SITECNO EQX 500-DC User manual

MATRIX Inverter System User Manual

C/ Can Balmes 1-3, Sta. M. de Palautordera, 08460 Barcelona, Spain. T: +34 938482544, F: +34 938480439, E-mail: info@spanishsolar.com, www.spanishsolar.com

EQX 500-DC Solar Charger

User’s Manual

MATRIX Inverter System User Manual

- 2 -

Contents

Important safety instructions................................................................................................................................. 6

1. Product description ............................................................................................................................................. 8

1.1 General description...................................................................................................................................... 8

1.2 Features........................................................................................................................................................ 8

1.3 Maximum setpoint voltage limit.................................................................................................................. 8

1.4 Temperature and output power.................................................................................................................... 8

1.5 Maximum power point tracking (MPPT) .................................................................................................... 9

1.6 How MPPT works....................................................................................................................................... 9

1.7 Over voltage / reverse polarity protection ................................................................................................... 9

1.8 Electrostatic handling precautions............................................................................................................... 9

1.9 EQX 500-DC solar charger setup.............................................................................................................. 10

1.9.1 Factory default settings................................................................................................................... 10

1.10 Three stage charge control....................................................................................................................... 10

1.10.1 Bulk charge................................................................................................................................... 10

1.10.2Absorption charge......................................................................................................................... 10

1.10.3 Float charge................................................................................................................................... 10

1.11 Battery temperature sensor (BTS) ........................................................................................................... 11

1.12 Equalization charge ................................................................................................................................. 11

1.12.1 Photovoltaic charge and load controller.........................................................................................11

1.12.2Automatic PV array night disconnect........................................................................................... 12

1.12.3 EQX 500-DC solar chargerload control........................................................................................ 12

1.12.4 Low voltage disconnect................................................................................................................ 12

1.12.5 Low voltage reconnect.................................................................................................................. 12

1.13 Optional accessories ................................................................................................................................ 13

2. Installation.......................................................................................................................................................... 14

2.1 Pre-Installation........................................................................................................................................... 14

2.2 Removing the topcover.............................................................................................................................. 14

2.3 Mounting the EQX 500-DC solar chargercontroller.................................................................................. 15

2.3.1 Mount the EQX 500-DC solar charger charge controller............................................................... 15

2.4 Configuring the EQX 500-DC solar charger charge controller................................................................. 16

2.4.1 Battery type selector can apply different charger method............................................................... 16

2.5 Temperature compensation........................................................................................................................ 17

2.5.1 Temperature compensation based on battery type.......................................................................... 18

2.5.2Automatic battery temperature compensation................................................................................. 18

2.6 Grounding.................................................................................................................................................. 19

2.7 DC terminal connector locations ............................................................................................................... 19

2.8 Wire Size and Over-current Protection Requirements............................................................................... 19

2.8.1 Current Rating ................................................................................................................................ 19

2.8.2 Surge Protection.............................................................................................................................. 20

2.8.3 Over-current Protection .................................................................................................................. 20

2.8.4 Long-distance wire runs.................................................................................................................. 20

2.9 PV Charge And Load Control Mode Wiring............................................................................................. 20

2.10 Easily install in parallel connection......................................................................................................... 22

2.11 Battery type selector................................................................................................................................ 22

2.12 Installing Optional Accessories............................................................................................................... 23

2.13 Reinstalling the Faceplate........................................................................................................................ 23

3. Operation............................................................................................................................................................ 25

3.1 Basic Operation ......................................................................................................................................... 25

3.2 LED Status Indicator ................................................................................................................................. 25

3.2.1 Charge control indications.............................................................................................................. 25

4. Troubleshooting................................................................................................................................................. 27

5. Specifications...................................................................................................................................................... 28

5.1 Specifications............................................................................................................................................. 28

5.2 Environmental............................................................................................................................................ 28

5.2.1 Temperature.................................................................................................................................... 28

5.3 Safety......................................................................................................................................................... 29

5.3.1American market............................................................................................................................. 29

5.3.2 European market............................................................................................................................. 29

MATRIX Inverter System User Manual

- 3 -

5.4 Humidity.................................................................................................................................................... 29

5.4.1 Operating Humidity........................................................................................................................ 29

5.4.2 Non-Operating Humidity................................................................................................................ 29

5.5 Mechanical features................................................................................................................................... 29

5.6 Detailed dimension drawing...................................................................................................................... 30

6. Batteries.............................................................................................................................................................. 31

6.1 Battery Types............................................................................................................................................. 31

6.2 Automotive Batteries................................................................................................................................. 31

6.3 Maintenance-Free Batteries....................................................................................................................... 31

6.4 Deep-Cycle Batteries................................................................................................................................. 31

6.5 Sealed Batteries ......................................................................................................................................... 31

6.6 NiCad and NiFe Batteries.......................................................................................................................... 31

6.7 Battery Sizing ............................................................................................................................................ 31

6.8 Equalization Charging............................................................................................................................... 32

6.9 Equalization Setpoints (Non-Sealed Batteries Only)................................................................................. 32

MATRIX Inverter System User Manual

- 4 -

Tables

Table 1 –1: Factory shipping settings ............................................................................................................. 10

Table 1 –2: Battery type selector switch settings............................................................................................ 16

Table 1 –3: Temperature compensation calculation........................................................................................ 18

Table 1 –4: Battery compensation coefficient................................................................................................. 18

Table 1 –5: Minimum wire size...................................................................................................................... 20

Table 1 –6: The LED indicators...................................................................................................................... 26

Table 1 –7: Troubleshooting list ..................................................................................................................... 27

Table 1 –8: Electrical specification................................................................................................................. 28

Table 1 –9: Mechanical specification ............................................................................................................. 29

Table 1 –10: Battery equalization................................................................................................................... 32

Figures

Figure 1 –1: Bulk charge curve....................................................................................................................... 10

Figure 1 –2: PV charge and load controller.................................................................................................... 12

Figure 1 –3: Load controller........................................................................................................................... 12

Figure 1 –4: Removing the topcover .............................................................................................................. 14

Figure 1 –5: Mounting the EQX 500-DC solar charger charge controller...................................................... 15

Figure 1 –6: Battery type selector (B.SEL) .................................................................................................... 16

Figure 1 –7: Safety (Earth) ground................................................................................................................. 19

Figure 1 –8: DC terminal connector locations................................................................................................ 19

Figure 1 –9: PV charge control mode wiring.................................................................................................. 21

Figure 1 –10: Parallel connection................................................................................................................... 22

Figure 1 –11: battery type selector.................................................................................................................. 22

Figure 1 –12: Install BTS ............................................................................................................................... 23

Figure 1 –13: Reinstalling the faceplate......................................................................................................... 24

Figure 1 –14: LED status indicator................................................................................................................. 25

Figure 1 –15: EQX 500-DC solar charger dimension drawing....................................................................... 30

MATRIX Inverter System User Manual

- 5 -

About This Manual

Purpose

The purpose of this manual is to provide explanations and procedures for installing, operating, maintaining, and

troubleshooting the Solar Charge Controller.

