Sitepower SP80 Technical manual

1

OPERATION INSTRUCTION

SP80(50)

Water Pump

Before using the SitePower™ SP80(50) Water Pump,

please read this manual carefully.

2

Thank you for purchasing the SitePower SP80(50) water pump.

For your safety, please pay attention to sentences that include the following marks:

WARNING

This means that if the pump is not operated correctly, as specified in this manual, there

is a risk of danger that can result in injury and even death.

PRECAUTION

This means that if the pump is not operated correctly, as specified in this manual, there

is a risk of danger that can result in damage to the pump or its functions.

Note

This means that there is helpful advise for pump operators.

Also, due to changes with pump specifications, details of your pump may not align with

information presented in this manual. Please consider this possible inconsistency.

Thank you again for having chosen the SitePower SP80(50) Water Pump!

3

Table of Contents

1. Preface……………………………………………………………………………….…… 2

2. Contents……………..…………………………………………………………………… 3

3. Safety Precautions………..…………………………………………………………… 4

4. Safety Mark Positions…………………………………………………………………. 4

5. Main Part Names……………….………………………………………………………. 5

6. Preparations Before Starting…………………………..…….…………..………….. 6

7. Starting……………………………..………………………….………..…..………….. 8

8. Water Pump Usage……………..…………………………….…………..………….. 10

9. Stopping the Engine….…………………………………….…….……..………….. 11

10.Maintenance…………………………………………………..…………..………….. 12

11.Transport and Long-Term Storage….…………………….…………..………….. 15

12.Troubleshooting……………………………………..……….…………..………….. 17

13.Main Specifications………………………………………….…………..………….. 19

4

3. Safety Precautions

WARNING

•Before starting, please check the engine (page 6) to avoid damaging the pump.

•Please do not suck combustible or corrosive liquids: such as gasoline, acid, sea

water, solution or alkaline liquid (used oil, wine, honey).

•Put the pump on a solid and horizontal surface. Gasoline may spill out if the

pump is inclined or turn over.

•In order to avoid fire, please put the pump in a ventilated place. Also, keep a

space of at least 1 meter (3 feet) from pump and wall of building and/or other

things (especially combustible).

•To avoid being scalded, please do not let children or pets go into the pump work

area.

•Operators must know how to stop the engine quickly.

PRECAUTIONS

•Gasoline is very combustible and it may explode in special conditions.

•When you need to add gasoline, please stop the engine and put the pump in a

ventilated area. Neversmoke when adding or storing gasoline.

•To prevent gasoline leakage, please twist cap of fuel tank tightly.

•Avoid gasoline splashing out. Even the gas vapors can be very combustible.

Please clean the engine before starting.

•Never start the engine indoors or in unventilated places. Carbon monoxide

displacement can cause stupor and even death.

4. Safety Mark Position

These marks point out potential dangers that can cause serious accidents. Please read

the user’s manual carefully - especially note the marked warnings and precautions

sections.

5

5. Main Part Names

6

6. Preparations Before Starting

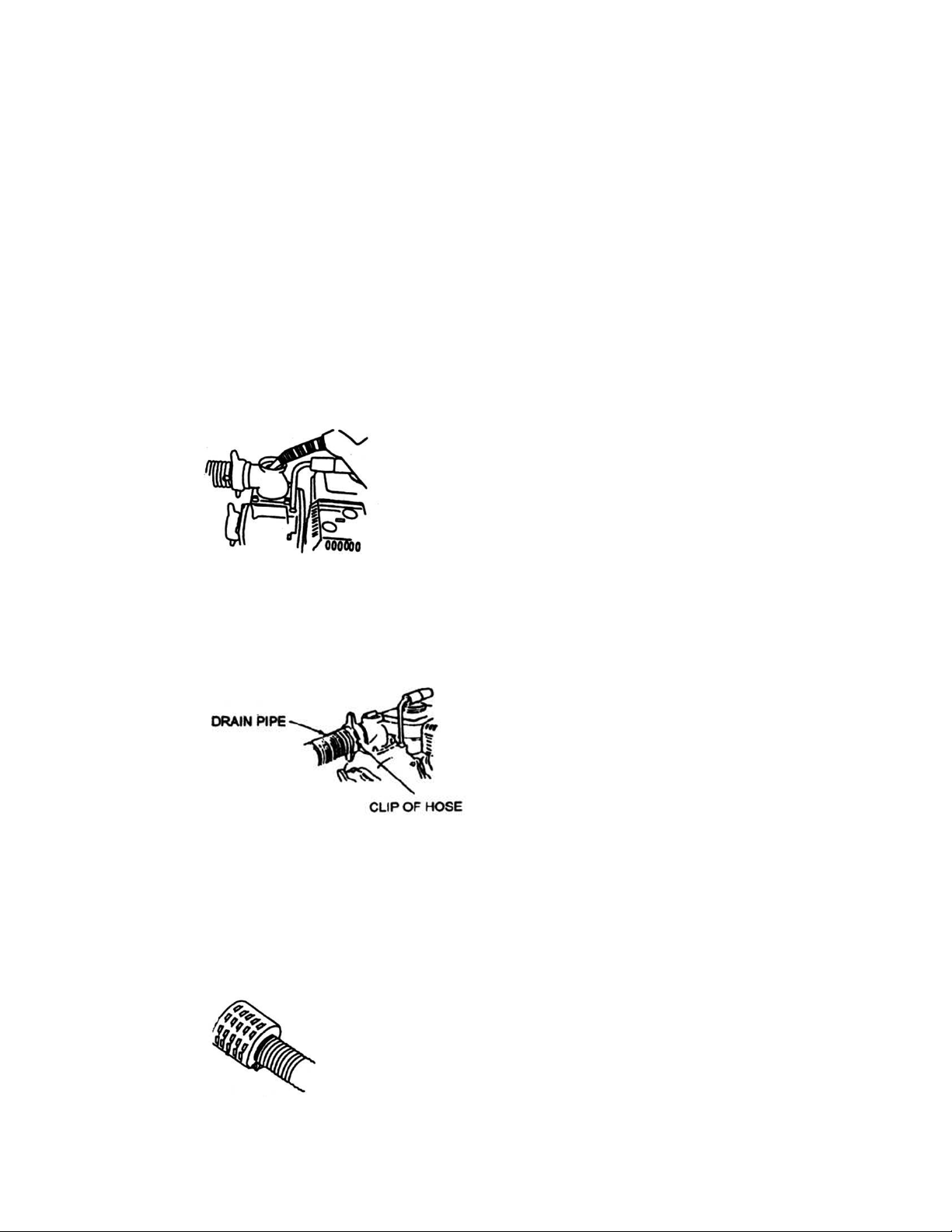

Joint Suction Hose

Use commercially available hose, connections and clips. Please be careful that

commercially available hose must be unfolded and kept to the necessary length. The

water pump will function better if it is near the water source. There is a direct ratio

between needed suction time and the length of the suction hose. The filter should be

assembled at the bottom of suction hose.

