Sistemes Electrònics Progrés s.a. AGRONIC 4000 User manual

1

INSTRUCTION

MANUAL

VERSION 3

INDEX

Section Theme Page

1. INDEX/PRESENTATION 1

2. BASIC FUNCTIONAL DESCRIPTION 2

Sections for the installer

3. DIMENSIONS 6

4. INSTALLATION 6

4.1. Placing the unit 6

4.2. Connection placing 7

4.3. Connection of units at 220 Vac 8

4.4. Connection of units at 12 Vdc 10

4.5. Connection of units at double voltage 12

4.6. Earth terminal connection 14

4.7. USB and RS485 connection links 14

4.8. Extensions 14

4.9. Maintenance 14

4.10. Codification of inputs and outputs 15

4.11. Installer’s configuration 18

5. TECHNICAL CHARACTERISTICS 19

6. PARAMETERS 20

6.1. Fertilization parameters 20

6.2. Filter cleaning parameters 22

6.3. General outputs parameters 22

6.4. Sensor parameters 25

6.5. Flow parameters 27

6.6. Sector parameters 28

6.7. Program parameters 29

6.8. Communication parameters 31

6.9. Various parameters 31

Sections for the user

7. PROGRAMS 32

8. READINGS 35

8.1. Total readings 35

8.2. Anomaly readings 36

8.3. History readings 37

8.4. Sensor readings 37

8.5 Communication readings 38

8.6 Software versions 38

9. ERASURE 38

10. MANUAL 38

11. CLOCK 39

12. CONSULTATION 40

12.1. General consultation 40

12.2. Programs consultation 41

Notes 42

GENERAL SUMMARY 43

PRESENTATION

We wish to take this opportunity to thank you for the confidence in us which you have demonstrated in ex-

pressing interest or acquiring the AGRÓNIC 4000.

This confidence, for our part, stimulates our efforts to meet and surpass the expectations of our clients to jus-

tify the traditional quality of our products.

This manual will explain the specification of the equipment as well as its installation and use.

However, if after reading this you still have any doubts, contact us and we will happily answer them.

2

2. BASIC FUNCTIONAL DESCRIPTION

Electronic unit for the control of irrigation, fertiliza-

tion, pH, pumping and filter cleaning, plus malfunction

detection and with the possibility of telemanaging the

data via PC or mobile phone.

Models with 16, 24, 32, 48, 64, 80 and 96 config-

urable outputs, plus 12 digital sensors at the base.

Extensions for the reading of analogical sensors; both

by direct connection to the unit or by external modules

(Agrónic Monocable or Agrónic Radio).

Possibility of programming by time and volume,

both in irrigation and fertilization as in filter cleaning,

with possibility of mixed performance (independent for

each sub-program).

By means of climatic or crop sensors, it can influ-

ence the start conditions or the irrigation and fertilizer

units.

IRRIGATION

It can control up to 99 irrigation sectors, gov-

erned by 35 sequential programs, with 12 sub-

programs in every sequence (total 420), and possibil-

ity of linking programs in order to carry out sequences

of 24, 36, or more sub-programs.

Every sub-program can activate from 1 to 10 irri-

gation sectors simultaneously.

Every program can start its performance at a con-

crete time, when another program finishes, when a

sensor reaches a certain value (°C, soil moisture, etc.),

due to an input when a contact is closed, by mobile

telephone via SMS message. It can also start its per-

formance according to the days of the week, the irriga-

tion frequency (irrigate every day, every 2 days, every

3days, etc.) or irrigate every day with several perform-

ances. The period of the year when the program has to

work can also be indicated. In a start by sensors, an

active period and a margin of time between starts can

be chosen.

Modification of irrigation and fertilization units by

a manual factor or by sensors which will have an influ-

ence depending on their values from the previous

irrigation, such as rain, evapotranspiration, integration

of the solar radiation, etc.

When an irrigation is taking place, a program can

be cancelled temporarily by sensor values such as

wind, temperature, level, etc.

Grouping of programs up to 9 groups so that only

one program of every group can irrigate at the same

time.

Complete control of instantaneous flow of four

possible irrigation meters, with programming of the

expected flow in each sector and tolerance percent-

age both for excess or lack. Each sector can be con-

nected to a digital flow sensor to detect the lack of

irrigation.

FERTILIZATION

Capacity to configure from 0 to 8 fertilizers, in in-

dependent tanks.

Independent pre- and post-irrigation values for

every program.

The time or volume of application of every fertil-

izer can be programmed independently for every sub-

program.

The use of mixers can be configured, with pre-

mixing and intermittent or non-stop mixing.

Fertilizers can be applied in three different ways:

In series: one type of fertilizer after the other, with

just one injector. In proportional fertigation, inde-

pendent proportions for every fertilizer.

In parallel: several fertilizers are applied simulta-

neously, with one injector for every one of them. In

proportional fertilization, independent proportions

for every type of fertilizer and sub-program.

Uniform: Sets the each fertilizer application to be

uniformly distributed between pre and post irriga-

tion. Application in parallel. For Venturis, injectors

or frequency variators.

Each injection track can be cleaned automati-

cally, with water, at the end of the fertilization.

Reading of the instantaneous flow of fertilizers, as

in irrigation.

With the option of “control pH”, it can be con-

trolled by injecting acid or base with a reference value

independent for every sub-program. With values of

alarm by excess or lack in the reading of the pH and in

the electrical conductivity (EC).

It is possible to choose the control of pH at the

pre-irrigation and post-irrigation.

PUMPING

It has from 1 to 4 general irrigation outputs, which

can be assigned to sectors, with independent activa-

tion and deactivation temporizations. The general

number 1, by means of the “pressure regulation op-

tion”, can give a 0-20 or 4-20 mA analog output, in

order to connect it to a frequency variator and main-

tain a pressure in the irrigation pipe line independent

for every sector.

Optional control of a diesel engine or generator,

with outputs for start, stop, contact and pre-heating.

Start and stop control of the electrical pumps.