Scope

This manual provides safety guidelines, detailed planning and setup information, procedures for installing the

Solar Charge Controller, as well as information about operating and troubleshooting the unit. It does not provide

details about particular brands of batteries. You need to consult individual battery manufacturers for this

information.

Audience

This manual is intended for anyone who needs to install and operate the Solar Charge Controller. Installers should

be certified technicians or electricians.

Organization

This Manual is organized into six chapters.

Chapter 1. Product description

Chapter 2. Installation

Chapter 3. Operation

Chapter 4. Troubleshooting

Chapter 5. Specification

Chapter 6. Battery

MATRIX Inverter System User Manual

- 6 -

I

Im

mp

po

or

rt

ta

an

nt

t

s

sa

af

fe

et

ty

y

i

in

ns

st

tr

ru

uc

ct

ti

io

on

ns

s

Save these instructions

This manual contains important instructions for EQX 500-DC solar charger that shall be followed during

installation and maintenance.

General

1. Refer installation and servicing to qualified service personnel. High voltage is present inside unit. Incorrect

installation or use may result in risk of electric shock or fire. No user serviceable parts in this unit.

2. Remove all sources of power, photovoltaic and battery before servicing or installing.

3. Warning –risk of explosive gases

When EQX 500-DC solar charger is working, Please DO NOT touch it because the temperature is

too high.

Working in the vicinity of lead-acid batteries is dangerous. Batteries produce explosive gasses

during normal battery operation.

To reduce risk of battery explosion, follow these instructions and those published by battery

manufacturer and manufacturer of any equipment you intend to use in vicinity of battery.

4. Personal precautions

Someone should be within range of your voice or close enough to come to your aid when you work

near a lead-acid battery.

Have plenty of fresh water and soap nearby in case battery acid contacts skin, clothing or eyes.

Wear complete eye protection and clothing protection.Avoid touching eyes while working near

battery.

If battery acid contacts skin or clothing, wash immediately with soap and water. If acid enters eye,

immediately flood eye with running cold water for at least 10 minutes and get medical attention

immediately.

NEVER smoke or allow a spark or flame in vicinity of battery.

Be extra cautious to reduce risk of dropping metal tool onto battery. It might spark or short circuit

battery or other electrical part that may cause explosion.

Remove personal metal items such as rings, bracelets, necklaces, and watches when working with a

lead-acid battery. A lead-acid battery can produce a short circuit current high enough to weld a ring

or the like to metal, causing a severe burn.

5. Preparing to charge

Never charge a frozen battery.

Be sure battery is mounted in a well-ventilated compartment.

Add distilled water in each cell until battery acid reaches level specified by battery manufacturer.

This helps purge excessive gas from the cells. Do not overfill. For a battery without cell caps,

carefully follow manufacturers charging instructions.

6. Charger location & installation

Controller employs components that tend to produce arcs or sparks. NEVER install in battery

compartment or in the presence of explosive gases.

Protect all wiring from physical damage, vibration and excessive heat.

Insure that the controller is properly setup for the battery being charged.

Do not expose the controller to rain or snow.

Insure all terminating connections are clean and tight to prevent arcing and overheating.

Charging system must be properly installed as described in these instructions prior to operation.

Do not connect to a PV array capable of producing greater than 40 amps of short circuit current @

25°C.

Do not connect input to DC source directly with load, EQX 500-DC solar charger need to .be

powered by solar panel.

MATRIX Inverter System User Manual

- 7 -

Symbol

--Warning

--Dangerous Voltage

--Alternative Current

--Direct Current

--Protective Earth

--ESD

Abbreviations and Acronyms

BTS

Battery Temperature Sensor

DC

Direct Current

LED

Light Emitting Diode

LVD

Low Voltage Disconnect

LVR

Low Voltage Reconnect

B.SEL

Battery type selector

CHG.MODE

Charge mode

PV

Photovoltaic

MPPT

Maximum Power Point Tracking

PWM

Pulse Width Modulation

RE

Renewable Energy

MATRIX Inverter System User Manual

- 8 -

1

1.

.

P

Pr

ro

od

du

uc

ct

t

d

de

es

sc

cr

ri

ip

pt

ti

io

on

n

1

1.

.1

1

G

Ge

en

ne

er

ra

al

l

d

de

es

sc

cr

ri

ip

pt

ti

io

on

n

EQX 500-DC solar charger is a 40 amp 12/24 voltage Maximum Power Point Tracking (MPPT) photovoltaic (PV)

battery charge controller. Through the use of MPPT technology, EQX 500-DC solar charger can increase charge

current up to 30% or more compared to conventional controllers. Solar Charge Controller’s sophisticated three

stage charge control system can be configured to optimize charge parameters to precise battery requirements. The

unit is fully protected against voltage transients, over temperature, over current, reverse battery and reverse PV

connections. An automatic current limit feature allows use of the full 40 amp capability without worrying about

overload or nuisance fuse blow from excessive current, voltage or amp-hour based load control.

Series pass Pulse Width Modulation (PWM) charge voltage control combined with a multistage charge control

algorithm leads to superior charging and enhanced battery performance. The filtered PWM power control system

uses highly efficient and reliable power MOSFET transistors. The MOSFET’s are turned on and off at high

frequency to precisely control charge voltage and MPPT.

Fully automatic temperature compensation of charge voltage is available to further improve charge control and

battery performance. The optional battery temperature sensor is built for long term reliability. The sensor element

is environmentally sealed and encapsulated into a plastic lug which adheres to directly to the battery terminal and

by RJ11 port connect with the unit, and the EQX 500-DC solar charger also includes an isolated RS232 port for

connection to a PC computer for data logging and system monitoring.

The EQX 500-DC solar charger can easily install in parallel connection, so it also suitable for large system current

application condition.

1

1.

.2

2

F

Fe

ea

at

tu

ur

re

es

s

High converting efficiency up to 97% for minimizing energy loss

Build-in MPPT tracker for optimizing the power transformation

Reversed current protection with fuse

Automatic battery temperature compensation for long-term reliability

Capable of selecting different charging mode for various type of batteries

Capable of connecting additional DC load for wider applications

Three stage charge control system (bulk, absorption, and float mode) with temperature

compensation

LED indicators display charge status in real time

Pulse Width Modulation (PWM) topology combined with a multi-stage charge control

algorithm leads to superior charging and enhanced battery performance

1

1.