PRECAUTION

Be sure to have assembled the filter at the bottom of the suction hose before starting.

The filter can prevent material from entering into the pump and damaging parts.

Notes

•Tighten the connections and clips to avoid air leak or decreased pressure.

•Joint drain pipe

•Use commercially available hose, connections and clips. Because of the high

pressure, tighten the clips securely to avoid loss

PRECAUTION: CHECK OIL

•Be sure to add 600 ml oil for four stroke gasoline engine before starting - or

engine will be damaged.

•Oil is a main factor in keeping the engine functioning successfully. We do not

recommend using dirty oil or vegetable oil.

•When it is necessary to check the oil after using the pump, please be sure to stop

the engine first - and put the pump in a horizontal place.

•Please use the oil that we supplied or the oil according to requirements of SF,SG

•Please choose oil according to local temperature.

•Never starting engine without oil! It will seriously damage the engine.

7

PRECAUTION: CHECK FUEL

•Take fuel tank cap off and check whether fuel level is sufficient or not. Please add

enough fuel, according to requirements.

•It is better to use gasoline with Pb or with a little Pb.

•Do not use a mixture of gasoline and oil, or dirty gasoline.

WARNING

•Gasoline is very combustible - and it may explode in special conditions.

•When you need to add gasoline, please STOP the engine and put the pump in a

ventilated place. NEVER smoke in the location where you add or store gasoline.

•Please twist cap of fuel tank tightly to prevent gasoline from leaking out.

•Please prevent gasoline from splashing out. Even gas vapors can be very

combustible. Please clean the engine before starting.

•Try to avoid touching gasoline or breathing the gasoline vapors. Put the gasoline

in a location that is out of reach of children.

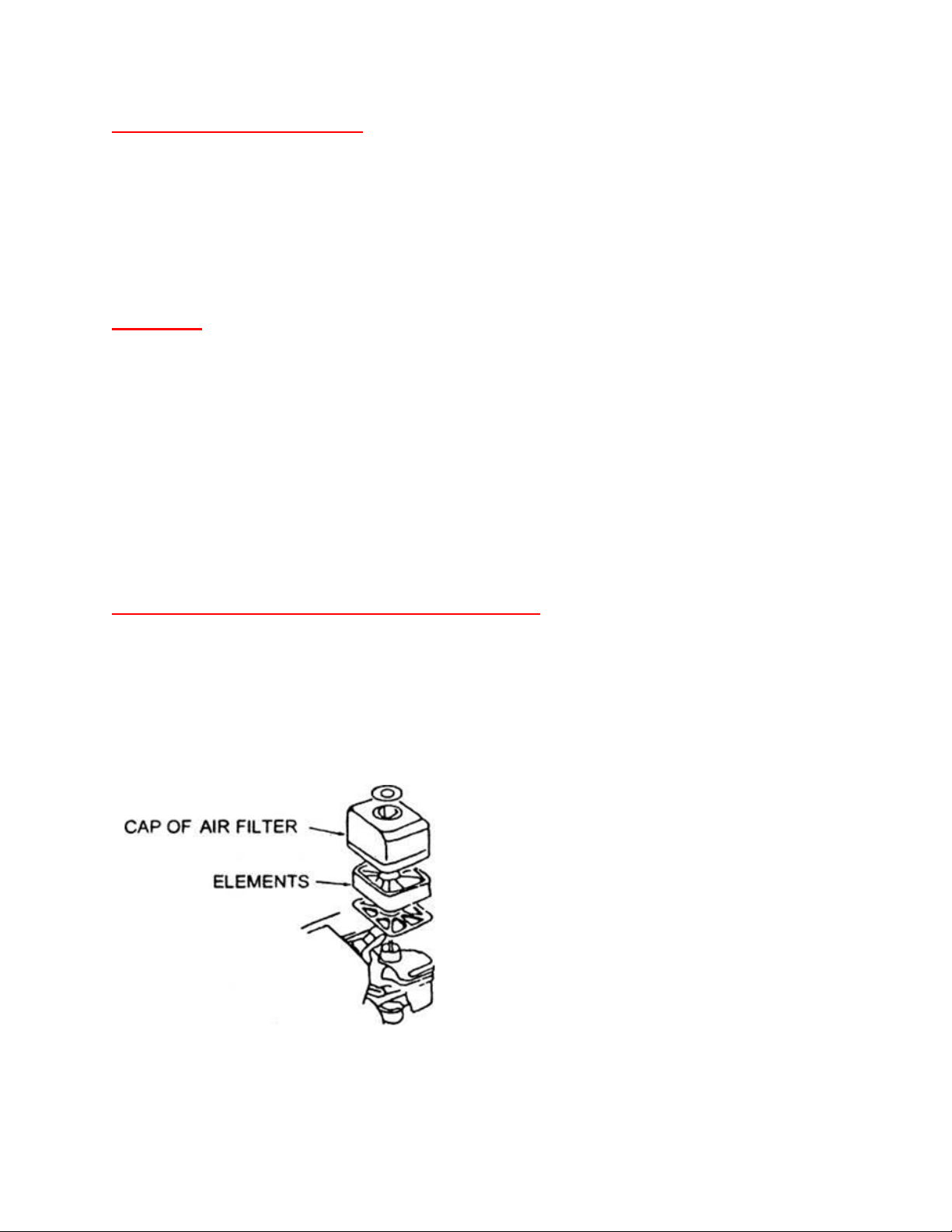

PRECAUTION: CHECKING AIR CLEANER FILTER

•Take off the nut, washer and cap of air filter.

•Check the filter, please clean it if it is too dirty or blocked up.

•NEVER start the engine without an air filter.

•If dust enters into the center of the engine through the carburetor, engine may

wear out quicker than normal.

8

PRECAUTION: CHECKING WATER

•Please fully add water before starting.

•NEVER start the pump before adding water. It may damage the sealing of THE

pump. Once the water is depleted, please stop the engine and add water - after

engine has cooled.