FLOWS

Every irrigation sector can be assigned to one of

the 4 possible volumetric meters to irrigate in liters or

m3. In the totals, the volume of irrigation and fertilizer

is shared in proportion to the nominal flow assigned to

every sector.

The fertilizer is programmed in liters, deciliters or

centiliters with 8 meters.

FILTER CLEANING

Up to four groups of independent filters, with the

following values:

The number of filters to be used in every group

can be configured. Two cleaning times for every filter

group. Pause time between filters. The cleaning can

be started by the differential pressure and/or by the

time or volume of water circulation. Start or not of the

sectors when cleaning. Assignation of generals and

meters. Control of continuous cleanings.

3

DETERMINING FACTORS

There are 4 determining factors which can affect

every one of the irrigation programs (“programs de-

termining factors” option) and they can run in the fol-

lowing ways:

Start the irrigation by solar energy, humidity, soil

moisture, temperature, etc.

Stop the irrigation by wind, temperature, etc.

Modify the irrigation units by radiation, rain, Eto, ...

Modify the fertilization units by radiation, rain, Eto, ...

These determining factors help adapt fertigation

immediately to climatic variations experienced by

crops.

MANUAL CONTROL

With manual control, you can start, stop and leave

out of service irrigation programs; out of service or gen-

eral Stop; start or stop the filter cleaning; end of alarms

and malfunctions; direct activation of the outputs.

READINGS

It can have the following records which are al-

ways updated:

Sector totals and a general one to show the irri-

gation units in time and volume plus the calculated

flow and the applied units of every fertilizer.

Anomalies which have taken place during a pe-

riod of several weeks, such as a power cut, flow cut,

filter cleaning, fertilizer without control, irrigation or

fertilizer meters, too much fertilizer, proportional fer-

tilization, lack of communication with external mod-

ules, due to sensors of general malfunction, defini-

tive, temporary or conditional stop, intrusion alarm,

pH and EC sensors, error in memory, start and pres-

sure in diesel engine, etc. All of them go with the day

and time when they took place and the most relevant

data in relation to the type of anomaly.

New anomalies: with this record, the anomalies

that have taken place since the last visualization are

displayed.

History of the last days, from 20 to 50, where

the starts of every program, the filter cleanings that

have taken place, the integration of the solar radia-

tion and the room temperature, the rain accumulated

that day and the evapotranspiration are showed. It

will also show, for every sector, the irrigating units

which have been carried out in time and volume, the

average of EC and pH applied and the fertilizer units.

When there is a connection to a PC, the average of

the readings of every 10 minutes, of every one of the

10 last days will be recorded from the first 14 sen-

sors, and the readings of all the active life of the unit

can be stored.

Sensors: with the instantaneous value of the dif-

ferent sensors connected to extensions, external

modules or MicroIsis connected to the Agrónic 4000.

Working record: stores the day and time of

every working the equipment undertakes, able to

hold more than 70 different records, each able to be

configured as an anomaly that can in turn generate

an alarm or SMS message. The register has a ca-

pacity of several weeks. The A-4000 only displays

anomalies, with the remaining activities being dis-

played on the connected PC.

Communication: the communication status with

External Modules and the PC.

ALARMS

There are three alarm outputs, each one able to

link events or workings.

Alarm sensor for intruder detection.

DIGITAL AND ANALOG INPUTS

It has 12 digital inputs (expandable) to operate

with 48 digital functions as temporary / conditional /

definitive stop, irrigation/ fertilizer impulses meter,

general malfunction, intrusion alarm, rain gauge, start

of irrigation programs, diesel oil pressure gauge or

engine stop.

Up to 40 sensors (analog inputs) can be con-

nected to extensions, external modules or SMS, to do

the instantaneous reading, to condition irrigation /

fertilization of different sectors, and make a record in

history of the first 14 sensors.

VISUALIZATION

Lightened screen of 2 lines of 40 characters, with

internal contrast adjustment. Membrane keyboard with

23 keys and pulsing acoustic warning device. “STOP”

key.

It includes languages Spanish, French, English,

Italian, Portuguese and Catalan.

MANAGEMENT THROUGH A PC

Agrónic PC is a software for Windows which lets

you manage the controllers Agrónic 4000, 2500, Bit

and 2000 from a PC, in a comfortable and easy way.

This software makes use of all the advantages of-

fered by the Windows environment in order to enter

parameters and programs intuitively, to modify these,

work in real time, as well as to consult anomalies,

totals, working record and what the Agrónic 4000 is

doing at any given moment.

The software can communicate with one or more

Agrónic. This way, irrigation that is taking place at any

moment can be controlled from the office or from

home and the programming can be changed or any

necessary operation carried out. In GPRS, the com-

munication is continuous and simultaneous with sev-

eral Agrónics. Each Agrónic manages the communica-

tion to three different Agrónic PC programs, for exam-

ple owner, farm manager and installer.

The main characteristics of the software Agrónic

PC are:

Connecting multiple controllers to a single pro-

gram by cable (USB, RS232, RS485 or Ethernet), by

telephone (modem, GSM, GPRS), or by radio (radio

modem, Wi-Fi or Wimax).

All the operations which can be made from the

Agrónic are carried out from the software.

4

Consultations of operations carried out by the

Agronics in 2 different ways, being able to pass from

one to the other by asimple movement of the mouse:

- By units: with different screens. It is a replica of

the consultation that is in the controller, but with

the commodity that provides the displays on a

computer screen.

- By synoptics: implementing planes or photo-

graphs of the farms, parcels or parts of the instal-

lation, and illuminated indicators. With all this, it

allows to see in a clear and fast way the actions

that are carried out by the controller, for example

illuminating the parcels on irrigation, marking

what engines, fertilizers or filters are acting and

showing the flow, pressure, soil humidity, etc.

Programming system on one single screen, on

which a name can be put to each one of the pro-

grams.

Records of all the operations that the Agrónic

carries out, saving them in the text files.

Possibility to save in text files the configuration,

programming, totals and records which can be dealt

with from other programs (spreadsheets, data

bases, etc.).