.3

3

M

Ma

ax

xi

im

mu

um

m

s

se

et

tp

po

oi

in

nt

t

v

vo

ol

lt

ta

ag

ge

e

l

li

im

mi

it

t

Very cold batteries combined with high charge voltage setpoints can produce voltages high enough to disrupt or

damage other equipment connected to the battery. To minimize possible damage a maximum voltage setpoint limit

feature is provided. The factory defaults can be adjustable using software. Regardless of what setpoint values

result from temperature compensation, the EQX 500-DC solar charger will never attempt to apply a charge

voltage greater than the maximum voltage setpoint limit value.

1

1.

.4

4

T

Te

em

mp

pe

er

ra

at

tu

ur

re

e

a

an

nd

d

o

ou

ut

tp

pu

ut

t

p

po

ow

we

er

r

Over temperature protection is provided to protect the unit from damage due to high output power at high ambient

temperatures. When mounted vertically as described in the installation section, the unit can deliver full output in a

temperature of up to 40ºC, and the unit will de-rate output in 40 –60ºC. While operating in charge mode, the

controller will decrease the charge current to reduce the transistor temperature and the green led will be solid

green. If the EQX 500-DC solar charger connected with DC load, the load is disconnected before the transistors

reach an excessive temperature and the green LED flashes. Once the temperature has dropped, the loads are

reconnected., reducing average power delivery to within safe limits. During thermal shutdown the charge status

indicator will display an “off” condition. Over temperature shutdown occurs when the ambient temperature

reaches 60ºC.

MATRIX Inverter System User Manual

- 9 -

1

1.

.5

5

M

Ma

ax

xi

im

mu

um

m

p

po

ow

we

er

r

p

po

oi

in

nt

t

t

tr

ra

ac

ck

ki

in

ng

g

(

(M

MP

PP

PT

T)

)

MPPT and associated current boost operation is fully automatic and will function whenever sufficient PV voltage

and current are available. The percent increase in output charge current relative to PV current is variable, and will

change with operating conditions. When conditions are such that insufficient PV power is available to produce an

increase in output current, the unit will stop it’s internal DC-DC power conversion and operate as a series pass

PWM controller with very low forward voltage drop.

The principal operating conditions which affect current boost performance are PV array temperature and battery

voltage. At constant solar intensity available PV power changes with PV temperature. A PV array’s power vs.

temperature characteristic is such that a cool PV array can produce a higher voltage and more power, than a hot

PV array. When PV voltage is sufficiently high for MPPT to operate, a constant power output is delivered to the

battery. Since output power is constant while MPPT is operating, a decrease in battery voltage produces

corresponding increase in charge current. This means that the greatest current increase occurs with a combination

of cool ambient temperature and low battery voltage. The unit delivers the greatest charge current increase when

you need it most, in cold weather with a discharged battery. Additionally, anything that can be done to lower PV

array temperature will also lead to increased charge current by increasing PV power production. In

cool/comfortable temperatures and typical battery states of charge, most systems see about 10 –20% increase.

Charge current increase can go to zero in hot temperatures, whereas charge current increase can easily exceed

30% with a discharged battery and freezing temperatures.

1

1.

.6

6

H

Ho

ow

w

M

MP

PP

PT

T

w

wo

or

rk

ks

s

A PV module is a constant current type device. As shown on a typical PV module voltage vs. current curve,

current remains relatively constant over a wide range of voltage. A typical 75 watt module is specified to deliver

4.45 amps @ 17 volts @ 25 C cell temperature. Conventional PV controllers essentially connect the PV array

directly to the battery when battery is discharged. When a 75 watt module is connected directly to a battery

charging at 12 volts, the module still provides approximately the same current. But, because output voltage is now

at 12 volts rather than 17 volts, module power production is artificially limited and the 75W module only delivers

53 watts. This wastes 22 watts of available power.

Solar Charge Controller’s MPPT technology operates in a very different fashion. Under these conditions EQX

500-DC solar charger calculates the maximum power voltage (V) at which the PV module delivers maximum

power, in this case 17 volts. It then MPPT operates the module 17 volts which extracts maximum available power

from the module. EQX 500-DC solar charger continually recalculates the maximum power voltage as operating

conditions change. Input power from the maximum power tracking controller, in this case 75 watts, feeds a

switching type power converter which reduces the 17 volt input to battery voltage at the output. The full 75 watts

which is now being delivered at 12 volts would produce a current of 6.25 amps. A charge current increase of 1.8

amps or 40% is achieved by converting the 22 watts that would have been wasted into useable charge current.

Note that this example assumes 100% efficiency to illustrate the principal of operation. In actual operation, boost

will be somewhat less.

1

1.

.7

7

O

Ov

ve

er

r

v

vo

ol

lt

ta

ag

ge

e

/

/

r

re

ev

ve

er

rs

se

e

p

po

ol

la

ar

ri

it

ty

y

p

pr

ro

ot

te

ec

ct

ti

io

on

n

EQX 500-DC solar charger is fully protected against reverse polarity and high voltage transients for both the PV

and the battery connections. If the battery is connected reverse polarity, EQX 500-DC solar charger will not

operate. If the PV array is connected reverse polarity the charge control system will not turn on.

1

1.

.8

8

E

El

le

ec

ct

tr

ro

os

st

ta

at

ti

ic

c

h

ha

an

nd

dl

li

in

ng

g

p

pr

re

ec

ca

au

ut

ti

io

on

ns

s

All electronic circuits may be damaged by static electricity. To minimize the likelihood of electrostatic damage,

discharge yourself by touching a water faucet or other electrical ground prior to handling the unit and avoid

touching components on the circuit boards. The risk of electrostatic damage is highest when relative humidity is

below 40%.

MATRIX Inverter System User Manual

- 10 -

1

1.

.9

9

E

EQ

QX

X

5

50

00

0-

-D

DC

C

s

so

ol

la

ar

r

c

ch

ha

ar

rg

ge

er

r

s

se

et

tu

up

p

1.9.1 Factory default settings

Table 1 –1: Factory shipping settings

Basic settings

Charge mode

3 stage

Absorption voltage

14.4/28.8V

Bulk voltage

14.6/29.2V

Float voltage

13.4/26.8V

Equalize

14/28V

1

1.

.1

10

0

T

Th

hr

re

ee

e

s

st

ta

ag

ge

e

c

ch

ha

ar

rg

ge

e

c

co

on

nt

tr

ro

ol

l

EQX 500-DC solar charger is typically configured for a three stage charging process, Bulk, Absorption and Float.

The three stage charge process provides a somewhat higher charge voltage to charge the battery quickly and safely.

Once the battery is fully charged a somewhat lower voltage is applied maintain the battery in a fully charged state

without excessive water loss. The three stage charge process charges the battery as quickly as possible while

minimizing battery water loss and maintenance.