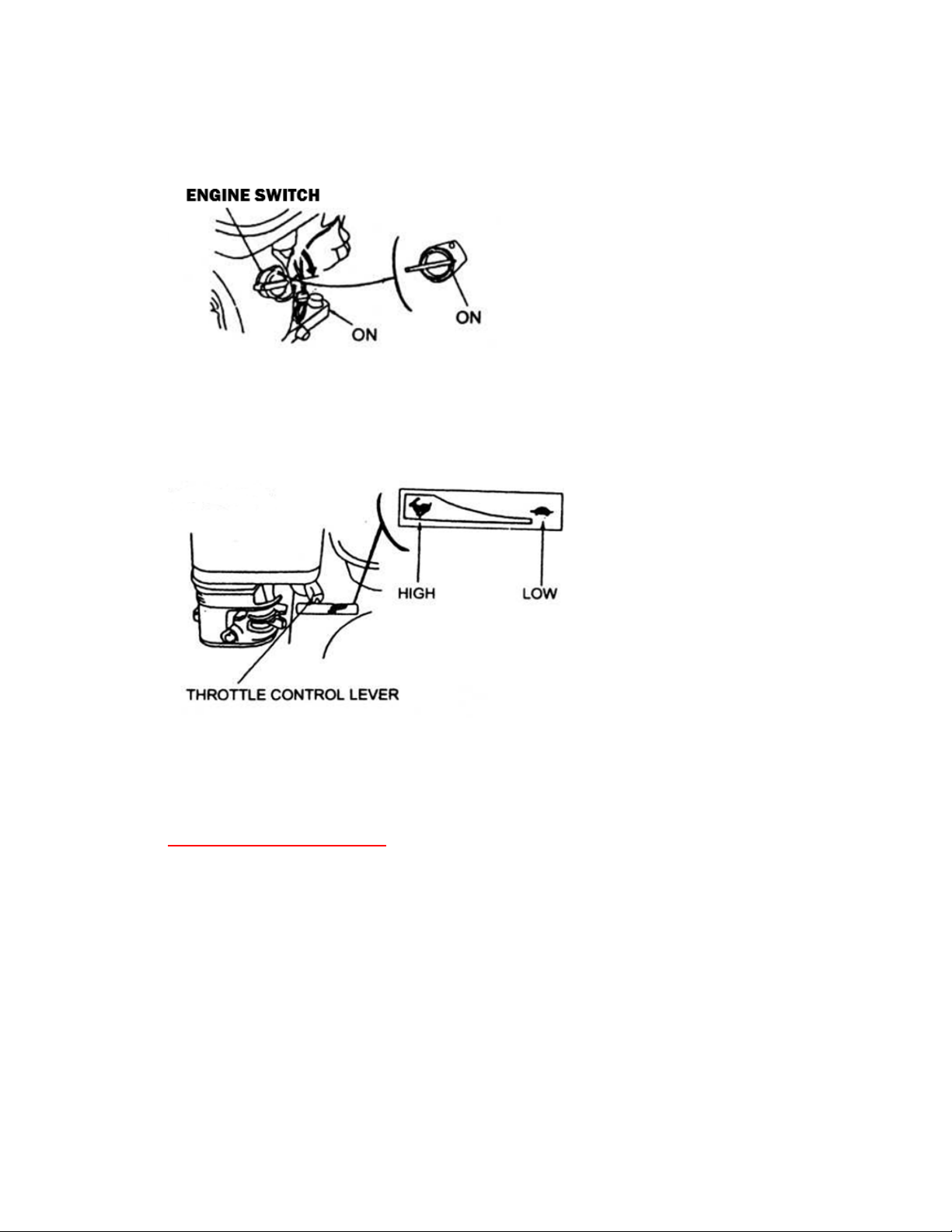

7. Starting

1. Move the fuel valve to OPEN position.

2. Move the choke lever to the CLOSE position.

Note: Do not close the choke when the temperature is very high or engine is hot.

9

3. Move the switch to the Open position.

4. Move the throttle control lever to the LEFT slowly.

5. Pull the starter with a sharp stroke.

PRECAUTION: STARTER

Never pull the entire rope.

Never let the rope return by freeing the rope.

10

8. Water Pump Usage

Using in Plateau: If you need to use this water pump in plateau, please inform us in

advance before purchasing so that we can adjust it in advance.

Standard Water Pump Usage:

1. As the engine warms up, gradually move the choke lever to the OPEN position.

2. Position the throttle control lever for the desired engine speed.

11

9. Stopping the Engine

To stop the engine in an emergency, turn the engine switch to the OFF position.

Under normal conditions, use the following procedure:

1. Move the throttle control lever full the RIGHT.

2. Turn the engine switch to the OFF position.

3. Turn the fuel valve to the OFF position.

PRECAUTION: STOPPING THE ENGINE

When you need to stop the engine quickly, it is important to move the throttle lever to

the OFF position.

12

10. Maintenance

The water pump has a life expectancy that is dependent upon the quality of

maintenance. It is recommended that you inspect your unit before and after every

operation.