SMS MESSAGES

With a GSM/GPRS modem connection, "SMS

messages" displaying alarms and events can be sent

to two mobile phones, and one of them can be sent

two reports per day related to the irrigation taken

place. It can also receive orders such as start or stop a

program, set at “Stop”, modify the manual factor of a

program, give the value of a virtual sensor such as the

evapotranspiration, etc.

Once a program has been started up or shut

down, an SMS can be sent to other equipment (A-

4000/A-2500/A-2000/...) to synchronize actions among

them. The text message is prepared by the user.

There is maximum number of 6 for these types of mes-

sages.

EXTERNAL MODULES

Capacity to connect with external modules of dif-

ferent types:

Agrónic Radio 868 and 868-16: up to 64 modules,

it is possible up to 16 latch solenoid outputs,

and up to 16 digital sensors, and 2 analog sen-

sors for each one of them.

Agrónic Radio 2.4: up to 120 modules, it is possi-

ble up to 16 latch solenoid outputs, and up to

16 digital sensors, and 2 analog sensors for

each one of them.

Agrónic Radio 433: up to 60 modules, it is possi-

ble up to 16 latch solenoid outputs, and up to

16 digital sensors, and 2 analog sensors for

each one of them.

Agrónic Monocable 120: up to 120 modules, it is

possible up to 8 latch solenoid outputs, and up

to 10 digital sensors and 1 analog sensor at

every one.

MicroIsis: up to 4 MicroIsis with 8 analog sensors

every one.

Expansion modules: up to 16 modules with 5 re-

lay outputs, 2 digital inputs and 2 analog sen-

sors every one

5

MODELS AND OPTIONS

Model to “to built-in” a frame or “box” in a wall.

Model with power supply at 230 Vac (115 Vac) or

at 12 Vdc.

Option for latch outputs (pulses) for two or three

wires.

Option double voltage in electric generator.

Option analog inputs and outputs with galvanized

isolation on one or two circuits, each one with 6 4-20

mA sensors and 5 4-20 mA outputs (or pulsed out-

puts by photo-relay).

Option serial port USB.

Option serial port RS232.

Option serial port RS485.

Options of serial port 3 (USB or RS232) and serial

port 4 (RS485) and link.

Option Ethernet port.

Option internal gsm/gprs modem

Option of modem for connection to expansion

modules.

Option diesel engine control.

Option of regulation of the pressure of the irriga-

tion water.

Option pH regulation and reading EC with alarm.

Option determining factors of programs.

Option software Agrónic PC

Option of sending and receiving SMS messages.

Option Agrónic Monocable.

Option Agrónic Radio.

Option MicroIsis.

GUARANTEE

The irrigation controller Agrónic 4000 meets all the

norms set by the CE.

The products created by PROGRÉS enjoy a two-

year warranty against all manufacturing defects.

Compensation for direct or indirect damage cau-

sed by the use of the equipment is excluded from the

warranty.

6

3. DIMENSIONS

4. INSTALLATION

4.1. PLACING THE UNIT

Place the unit at the right position and height.

Avoid direct sun exposure, humidity, dust and vi-

brations.

Avoid proximity to any source of interference

which could affect the correct operation of the unit.

The A-4000 is made up

of just one piece, except the

built-in models with more

than 32 outputs, which go

with a second box.

In the “built-in model”, a

hole is to be done in the fron-

tal part of the wall or desk,

according to the measures in the section DIMEN-

SIONS. It will be held with the screws of the corners,

using the four pieces which are included in the unit.

The wardrobe must have a double isolation with

protection for the operation relationship to the net

power supply circuit.

In the “box” model, the unit is held by the upper

pieces at the corners and by the two holes placed at

the below cover of the connection housing, according

to the measures shown in the section DIMENSIONS.

In the version with “box”, the equipment is pro-

vided in a hermetically sealed (box IP65) with a trans-

parent front cover for the keyboard/display and an

opaque cover for the connection housing.

In order to maintain isolation of the box it is nec-

essary to maintain the covers always closed, as well

as install grommets at the outputs of the cables.

7

4.2. CONNECTION PLACING

In order to carry out the connections in the unit of

the “built-in” model, access the connectors placed at

the back.

In the “box” model, take the below cover off to

access the connectors.

The necessary terminals have to be taken out to

enter the cables (do it with the connection cover on

and screwed, in order to avoid possible malfunctions).

It is advisable to link the cables to the terminals

with connection terminals, which are supplied with the

unit. (The terminals accept cables of up to 2.5 mm2of

section).

8

4.3. CONNECTION OF UNITS AT 220 Vac

The unit has to be installed following the prevail-

ing regulations for electrical installations. The unit will

not be completely protected if it is not used according

to the information given in the manual.

The unit has to be placed in such a way that the

elements which may get interferences, such as the

sensor inputs, the sensor power supply, the links to

the PC and modem, have their cables in the best em-

placement, so that they do not receive interferences

from power elements which might be in their sur-

roundings.

All the connection terminals of the Agrónic 4000

can be switched which allows a fast maintenance.

PROGRÉS also offers a protection box for all the

terminals, in case there is a high risk of electrical

sparks from storms entering the cables.

4.3.1. Power connection

Before connecting the unit, it is necessary to

check its identification label where the characteristics

of the power supply are to be found.

The standard power supply is at 230 Vac, being

possible at 115 Vac. but it is necessary to ask PRO-

GRÉS about this last one.

Connect the phase and the power supply neutral

to the terminals marked as “F” and “N”.

A 6 Amp magneto-thermal switch is to be in-

cluded in the installation. It will be used as a discon-

nection device and it has to be placed near the unit at

an accessible place for the user.

It is recommendable to do this as directly as pos-

sible, avoiding that the same cable supplies other

devices. Use cable of the H05VV-F type, 1 mm2.

The power supply input is protected by a fuse,

marked as General Fuse and a varistor. The varistor

might short-circuit the fuse automatically, on detecting

an overload on the line (lightning, etc.). Replace it with

one of the same characteristics.

For unstable or fluctuating voltages use grid sta-

bilizers.

4.3.2. Digital input connection

The different elements of the installation, such as

pressure gauges, levels, meters, etc. are to be con-

nected to the group of 12 terminals labeled as “Digital

inputs (D)”. This is done by connecting one contact

pole to the corresponding input and the other pole to

the 24 Vac “COMMON”.