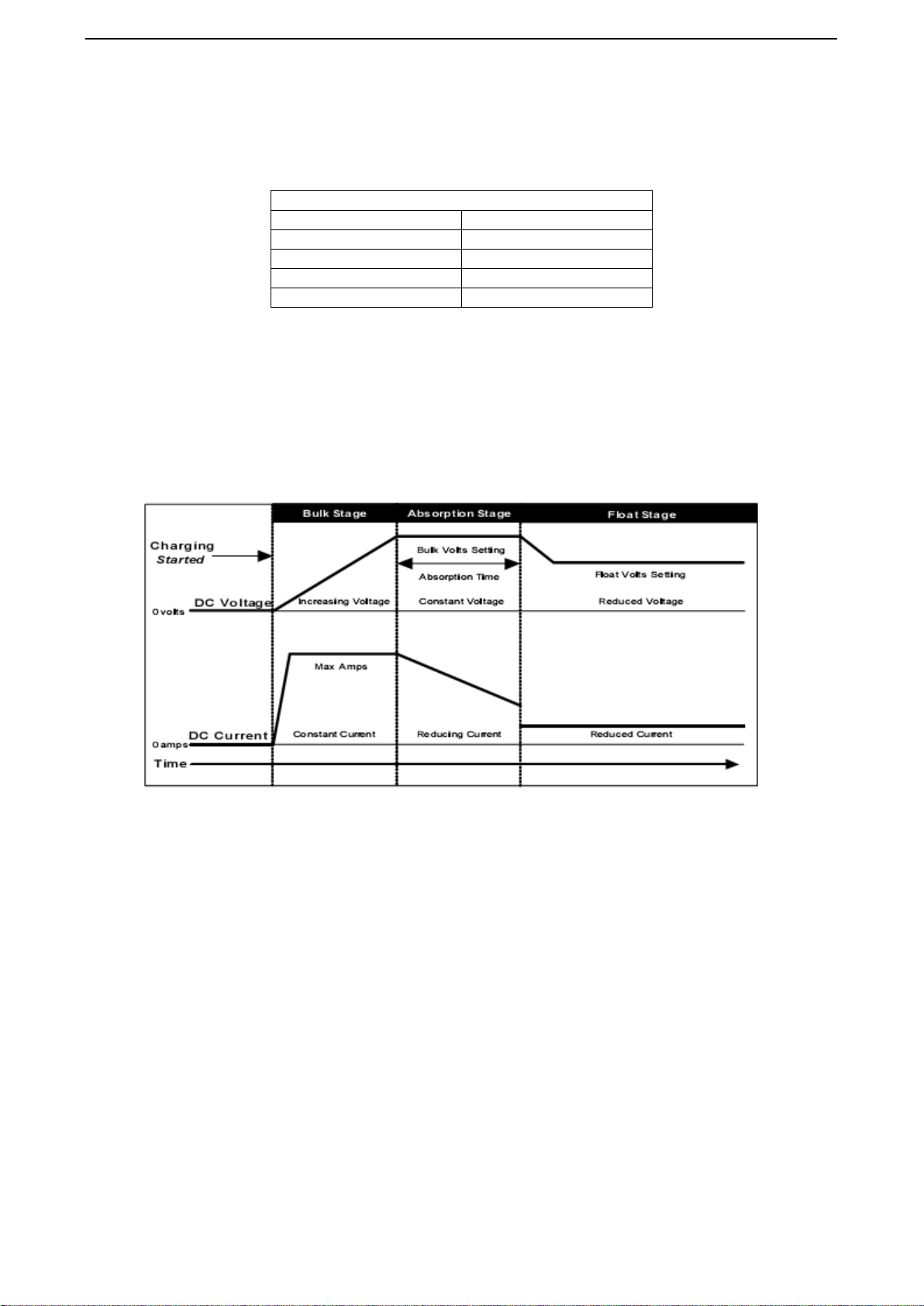

Figure 1 –1: Bulk charge curve

1.10.1 Bulk charge

When charge starts the EQX 500-DC solar charger attempts to apply the bulk charge voltage to the

battery. The system will switch to Bulk charge if the battery is sufficiently discharged and/or insufficient

charge current is available to drive the battery up to the bulk voltage setpoint. During the Bulk charge

stage the unit delivers as much charge current as possible to rapidly recharge the battery. Once the charge

control system enters Absorption or Float, the unit will again switch to Bulk charge if battery voltage

drops below the present charge voltage setpoint.

1.10.2Absorption charge

During this stage, the unit changes to a constant voltage mode where the absorption voltage is applied

to the battery. When charge current decreases to the float transition current setting, the battery is fully

charged and the unit switches to the float stage.

1.10.3 Float charge

During this stage, the float voltage is applied to the battery to maintain it in a fully charged state.

When battery voltage drops below the float setting for a cumulative period, a new bulk cycle will be

triggered.

MATRIX Inverter System User Manual

- 11 -

1

1.

.1

11

1

B

Ba

at

tt

te

er

ry

y

t

te

em

mp

pe

er

ra

at

tu

ur

re

e

s

se

en

ns

so

or

r

(

(B

BT

TS

S)

)

The charge voltage required by batteries changes with battery temperature. Temperature compensation of charge

voltage enhances battery performance and life, and decreases battery maintenance. Automatic temperature

compensation can be provided through use of the optional battery temperature sensor. The following table

describes approximately how much the voltage may vary depending on the temperature of the batteries.

1

1.

.1

12

2

E

Eq

qu

ua

al

li

iz

za

at

ti

io

on

n

c

ch

ha

ar

rg

ge

e

Equalize charging is a special mode of battery charging. During use, the battery’s cells can become unequal in the

voltage and current they can deliver. This is due to a buildup of sulfate on the plates as well as stratified

electrolyte. Sulfate prevents the cells from receiving or delivering full power. If the sulfate is left on the plates, it

will harden, and permanently reduce the battery’s capacity. Stratification separates the heaver acid from the water,

and the concentrated acid remains at the lower portion of the plates, eventually corroding them. Equalizing the

batteries every month or two (depending on usage) prolongs the life of the batteries and provides better battery

performance.

To set the Equalize Charge:

Remove all DC loads connected to the batteries.

Remove all battery vent caps.

Check the battery water level, it should be just over the top of the plates (do not over fill). Use only

distilled water for filling batteries.

Set the BATTERY TYPE SELECTOR switch to position “0” or “1”.

Reset the BATTERY TYPE SELECTOR potentiometer to the appropriate setting for the system

batteries when the Equalize charge has completed.

1.12.1 Photovoltaic charge and load controller

The EQX 500-DC solar charger charge controller can operate as a PV charge controller. the controller can

regulate up to 40amps of continuous photovoltaic (PV) array current at 12 / 24-volts DC for charging batteries.

This rating includes the NEC required derating. But at the same time the EQX 500-DC solar charger charge

controller can provide the maximum 15Amp current to DC load , however the rating charge current 40Amp will

decrease. That is to say, the rating 40Amp current is shared battery with DC load.

