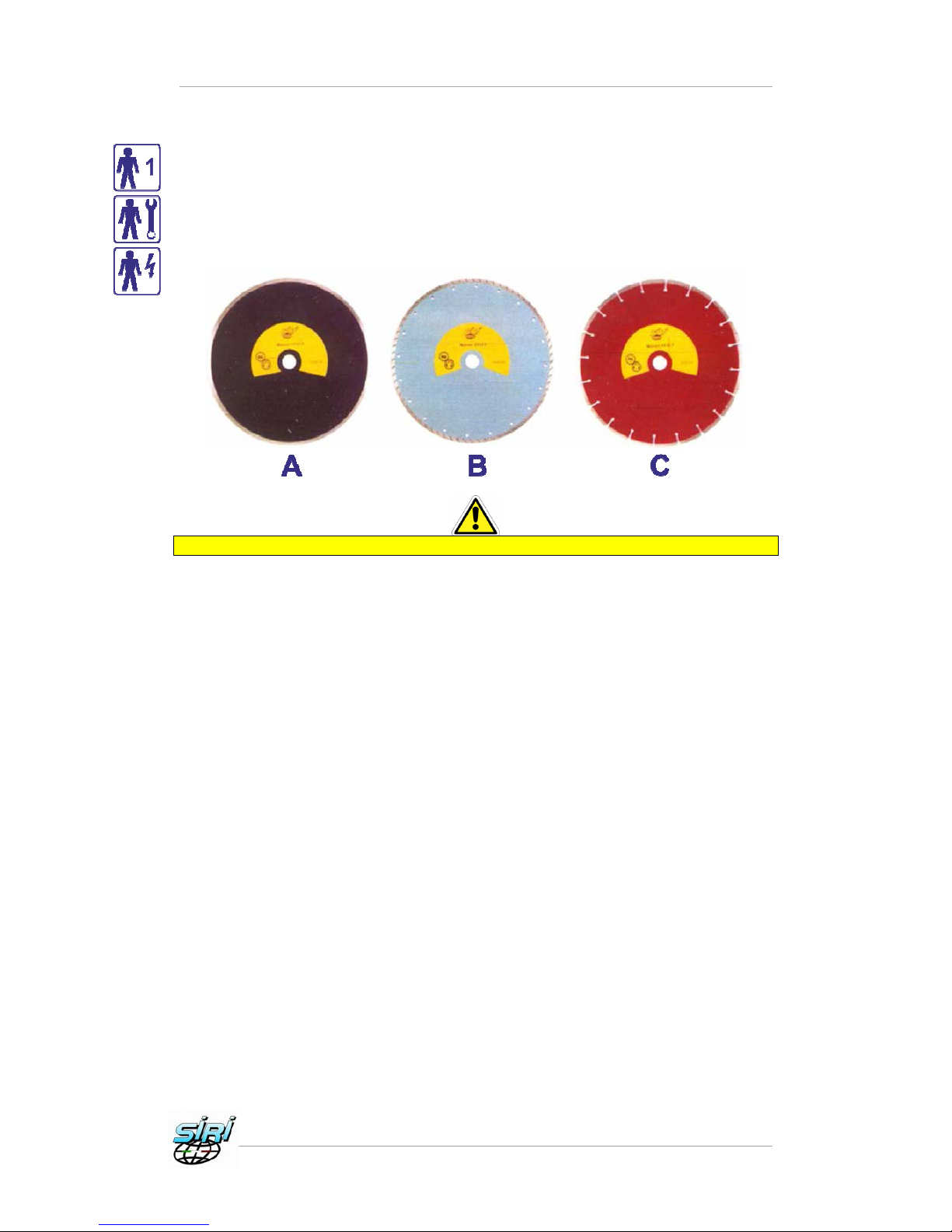

2.6 TYPE OF DISCS USABLE

The machine may only be used with the cutting discs listed and shown below:

A) Continuous crown disc for ceramic and porcelain stoneware tiles

B) Turbo disc for terracotta, ceramic and marble tiles

C) Sector disc for stone, concrete, granite, hard stone and marble

WARNING

Mount only safety continuous crown or turbo discs on the cutter.

It is strictly prohibited to use toothed discs normally used for cutting wood,

iron or similar. SIRI declines all responsibility for improper disc use.

Italy 100 cutter Use and Maintenance Manual Ver. 1.1

12

3 Safety components and residual risks

3.1 MECHANICAL SAFETY DEVICES

3.1.1 Disc guard

The cutting disc is protected by a plastic guard that prevents access to the largest part

of its circumference excluding the lower area where the material is cut. The guard is

made up of two parts (internal and external) joined to each other with four screws; the

internal part is fastened to the motor unit. The external part may be removed only and

exclusively when the machine is disconnected from the mains, when you need to

replace the cutting disc.