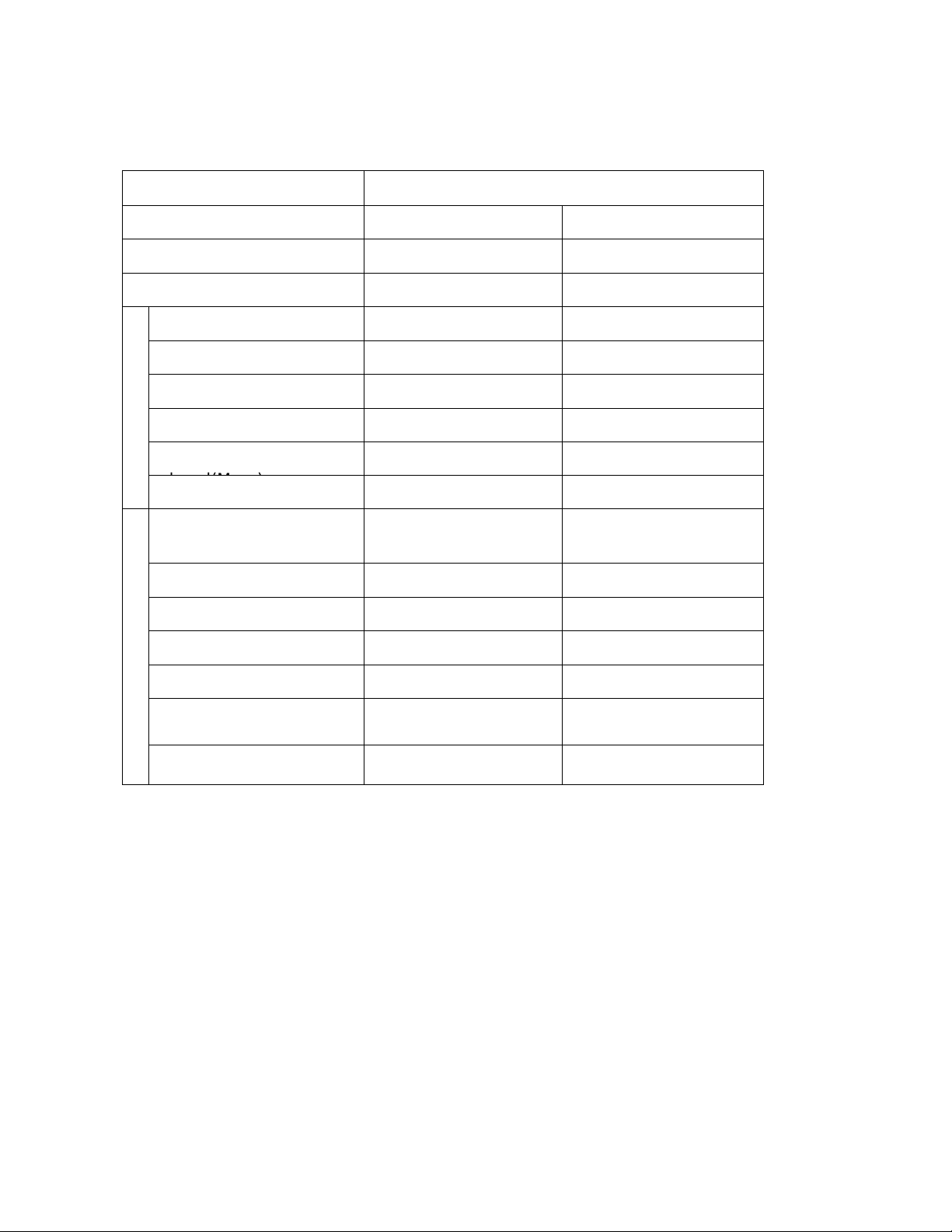

REGULAR SERVICE PERIOD

Performed at every indicated month or at

Item operating hour interval

(whichever comes first)

Each

use

First month

or 20 Hrs.

Every 3

months or

50 Hrs.

Every 6

months or

100 Hrs.

Every year or

300 Hrs.

Engine oil

Check level

o

Grange

o

o

Air cleaner

Check

o

Clean

o

Maintain spark plug

o

o

Adjust valve clearance

Clean firebox

Spark arrester

Clean once every 100 Hrs.

Fuel pipe

Change once every 2 years

Check impeller

o

Water pump tank cover

o

Greek suction valve

o

WARNING: MAINTENANCE

Make sure to stop the engine prior to maintenance.

If you have to perform maintenance while the engine is running, please do it in a

ventilated environment. The water pump’s exhaust gas contains Carbon Dioxide, which

can cause stupor and even death.

PRECAUTION: MAINTENANCE

•If the water pump has used seawater, please draw clean water afterwards. This

will help avoid the parts from becoming corroded.

•Please use original parts for repair and maintenance.

NOTE: MAINTENANCE

•If the pump has used dirty water or is put in filthy environment, please check the

pump afterwards.

13

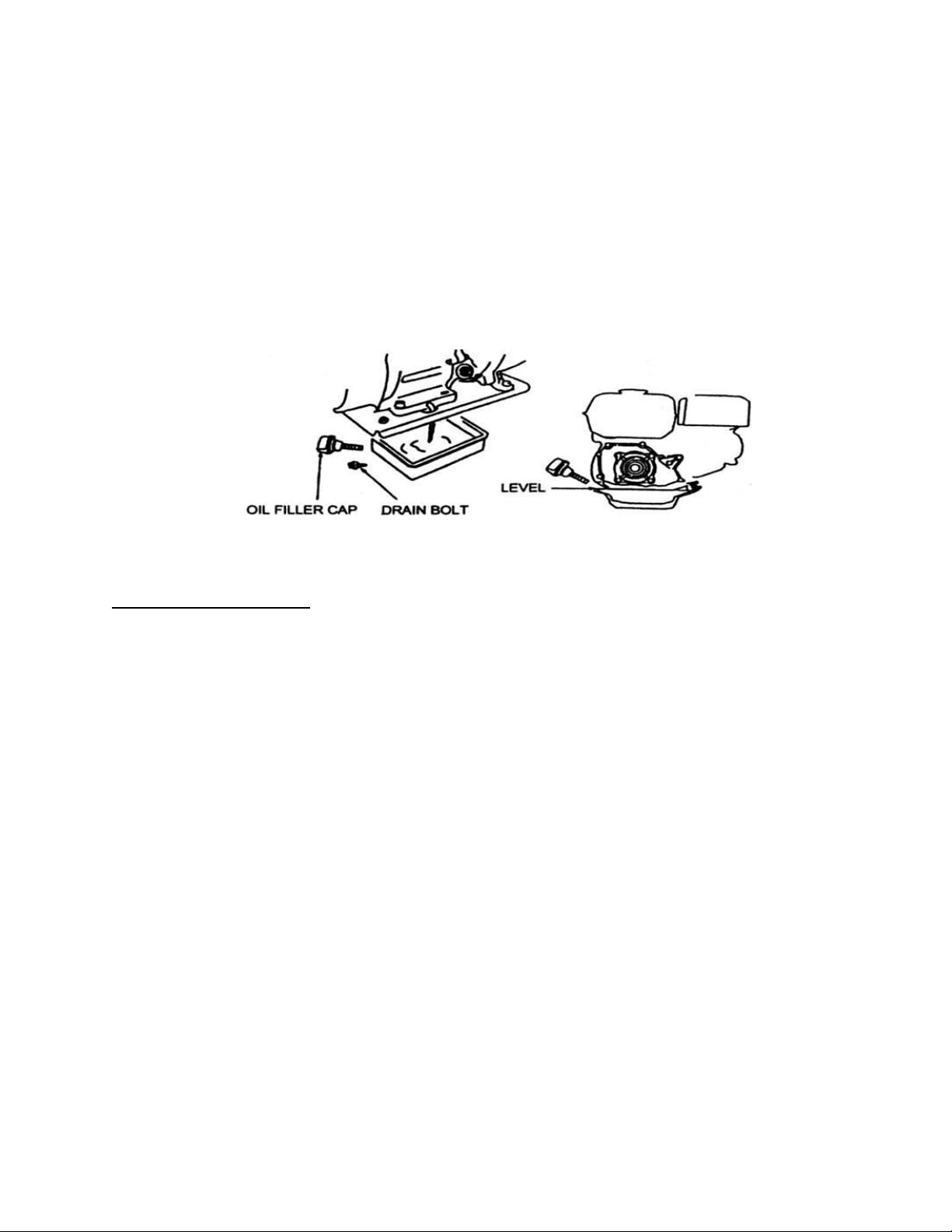

1. Renewal of Engine Oil

The engine oil shall be drained while the engine is warm.

a. Take off the oil gauge and remove the oil inlet port. Then drain the oil.

b. Assemble the oil inlet port bolt.

c. Put in the new oil, up to the level mark.

d. 0.6 L oil can be put in.