When the PV voltage is lower, the battery will provide the power to the DC load , In the load control condition,

the EQX 500-DC solar charger controls when to remove load from the system when an over-discharge or

over-load situation occurs. The EQX 500-DC solar charger charge controller uses the software setpoints to

determine when to connect or reconnect loads depending on battery voltage. EQX 500-DC solar charger prevents

damage to the battery from over-discharge during periods of poor weather or excessive loads. The unit can charge

the batteries when in this function.

If the PV array’s output increases above the rated amp level, the controller will continue to operate because of

input current limit

MATRIX Inverter System User Manual

- 12 -

Figure 1 –2: PV charge and load controller

1.12.2 Automatic PV array night disconnect

When using PV Charge Control mode, the PV array is automatically disconnected from the battery at night to

prevent reverse leakage of power.

1.12.3 EQX 500-DC solar charger load control

The EQX 500-DC solar charger charge controller can operate as a low voltage disconnect (LVD) for DC loads to

prevent over-discharge to batteries during periods of poor charging or excessive loads. The EQX 500-DC solar

charger charge controller uses the software setpoints to determine when to disconnect or reconnect loads

depending on battery voltage.

1.12.4 Low voltage disconnect

When configured as a load controller, the EQX 500-DC solar charger charge controller will disconnect the load

from the batteries when it reaches the LVD setting. There will be a 1-minute delay after the voltage drops below

the Low Voltage Disconnect (LVD) setting before the controller actually disconnects the load.

1.12.5 Low voltage reconnect

It can also provide automatic reconnection of the loads at the low voltage reconnect (LVR) setting. Reconnection

of the load is allowed once the battery voltage has exceeded the low voltage reconnect (LVR) setting. Loads are

either automatically when battery voltage exceeds the low voltage reconnect (LVR) setting for 1 minutes.

Figure 1 –3: Load controller

MATRIX Inverter System User Manual

- 13 -

Important: When using the EQX 500-DC solar charger load control:

Do not temperature-compensate these settings.

Do not install the optional battery temperature compensation sensor.

1

1.

.1

13

3

O

Op

pt

ti

io

on

na

al

l

a

ac

cc

ce

es

ss

so

or

ri

ie

es

s

The follow accessories can be purchased for use with the EQX 500-DC solar charger charge Multifunction DC

Controller:

Battery Temperature Sensor (BTS): The BTS is installed on the side of the battery and attaches to RS232 port

inside the EQX 500-DC solar charger charge controller. It provides accurate sensing of the battery temperature

and uses this reading to control charging. Using this accessory can extend battery life and improve overall

charging.

MATRIX Inverter System User Manual

- 14 -

2

2.

.

I

In

ns

st

ta

al

ll

la

at

ti

io

on

n

2

2.

.1

1

P

Pr

re

e-

-I

In

ns

st

ta

al

ll

la

at

ti

io

on

n

The instructions that follow are applicable to the typical installation. For special applications, consult a qualified

electrician or your Certified Dealer. Installation procedures will vary according to your specific application.

Important: Installations should meet all local codes and standards. Installations of this equipment should only

be performed by skilled personnel such as qualified electricians and Certified Renewable Energy (RE)

System Installers.

2

2.

.2

2

R

Re

em

mo

ov

vi

in

ng

g

t

th

he

e

t

to

op

pc

co

ov

ve

er

r

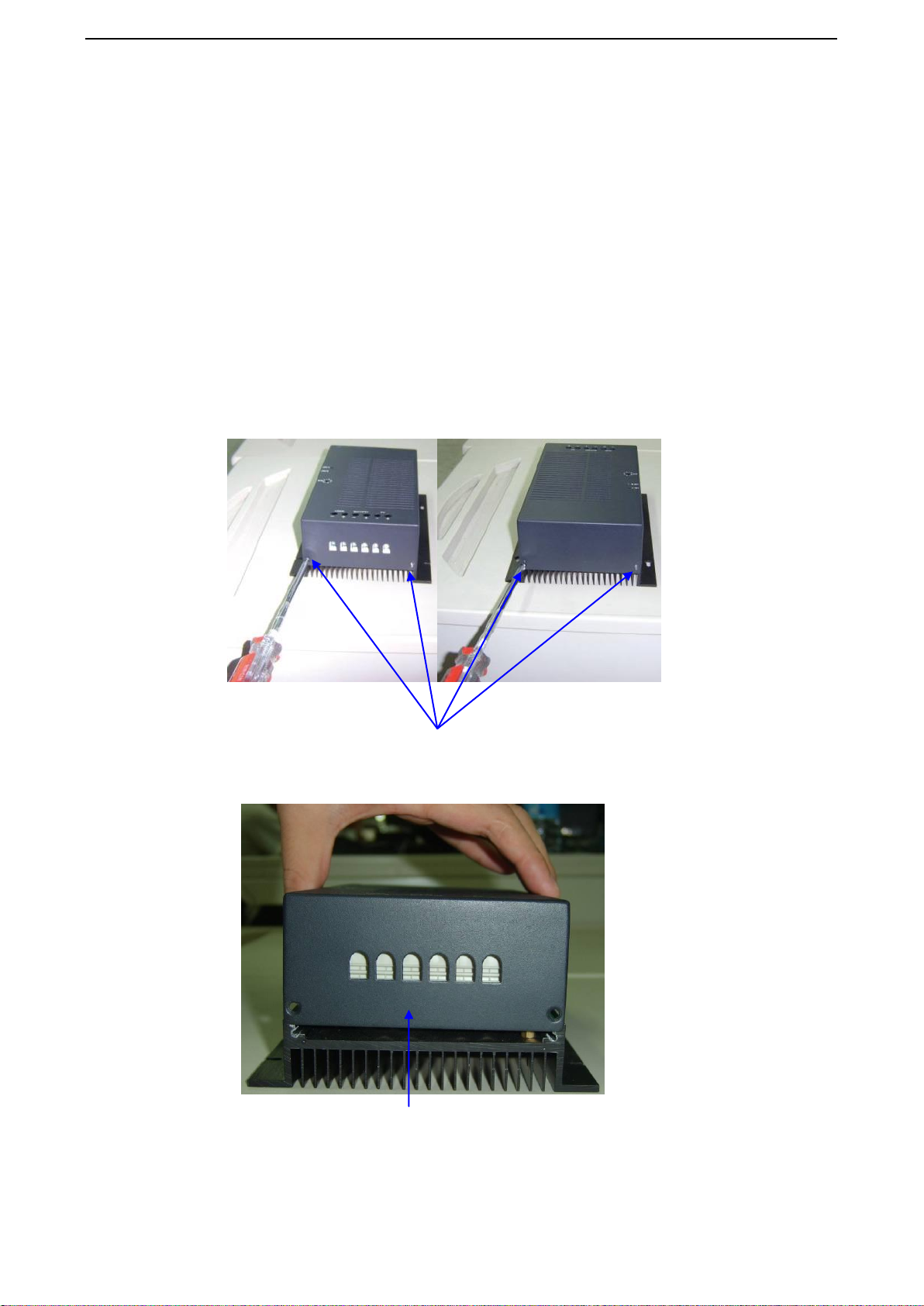

1. Access the inside of the controller by removing the four screws M3*6 on the cover of the unit.

2. Remove the topcover of EQX 500-DC solar charger charge controller.

Figure 1 –4: Removing the topcover

Remove these screws M3*6 (*4) from the topcover to access the heatsink of controller

Remove the topcover

MATRIX Inverter System User Manual

- 15 -

2

2.