As well as providing protection against contact with the blade, it performs the function

of directing the cooling water flow down into the collection tank.

WARNING

It is strictly prohibited to start the machine when the external part of the

guard is not in place.

3.2 ELECTRICAL SAFETY DEVICES

3.2.1 Magnetothermal switch

The cutter is equipped with a magnetothermal press switch with a minimum voltage

disconnecting switch. The switch is open (i.e. machine off) when it is in position “0” and

closed (i.e. machine started) when it is in position “1”. If the power fails when the

switch is in position “1”, it is automatically switched to “0”. This prevents the machine

from restarting when the power is restored until the switch is pressed back into position

“1”. The switch also has the function of protecting the motor, automatically switching to

“0” following a short-circuit or prolonged use in overload conditions. If the switch trips

due to an overload, before restarting the machine, wait a few minutes to allow the

thermal device incorporated in the switch to cool down.

Italy 100 cutter Use and Maintenance Manual Ver. 1.1

13

3.3 RESIDUAL RISKS

Despite the safety devices adopted, there are some residual risks intrinsic to cutting

operations.

3.3.1 Risk of cuts

There is a risk of being cut by the cutting blade in the arched section where it cannot be

protected by the guard. It is therefore strictly prohibited to come close to the cutting

disc with any part of the body, both when the machine is off and operating. All the

machine operators and anyone that passes close by or might be passing close by the

machine must be informed of this risk and how to behave.

WARNING

It is strictly prohibited to come close to the cutting blade with the hands and

the face when the machine is connected to the mains.

3.3.2 Risk to the eyes

There is a risk of the cooling water splashing or fragments projecting onto the hands

and face. It is therefore obligatory to wear goggles during machine operation

WARNING

It is strictly prohibited to use the machine without wearing protective goggles.

3.3.3 Risk to hearing

The sound level reached during operation is such that it will damage hearing in the

event of prolonged exposure. It is therefore obligatory to wear an anti-noise headset

during machine operation.

WARNING

It is obligatory to wear an anti-noise headset during machine operation.

Italy 100 cutter Use and Maintenance Manual Ver. 1.1

14

4 Instructions for use and maintenance

In relation to the characteristics of the materials cut, before carrying out any

operations on the machine, carefully read the entire operating manual paying

particular attention this section. All the operators that will be working on the

machine must read the instructions contained in this section and they must be

easily accessible and clearly visible.

4.1 INTRODUCTION

The machine has been designed and constructed in compliance with the requirements of

Machine Directive 2006/42/EC taking into account normal and reasonably foreseeable

improper use.

4.2 PERMITTED USE

The Italy 100 cutter has been designed and constructed to make linear, diagonal and

45° angle cuts in ceramic, marble, granite, porcelain stoneware, Klinker and terracotta

tiles. The diamond disc supplied with the machine is only suitable for cutting ceramic

tiles; for all other materials, use specific discs.

4.3 REQUIRED PERSONAL PROTECTION DEVICES

It is obligatory to wear protective goggles and an anti-noise headset. These devices are

at the expense of the customer.

Wear a protective headset

Wear protective goggles

4.4 GENERAL WARNINGS

•Operators, maintenance technicians and anyone who is to operate and/or come

close to the machine may not wear clothes with wide sleeves nor laces or belts

that may pose a risk to safety. Long hair must be tied up and a cap worn so

that it cannot pose a risk.

•The working area must be kept clear of any foreign objects and the floor must

be treated with a non-slip coating (at the expense of the customer).

Alternatively, non-slip mats may be used.

•The machine must be used and maintained according to the instructions

contained in this manual and the procedures described case by case.

•The operators that are to work on the machine must be adequately trained

through training and refresher courses.

Italy 100 cutter Use and Maintenance Manual Ver. 1.1

15

•The machine connections (and any accessory devices) must be earthed for

electrostatic discharge.

•It is strictly prohibited to operate on any part of the machine before it has come

to a complete halt and only after pulling the plug from the power socket. Only

following this operation may the mechanics and workers carry out maintenance

or repair procedures.

•Do not deactivate the safety devices or ignore the warnings and alarms, be they

automatically communicated or given on labels fixed on the machine.

•Do not operate the machine when the guards have been removed.

4.5 WARNINGS ON USE

The cutter must be used only for the intended use declared by the manufacturer. In

particular, it is prohibited to use the cutter, even partially, in one of the

following conditions:

•With the guards removed and/or with the safety devices deactivated, faulty or

missing

•If the cutter has not properly been installed

•In explosive atmospheres or in places where there is a risk of fire

•In dangerous conditions or when the cutter is malfunctioning

•Improper use of the cutter by untrained personnel

•Use not in compliance with the specific regulations

•In the event of power supply defects

•After unauthorised modifications or operations

•Total or partial inobservance of the instructions

•With materials and tools different from those specified by the manufacturer.