NOTE: MAINTENANCE

Please take attention to environmental protection. Do not throw the waste oil on the

ground directly.

2. Air Cleaner Inspection

a. To minimize contamination, please wash the element regularly. If the

operating environment is dirty, the element should be washed frequently.

b. Please do not use gasoline or a low burning point solution to wash the

element.

c. Do not use the water pump without air cleaner. The dust that is drawn into

the engine will increase the wear and tear of the pump.

i. Take off the screw, the cover, and the element.

ii. Wash the element by an un-combustible solution.

iii. Put the element into fresh oil and then squeeze out the oil.

iv. Assemble the element and the cover again.

14

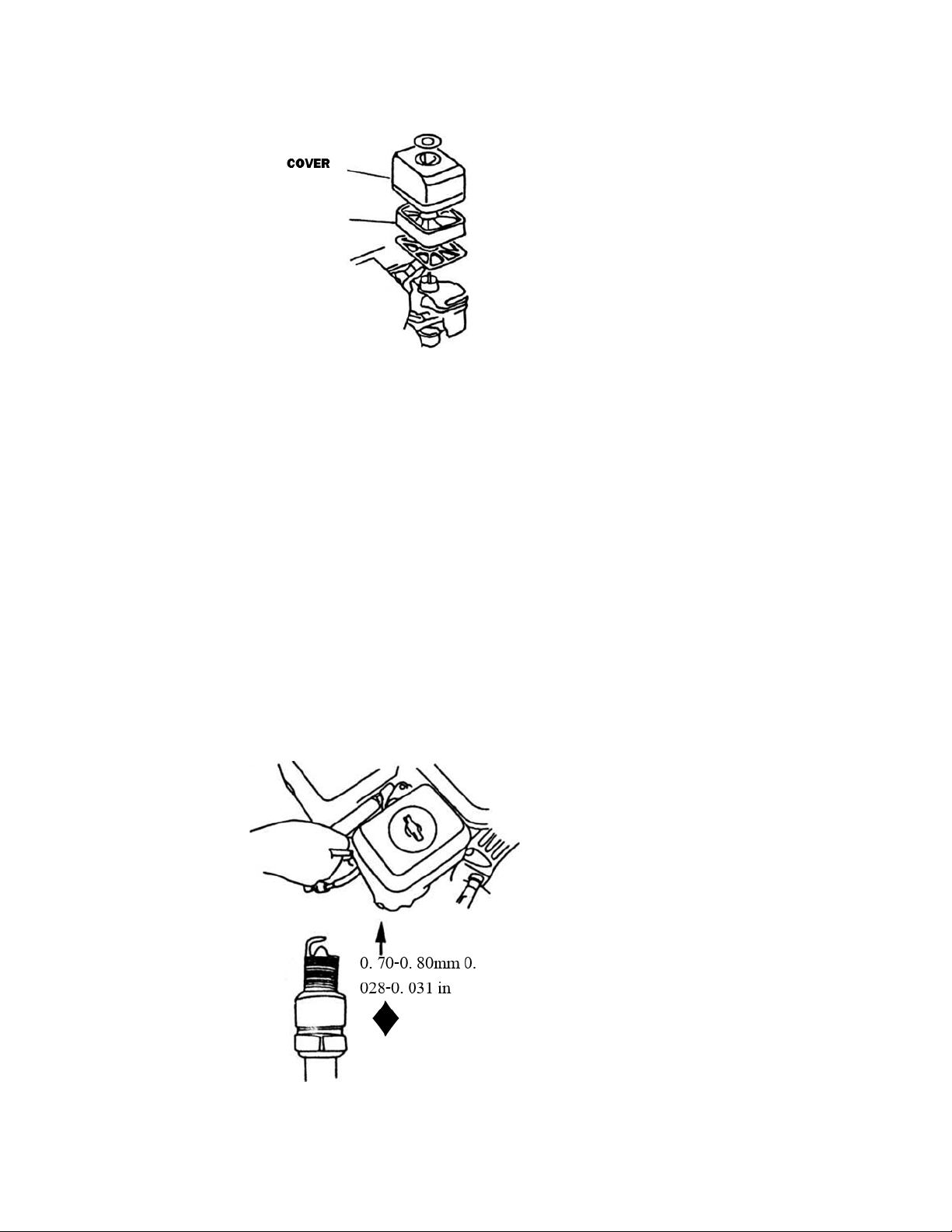

3. Spark Plug

We recommend using NHSP LD F7TC

a. Remove the cap.

If the machine was just stopped, please be careful to avoid being scalded

by the muffler.

b. Visually inspect the plug. If it is badly damaged – or if the insulator is

cracked/broken, then please replace with a new one.

c. Adjust the electrode distance to 0.7-0.8mm.

d. Inspect the sealing, adjust it if needed.

15

PRECAUTION: SPARK PLUG

Please make sure that the plug is assembled tightly. If not, the engine may be too hot

and even damage the motor. Do not use a spark plug of poor quality.

10. Transport and Long-Term Storage

WARNING: TRANSPORT AND LONG-TERM STORAGE

•Before transport or storing the machine - to avoid fire and injury - please make

sure that the pump has cooled down.

•Before transport, put the fuel valve to the OFF position and keep the pump

horizontally. This will help avoid gas and oil from spilling out.

Storing Long Term

1. The storage environment should not be moist and dirty.

2. Clean the inner parts through using clean water and then drain the water

completely.