Contacts must normally be open and free of volt-

age.

One of the 48 possible functions can be assigned

to everyone of the inputs in the section “Parameters -

Sensors”.

The inputs are optically isolated from the internal

circuitry and depend on the same 24 Vac power sup-

ply of the outputs.

4.3.3. Output connection

All outputs are ready to work at 24 Vac (it is very

important not to supply the unit with voltages above to

30 V).

The unit must have a external transformer with 24

Vac output and double isolation according to the UNE

EN61010 norm. Its input will be connected to the out-

put of the magneto-thermal switch which protects the

Agrónic 4000. The 24 Vac output is connected to the

terminals marked with this voltage, entering a pole of

the output of the transformer into one of the terminals

marked as “COMMON / 24 V N”, and the other pole

into one of the terminals marked as “24 V F”.

Connect the solenoids, relays, etc., between the

output common “COMMON” and the corresponding

output.

Do not exceed the maximum power by output of

1 Amp. and the general of 6.3 Amp. If this happens

insert external relays.

The “output fuse” protects from overloads and

short-circuits; to replace it half turn the cover of the

fuses box and replace it by another one of similar cha-

racteristics.

The “AUX” terminal corresponds to the “PHASE”

of the 24 Vac which goes through the fuse. It will be

useful to connect auxiliary elements of manual com-

mand and extensions of relays above to 32 outputs.

The outputs are isolated from the internal circuitry

by relays and protected by a varistor at everyone of

them, plus a general gas discharger in the lines of 24

Vac.

The number of outputs can vary from 16 to 24,

32, 48, 64, 80 or 96 in the same unit. It is possible to

extend the outputs at a distance, in external modules

“via radio” or “via cable”. The maximum number of

sectors to be controlled by the Agrónic 4000 is 99.

9

Every output can be assigned to an irrigation sec-

tor (one or more electrovalves) or to a general output

(pumps, filters, mixers, etc.). To do so, go to the sec-

tion of “Parameters - Sectors” or “Parameters -

Generals”.

Example of connection :

10

4.4. CONNECTION OF UNITS AT 12 Vdc

The unit has to be installed following the prevail-

ing regulations for electrical installations. The unit will

not be completely protected if it is not used accord-

ing to the information given in the manual.

The unit has to be placed in such a way that the

elements which may get interferences, such as the

sensor inputs, the sensor power supply, the links to

the PC and modem, have their cables in the best

emplacement, so that they do not receive interfer-

ences from power elements which might be in their

surroundings.

All the connection terminals of the Agrónic 4000

can be switched which allows a fast maintenance.

PROGRÉS also offers a protection box for all the

terminals, in case there is a high risk of electrical

sparks from storms entering the cables.

4.4.1. Power connection

Before connecting the unit, it is necessary to

check its identification label where the characteristics

of the power supply are to be found.

The power supply is at 12 Volts of direct current.

Connect the positive and negative poles on the

battery to the positive (+) and negative (-) terminals

marked as “+12 Vdc”.

A 6 Amp magneto-thermal switch is to be in-

cluded in the installation. It will be used as a discon-

nection device and it has to be placed near the unit

at an accessible place for the user.

It is recommendable to do this as directly as

possible, avoiding that the same cable supplies

other devices. Use cable of the H05VV-F type, 1mm2.

The power supply input is protected by a fuse,

marked as General Fuse and a varistor. The varistor

might short-circuit the fuse automatically, on detect-

ing an overload on the line (lightning, etc.). Replace

it with one of the same characteristics.

4.4.2. Digital input connection

The different elements of the installation, such

as pressure gauges, levels, meters, etc. are to be

connected to the group of 12 terminals labeled as

“Digital inputs (D)”. This is done by connecting one

contact pole to the corresponding input and the other

pole to the “NEGATIVE” of battery.

Contacts must normally be open and free of volt-

age.

One of the 48 possible functions can be assigned

to everyone of the inputs in the section “Parameters -

Sensors”.

4.4.3. Output connection

All outputs are ready to work at 12 Vdc (it is very

important not to supply the unit with voltages above to

30 V).

Connect the solenoids, relays, etc., between the

output “COMMON OUTPUTS +” and the correspond-

ing output.

Do not exceed the maximum power by output of 1

Amp. and the general of 6.3 Amp. If this happens insert

external relays.

The “output fuse” protects from overloads and

short-circuits; to replace it half turn the cover of the

fuses box and replace it by another one of similar char-

acteristics.

The “AUX” terminal corresponds to the “Negative”

of the 12 Vdc which goes through the fuse. It will be

useful to connect auxiliary elements of manual com-

mand and extensions of relays above to 32 outputs.

The outputs are isolated from the internal circuitry

by relays and protected by a varistor at everyone of

them, plus a general gas discharger in the lines of 12

Vdc.

The number of outputs can vary from 16 to 24, 32,

48, 64, 80 or 96 in the same unit. It is possible to extend

the outputs at a distance, in external modules “via ra-

dio” or “via cable”. The maximum number of sectors to

be controlled by the Agrónic 4000 is 99.

Every output can be assigned to an irrigation sec-

tor (one or more electrovalves) or to a general output

(pumps, filters, mixers, etc.). To do so, go to the section

of “Parameters - Sectors” or “Parameters - Generals”.

11

Example of connection in conventional unit at 12 Vdc :

Example of connection in unit at 12 Vdc with diesel engine control :

12

4.5. CONNECTION OF UNITS AT DOUBLE

VOLTAGE

The unit has to be installed following the prevail-

ing regulations for electrical installations. The unit will

not be completely protected if it is not used according

to the information given in the manual.

The unit has to be placed in such a way that the

elements which may get interferences, such as the

sensor inputs, the sensor power supply, the links to

the PC and modem, have their cables in the best em-

placement, so that they do not receive interferences

from power elements which might be in their sur-

roundings.

All the connection terminals of the Agrónic 4000

can be switched which allows a fast maintenance.