The machine is not intended for use in one or more of the following conditions:

•Environments with an average temperature higher than +35°C in a period of 24

hours

•Environments with relative humidity higher than 95%

•At altitudes of over 3000 m above sea level.

If finding potentially dangerous situations for the operator during machine

use, the employer is obliged to immediately inform SIRI S.r.l. thereof in

writing.

IMPORTANT

Any deviation or departure from the above mentioned rules requires a specific

written declaration by SIRI S.r.l. Any modification not authorised by the

manufacturer which alters the machine functions affecting the risks and/or

generating additional risks, shall be the sole responsibility of the person who

made the said modifications. Modifications made without the manufacturer’s

authorisation shall lead to forfeiture of the warranty and invalidate the

declaration of conformity issued in accordance with Machine Directive

2006/42/CE.

Italy 100 cutter Use and Maintenance Manual Ver. 1.1

16

4.6 WARNINGS ON MACHINE MAINTENANCE

WARNING

All the routine and extraordinary maintenance operations must be carried out

with the machine off.

Disconnect the machine from the mains by pulling the plug from the power

socket.

•Only specialised and specially trained staff should be allowed access to the

machine for any maintenance operation.

•It is not permitted for any reason whatsoever to modify, tamper with or alter

the machine structure and/or the devices fitted.

Italy 100 cutter Use and Maintenance Manual Ver. 1.1

17

5 Machine installation and startup

5.1 HANDLING THE MACHINE

The machine can be handled manually or with a pallet transporter. Two persons are

required for manual handling, gripping the machine standing in front of the short sides

of the tank. Before any type of machine handling operation, lock the motor carriage

using the locking hook provided to prevent the cutting head from sliding during

transport. Be careful during lifting and transport to prevent the machine from falling or

overturning.

If handling the machine with a pallet transporter, position in front of one of two long

sides, insert the forks and make sure that they completely engage the containment tank

until emerging on the opposite side. Also make sure that the symmetry axis of the forks

is on the same vertical as the barycentre of the machine with the motor unit locked

using the hook provided.

Some machine versions are equipped with two legs with castors. In this case, the

machine can be moved by one person lifting it from the opposite side (feet side, without

rollers) and pushing it in the desired direction.

5.2 PREPARING THE WORKING AREA

The working area must be prepared by the user creating the following conditions:

- Prepare the place of installation as required by the local regulations in force on health

and safety in the workplace

- Prepare suitable natural and/or artificial lighting in order to guarantee good visibility

at any point of the machine and without dangerous reflections and stroboscopic effects.

It is advisable to provide for an average lighting of 500 Lux

- Prepare the electric power supply in compliance with the regulations in force in the

place of installation as well as an efficient earthing system.

- Prepare a disconnecting switch with automatic protection against short-circuits,

discharges to earth and leakage between the electric power line and the machine

(differential magnetothermal switch)