.3

3

M

Mo

ou

un

nt

ti

in

ng

g

t

th

he

e

E

EQ

QX

X

5

50

00

0-

-D

DC

C

s

so

ol

la

ar

r

c

ch

ha

ar

rg

ge

er

r

c

co

on

nt

tr

ro

ol

ll

le

er

r

The EQX 500-DC solar charger charge controller is designed for indoor mounting. Care should be taken in

selecting a location and when mounting the enclosure. Avoid mounting it in direct sunlight to prevent heating of

the enclosure. The enclosure should be mounted vertically on a wall. In outdoor installations, the EQX 500-DC

solar charger charge controller must be installed in a rainproof enclosure to eliminate exposure to rain, mist or

water-spray.

Caution: Damage to EQX 500-DC solar charger charge Controller, Install the EQX 500-DC solar charger

charge controller in a dry, protected location away from sources of high temperature, moisture, and vibration.

Exposure to saltwater is particularly destructive. Corrosion is not covered by the warranty.

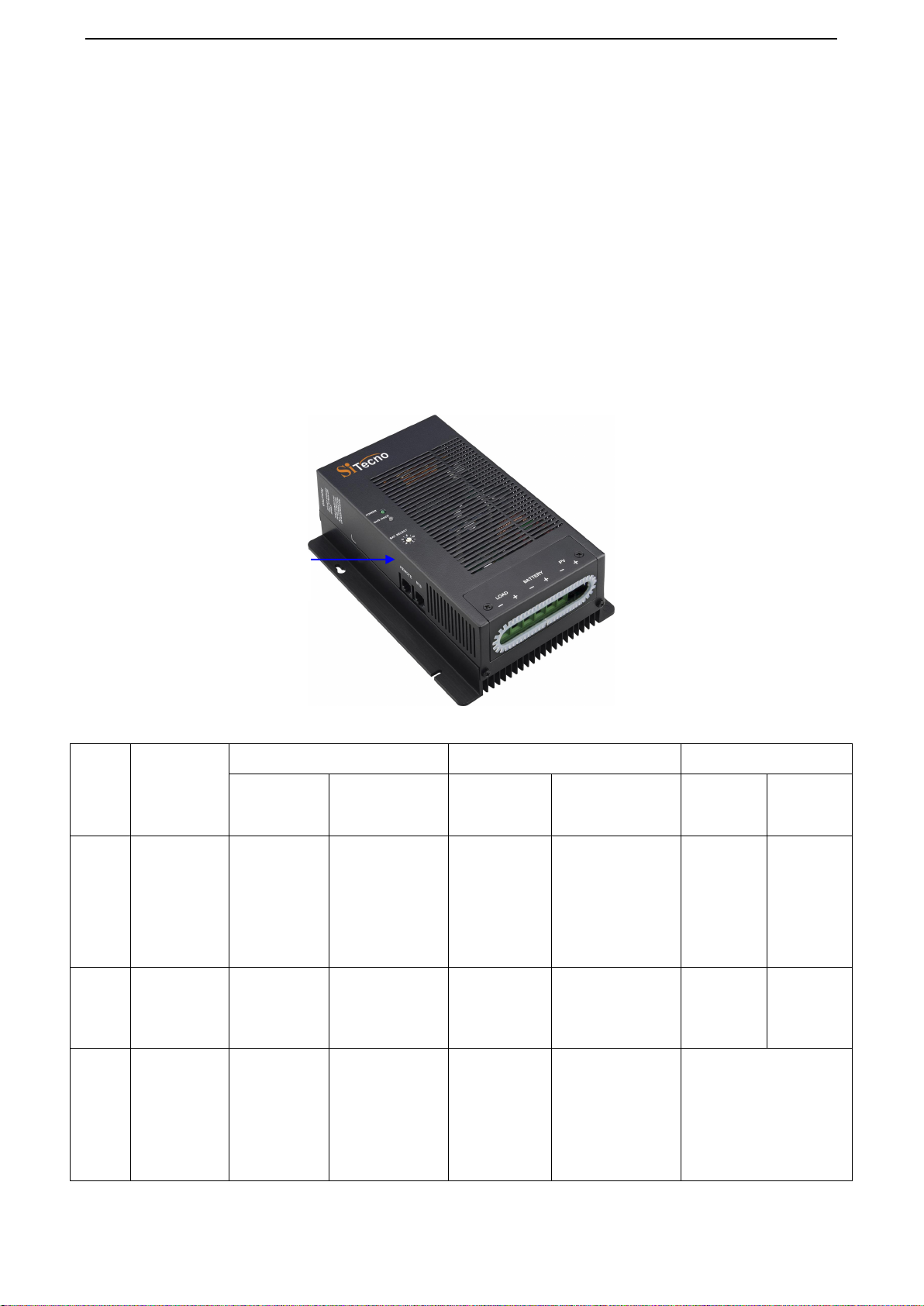

2.3.1 Mount the EQX 500-DC solar charger charge controller

1. Place the controller on the desired mounting surface and mark the location of the keyhole slots on the wall.

2. Move the controller out of the way, and secure two mounting screws in the locations marked. Leave the screw

heads backed out approximately 1/4inch (6 mm) or less.

3. Place the controller onto the screws and pull it down into the keyhole slots.

4.Then insert the two screws provided to secure the enclosure onto the wall.

Warning: Explosion/Corrosion Hazard

Do not locate the EQX 500-DC solar charger charge controller in a sealed compartment with the batteries.

Batteries can vent hydrogen-sulfide gas, which is corrosive to electronic equipment. Batteries also generate

hydrogen and oxygen gas that can explode when exposed to a spark.

Figure 1 –5: Mounting the EQX 500-DC solar charger charge controller

Keyhole Slots (*2) for mounting

Additional Mounting Holes (*2)

MATRIX Inverter System User Manual

- 16 -

2

2.

.4

4

C

Co

on

nf

fi

ig

gu

ur

ri

in

ng

g

t

th

he

e

E

EQ

QX

X

5

50

00

0-

-D

DC

C

s

so

ol

la

ar

r

c

ch

ha

ar

rg

ge

er

r

c

ch

ha

ar

rg

ge

e

c

co

on

nt

tr

ro

ol

ll

le

er

r

Before making any wiring connections to the EQX 500-DC solar charger charge controller, it must be configured

for the desired mode of operation. The following sections describe the how to configure the unit for the desired

application and function.