PROGRÉS also offers a protection box for all the

terminals, in case there is a high risk of electrical

sparks from storms entering the cables.

4.5.1. Power connection

Before connecting the unit, it is necessary to

check its identification label where the characteristics

of the power supply are to be found.

The power supply is at 12 Volts of direct current.

Connect the

positive and nega-

tive poles on the

battery to the posi-

tive (+) and nega-

tive (-) terminals

marked as “+12

Vdc”.

A 6 Amp magneto-thermal switch is to be in-

cluded in the installation. It will be used as a discon-

nection device and it has to be placed near the unit at

an accessible place for the user.

It is recommendable to do this as directly as pos-

sible, avoiding that the same cable supplies other

devices. Use cable of the H05VV-F type, 1mm2.

The power supply input is protected by a fuse,

marked as General Fuse and a varistor. The varistor

might short-circuit the fuse automatically, on detecting

an overload on the line (lightning, etc.). Replace it with

one of the same characteristics.

4.5.2. Digital input connection

The different elements of the installation, such as

pressure gauges, levels, meters, etc. are to be con-

nected to the group of 12 terminals labeled as “Digital

inputs (D)”. This is done by connecting one contact

pole to the corresponding input and the other pole to

the “NEGATIVE -” of battery.

Contacts must normally be open and free of volt-

age.

One of the 48 possible functions can be assigned

to every one of the inputs in the section “Parameters -

Sensors”.

4.5.3. Output connection

In double-voltage equipment, the first four out-

puts operate at 12 Vdc (- negative) and the remainder

at 24 Vac (it is very important not to supply the unit

with voltages above to 30 V).

Connect the solenoids, relays, etc. between the

output common “OUTPUT COMMON +” and their

corresponding output, except for the first four outputs,

whose common will be the battery’s positive pole.

Do not exceed the maximum power by output of

1 Amp. and the general of 6.3 Amp. If this happens

insert external relays.

The “output fuse” protects from overloads and

short-circuits; to replace it half turn the cover of the

fuses box and replace it by another one of similar cha-

racteristics.

Outputs 1 to 4 control the diesel engine and op-

erate at 12 volts. They are grounded by an interior

thermal fuse.

The “AUX” terminal corresponds to the “PHASE”

of the 24 Vac which goes through the fuse. It will be

useful to connect auxiliary elements of manual com-

mand and extensions of relays above to 32 outputs.

The outputs are isolated from the internal circuitry

by relays and protected by a varistor at everyone of

them, plus a general gas discharger.

The number of outputs can vary from 16 to 24,

32, 48, 64, 80 or 96 in the same unit. It is possible to

extend the outputs at a distance, in external modules

“via radio” or “via cable”. The maximum number of

sectors to be controlled by the Agrónic 4000 is 99.

Every output can be assigned to an irrigation sec-

tor (one or more electrovalves) or to a general output

(pumps, filters, mixers, etc.). To do so, go to the sec-

tion of “Parameters - Sectors” or “Parameters - Gen-

erals”.

When a diesel engine is controlled in equipment

outfitted with “double-voltage”, it is necessary to as-

sign outputs for the contact, start-up, stopping, and

pre-heating mechanisms in the first four outputs.

13

Example of connection in unit with “double voltage in outputs” :

Example of connection in unit with “double voltage in outputs” and with diesel engine control :

14

4.6. EARTH TERMINAL CONNECTION

The “built-in” model has a terminal screw to con-

nect the protection earth terminal (in the “box” model

it is not necessary as it has not got a metallic casing).

A pressed terminal will be applied to the cable when

joining it to the screw.

The box terminal marked as is internally con-

nected to the filters and protections.

Both the earth and the box terminals are used to

screen the circuitry, for this reason, it is very important

that the earth line is correctly installed and free of elec-

tric noise. It is also used to protect the unit by direct-

ing all electrical sparks through the internal gas dis-

charger to the earth. These sparks can come in

through the output cables when lightning strikes dur-

ing a storm.

4.7. USB AND RS485 CONNECTION

LINKS

An Agrónic 4000 with USB (or RS232) option will

have a side connector where the power cable may be

linked to a PC and an adapter for connection to mo-

dem.

An Agrónic 4000 with RS485 link will have a side

connector (box model) or on the top (built-in model).

This link is always made with bifilar wire: wires A and

B. The connection shall be made by inserting wire “A”

in terminal “1” of the connector and wire “B” in termi-

nal “2”. To connect different equipment through RS-

485 communication a linear bus must be used, with a

single start and end; it must not be in star topology.

4.8. EXTENSIONS

On installing extensions in the Agrónic 4000, pro-

tecting measures have to be taken in order not to da-

mage the circuits.

It is very important to disconnect any connection

to the mains to avoid electro-shock.

Follow the installation instructions enclosed in the

extension element.

4.9. MAINTENANCE

4.9.1. Fuses

In order to replace the fuses it is necessary, for

precaution, to disconnect the unit from the general

mains, half turn the cover of the fuse holder and insert

one of the same characteristics, as it is indicated at

the label placed next to the fuse holder. Spare fuses

are included in the unit.

The fuse marked as “General fuse” protects the

power supply input. Replace it with one of the same

characteristics as it may damage the unit if this is not

taken into account.

The fuse marked as “Output fuse” protects the

outputs from short-circuits. Replace it with one with

the same characteristics as it may damage the unit if

this is not taken into account.

4.9.2. Cleaning

The frontal part is cleaned with a slightly humid

cloth, disconnecting the unit from the mains previ-

ously.

15

4.10. CODIFICATION OF INPUTS AND OUTPUTS

Both the analog and digital sensor inputs as well as the digital outputs (relays) are coded using an 8-digit

number that indicates its physical location. Following tables are shown to help code them.