3. Drain the oil completely.

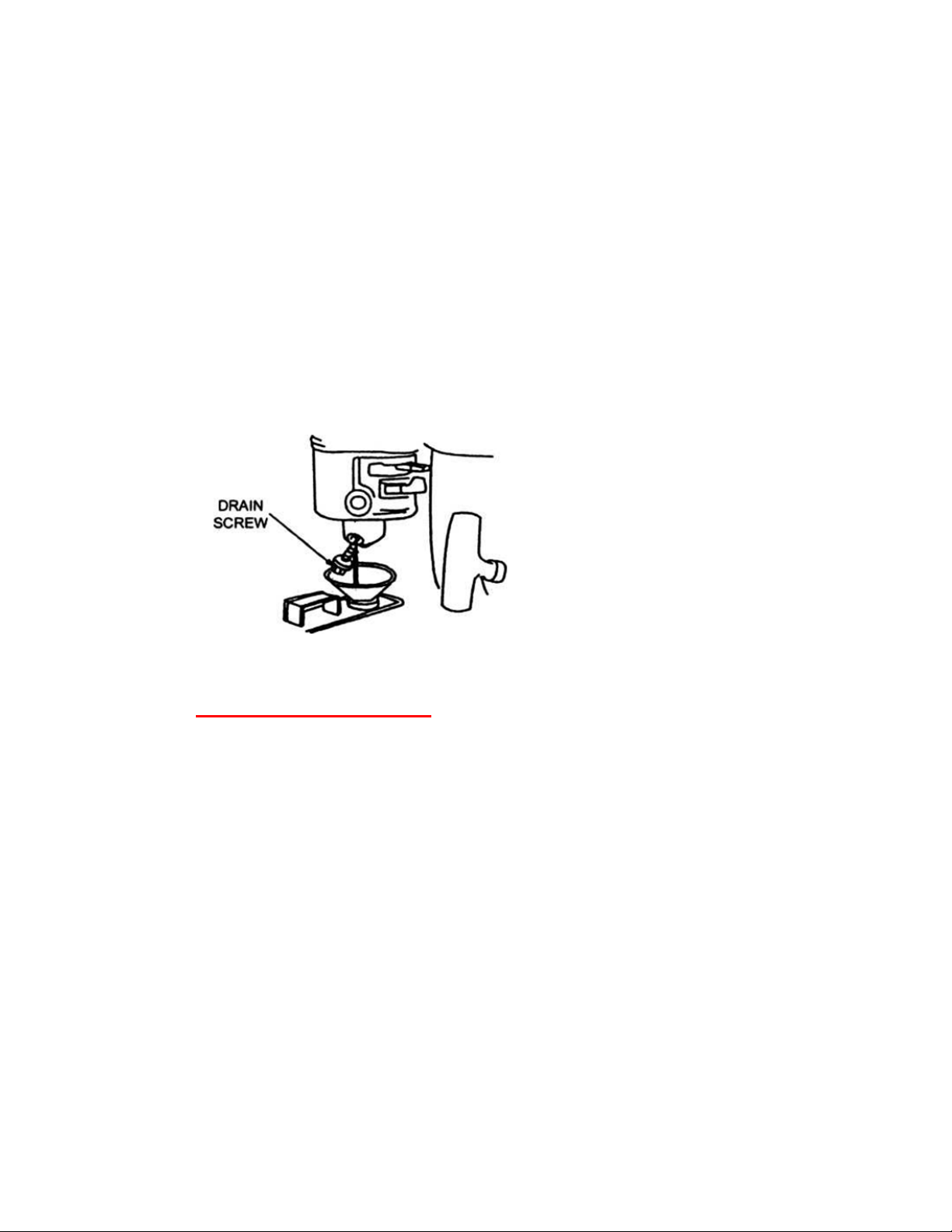

a. Put the fuel valve to the OFF position and then take the drain screw off

in float room. Then drain the gasoline in the carburetor.

16

b. Drain the gasoline in the fuel tank.

c. Assemble the screw in float room.

d. Renew the oil.

e. Take off the spark plug, put a spoonful of clean engine oil into cylinder.

Turn the engine several revolutions to make the oil spread evenly.

Then reinstall the spark plug.