2.4.1 Battery type selector can apply different charger method

The battery type selector is a 10 position rotary switch used to set the EQX 500-DC solar charger for the proper

float and bulk voltage levels. These levels are selected depending on the type of batteries used. Refer to the table

below for the charge voltages in the various switch positions. Consult the battery manufacturer for optimum

battery voltage charging settings.

Figure 1 –6: Battery type selector (B.SEL)

Table 1 –2: Battery type selector switch settings

Switch

Position

Description

12-volt

24-volt

Charge Function

Float voltage

(V)

Bulk/ Equalize

voltage (V)

Float voltage

(V)

Bulk/ Equalize

voltage (V)

Equalize

charge rate

Equalize

time

0

Equalize 1 -

equalizes at a

rate equal to

the battery

bank capacity

(in amp hours)

divided by 40.

13.2

*15

26.4

*30

Max 40Amp

Depend on

battery

capacity

1

Equalize 2

–depend on

customer

reset .

reserved

reserved

reserved

reserved

2

Deep Cell

Lead Acid 2

13.3

15

26.6

30

Provides an additional

Float and Bulk settings

for deep cycle, lead acid

batteries. Refer to the

battery manufacturer

recommendation for

Float and Bulk settings.

B.SEL

MATRIX Inverter System User Manual

- 17 -

3

Not Specified

13.6

14.3

27.2

28.6

Provides an additional

setting of Bulk and Float

voltages.

4

Gel Cel 2

13.7

14.4

27.4

28.8

Recommended for gel

cell batteries that specify

high float voltages.

Check with the battery

manufacturer.

5

Gel Cell 1

13.5

14.1

27

28.2

Typical gel cell setting.

6

PcCa-lead

Calcium

13.2

14.3

26.4

28.6

Use this setting for sealed

type car batteries.

7

Deep Cycle

Lead Acid 1

(Default

Setting)

13.4

14.6

26.8

29.2

Factory setting for typical

deep cycle lead acid

batteries.

8

NiCad 1

14

16

28

32

Use for NiCad battery

systems.

9

NiCad 2

14.5

16

29

32

Recommended for use

with nickel iron batteries.

Important:

1. Switch positions “0” and “1” are for monthly battery maintenance only. Equalize voltages are displayed in the

table with an asterisk (*) –Switch positions “0” and “1” only.

2. Switch position “7” is the default values as shipped from the factory.

3. Always refer to the battery manufacturer’s specifications for equalization.

2

2.

.5

5

T

Te

em

mp

pe

er

ra

at

tu

ur

re

e

c

co

om

mp

pe

en

ns

sa

at

ti

io

on

n

For optimal battery charging, the Bulk and Float charge rates should be adjusted according to the temperature of

the battery. When battery charging voltages are compensated based on temperature, the charge voltage will vary

depending on the temperature around the batteries.

MATRIX Inverter System User Manual

- 18 -

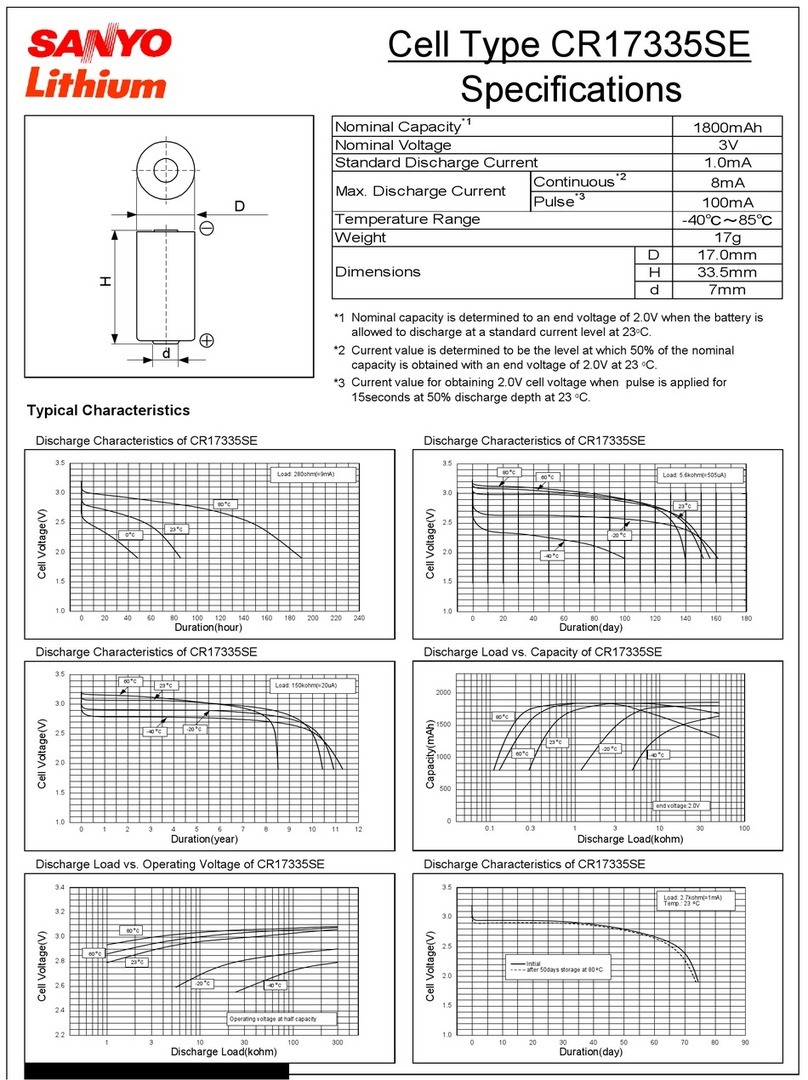

2.5.1 Temperature compensation based on battery type

The charge voltage required by batteries changes with battery temperature. Temperature compensation of charge

voltage enhances battery performance and life, and decreases battery maintenance. Automatic temperature

compensation can be provided through use of the optional battery temperature sensor. The following table

describes approximately how much the voltage may vary depending on the temperature of the batteries.

Temperature compensation is based on battery type-5mv /cell for lead acid type batteries and 2mv/cell for alkaline

type batteries (NiCad or NiFe). The temperature compensation calculations are derived from the following table.

Table 1 –3: Temperature compensation calculation

Battery Type

12 -volt

24-volt

Lead Acid

0.03 volts (30mv) per degree Celsius

0.06 volts (60mv) per degree Celsius

NiCad

0.02 volts (20mv) per degree Celsius

0.04 volts (40mv) per degree Celsius

2.5.2Automatic battery temperature compensation

Temperature compensation can be accomplished automatically by using a Battery Temperature Sensor (BTS). The

sensor attaches directly to the side of one of the batteries in the bank and provides precise battery temperature. See

“Installing the Battery Temperature Sensor” for detailed instructions on how and where to install the BTS. If a

BTS is installed, the charge controlling process will be automatically adjusted for the battery temperature. When

using a BTS, set the Bulk and Float voltage for a battery at normal room temperature for 25 °C.