4.10.1. Digital sensor inputs

Device Module Sensor

00: Base 0 000 01 to 12

01: Expansion modules 0 001 to 016 01 to 02

07: Agrónic Monocable 120 modules 1 001 to 120 01 to 10

08: Agrónic Radio 868-16 modules 1 001 to 064 01 to 16

09: Agrónic Radio 2.4 modules 1 001 to 120 01 to 16

10: Agrónic Radio 433 modules 1 001 to 060 01 to 16

Examples: 00000008: digital input 8 of the base

08101502: digital input 2 of the Agrónic Radio 868-16, Agrónic Radio module 15 (MAR15)

09102301: digital input 1 of the Agrónic Radio 2.4, Agrónic Radio module 23 (MAR023)

07109007: digital input 7 of the Agrónic Monocable 120, Agrónic Monocable module 90 (MAM90)

4.10.2. Analog sensor inputs

Device Module Sensor

00: Base 0 000 01 to 12

01: Expansion modules 0 001 to 016 01 to 02

04: SMS messages 0 000 01 to 08

05: MicroIsis 0 001 to 004 01 to 08

07: Agrónic Monocable 120 modules 1 001 to 120 01

08: Agrónic Radio 868-16 modules 1 001 to 064 01 to 02

09: Agrónic Radio 2.4 modules 1 001 to 120 01 to 02

10: Agrónic Radio 433 modules 1 001 to 060 01 to 02

Examples: 00000003: analog input 3 of the Base

01001601: analog input 1 of the Expansion module 16 (ME16)

04000003: input of SMS message 3

05000203: analog input 3 of the MicroIsis 2

07101001: analog input 1 of the Agrónic Monocable 120, Monocable module 10 (MAM10)

4.10.3. Digital outputs (relays)

Device Module Output

00: Base 0 000 01 to 96

01: Expansion modules 0 001 to 016 01 to 05

07: Agrónic Monocable 120 modules 1 001 to 120 01 to 08

08: Agrónic Radio 868-16 modules 1 001 to 064 01 to 16

09: Agrónic Radio 2.4 modules 1 001 to 120 01 to 16

10: Agrónic Radio 433 modules 1 001 to 060 01 to 16

Examples: 00000001: output 1 of the Base

01000103: output 3 of the Expansion module 1 (ME1)

09102301: output 1 of the Agrónic Radio 2.4, Agrónic Radio module 23 (MAR023)

07101005: output 5 of the Agrónic Monocable 120, Agrónic Monocable module 10 (MAM10)

4.10.4. Analog outputs

Device Module Output

00: Base 0 000 01 to 10

Example: 00000001: output 1 of the Base

16

4.10.5. Charts to write down of outputs to generals and sectors :

PUMPS ALARMS

Pump 1 Alarm 1

Pump 2 Alarm 2

Pump 3 Alarm 3

Pump 4

FERTILIZERS

Fertilizer general output

Fertilizer 1 Analog output F1

Fertilizer 2 Analog output F2

Fertilizer 3 Analog output F3

Fertilizer 4 Analog output F4

Fertilizer 5 Analog output F5

Fertilizer 6 Analog output F6

Fertilizer 7 Analog output F7

Fertilizer 8 Analog output F8

Fertilizer Cleaning 1 Fertilizer auxiliary 1

Fertilizer Cleaning 2 Fertilizer auxiliary 2

Fertilizer Cleaning 3 Fertilizer auxiliary 3

Fertilizer Cleaning 4 Fertilizer auxiliary 4

Fertilizer Cleaning 5 Fertilizer auxiliary 5

Fertilizer Cleaning 6 Fertilizer auxiliary 6

Fertilizer Cleaning 7 Fertilizer auxiliary 7

Fertilizer Cleaning 8 Fertilizer auxiliary 8

Fertilizer Mixer 1

Fertilizer Mixer 2

Fertilizer Mixer 3

Fertilizer Mixer 4

Fertilizer Mixer 5

Fertilizer Mixer 6

Fertilizer Mixer 7

Fertilizer Mixer 8

FILTERS

Filter outputs G1 From to Filter general output G1

Filter outputs G2 From to Filter general output G2

Filter outputs G3 From to Filter general output G3

Filter outputs G4 From to Filter general output G4

Diesel control option pH/EC control option

Starter output

pH control general output

Stop output

pH analog output

Contact output

Pre-heating output Pressure regulation option

Pressure regulation analog output

Device Module Output

Base : 00 0 000 01 to 96

Expansion modules : 01 0 001 to 016 01 to 05

Agrónic Monocable 120 modules : 07 1 001 to 120 01 to 08

Agrónic Radio 868-16 modules : 08 1 001 to 064 01 to 16

Agrónic Radio 2.4 modules : 09 1 001 to 120 01 to 16

Digital

Outputs

Codification

Summary

Agrónic Radio 433 modules : 10 1 001 to 060 01 to 16

17

SECTOR OUTPUT AUXILIARY

Output Sensor digi.

Flow detector SECTOR OUTPUT AUXILIARY

Output Sensor digi.

Flow detector

1 51

2 52

3 53

4 54

5 55

6 56

7 57

8 58

9 59

10 60

11 61

12 62

13 63

14 64

15 65

16 66

17 67

18 68

19 69

20 70

21 71

22 72

23 73

24 74

25 75

26 76

27 77

28 78

29 79

30 80

31 81

32 82

33 83

34 84

35 85

36 86

37 87

38 88

39 89

40 90

41 91

42 92

43 93

44 94

45 95

46 96

47 97

48 98

49 99

50

18

4.11. INSTALLER’S CONFIGURATION

This programming operation is only done by the

installer the first time the equipment has been started

up. It will only be modified when having to make varia-

tions or extensions to the facilities or equipment.

Upon entering in this section the following menu

is displayed:

Comunica. :1 Events :2 Various :3

Options :4 Language :5 Anal.Out. :6

Erasure :7 Record :8

4.11.1. Communications:

[ check the Communication Options pamphlet ]

4.11.2. Events:

In this section, the events that must set off alarms

are configured, whether these will send off an SMS

when triggered and what type of register will be cre-

ated. For each event, the following questions are as-

ked:

Type: 0-anomaly, 1-working, 2-internal (only can

be read in the installer configuration area).

T1: YES, sends an SMS to telephone 1.

T2: YES, sends an SMS to telephone 2.

A1: YES, activates alarm 1.

A2: YES, activates alarm 2.

A3: YES, activates alarm 3.