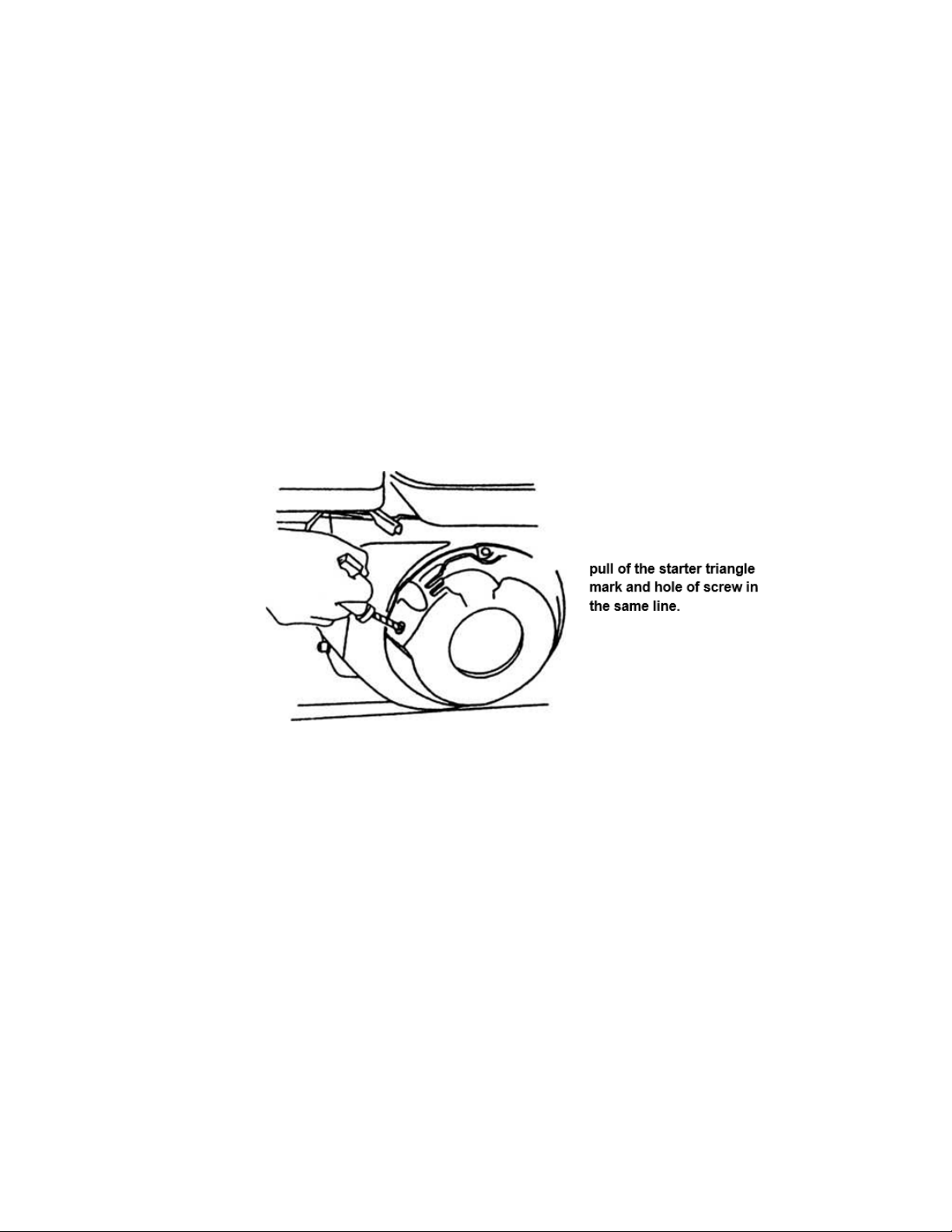

f. Take the handle of the starter into your hand until you feel resistance.

Then pull it to the triangle mark and hole of screw in the same line. In

this position, both the inlet and outlet are closed - which is better for

avoiding rust.

g. Cover the water pump.

17

11. Troubleshooting

Not Able To Start

1. There may be no fuel in tank.

2. Is the fuel valve at the ON position?

3. Can gasoline enter into the carburetor?

Open the valve and take-off the drain screw at the bottom of carburetor. Then

inspect it.

WARNING: DRAIN SCREW

If there is spilt fuel, please clean it before testing the spark plug and starting

the engine (to avoid fire).

4. Put switch to the ON position.

5. Inspect oil in the crankcase. If needed, add enough oil into it.

6. Inspect fire of the spark plug.

a. Remove the cap. Clean the dirt around it and then take off the spark

plug.

b. Assemble the plug on the cap.

c. Put the switch to the ON position.

18

d. Let the spark touch the engine and then pull the starter to check

whether there is fire or not.

e. Change a new spark plug if there is no spark.

7. If the engine still does not start, take the engine to the authorized dealer.

Not Able To Suction

1. No water or water shortage in pump.

2. Filter is blocked.

3. Clip of hose is loose.

4. The hose is damaged.

5. Total water level is too high.

6. If the water pump still does not suction, please take it to authorized dealer.

19

12. Main Specifications

Name Water pump

Model

SP80

SP50

Dimensions (L X W X H)

530x380x445mm

500x380x430mm

Weight

27kg

24kg

P

U

M

P

Suction port diameter

80mm(3.0inch)

50mm(2.0inch)

Discharge port diameter

80mm(3.0inch)

50mm(2. Oinch)

Discharge(Max.)

50m3/h

25m3/h

Total water head(Max.)

20m

30m

Suction water

h d(M )