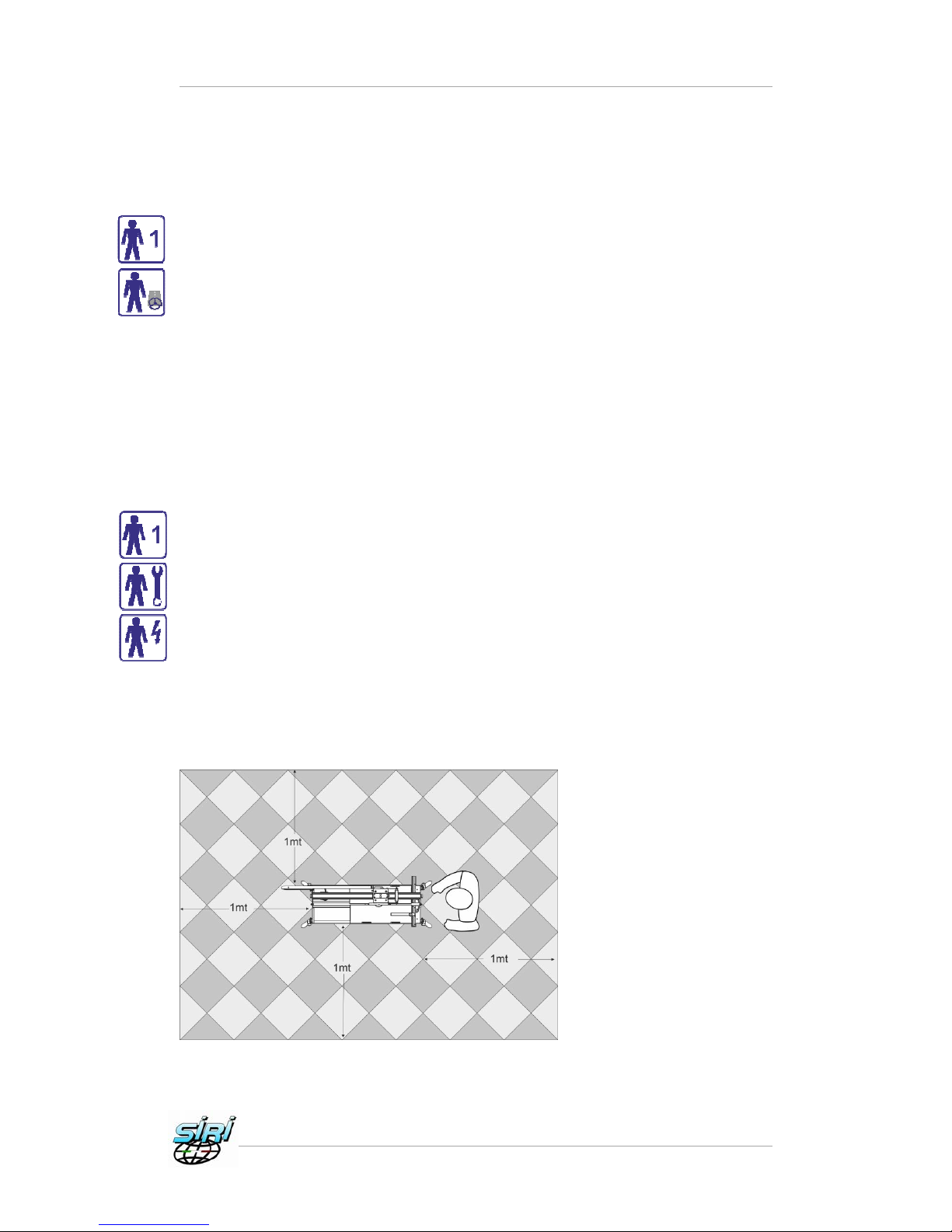

The machine must be

positioned in such a way that

the minimum spaces

indicated in the figure are

respected. The floor must be

perfectly level and not

slippery. The same figure

shows the position of the one

operator required to operate

the machine.

Italy 100 cutter Use and Maintenance Manual Ver. 1.1

18

5.3 ASSEMBLING THE MACHINE

The machine must be installed by qualified staff who have carefully read and

understood the information contained in this manual. In case of doubt, consult

the manufacturer. The user is responsible for ensuring that the installation

complies with the relative regulations in force.

5.3.1 Material provided

The following tools are provided with the machine, which are useful for machine

adjustments and disc replacement:

1) 19mm socket wrench

2) 10mm/13mm monkey spanner

3) 5mm Allen wrench

A tank plug is also provided

5.3.2 Fitting the legs

The machine is supported on four square tubular legs. Two operators are required to

assemble them on the machine body. One at a time, fit the four legs in the respective

housings on the four corners of the tank as shown in the figure. Then, when the upper

through hole of the leg is in correspondence to the upper part of the oblique slit in the

leg, fit the pin and the upper nut. Then fit the second pin and the relative knob and

tighten everything so that you have the configuration shown in the enlargement in the

figure. If the machine is supplied with 2 legs equipped with castors, these must be fitted

on the side opposite to where the operator stands.

Italy 100 cutter Use and Maintenance Manual Ver. 1.1

19

5.3.3 Releasing the carriage

After fitting the four legs and checking that the machine is stable, fit the flexible

corrugated tube from the inside of the tank and let it drop to the outside so that it can

move freely.

Then release the carriage held in place at the end of travel by

means of a hook-shaped tab that ties the carriage to the rear

upright of the track preventing it from moving during the

machine movement operations. Then loosen the bolt (which

may also be the butterfly type) positioned on the cutting head

and slightly turn the hook around the bolt that fastens it to the

track upright as shown in the detail in the figure. In so doing,

the carriage will be free to move along the track.

Table of contents

Popular Saw manuals by other brands

Milwaukee

Milwaukee MS 304 DB Original instructions

Laguna Tools

Laguna Tools DAKE Euromatic 370S Instructional manual

Festool

Festool HK 55 EBQ Original instruction

Bosch

Bosch EasySaw 12 Original instructions

Porter-Cable

Porter-Cable BAYONET SAWS 7548 instruction manual

Hitachi

Hitachi FC 6SB Handling instructions