In the default settings, alarm 1 is associated with

the general alarm, alarm 2 as the fertilizer alarm and

alarm 3 as the pH adjustment alarm.

4.11.3. Various:

Increase the format of the instantaneous flow

limit for irrigation and fertilizing meters, going

from 650.00 m2o liters per hour to 6500.0.

The minutes for control of error in irrigation or

fertilizer meters; by default there are 10 minutes.

A 0 does not carry out any checks.

When a irrigation program is outside of the ac-

tive schedule or of the active period, and has

pending activations to be completed, it can be

configured if it is to be cancelled.

When a program comes out of its active timeta-

ble, the irrigation in progress may be cancelled.

To be able to keep the pumps on when there is

a conditional stop by digital or analog sensor.

In uniform fertilization, it is necessary when using

the relays of the base to enter the time in sec-

onds in the “Modulation Cycle”. Within this cy-

cle, the proportional amount of fertilizer is ap-

plied. The default setting is 20”, while the mini-

mum is 10”. (If you use the pulsed outputs of the

option “Analog Inputs and Outputs” the modula-

tion cycle will apply when entering “Parameters –

Fertilization”).

Fertilization may be stopped on cleaning the fil-

ters.

In parallel and proportional fertilization, the pul-

ses that occur as the proportion ends may be

counted (useful when the time between pulses is

less than two seconds).

Summer/winter time change: setting to YES au-

tomatically changes the summer and winter

hours.

Time between sensors record: indicates how of-

ten a sample from the sensors is recorded. From

6 to 60 minutes. The default setting is every 10

minutes.

Flow sensor delay: the time in minutes to ensure

the digital sensors assigned to the sectors detect

a lack of flow.

Delay in determining factors 5 and 6, delay in the

activation and deactivation of the determining

factors 5 and 6. From 0 to 999”. By default 30”.

4.11.4. Options:

Activation or deactivation of options once the

equipment is installed, to activate enter the code sup-

plied by PROGRÉS and to deactivate enter an incor-

rect code.

4.11.5. Language:

In this section, the language of the texts dis-

played on the Agrónic 4000 can be changed. The

available languages are: Spanish, English, French,

Italian, Portuguese and Catalan.

4.11.6. Analog outputs:

Pressure regulation.

Pressure reference in SA: YES, through the analog

output of the pressure regulation you will get a cur-

rent proportional to the reference that has been

asked for. It is being used to pass the reference to

another operator. NO, the analog output is being

used to regulate the pressure.

Minimum and maximum: to set up the mA ratio

with pressure for the output. It is only used when

the output is to pass the reference.

For each of the ten 0 to 20 mA analog outputs

available on the Agrónic 4000, the minimum (1%) and

maximum (100%) values are configured.

Resistance value: this indicates the value of the

resistance needed to convert the electrical current

into power, normally set at 200 ohms.

Minimum (1%): value in mA that the output must

provide when set at 1%. The number in parenthesis

indicates this value converted into voltage.

Maximum (100%): value in mA that the output must

provide when set at 100%. The number in paren-

thesis indicates this value converted into voltage.

4.11.7. Erasure:

Carry out a total erasure.

Carry out a erasure of the working record

Carry out a erasure of the sensor record

4.11.8. Record

Displays the events that have been configured as

internal.

19

5. TECHNICAL CHARACTERISTICS

Power supply Units for alternating current Units for direct current

Tension 230 Vac or 115 Vac +5 % -10 % CAT II 12 Vdc +10 % -5 %

Frequency 50-60 Hz = = =

Energy consumption Below to 43 VA Below to 18 W (at rest 1.7 W)

Input 0.800 A, T type, 250 V (slow) 1.5 A, T type, 250 V (slow)

Fuses

Output 6.3 A, F type, 250 V (fast) 6.3 A, F type, 250 V (fast)

Keeping the memory which

can be erased when there is

a power cut

Lithium Battery, at 3 V.

Number 16, extensibles to 24, 32, 48, 64, 80, 96.Digital

Type By relay contact, with potential of 24 Vac (External transformer)

Limits 30 Vac / 30 Vdc, 1 Amp, 50-60 Hz, CAT ll

Number 5 or 10Analog

(option) Type By current of 0/4 to 20 mA

Outputs

All outputs have double isolation in reference to the net input.

Number 12Digital

Type Optolinked, work at 24 Vac

Number 6 or 12

Inputs

Analog

(option) Type 4-20 mA (with galvanic separation)

Temperature 0 °C to 45 °C

Humidity < 85 % Box model Built-in model

Heigh 2000 m

Atmosphere

Pollution Grade 2

Weight

(Kg.)

From 3.2 to 6.3 From 4.0 to 5.0

Memory backup Clock and data Above to 5 years

DECLARATION OF CONFORMITY

It follows the 89/336/CEE guidelines for the Electromagnetic Compatibility and the

73/23/CEE guidelines of Low tension for the fulfillment of the product security. The fulfillment

of the following specifications was demonstrated as indicated in the Official Diary of the Euro-

pean Communities:

Emissions EN 50081-1:94 EN 55022:1994 Type B Radiated and conducted emissions.

Immunity EN 50082-1:97 EN 61000-4-2 (95) Immunity to electrostatic discharges.

EN 61000-4-3 (96) Immunity to the electromagnetic field of radioelectric fre-

quency.

EN 61000-4-4 (95) Immunity to fast transitional in gusts.

EN 61000-4-5 (95) Immunity to crash waves.

EN 61000-4-6 (96) Current injection

EN 61000-4-11 (94) Variations to the power supply.

Harmonics EN 61000-3-2 (95) Current harmonics.

Fluctuations EN 61000-3-3 (95) Tension fluctuations (Flickers).

Low tension guidelines: EN 61010-1 Security requirements of measurement electric units, con-

trol and use in laboratory.

Symbols which may

appear in the product

Protection

earth terminal

Danger, risk of

electroshock

Box ter-

minal

Double

isolation

This symbol indicates that the electrical and electronic equipment should not be disposed of as gen-

eral household waste at its end-of-life. Instead, the product should be handed over to the applicable

collection point for the recycling of electrical and electronic equipment for proper treatment, recovery

and recycling in accordance with your national legislation.