8m 8m

Continuous work time 150min 150min

E

N

G

I

N

E

Type

Four stroke, one

cylinder

Four stroke , one

cylinder

Model 168F 168F

12h Power

3.2kW/3600r/min

3.2kW/3600r/min

Total diaplacement

163cc

163cc

Way of ignition

TCI

TCI

Rolling direction of

shaft

Counterclockwise

Counterclockwise

Cooling system Air-cooled Air-cooled

This manual suits for next models

1

Table of contents

Popular Water Pump manuals by other brands

Hayward

Hayward TriStar VS 900 owner's manual

SGS

SGS SWP80 owner's manual

Grundfos

Grundfos UPS Installation and operating instructions

Agilent Technologies

Agilent Technologies G6697A IDP-10 installation guide

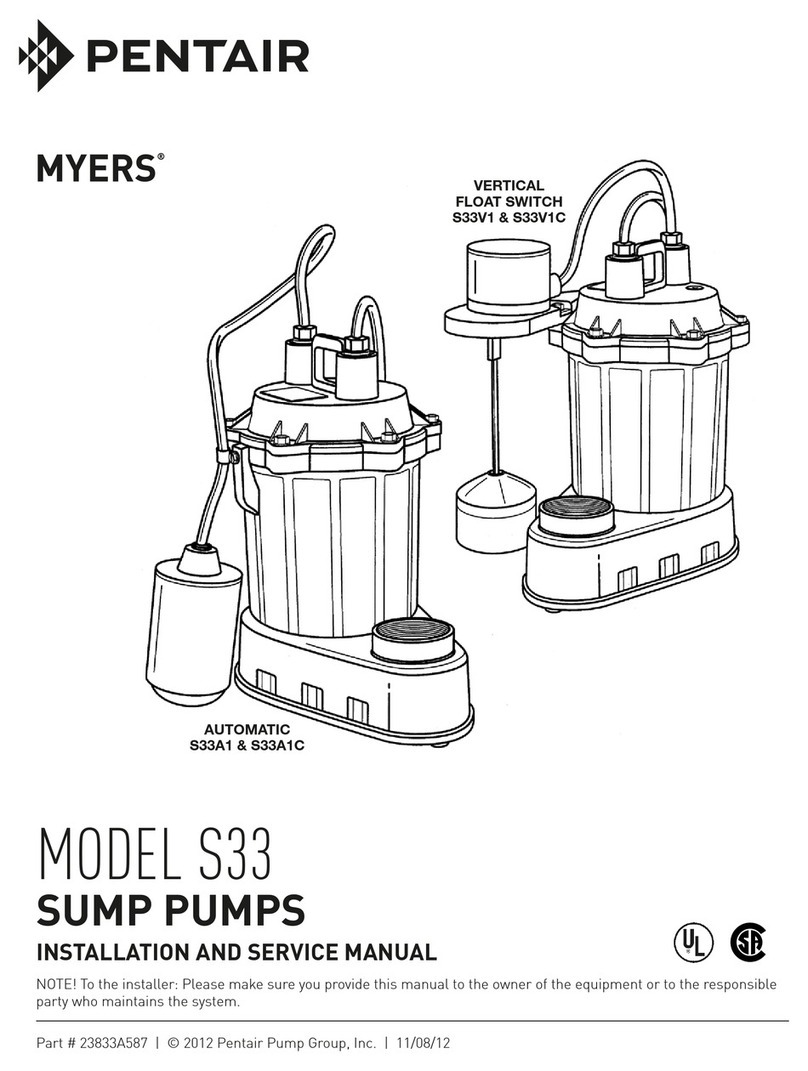

Pentair

Pentair MYERS S33 Installation and service manual

Wilden

Wilden P4 series Engineering, operation & maintenance

ARO

ARO TWO_BALL PUMP SERIES 650485-XXX Operator's manual

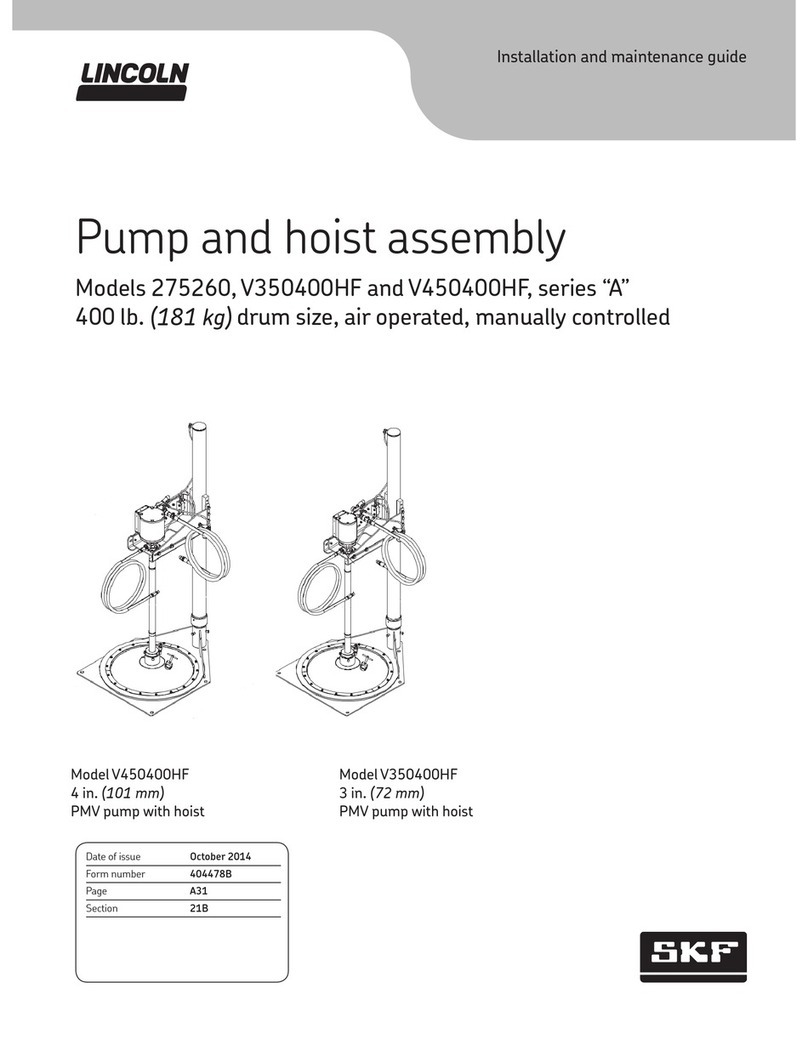

Lincoln

Lincoln A Series Installation and maintenance guide

Jefferson Professional Tools & Equipment

Jefferson Professional Tools & Equipment JEFSUBPIDW210-12 user manual

Dover

Dover PSG Mouvex AF HT Installation operation & maintenance

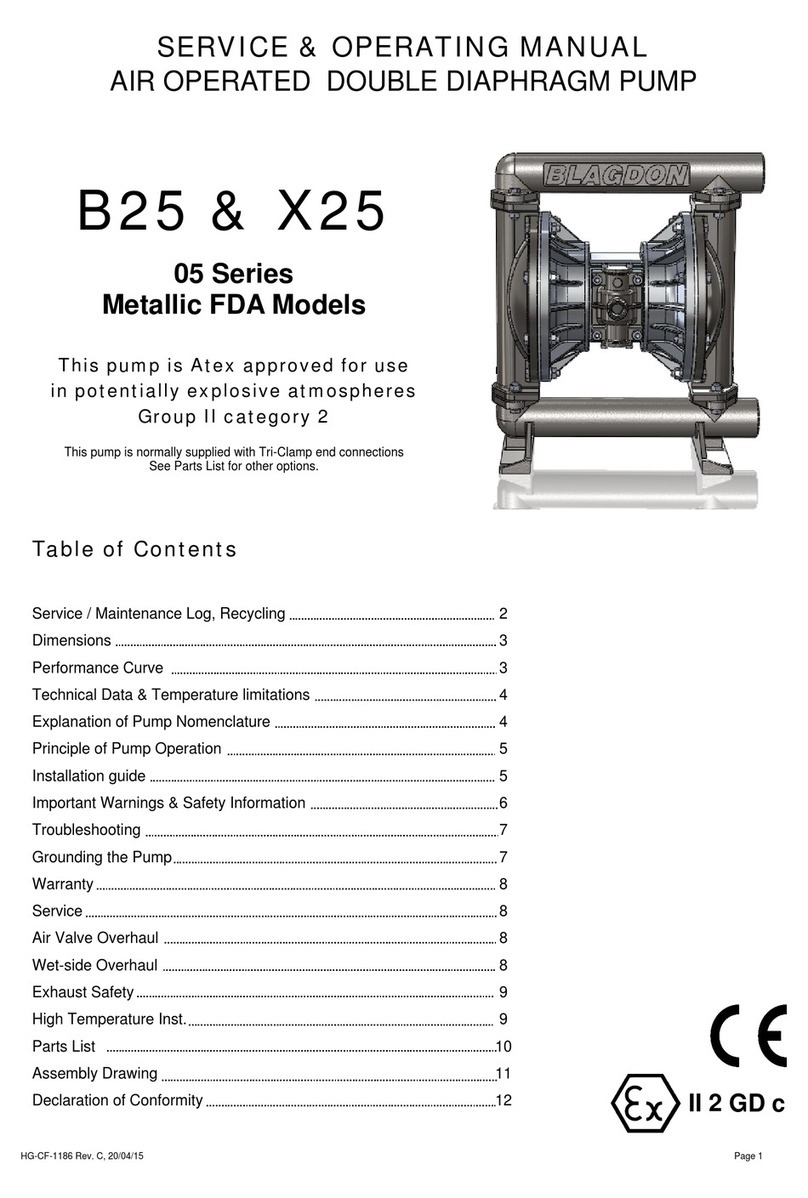

Blagdon

Blagdon X25 operating manual

P.I.T.

P.I.T. PSW400-C Operation manual