Table 1 –4: Battery compensation coefficient

Temperature

(around the BTS)

12-volt

24-volt

Celsius

Fahrenheit

Lead Acid

(6 cells)

NiCad

(10 cells)

Lead Acid

(12 cells)

NiCad

(20 cells)

60

140

-1.05

-0.7

-2.1

-1.4

55

131

-0.9

-0.6

-1.8

-1.2

50

122

-0.75

-0.5

-1.5

-1

45

113

-0.6

-0.4

-1.2

-0.8

40

104

-0.45

-0.3

-0.9

-0.6

35

95

-0.3

-0.2

-0.6

-0.4

30

86

-0.15

-0.1

-0.3

-0.2

25

77

0

0

0

0

20

68

0.15

0.1

0.3

0.2

15

59

0.3

0.2

0.6

0.4

10

50

0.45

0.3

0.9

0.6

5

41

0.6

0.4

1.2

0.8

0

32

0.75

0.5

1.5

1

-5

23

0.9

0.6

1.8

1.2

-10

14

1.05

0.7

2.1

1.4

-15

5

1.2

0.8

2.4

1.6

-20

-4

1.35

0.9

2.7

1.8

-25

-13

1.5

1

3

2

-30

-22

1.65

1.1

3.3

2.2

-35

-31

1.8

1.2

3.6

2.4

-40

-40

1.95

1.3

3.9

2.6

If using a BTS, when the battery temperature drops below 25 °C, the regulation voltage setting automatically

increases. When the temperature rises above 25 °C the regulation battery voltage setting automatically decreases.

MATRIX Inverter System User Manual

- 19 -

2

2.

.6

6

G

Gr

ro

ou

un

nd

di

in

ng

g

The EQX 500-DC solar charger charge controller is designed to work with grounded electrical systems. The metal

screw must be grounded for either system by connecting it with the heatsink. If a negative ground system is

desired, connect the negative current carrying conductor to the grounding system at one point in the system.

Consult local and national electrical codes for more information and any additional requirements.

Figure 1 –7: Safety (Earth) ground

2

2.

.7

7

D

DC

C

t

te

er

rm

mi

in

na

al

l

c

co

on

nn

ne

ec

ct

to

or

r

l

lo

oc

ca

at

ti

io

on

ns

s

Terminal connectors for DC wiring are located on the lower edge of the circuit board. Terminal Torque

Requirements. Once the wires have been installed, torque the terminals as follows. Be careful not to overtighten.

Figure 1 –8: DC terminal connector locations

2

2.

.8

8

W

Wi

ir

re

e

S

Si

iz

ze

e

a

an

nd

d

O

Ov

ve

er

r-

-c

cu

ur

rr

re

en

nt

t

P

Pr

ro

ot

te

ec

ct

ti

io

on

n

R

Re

eq

qu

ui

ir

re

em

me

en

nt

ts

s

The wiring, over-current protection devices (fuses), and installation methods used must conform to all national

and local electrical code requirements. Wiring should be protected from physical damage with conduit or a strain

relief clamp.

2.8.1 Current Rating

EQX 500-DC solar charger charge controller is rated for a rating continuous current of 40 amps. Since PV outputs

can vary due to the array size or sunlight striking it, the safe minimum wire size should be based on the maximum

current ratings.

Safety (Earth) ground

PV Negative (-)

PV Positive (+)

Battery Positive (+)

Battery Negative (-)

Load Negative (-)

Load Positive (+)

MATRIX Inverter System User Manual

- 20 -

2.8.2 Surge Protection

Since PV arrays are often mounted on an elevated structure and thus are more susceptible to lightning strikes,

protection from lightning-induced power surges and other transient power disturbances between the PV array and

the EQX 500-DC solar charger charge controller are strongly recommended. Because the EQX 500-DC solar

charger have wider input voltage range 15-55VDC.

2.8.3 Over-current Protection

If the controller detects an overload, it will automatically resets the over current protection system every 6 minutes.

If the default is still present, the controller will shut off and wait another 6 minutes. This will occur continuously

until the problem is corrected.

Table 1 –5: Minimum wire size

Controller

Minimum Wire Size

12/24 VDC

#8AWG

2.8.4 Long-distance wire runs

If there is a significant distance between the PV array and the controller and/or the controller and the battery,

larger wires can be used to reduce the voltage drop and improve performance. To use a larger size wire, use a

splicer block (terminal block) intended for this purpose. This allows the larger cable size from the batteries to be

“spliced” to the smaller wire size connected to the controller. Split-bolt kerneys can also be used for wire splices.

Follow manufactures recommendations for torque and mounting (if required). Splicer blocks and split-bolt

kerneys are available from renewable energy suppliers.

2

2.

.9

9

P

PV

V

C

Ch

ha

ar

rg

ge

e

A

An

nd

d

L

Lo

oa

ad

d

C

Co

on

nt

tr

ro

ol

l

M

Mo

od

de

e

W

Wi

ir

ri

in

ng

g

The procedure below is illustrated in Figure 1 –9.

WARNING: Shock Hazard

PV arrays generate voltage whenever light strikes the surface of the array. Before connecting the EQX 500-DC

solar charger charge controller, cover or disconnect the array to prevent any current from being generated.

1. Connect the PV array’s positive (+) output to the terminal marked PV positive (+) on the EQX 500-DC solar

charger charge controller and tighten the screw.

2. Connect the PV array’s negative (–) output to the terminal marked PV negative (–) on the EQX 500-DC solar

charger charge controller and tighten the screw.

3. Connect the terminal marked battery negative (–) on the EQX 500-DC solar charger charge controller to the

negative (–) battery terminal and tighten the screw.

4. Connect the terminal marked battery positive (+) on the EQX 500-DC solar charger charge controller to the

positive (+) battery terminal and tighten the screw.

5. Connect the terminal marked load negative (–) on the EQX 500-DC solar charger charge controller to the

negative (–) load terminal and tighten the screw.

6. Connect the terminal marked load positive (+) on the EQX 500-DC solar charger charge controller to the

positive (+) battery terminal and tighten the screw.

7. Connect a cable from the controller’s other terminal marked load negative (–) to the negative terminal of your

DC load and tighten the screw.

Table of contents

Popular Batteries Charger manuals by other brands

Tripp Lite

Tripp Lite U280-010-ST owner's manual

Autoenterprise

Autoenterprise I-STATION user manual

Aegis

Aegis CRG-06005P user manual

Herth+Buss

Herth+Buss ELPARTS Quicky operating instructions

Hitachi

Hitachi UC 24YFB Instruction manual and safety instructions

Sunoptic Technologies

Sunoptic Technologies SSL-3736-2 Operator's manual