20

6. PARAMETERS

In order to install the unit, it is necessary to enter

in the section of “Parameters” to adapt it to the par-

ticular necessities of each installation. Press “FUN”

(functions) and choose the function by its number (4).

Then press “Enter".

Programs : 1 Readings : 2 Erasure : 3

Parameters: 4 Manual : 5 Clock : 6

There are 9 options to choose in the “Parame-

ters” menu:

PARAMETERS Fertiliz. : 1 Cleaning : 2

Generals : 3 Sensors : 4 Flows : 5

PARAMETERS Sectors : 6 Programs : 7

Communic. : 8 Various : 9

In order to get placed in one of the two screens of

the menu, press the up and down arrow keys. Then

press the number of the option and the “Enter” key.

6.1. FERTILIZATION PARAMETERS

Of the 8 possible fertilizers, the ones which are

going to work have to be configured. It has to be also

defined if the fertilization will be in series [1] (apply

one fertilizer after the other), parallel [2] (apply several

at a time) or uniform [3] (several at a time in efficient

distribution).

Fertilizers number ( 0 – 8 ) : 3

Appl. serial-1 parallel-2 uniform-3 : 1

In series or parallel modes, the continuous or

proportional application of the irrigation units can be

configured.

As shown in the picture above, the continuous

fertilization applies each one of the fertilizers for the

total of the programmed value once its addition starts.

When the series fertilization is programmed the totality

is applied before the next one. They are applied at a

time and in its totality when it is programmed in paral-

lel. They stop when the programmed units in one of

them finish. Look at the explicative drawings.

The proportional fertilization consists in apply-

ing each type of fertilizer not one after the other but in

several activations, with doses which will maintain a

prefixed proportionality in relation to the amount of

water circulating.

Fertilization proportional (Y/N) : Y.

If the proportional modality is chosen, at the se-

ries application format will ask for the proportions for

each one of the fertilizers and at the irrigation pro-

grams, the total quantity of water and fertilizer to be

applied to the crop will be programmed.

Proportion series :

F1 005/012 F2 005/014 F3 005/009 F4 010/002

For example, the proportion “010/002” corre-

sponds to 10 irrigation units per each 2 fertilizer units.

These units can be in time (hours: minutes, minutes’

seconds’’) or in volume (m3, L, dl, cl), in relation to the

units each sub-program has.

At the parallel fertilization modality it does not ask

here for the proportions of the different fertilizers, but it

does for each one of the irrigation programs.

Table of contents

Other Sistemes Electrònics Progrés s.a. Control Unit manuals

Popular Control Unit manuals by other brands

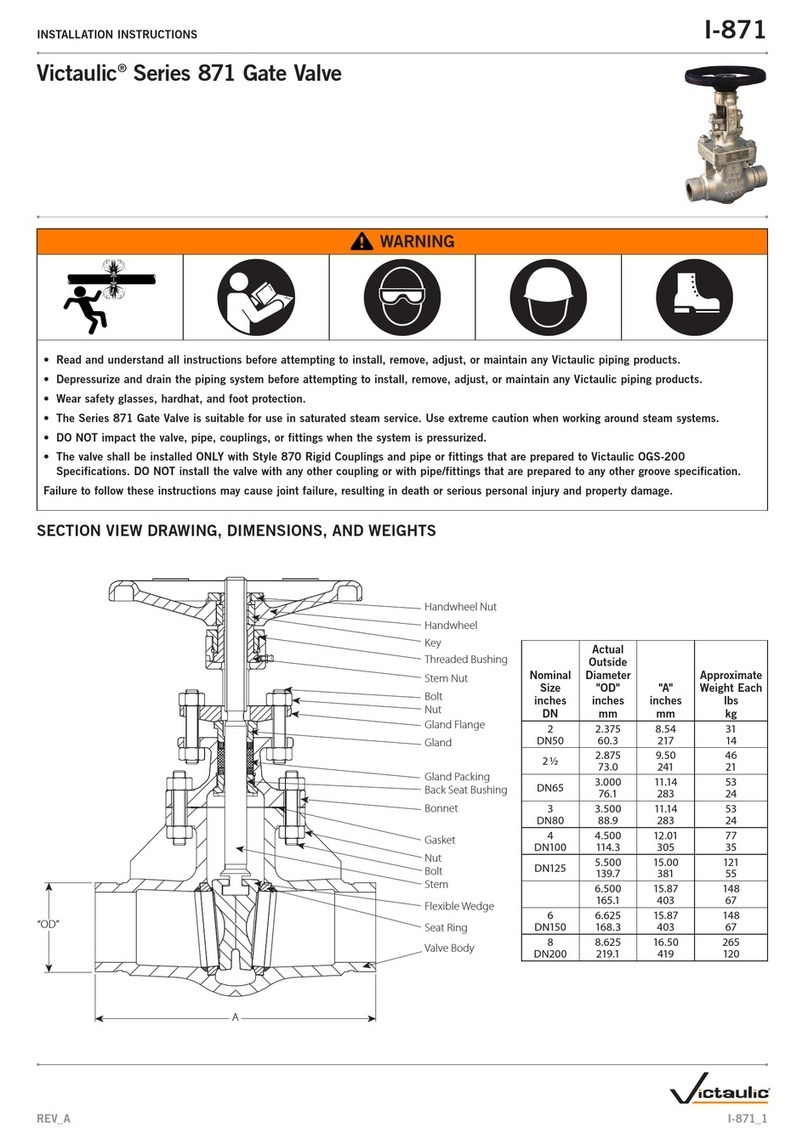

Victaulic

Victaulic 871 Series installation instructions

EM-Technik

EM-Technik 6M Operation and assembly instructions

CEL-MAR

CEL-MAR ADA-DIOC40 user manual

Nexta Tech

Nexta Tech MCX-M/ONE manual

Fulling Motor

Fulling Motor FD542 user manual

Victaulic

Victaulic FireLock NXT 768 Series Installation, Maintenance, and Testing Manual